Beruflich Dokumente

Kultur Dokumente

P Kerchev

Hochgeladen von

Willy YanuwarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

P Kerchev

Hochgeladen von

Willy YanuwarCopyright:

Verfügbare Formate

ARTICLES

A&EB

INFLUENCE OF EXTRACTION TECHNIQUES AND SOLVENTS ON THE

ANTIOXIDANT CAPACITY OF PLANT MATERIAL

P. Kerchev1 and S. Ivanov2

Bulgarian Academy of Sciences, Institute of Plant Physiology, Sofia, Bulgaria1

Centre of Food Biology, Sofia, Bulgaria2

Correspondence to: Sergei Ivanov

E-mail: sivanov714@abv.bg

ABSTRACT

The influence of extraction medium and sample preparation on the total antioxidant capacity (TAC) of pea plants leaves is

investigated. Sodium acetate buffer (pH 5), potassium phosphate buffer (pH 7.5), methanol or 0.1% w/v trichloroacetic acid

(TCA) were used for homogenization. TAC was measured in the crude supernatants (one-step procedure). The pellets were

extracted with acetone and their TAC values were added to those from the previous assay (two-step procedure). The values

for TAC of the acetone extract, the low-molecular and protein fractions derived from a partial fractionation of the probes are

used in the proposed by us new three-step method. The results indicate that TAC of the probes processed with the two or threestep procedure is significantly higher than that of the crude supernatants (one-step procedure). On the basis of this study we

recommend two-step protocol as a minimum and buffer with slightly acid pH or TCA for extraction when plant material is

investigated. The highest results were obtained when the new three-step procedure for sample preparation and sodium acetate

buffer as an extracting agent were applied. Moreover, the separation of the cellular antioxidants into three different fractions is

especially useful for studying the effects of aging, processing and storage on the antioxidant capacity.

Keywords: antioxidant capacity, pea plants, TEAC, FRAP,

sample preparation

Introduction

The antioxidant system in plants is very complex, with

antioxidants having different targets, sizes and interactions

with each other. Halliwell (8) defined biological antioxidants

as molecules which, when present in small concentrations

compared to the biomolecules they are supposed to protect,

can prevent or reduce the extent of oxidative destruction of

biomolecules. They can be divided into enzymatic (e.g

superoxide dismutase, catalase, glutathione peroxidase) and

nonenzymatic (e.g. glutathione, vitamin E, ascorbic acid).

Total Antioxidant Capacity (TAC) is a parameter that takes into

account all the synergistic and cumulative interactions between

the known and unknown antioxidants present in the sample.

Several methods have been developed to measure the TAC of

biological samples including plants. Some of the most used

are TRAP (Total Radical-Trapping Antioxidant Parameter),

TEAC (Trolox Equivalent Antioxidant Capacity), ORAC

(Oxygen-Radical Absorbance Capacity), FRAP (Ferric/

Reducing Antioxidant Power) (24). Sample preparation and

extraction solvents are vital (3) but the information on how it

affects the subsequent measurements is insufficient. Different

authors used various protocols for extraction of antioxidants.

Usually, water-soluble and water-insoluble fractions were

assessed separately (two-step procedure). For extraction of

water-soluble antioxidants water or different buffers were used.

Water-insoluble antioxidants were extracted with acetone or

chloroform. Numerous authors used solely methanol (one-step

procedure) as an extracting agent.

556

The purpose of this work is to determine how different

extraction mediums and sample preparation affect the TAC of

plant material. In addition to the one and two steps procedures

used by other authors, we developed a three-step method

for sample preparation. The new approach shows highest

values for TAC in comparison to the standard procedures.

Moreover, our method discriminates between water-soluble,

water-insoluble lipophilic and protein antioxidants within one

sample. For TAC evaluation two widespread assays, TEAC

and FRAP were used.

