Beruflich Dokumente

Kultur Dokumente

Wall Mounted CHW FCU Catalogue

Hochgeladen von

saw1511985Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wall Mounted CHW FCU Catalogue

Hochgeladen von

saw1511985Copyright:

Verfügbare Formate

MCAC-KTSM-2008-06

Contents

Part 1 General Information .................................................................................................... 1

Part 2 Indoor Unit ................................................................................................................... 3

Part 3 Installation.................................................................................................................. 19

Part 4 Control........................................................................................................................ 33

Contents

Contents

MCAC-KTSM-2008-06

Introduction

MKG fan coil is a kind of newly designed fan coil units, which is mounted on the wall. It has two kinds of body,

both have 3-way valve inside the body. In additional, it has panels of different color can be optional.

MKG series fan coil is designed and manufactured on the base of fully adoption advanced technology. The

acute and thin body makes it save a lot of space and easy for installation. Quality materials and

state-of-the-art technology ensure optimal performance with virtually imperceptible noise levels and keep

running smoothly.

Midea MKG series fan coil unit has been tested by national AC quality supervise testing center, as low noise

level, high efficiency, stable operation and low power consumption make it as the advanced production in the

world,. Due to their reduced dimensions and pleasing design, these units are ideally suited for Commercial

and Residential environments.

ii

Contents

MCAC-KTSM-2008-06

General Information

Part 1

General Information

1. Model Names of Fan Coil .............................................2

2. External Appearance ....................................................2

3. Nomenclature ................................................................2

General Information

Model Names of Fan Coil

MCAC-KTSM-2008-06

1. Model Names of Fan Coil

No

1

2

3

4

5

Type

Wall-mounted type

Model

MKG-250

MKG-300

MKG-400

MKG-500

MKG-600

Power source

220-230V~,1Ph, 50Hz

2. External Appearance

3. Nomenclature

G 250

Air volume (CFM)

Product Type

G: Wall-mounted type

Chilled water fan coil

Midea

General Information

MCAC-KTSM-2008-06

Indoor Unit

Part 2

Indoor Unit

1. Features .........................................................................4

2. Specification ..................................................................5

3. Dimensions....................................................................7

4. Service Spaces ..............................................................8

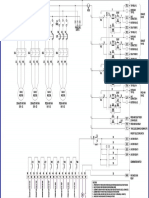

5. Wiring Diagram..............................................................8

6. Capacity Tables .............................................................9

7. Electric Characteristics ..............................................15

8. Sound Levels...............................................................15

9. Exploded View.............................................................16

10. Operation Limits........................................................18

Indoor Unit

Features

MCAC-KTSM-2008-06

1. Features

LED

display

1. LED display.

2. Big and small panels have different colors for choose: white and brown for big panel, blue and brown for

small panel, and the other colors can be customized according to the customers demands.

3. Multi-connection outlet pipe method: left\right\rear, satisfy the need of different rooms.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Built-in the electromagnetic 3-way valve.

Adopt new type installation plate, easy for installation and stable.

Three air flow speed: highmiddle and low, double air guides.

Low noise, creates quite and comfortable environment.

Air cleaning equipment and the high efficiency filter, keep the air fresh.

The same controller as DX system, Remote control is standard, wire control, central control can be

optional.

Copper tube/aluminum fin coils

ON/OFF terminal for remote control

Reserve control port for water pump & water level switch in the PCB

Accessorial electric heater, carbanion filter, electrostatic dust wipe off

Indoor Unit

MCAC-KTSM-2008-06

Specification

2. Specification

Type

MKG-250

Power Source

V-Ph-Hz

MKG-300

MKG-400

220-230V~, 1Ph, 50Hz

CFM

250

300

400

m /h

425

510

680

2200

2638

3077

Btu/h

7500

9000

10500

3019

3693

4338

Btu/h

10300

12600

14800

Rated Input

28

40

44

Rated Current

0.13

0.18

0.20

Indoor sound level (sound pressure level)

dB(A)