Materials and Methods

In the experiments, pea plants (Pisim sativum, L.) cv. Pleven

4 were used. Seeds were soaked in tap water for 6 hours,

and germinated for 3 days on a moisturized filter paper in a

germination chamber at 25C. Plants were grown hydroponically

on a half-strength Hoaglands solution with trace microelements

in a growth chamber (photoperiod 12/12h, photon flux density

70-90 mol.s-1.m-2, temperature 25C, relative air humidity 6070%). All samples were collected from second leaf stage.

A scheme describing the procedure for sample preparation

is presented in Fig. 1. The plant material for homogenizations

was gathered at the same time from a random sample. The

0.5 g leaves were ground with a pestle and mortar in sodium

acetate buffer (0.1 M, pH 5), potassium phosphate buffer

(0.1 M, pH 7.5), methanol or 0.1% (w/v) trichloroacetic acid,

respectively. The homogenate were centrifuged at 15 000 g for

30 min and the resulting supernatants (crude fraction) were

analyzed for TAC, as reported below (one-step procedure).

In the two-step procedure all pellets, except that from the

methanol slurry, were extracted with 3 mL of acetone under

BIOTECHNOL. & BIOTECHNOL. EQ. 22/2008/1

agitation for 30 min at room temperature, centrifuged at

15 000 g for 15 min and the supernatants collected for analysis

(acetone fraction). For the three-step procedure the initial

supernatants from phosphate and acetate buffers were further

processed by adding 60% TCA to a final concentration of 1%.

After centrifugation at 12 000 g for 15 min in the supernatants

TAC (low-molecular fraction) was evaluated. The protein

pellets were resuspended in a detergent solution (6 M Urea,

0.1 M acetate buffer, pH 5) and used in the analyses (protein

fraction). The presented results are means + SE (standard error)

from three independent experiments.

Plant material ~ 0.5 g

Homogenization

Centrifugation, 15 000g for 30 min.

TAC of

crude extract (1)

Supernatant

Pellet

Saturation with TCA

Centrifugation, 12 000g

for 15 min.

Supernatant

Extraction with acetone

for 30 min at room temp.

Results and Discussion

Centrifugation, 15 000g

for 15 min.

TAC of water-insoluble

lypophilic fraction (2)

Pellet

Calculation of TAC:

TAC of

low-molecular fraction (3)

TAC of

protein fraction (4)

of the results. The results were calculated by standard curves

prepared with known concentrations of Trolox, and were

expressed as mol Trolox/g FW.

The FRAP assay is based on the reduction of the Fe3+

TPTZ complex to the ferrous form at low pH (4). The working

solution is prepared daily according to a procedure described

by the authors of the method. Freshly prepared FRAP reagent

(0.2 mL) was added to 20 L of the diluted sample on a 96-well

micro plate and the absorbance at 593 nm was recorded after a

30 min incubation at 37C. A blank probe without plant extract

is used for correction of the results. The results were calculated

by standard curves prepared with known concentrations of

Fe2+, and were expressed as mol Fe2+/g FW.

All spectrophotometrical measurements were made with

microplate instrument (Multiscan Spectrum, Thermo Electron

Corporation).

One-step TAC= (1)

Two-step TAC= (1) + (2)

Three-step TAC= (2) + (3) + (4)

Fig. 1. Outline of procedure for sample preparation for detailed protocols see

Materials and Methods)

The TEAC assay is based on the ability of antioxidant

molecules to quench the long-lived ABTS+ radical, a bluegreen chromophore with characteristic absorption at 734 nm,

compared with that of Trolox, a water-soluble vitamin E analog.

A stable stock solution of ABTS+ was produced by reacting

a 7 mM aqueous solution of ABTS with 2.45 mM potassium

persulfate (final concentration) and allowing the mixture to

stand at dark at room temperature for 12-16 h before use (22).