30/28/23

35/32/27

35/32/27

Water flow

LPH

378

454

529

Water resistance

kPa

12

18

22

Airflow

Cooling Capacity

Heating Capacity

Number of rows

Indoor Coil

Tube pitch(a)x row pitch(b)

mm

2113.37

2113.37

2113.37

Fin spacing

mm

1.5

1.5

1.5

Fin type

hydrophilic aluminium

Tube outside dia. and type

mm

7, bare tube

Coil length x height x width

mm

63531526.74

Number of circuits

Indoor fan motor

Indoor unit

Model

YDK9-6A

YDK15-4

YDK15-4

Brand

Weilling

Weilling

Weilling

Input

23/21/20

41/33/27

41/33/27

Capacitor

uF

0.8

1.2

1.2

Speed

r/min

740/670/620

1000/860/730

1000/860/730

Dimension (WHD)

mm

915 x210x290

Packing

mm

1020X300X385

(WHD)

Net/Gross weight

kg

12/16

Control mode

Pipe

12/16

12/16

Remote controller (standard) ( R51/E)

Water-inlet pipe

mm(inch)

19.1(3/4)

19.1(3/4)

19.1(3/4)

Water-return pipe

mm(inch)

19.1(3/4)

19.1(3/4)

19.1(3/4)

mm

20

20

20

Condensation water-outlet pipe

Remark:

1.

All performance data above is based upon 0Pa ambient static pressure.

2.

Cooling capacity test condition: air inlet Temp. : 27DB/19WB, water inlet Temp. 7, water Temp. difference 5.

3.

Heating capacity test condition: Air inlet Temp. 20DB, water inlet Temp. 50 DB, the volume of air and water is same as

4.

cooling.

Noise level is tested in full-anechoic room.

Indoor Unit

Specification

MCAC-KTSM-2008-06

Type

MKG-500

Power Source

V-Ph-Hz

MKG-600

220-230V~, 1Ph, 50Hz

CFM

500

600

m /h

850

1020

4074

4455

Btu/h

13900

15200

5686

6300

Btu/h

19400

21500

Rated Input

50

60

Rated Current

0.23

0.27

Indoor sound level (sound pressure level)

dB(A)

38/35/31

38/35/31

Water flow

LPH

701

766

Water resistance

kPa

26

29

Airflow

Cooling Capacity

Heating Capacity

Number of rows

Indoor Coil

Tube pitch(a)x row pitch(b)

mm

2113.37

2113.37

Fin spacing

mm

1.5

1.5

Fin type

hydrophilic aluminium

Tube outside dia. and type

mm

7, bare tube

Coil length x height x width

mm

78531526.74

Number of circuits

Indoor fan motor

Indoor unit

Model

YDK18-4

Brand

Weilling

Input

Capacitor

uF

44/42/39

1

1.5

Speed

r/min

1030/980/880

Dimension (WHD)

mm

1070 x210x315

Packing

mm

1180X300X410

kg

15/19

(WHD)

Net/Gross weight

Control mode

Pipe

Remote controller (standard) ( R51/E)

Water-inlet pipe

mm(inch)

19.1(3/4)

19.1(3/4)

Water-return pipe

mm(inch)

19.1(3/4)

19.1(3/4)

mm

20

20

Condensation water-outlet pipe

Remark:

1.

All performance data above is based upon 0Pa ambient static pressure.

2.

Cooling capacity test condition: air inlet Temp. : 27DB/19WB, water inlet Temp. 7, water Temp. difference 5.

3.

Heating capacity test condition: Air inlet Temp. 20DB, water inlet Temp. 50 DB, the volume of air and water is same as

4.

cooling.

Noise level is tested in full-anechoic room.

Indoor Unit

MCAC-KTSM-2008-06

Dimensions

3. Dimensions

Model

MKG-250

MKG-300

MKG-400

MKG-500

MKG-600

915

915

915

1070

1070

290

290

290

315

315

725

725

725

885

885

670

670

670

815

815

Indoor Unit

Service Spaces

MCAC-KTSM-2008-06

4. Service Spaces

5. Wiring Diagram

Indoor Unit

MCAC-KTSM-2008-06

Capacity Tables

6. Capacity Tables

Cooling Capacity Table:

Model

Water

Inlet

temp.

()

MKG-250

10

Water

flow

volume

(L/H)

Hydraulic

pressure

drop

(kPa)

330

Air inlet condition

DB25

DB17

DB26

DB18

DB27

DB19

DB28

DB20

SH

TH

SH

TH

SH

TH

SH

TH

10.5

1647

1891

1709

2019

1762

2148

1832

2277

380

12.0

1685

2033

1748

2171

1802

2310

1874

2449

430

13.6

1733

2175

1798

2323

1854

2472

1928

2620

480

15.2

1756

2327

1821

2486

1878

2645

1953

2803

330

10.5

1616

1854

1676

1981

1728

2107

1797

2234

380

12.0

1739

2072

1804

2213

1860

2354

1934

2495

430

13.6

1743

2217

1808

2368

1864

2519

1938

2670

480

15.2

1789

2372

1856

2533

1914

2695

1990

2857

330

10.5

1588

1800

1647

1923

1698

2046

1766

2169

380

12.0

1625

1936

1686

2068

1738

2200

1808

2332

430

13.6

1651

2072

1713

2213

1766

2354

1836

2495

480

15.2

1696

2217

1759

2368

1814

2519

1886

2670

330

10.5

1423

1674

1477

1789

1522

1903

1583

2017

380

12.0

1473

1800

1528

1923

1575

2046

1638

2169

430

13.6

1535

1927

1593

2058

1642

2189

1708

2321

480

15.2

1555

2061

1613

2202

1663

2342

1730

2483

330

10.5

1366

1548

1417

1654

1460

1760

1519

1865

380

12.0

1380

1665

1431

1778

1476

1892

1535

2006

430

13.6

1457

1782

1512

1903

1559

2024

1621

2146

480

15.2

1458

1906

1513

2036

1560

2166

1622

2296

330

10.5

1119

1350

1161

1442

1197

1535

1245

1627

380

12.0

1157

1452

1200

1551

1238

1650

1287

1749

430

13.6

1205

1554

1250

1660

1289

1766

1340

1871

480

15.2

1201

1662

1246

1776

1285

1889

1336

2002

Remark

1. 1. DB: Dry Bulb Temp.

WB: Wet Bulb Temp.

TH: Total heat

SH: Sensible heat

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed air flow volume

should multiply with corresponding capacity modification coefficient

Cooling capacity modification coefficient table:

Model

MKG-250

Indoor Unit

Mid-speed

Low-speed

SH

TH

SH

TH

0.83

0.85

0.68

0.72

Capacity Tables

MCAC-KTSM-2008-06

Cooling Capacity Table:

Model

Water

Inlet

temp.

()

MKG-300

10

Water

flow

volume

(L/H)

Hydraulic

pressure

drop

(kPa)