The plant sample (20 l) is added to 200 l of the reagent in a

96-well micro plate. The absorption is read after 30 min at 734

nm. A blank sample without plant extract is used for correction

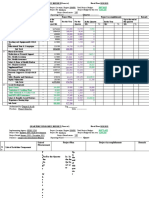

Both TEAC and FRAP methods were used for determination of

TAC in the crude extracts according to the one-step procedure.

The values obtained by the TEAC assay varied from 10.41

mol Trolox equivalents/g FW for the probe homogenized

with methanol to 15.81 for the probe homogenized with 0.1%

TCA (Table 1). The result concerning the usage of phosphate

buffer was not taken into consideration. Analogically, when the

FRAP method was used the TAC of the sample homogenized

with phosphate buffer was very low 5.45 mol Fe2+ equivale

nts/g FW (Table 2). The antioxidant activities of the remaining

samples were in the same range (acetate buffer 17.95; 0.1%

TCA 18.43; methanol 19.58 mol Fe2+/g FW).

Water-insoluble lipophilic antioxidants present in the

acetone extract from the initial pellet, which consisted of

cell walls, broken nucleus, chloroplasts, and mitochondrion

possess less activity than the crude extract. The values ranged

from 6.94 (0.1% TCA) to 8.06 mol Trolox/g FW (acetate

buffer) (Table 1). The data obtained by the FRAP assay

were similar. The highest result was obtained for the probes

initially homogenized with acetate buffer 13.87 mol Fe2+/

TABLE 1

TAC according to the TEAC assay

Crude extract

mol Trol.

%

100.0

a 10.660.42

1 b 10.660.42

56.9

c

a n.d.

2 b 29.8

c

100.0

a 15.810.22

3

69.6

b 15.810.22

4 a 10.410.05

100.0

Acetone extract

%

8.060.78

43.1

8.060.78

32.5

7.580.485

32.4

7.580.485

32.4

6.940.50

30.5

mol Trol.

Low-molecular fraction

%

6.280.51

25.3

6.980.53

29.8

mol Trol.

Protein fraction

%

10.470.08

42.2

8.840.38

37.8

mol Trol.

Total

mol Trol.

10.66

18.72

24.81

n.d.

7.58

23.38

15.81

22.75

10.41

n.d. not detected

Measurements are made after homogenization with (1) sodium acetate buffer with pH 5, (2) potassium phosphate buffer with pH 7.5, (3) 0.1% TCA and (4)

methanol. As Total is represented the capacity of the sample calculated as a sum of the different fractions according to: a one-step procedure, b two-step

procedure, c three-step procedure. Data are presented as mol Trolox g-1 FW SE (n= 6), and respective % from total TAC (at the right side of each value).

For details see materials and methods.

BIOTECHNOL. & BIOTECHNOL. EQ. 22/2008/1

557

g FW (Table 2). The share of the water-insoluble lipophilic

antioxidants, calculated as a percent of the total antioxidant

activity was estimated and is also present in the tables. When

the two-step procedure was used their part was about 44%

for the acetate buffer, 30% for TCA and up to 70% after

homogenization of the leaf material with phosphate buffer and

consequential evaluation with the FRAP assay (Table 2). If

three-step procedure is used the percentages of water-insoluble

lipophilic antioxidants are 44.7% and 32.5% (FRAP, TEAC

acetate buffer, Tables 1, 2), and 63.1% and 32.4% (FRAP

phosphate buffer, Table 2).

After the addition of TCA to the crude extracts obtained

by homogenization with phosphate and acetate buffers the

proteins present in the sample precipitate. This step allows

each probe to be divided into three fractions - low-molecular

fraction, acetone extract from the initial pellet and protein

fraction (three-step procedure). The TAC of the low-molecular

fraction according to the TEAC assay is similar regardless

of the initial homogenization technique (Table 1). When

evaluated with the FRAP assay the probes homogenized with

sodium acetate buffer had substantially higher values (Table

2). The protein fraction showed different antioxidant capacity

depending on the method for TAC estimation. According to the

TEAC (Table 1) and FRAP (Table 2) assays their contribution

to the TAC of the sample is 42.2% (TEAC acetate buffer),

37.8% (TEAC phosphate buffer), 4.8% (FRAP acetate

buffer), and 12% (FRAP phosphate buffer), respectively.