410

Air inlet condition

DB25

DB17

DB26

DB18

DB27

DB19

DB28

DB20

SH

TH

SH

TH

SH

TH

SH

TH

16.1

1975

2267

2049

2421

2112

2576

2197

2731

460

18.0

2020

2438

2096

2604

2161

2770

2247

2936

510

20.2

2078

2608

2156

2786

2223

2964

2312

3142

560

22.2

2105

2791

2184

2981

2252

3171

2342

3362

410

16.1

1937

2224

2010

2375

2072

2527

2155

2679

460

18.0

2085

2484

2163

2653

2230

2823

2319

2992

510

20.2

2090

2658

2168

2839

2235

3020

2324

3201

560

22.2

2145

2844

2226

3038

2294

3232

2386

3426

410

16.1

1904

2159

1975

2306

2036

2453

2118

2601

460

18.0

1949

2321

2021

2480

2084

2638

2167

2796

510

20.2

1979

2484

2053

2653

2117

2823

2202

2992

560

22.2

2033

2658

2109

2839

2175

3020

2262

3201

410

16.1

1707

2008

1771

2145

1825

2282

1898

2419

460

18.0

1766

2159

1832

2306

1889

2453

1965

2601

510

20.2

1841

2310

1910

2468

1969

2625

2048

2783

560

22.2

1865

2472

1934

2640

1994

2809

2074

2977

410

16.1

1637

1857

1699

1983

1751

2110

1821

2236

460

18.0

1655

1996

1716

2133

1770

2269

1840

2405

510

20.2

1748

2136

1813

2282

1869

2427

1944

2573

560

22.2

1749

2286

1814

2442

1870

2597

1945

2753

410

16.1

1342

1619

1392

1730

1435

1840

1493

1950

460

18.0

1387

1741

1439

1860

1484

1979

1543

2097

510

20.2

1445

1863

1499

1990

1545

2117

1607

2244

560

22.2

1440

1993

1494

2129

1540

2265

1602

2401

Remark

1. 1. DB: Dry Bulb Temp.

WB: Wet Bulb Temp.

TH: Total heat

SH: Sensible heat

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed air flow volume

should multiply with corresponding capacity modification coefficient

Cooling capacity modification coefficient table:

Model

MKG-300

10

Mid-speed

Low-speed

SH

TH

SH

TH

0.84

0.86

0.70

0.74

Indoor Unit

MCAC-KTSM-2008-06

Capacity Tables

Cooling Capacity Table:

Model

Water

Inlet

temp.

()

MKG-400

10

Air inlet condition

Water

flow

volume

(L/H)

Hydraulic

pressure

drop

(kPa)

SH

TH

SH

TH

SH

TH

SH

TH

430

17.8

2304

2644

2390

2824

2464

3005

2562

3185

530

22.0

2356

2843

2444

3037

2520

3231

2621

3425

630

26.2

2424

3042

2515

3250

2593

3457

2696

3664

730

30.3

2456

3255

2548

3477

2626

3699

2731

3921

430

17.8

2260

2594

2344

2771

2417

2947

2514

3124

530

22.0

2432

2897

2523

3095

2601

3292

2705

3490

630

26.2

2437

3100

2529

3311

2607

3523

2711

3734

730

30.3

2502

3317

2596

3543

2676

3769

2783

3996

430

17.8

2221

2518

2304

2690

2375

2862

2470

3033

530

22.0

2273

2708

2358

2892

2431

3077

2528

3262

630

26.2

2309

2897

2395

3095

2469

3292

2568

3490

730

30.3

2372

3100

2460

3311

2536

3523

2638

3734

430

17.8

1991

2342

2065

2502

2129

2661

2214

2821

530

22.0

2060

2518

2137

2690

2203

2862

2292

3033

630

26.2

2147

2694

2228

2878

2296

3062

2388

3246

730

30.3

2175

2883

2256

3080

2326

3276

2419

3473

430

17.8

1910

2166

1981

2313

2043

2461

2124

2609

530

22.0

1930

2329

2002

2487

2064

2646

2147

2805

630

26.2

2039

2492

2115

2662

2180

2831

2267

3001

730

30.3

2040

2666

2116

2848

2181

3030

2269

3211

430

17.8

1565

1889

1624

2017

1674

2146

1741

2275

530

22.0

1618

2031

1679

2169

1731

2308

1800

2446

630

26.2

1685

2173

1749

2321

1803

2469

1875

2617

730

30.3

1680

2325

1743

2484

1797

2642

1869

2801

DB25

DB17

DB26

DB18

DB27

DB19

DB28

DB20

Remark

1. 1. DB: Dry Bulb Temp.

WB: Wet Bulb Temp.