The low values for the FRAP method are probably due to the

precipitation of proteins at low pH (5).

The one-step procedure for sample preparation due to its

simplicity is used by many authors. Usually, the material is

homogenized with water (2, 13, 14, 27), water/acetone (19, 30),

pure methanol (20), water/ethanol (or ethyl acetate, diethyl ether,

chloroform) in different ratios (7, 10, 25, 26), acid (16), neutral or

alkaline buffers (11, 28). With the exception of TCA, the solvents

applied in our study are widely used for evaluation of TAC. The

results indicate that if one-step procedure is used the highest

result is obtained for the probes homogenized with TCA (TEAC

Table 1) and with methanol (FRAP Table 2). However, with

the exception of the extract with phosphate buffer, data for TAC

according to the FRAP assay were very similar.

The two-step procedure for sample preparation allows the

antioxidant capacity of both water-soluble and water-insoluble

lipophilic antioxidants to be measured. Normally, the probe is

initially homogenized with water or buffer and afterwards the

insoluble pellet is extracted with an organic solvent. Acetone

and chloroform are usually used in this step. Numerous studies

of the TAC in foods and beverages are carried out with the twostep procedure (16, 18, 21). In our work the data from the twostep protocol were 1.5 to 3-fold higher than those of the crude

extract for both TEAC and FRAP assay (Tables 1, 2). The

TEAC values obtained with TCA as an extracting agent were

the highest (Table 1). In the case of the FRAP assay the highest

results were observed with sodium acetate buffer (Table 2).

The low-molecular antioxidants, the water-insoluble

lypophilic antioxidants, and the scavenging activity of the

proteins against free radicals can be assessed with the three

step procedure. The highest values for TAC were obtained by

both analytical methods when the three-step procedure after

homogenization with sodium acetate buffer was applied.

Moreover, the contribution of the antioxidant compounds

present in the three fractions to the total antioxidant capacity

can be outlined. The principal antioxidants related to the lowmolecular fraction included glutathione, ascorbate, free proline

and various phenolic compounds. The tripeptide glutathione

is the main non-protein, acid-soluble thiol compound in most

organisms (1). Analogically, vitamin C is a water-soluble

antioxidant that has a high reducing potential and is a powerful

scavenger of oxygen radicals and quencher of singlet O2.

Ascorbate co-operates with glutathione in glutathione-ascorbate

shuttle the main mechanism of detoxifying the AOS in plants

(17, 29). Carotenoids and Vitamin E are easily extracted from

the pellet with acetone. Vitamin E is a generic term for a series

of natural tocopherols and tocotrienols (, , and d) also

called tocols, and it is regarded as the most important lipidsoluble antioxidant (9). The major role of carotenoids in plants

is light harvesting as auxiliary components and quenching of

excited states that might be formed during photosynthesis (12).

TABLE 2

TAC according to the FRAP assay

Crude extract

%

mol Fe2+

100.0

a 17.950.24

1 b 17.950.24

56.4

c

100.0

a 5.450.10

2 b 5.450.10

29.8

c

100.0

a 18.430.34

3

67.2

b 18.430.34

4 a 19.580.40

100.0

Acetone extract

mol Fe2+

%

13.870.61

43.6

13.870.61

44.8

12.860.04

70.2

12.860.04

63.1

8.580.47

32.8

-

Low-molecular fraction

mol Fe2+

%

15.660.32

50.4

5.070.04

24.9

-

Protein fraction

mol Fe2+

%

1.500.01

4.8

2.460.03

12.0

-

Total

mol Fe2+

17.95

31.87

31.03

5.45

18.31

20.39

18.43

27.01

19.58

Measurements are made after homogenization with (1) sodium acetate buffer with pH 5, (2) potassium phosphate buffer with pH 7.5, (3) 0.1% TCA and (4)

methanol. As Total is represented the capacity of the sample calculated as a sum of the different fractions according to: a one-step procedure, b two-step

procedure, c three-step procedure. Data are presented as mol Fe2+ g-1 FW SE (n= 6), and respective % from total TAC (at the right side of each value). For

details see materials and methods.