TH: Total heat

SH: Sensible heat

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed air flow volume

should multiply with corresponding capacity modification coefficient

Cooling capacity modification coefficient table:

Model

MKG-400

Indoor Unit

Mid-speed

Low-speed

SH

TH

SH

TH

0.85

0.87

0.71

0.75

11

Capacity Tables

MCAC-KTSM-2008-06

Cooling Capacity Table:

Model

Water

Inlet

temp.

()

MKG-500

10

Air inlet condition

Water

flow

volume

(L/H)

Hydraulic

pressure

drop

(kPa)

SH

TH

SH

TH

SH

TH

SH

TH

600

22.2

3050

3501

3164

3740

3262

3978

3393

4217

700

26.0

3120

3764

3237

4021

3337

4278

3470

4534

800

29.7

3210

4028

3330

4303

3433

4577

3570

4852

900

33.4

3251

4310

3373

4604

3477

4898

3616

5191

600

22.2

2992

3434

3104

3668

3200

3902

3328

4137

700

26.0

3220

3836

3340

4098

3444

4359

3582

4621

800

29.7

3227

4105

3348

4384

3452

4664

3590

4944

900

33.4

3313

4392

3437

4691

3543

4991

3685

5290

600

22.2

2940

3334

3050

3561

3145

3789

3271

4016

700

26.0

3009

3585

3122

3830

3218

4074

3347

4318

800

29.7

3057

3836

3171

4098

3269

4359

3400

4621

900

33.4

3140

4105

3258

4384

3358

4664

3493

4944

600

22.2

2636

3101

2734

3312

2819

3524

2932

3735

700

26.0

2728

3334

2830

3561

2917

3789

3034

4016

800

29.7

2843

3568

2949

3811

3041

4054

3162

4297

900

33.4

2880

3817

2987

4078

3080

4338

3203

4598

600

22.2

2529

2867

2623

3063

2704

3258

2813

3454

700

26.0

2555

3083

2651

3293

2733

3504

2842

3714

800

29.7

2699

3299

2800

3524

2887

3749

3002

3974

900

33.4

2700

3530

2802

3771

2888

4011

3004

4252

600

22.2

2072

2501

2150

2671

2216

2842

2305

3012

700

26.0

2143

2689

2223

2872

2292

3056

2383

3239

800

29.7

2232

2877

2315

3073

2387

3269

2482

3466

900

33.4

2224

3078

2307

3288

2379

3498

2474

3708

DB25

DB17

DB26

DB18

DB27

DB19

DB28

DB20

Remark

1. DB: Dry Bulb Temp.

WB: Wet Bulb Temp.

TH: Total heat

SH: Sensible heat

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed air flow volume

should multiply with corresponding capacity modification coefficient

Cooling capacity modification coefficient table:

Model

MKG-500

12

Mid-speed

Low-speed

SH

TH

SH

TH

0.85

0.87

0.70

0.75

Indoor Unit

MCAC-KTSM-2008-06

Capacity Tables

Cooling Capacity Table:

Model

Water

Inlet

temp.

()

MKG-600

10

Air inlet condition

Water

flow

volume

(L/H)

Hydraulic

pressure

drop

(kPa)