558

BIOTECHNOL. & BIOTECHNOL. EQ. 22/2008/1

The protein fraction included proteins in pellet, protein-bound

phenolic compounds, and various high-molecular biopolymers.

The primary antioxidants in the protein fraction are the reactive

thiol groups of the cysteine residues and some membranebound molecules. Interestingly, when evaluated according to

the TEAC assay, the protein fraction contributed 42.2% (for

acetate buffer) to the total antioxidant capacity (Table 1),

whereas this percent was significantly lower (4.8% for same

buffer) when the fraction was assessed for its reducing (FRAP)

capacity (Table 2). This is due to the fact that the FRAP assay

does not measure thiol antioxidants (23).

As a whole, the changes in the total antioxidant capacity

of plant products could be evaluated more accurately when

the probes are fractionated into 3 fractions. This approach is

especially useful for studying the effects of aging, processing

and storage on the antioxidant capacity. For example, during

storage of potato tubers (6) were observed a decrease in the

levels of the water-soluble ascorbate, whereas the contents of

the lypophilic tocopherol remained virtually unchanged (15).

The degree of degradation of the water-soluble and waterinsoluble lypophilic antioxidants in plant products is variable

and most probably depends substantially on the severity and

duration of processing, packaging material, storage conditions,

etc. Moreover, the initial levels of antioxidant compounds

vary significantly among species. The effects of geographical

locations, cultivar, and ripening should also be kept in mind

(10, 18). All this sets the necessity for a complex approach in

sample preparation prior to measuring the antioxidant capacity

of plant material.

Conclusions

Generally, based on our results we recommend the newest

three-step procedure and homogenization of the samples with

moderate acid pH buffer, e.g. acetate buffer pH 5, as the most

reliable way of evaluating the TAC of plant material. The twostep procedure can be used as an alternative. Most appropriate

solvents for the initial extraction are TCA or acetate buffer. The

water-insoluble lypophilic antioxidants are easily extracted

with acetone. The two-step procedure is simple to perform and

is suitable for large-scale investigations. Finally, the one-step

procedures for sample preparation regardless of the extraction

solvent are unsatisfactory.

Acknowledgements

This study is partly supported by projects CC1413 and MU-B1505 (Ministry of Education and Science of Bulgaria).

REFERENCES

1. Alsher R. (1989) Physiol. Plant., 77, 457464.

2. Anza M., Riga P. Garbisu C. (2006) J. Food Quality, 29,

1937.

3. Becker E.M., Nissen L.R., Skibsted L.H. (2004) Eur.

Food Res. Technol., 219, 561571.

4. Benzie I.F.F, Strain J.J. (1996) Anal. Biochem., 239, 70-76.

BIOTECHNOL. & BIOTECHNOL. EQ. 22/2008/1

5. Chen J., Lindmark-Mansson H., Gorton L., Aksson B.

(2003) Int. Dairy J., 13, 927935.

6. Dale M., Griffitsh D., Todd D. (2003) J. Agric. Food

Chem., 51(1), 244248.

7. Duenas M., Hernndez T., Estrella I. (2006) Food Chem.,

98, 95103.

8. Halliwell B. (1990) Free Radical Res. Commun. 9, 132.

9. Halliwell B., Gutteridge J. (1999) Free radicals in biology

and medicine (3rd edn). Oxford University Press.