SH

TH

SH

TH

SH

TH

SH

TH

670

25.4

3335

3828

3460

4089

3567

4350

3710

4611

770

29.0

3411

4116

3539

4397

3649

4678

3795

4958

870

32.9

3510

4405

3641

4705

3754

5005

3904

5306

970

36.7

3555

4713

3688

5034

3802

5356

3955

5677

670

25.4

3272

3755

3394

4011

3499

4267

3639

4523

770

29.0

3521

4195

3653

4481

3766

4767

3916

5053

870

32.9

3529

4488

3661

4794

3774

5101

3925

5407

970

36.7

3623

4803

3759

5130

3875

5458

4030

5785

670

25.4

3215

3646

3336

3895

3439

4143

3576

4392

770

29.0

3291

3920

3414

4188

3519

4455

3660

4722

870

32.9

3343

4195

3468

4481

3575

4767

3718

5053

970

36.7

3434

4488

3562

4794

3672

5101

3819

5407

670

25.4

2882

3391

2990

3622

3083

3853

3206

4084

770

29.0

2983

3646

3095

3895

3190

4143

3318

4392

870

32.9

3109

3901

3225

4167

3325

4433

3458

4699

970

36.7

3149

4174

3267

4459

3368

4743

3503

5028

670

25.4

2765

3136

2869

3349

2957

3563

3076

3777

770

29.0

2794

3372

2899

3601

2988

3831

3108

4061

870

32.9

2951

3608

3062

3854

3157

4099

3283

4345

970

36.7

2953

3860

3064

4123

3158

4386

3285

4650

670

25.4

2266

2734

2351

2921

2424

3107

2521

3294

770

29.0

2343

2940

2431

3141

2506

3341

2606

3542

870

32.9

2440

3146

2532

3361

2610

3575

2714

3790

970

36.7

2432

3366

2523

3596

2601

3825

2705

4055

DB25

DB17

DB26

DB18

DB27

DB19

DB28

DB20

Remark

1. DB: Dry Bulb Temp.

WB: Wet Bulb Temp.

TH: Total heat

SH: Sensible heat

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed air flow volume

should multiply with corresponding capacity modification coefficient

Cooling capacity modification coefficient table:

Model

MKG-600

Indoor Unit

Mid-speed

Low-speed

SH

TH

SH

TH

0.85

0.87

0.70

0.75

13

Capacity Tables

MCAC-KTSM-2008-06

Heating Capacity Table:

Model

MKG-250

MKG-300

MKG-400

MKG-500

MKG-600

Water

flow

volume

(L/H)

Hydraulic

pressure

drop (kPa)

330

Air inlet temp.DB20

Water inlet temp.

40

45

50

55

60

70

8.4

2180

2524

2868

3442

4130

4956

380

9.6

2294

2657

3019

3623

4347

5217

430

10.9

2432

2816

3200

3840

4608

5530

480

12.2

2529

2929

3328

3994

4793

5751

410

12.9

2666

3087

3508

4210

5052

6062

460

14.4

2807

3250

3693

4432

5318

6382

510

16.2

2975

3445

3915

4697

5637

6764

560

17.8

3094

3583

4071

4885

5862

7035

430

14.2

3132

3627

4121

4945

5934

7121

530

17.6

3297

3817

4338

5206

6247

7496

630

20.9

3495

4046

4598

5518

6622

7946

730

24.2

3634

4208

4782

5739

6886

8264

600

17.8

4105

4753

5402

6482

7778

9334

700

20.8

4321

5004

5686

6823

8188

9825

800

23.7

4581

5304

6027

7233

8679

10415

900

26.7

4764

5516

6268

7522

9026

10832

670

20.3

4549

5267

5985

7182

8618

10342

770

23.2

4788

5544

6300

7560

9072

10886

870

26.3

5075

5877

6678

8014

9616

11540

970

29.3

5278

6112

6945

8334

10001

12001

Remark

1. DB: Dry Bulb Temp.

WB: Wet Bulb Temp.

TH: Total heat

SH: Sensible heat

2. Table above is based on normal type fan coil high speed air-flow volume; heating capacity on other speed air flow volume

should multiply with corresponding capacity modification coefficient

Heating capacity modification coefficient table:

Model

MKG-250

MKG-300

MKG-400

MKG-500

MKG-600

Mid-speed

0.85

0.86

0.88

0.88

0.88

Low-speed

0.73

0.76

0.72

0.73

0.74

14

Indoor Unit

MCAC-KTSM-2008-06

Electric Characteristics

7. Electric Characteristics

Indoor Unit

Model

Power Supply

IFM

Hz

Voltage

Min.

Max.

MCA

MFA

KW

FLA

MKG-250

50

220-230V

209

252

0.12

15

0.009

0.1

MKG-300

50

220-230V

209

252

0.19

15

0.015

0.185

MKG-400

50

220-230V

209

252

0.2

15

0.015

0.185

MKG-500

50

220-230V

209

252

0.24

15

0.018

0.19

MKG-600

50

220-230V

209

252

0.33

15

0.018

0.19

Remark:

MCA: Min. Current Amps. (A)

MFA: Max. Fuse Amps. (A)

KW: Fan Motor Rated Output (kW)

FLA: Full Load Amps. (A)

IFM: Indoor Fan Motor

8. Sound Levels

Test condition

Unit Number

Model

Noise level under three speeds of fan (dB(A))

H

MKG-250

30

28

23

MKG-300

35

32

27

MKG-400

35

32

27

MKG-500

38

35

31

MKG-600

38

35

31

Indoor Unit

15

Exploded View

MCAC-KTSM-2008-06

9. Exploded View

9.1 MKG-250

MKG-300

No.

Part

MKG-400

Quantity

No.

Filter

Name

14

Louver

Part

Name

Quantity

1

Evaporator I

15

Panel dalle

Evaporator II

16

Panel

Evaporator

17

Panel frame ass'y

Coil temp sensor

18

Stepper motor

Evaporate connect board

19

Screw cover

Display board ass'y

20

Pipe clamp

Motor

21

Drainage pan

Base pan assembly

22

Bearing base

10

Motor spud

23

Evaporator left clapboard

11

E-part box ass'y

24

Water inlet pipe ass'y

Dial code switch box cover

25

Water outlet pipe ass'y

11.2

Electric control box seat

26

Three-way valve

11.3

E-Part box cover

27

Control wire for 3-Ways valve

11.4

Electric control box soleplate

28

Outlet screw pipe ass'y

11.1

11.5

Electric control box side board ass'y

29

Inlet screw pipe ass'y

11.6

Dial code switch board ass'y

30

Discharge valve

11.7

Main controller ass'y

31

Cross fan

11.8

Transformer

32

Base pan holder

11.9

Wire joint

33

Formaldehyde killer

11.10

Wire joint, 3p

34

Room Temperature Sensor

11.11

16

Ass'y

Motor capacitor

35

Network matching wire

12

Air outlet frame mount ass'y

36

Remote controller

13

Louver board

37

Remote controller holder ass'y

Indoor Unit

MCAC-KTSM-2008-06

9.2 MKG-500

No.

Exploded View

MKG-600

Quantity

No.

Part

Filter

14

Air outlet frame mount ass'y

Evaporator I

15

Louver board

Part

Name

Name

Quantity

Evaporator II

16

Louver

Evaporator

17

Panel dalle

Coil temp sensor

18

Panel

Evaporate connect board

19

Stepper motor

Cross fan

20

Screw cover

Display board ass'y

21

Pipe clamp

Motor

22

Drainage pan

10

Base pan assembly

23

Bearing base

11

Motor spud

24

Water inlet pipe ass'y

12

Panel frame ass'y

25

Water outlet pipe ass'y

E-part box ass'y

26

Three-way valve

13.1

Dial code switch box cover

27

13.2

13

Electric control box seat

28

Control wire for 3-Ways valve

Outlet screw pipe ass'y

13.3

E-Part box cover

29

Inlet screw pipe ass'y

13.4

Electric control box soleplate

30

Discharge valve

13.5

Electric control box side board ass'y

31

Evaporator left clapboard

13.6

Dial code switch board ass'y

32

13.7

Main controller ass'y

33

Base pan holder

Formaldehyde killer

13.8

Transformer

34

Room Temperature Sensor

13.9

Motor capacitor

35

Network matching wire

13.10

Wire joint, 3p

36

Remote controller

13.11

Wire joint

37

Remote controller holder ass'y

Indoor Unit

Ass'y

17

Operation Limits

MCAC-KTSM-2008-06

10. Operation Limits

Use the system in the following temperature for safe and effective operation.