10. Halvorsen B.L., Holte K., Myshrastad M.C.W., Barikmo

I., Hvattum E., Remberg S.F., Wold A., Haffner K.,

Baugerod H., Andersen L.F., Moskaug J., Jacobs D.R.,

Blomhoff R. (2002) J. Nutr., 132, 461471.

11. Kiss S., Varga I.S., Galbacs Z., Maria T-H., Anna C-S.

(2003) Acta Biol. Szegediensis, 47(1-4), 127130.

12. Krieger-Liszkay A. (2005) J. Exp. Botany 13, 110.

13. Leonard S.S., Cutler D., Ding M., Vallyathan V.,

Castranova V., Shi, X. (2002) Annals Clinical &

Laboratory Sci. 32(2), 193200.

14. Miller H., Rigelhof F., Marquart L., Prakash A., Kanter

M. (2000) J. American College Nutr., 19(3), 312319.

15. Morris W., Ducreux, L., Ggriffitsh D., Stewart D., Davies

H., Taylor M. (2004) J. Exp. Botany, 55, 975982.

16. Nilsson J. (2003) PhD Thesis, Lund University, Sweden.

17. Noctor G. (2006) Plant Cell Environ., 29, 409425.

18. Olsson M., Ekvall J., Gustavsson K-E., Nilsson J., Pillai

D., Sjholm I., Svensson U., Kesson B., Nyman M.

(2004) J. Agric. Food Chem., 52, 24902498.

19. Ou B., Huang D., Hampsch-Woodill M., Flanagan J.A.,

Deemer E.K. (2002) J. Agric. Food Chem., 50, 31223128.

20. zkan G., Sagjdic O., Baydar N., Baydar H. (2004)

Food Sci. Tech. Int., 10(4), 271281.

21. Pellegrini N., Serafini M., Colombi B., Rio D., Salvatore S.,

Bianchi M., Brighenti F. (2003). J. Nutr., 133, 28122819.

22. Pellegrini N., Re R., Yang M., Rice-Evans C.A. (1999)

Methods Enzymol., 299, 1527.

23. Prior R., Wu X., Schaich K. (2005) J. Agric. Food Chem.,

53, 42904302.

24. Sanchez-Moreno C. (2002) Food Sci. Tech. Int., 8(3),

121137.

25. Siriwardhana N., Lee K.W., Kim S.H., Ha J.W., Jeon

Y.J. (2003) Food Sci. Tech. Int. 9(5), 339346.

26. Stefanovits-Bnyai E., Tulok M.H., Hegeds A., Renner

C., Varga I.S. (2003) Acta. Biol. Szegediensis, 47(1-4),

111113.

27. Sveto Y.T., Brian T., Benzie I.F. (2002) Brit. J. Nutr., 87,

5559.

28. Szllsi R., Varg I.S. (2002) Acta Biol. Szegediensis,

46(3-4), 125127.

29. Tausz M., Sircelj H., Grill D. (2004) J. Exp. Bot., 55,

19551962.

30. Wada L., Ou B. (2000) J. Agric. Food Chem., 50, 3495

3500.

559

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Harmonized Household Profiling ToolDokument2 SeitenHarmonized Household Profiling ToolJessa Mae89% (9)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Gloria Pfoltzer Theresa Morris, an Infant, by Mother and Next Friend Christopher Morris, an Infant, by Mother and Next Friend Randy Morris, an Infant, by Mother and Next Friend v. Fairfax County Department of Human Development Susan Manzo Paulette Byrd Florence Hannigan, and Louis Villafane, 966 F.2d 1443, 4th Cir. (1992)Dokument10 SeitenGloria Pfoltzer Theresa Morris, an Infant, by Mother and Next Friend Christopher Morris, an Infant, by Mother and Next Friend Randy Morris, an Infant, by Mother and Next Friend v. Fairfax County Department of Human Development Susan Manzo Paulette Byrd Florence Hannigan, and Louis Villafane, 966 F.2d 1443, 4th Cir. (1992)Scribd Government DocsNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- TFALL CaseStudy-Chandni+Chopra 072020+Dokument5 SeitenTFALL CaseStudy-Chandni+Chopra 072020+Luis Gustavo Heredia VasquezNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Editorship, Dr. S.A. OstroumovDokument4 SeitenEditorship, Dr. S.A. OstroumovSergei OstroumovNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Toaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRDokument17 SeitenToaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRBhumika SahuNoch keine Bewertungen

- Roadmap Video: Answer KeyDokument4 SeitenRoadmap Video: Answer KeyMaria JuneNoch keine Bewertungen

- SUPERHERO Suspension Training ManualDokument11 SeitenSUPERHERO Suspension Training ManualCaleb Leadingham100% (5)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Earth As A PlanetDokument60 SeitenEarth As A PlanetR AmravatiwalaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Assignment Nutrition and HydrationDokument17 SeitenAssignment Nutrition and Hydrationmelencio olivasNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- TelfastDokument3 SeitenTelfastjbahalkehNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Ammonium Chloride: Product InformationDokument2 SeitenAmmonium Chloride: Product InformationusamaNoch keine Bewertungen

- Readers Digest November 2021 PDF RD 2021 PDF EnglishDokument172 SeitenReaders Digest November 2021 PDF RD 2021 PDF EnglishIslam Gold100% (1)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Durock Cement Board System Guide en SA932Dokument12 SeitenDurock Cement Board System Guide en SA932Ko PhyoNoch keine Bewertungen

- The Superhero LifestyleDokument9 SeitenThe Superhero LifestyleDerp Blood0% (3)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- BlackCat ManualDokument14 SeitenBlackCat ManualNestor Marquez-DiazNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayDokument356 SeitenThe Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayClinica MonserratNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Waste Sector ProjectsDokument5 SeitenWaste Sector ProjectsMrcoke SeieNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- German Specification BGR181 (English Version) - Acceptance Criteria For Floorings R Rating As Per DIN 51130Dokument26 SeitenGerman Specification BGR181 (English Version) - Acceptance Criteria For Floorings R Rating As Per DIN 51130Ankur Singh ANULAB100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Community Medicine DissertationDokument7 SeitenCommunity Medicine DissertationCollegePaperGhostWriterSterlingHeights100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- AppendicitisDokument7 SeitenAppendicitisTim LuoNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Afforestation Powerpoint For NandniDokument9 SeitenAfforestation Powerpoint For NandniFagun Sahni100% (1)

- Richard Teerlink and Paul Trane - Part 1Dokument14 SeitenRichard Teerlink and Paul Trane - Part 1Scratch HunterNoch keine Bewertungen

- CL Analyzer: Coagulometric, Chromogenic and Immunological AssaysDokument2 SeitenCL Analyzer: Coagulometric, Chromogenic and Immunological AssaysEdwinNoch keine Bewertungen

- Course Syllabus Manufacturing Processes (1) Metal CuttingDokument4 SeitenCourse Syllabus Manufacturing Processes (1) Metal CuttingG. Dancer GhNoch keine Bewertungen

- Soal 2-3ADokument5 SeitenSoal 2-3Atrinanda ajiNoch keine Bewertungen

- Quarterly Progress Report FormatDokument7 SeitenQuarterly Progress Report FormatDegnesh AssefaNoch keine Bewertungen

- Tracheo Esophageal FistulaDokument6 SeitenTracheo Esophageal Fistulablast2111Noch keine Bewertungen

- 10.0 Ms For Scaffolding WorksDokument7 Seiten10.0 Ms For Scaffolding WorksilliasuddinNoch keine Bewertungen

- Practice Problems Mat Bal With RXNDokument4 SeitenPractice Problems Mat Bal With RXNRugi Vicente RubiNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)