Temperature

Mode

18

water inlet

temperature

Cooling operation

3C20C

Heating operating

30C70C

Dry operation

3C20C

Indoor Unit

MCAC-KTSM-2008-06

Installation

Part 3

Installation

1. Installation Attention...................................................20

2. Accessory ....................................................................22

3. Inspecting and Handling the unit ..............................22

4. Indoor Unit Installation ...............................................23

5. Water Pipe Installation................................................27

6. Wiring ...........................................................................28

Installation

19

Installation Attention

MCAC-KTSM-2008-06

1. Installation Attention

Warning:

Be sure only trained and qualified service personnel to install, repair or service the equipment.

Improper installation, repair, and maintenance may result in electric shocks, short-circuit, leaks, fire or other

damage to the equipment.

Install according to this installation instructions strictly.

If installation is defective, it will cause water leakage, electrical shock and fire.

When installing the unit in a small room, take measures against to keep water concentration from

exceeding allowable safety limits in the event of water leakage.

Contact the place of purchase for more information.

Use the attached accessories parts and specified parts for installation.

Otherwise, it will cause the set to fall, water leakage, electrical shock fire.

Install at a strong and firm location which is able to withstand the sets weight.

If the strength is not enough or installation is not properly done, the set will drop to cause injury.

The appliance must be installed 2.3m above floor.

The appliance shall not be installed in the laundry.

Before obtaining access to terminals, all supply circuits must be disconnected.

The appliance must be positioned so that the plug is accessible.

The enclosure of the appliance shall be marked by word, or by symbols, with the direction of the

fluid flow.

For electrical work, follow the local national wiring standard, regulation and this installation

instruction. An independent circuit and single outlet must be used.

If electrical circuit capacity is not enough or defect in electrical work, it will cause electrical shock fire.

Use the specified cable and connect tightly and clamp the cable so that no external force will be

acted on the terminal.

If connection or fixing is not perfect, it will cause heat-up or fire at the connection.

Wiring routing must be properly arranged so that control board cover is fixed properly.

If control board cover is not fixed perfectly, it will cause heat-up at connection point of terminal, fire

or electrical shock.

If the supply cord is damaged, it must be replaced by the manufacture or its service agent or a similarly

qualified person in order to avoid a hazard.

An all-pole disconnection switch having a contact separation of at least 3mm in all poles should be

connected in fixed wiring.

Do not modify the length of the power supply cord or use of extension cord, and do not share the

single outlet with other electrical appliances.

Otherwise, it will cause fire or electrical shock.

Carry out the specified installation work after taking into account strong winds, typhoons or

earthquakes.

Improper installation work may result in the equipment falling and causing accidents.

If the water leaks during installation, ventilate the area immediately.

After completing the installation work, check that water does not leak.

20

Installation

MCAC-KTSM-2008-06

Installation Attention

Caution:

Ground the air conditioner.

Do not connect the ground wire to gas or water pipes, lightning rod or a telephone ground wire. Incomplete

grounding may result in electric shocks.

Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric shocks.

Connect the outdoor unit wires, then connect the indoor unit wires.

You are not allowed to connect the air conditioner with the power source until wiring and piping the air

conditioner is done.

While following the instructions in this installation manual, install drain piping in order to ensure

proper drainage and insulate piping in order to prevent condensation.

Improper drain piping may result in water leakage and property damage.

Install the indoor and outdoor units, power supply wiring and connecting wires at least 1 meter away

from televisions or radios in order to prevent image interference or noise.

Depending on the radio waves, a distance of 1 meter may not be sufficient enough to eliminate the noise.

The appliance is not intended for use by young children or infirm persons without supervision.

Don't install the air conditioner in the following locations:

z There is petrolatum existing.

z There is salty air surrounding (near the coast).

z There is caustic gas (the sulfide, for example) existing in the air (near a hot spring).

z The Volt vibrates violently (in the factories).

z In buses or cabinets.

z In kitchen where it is full of oil gas.

z There is strong electromagnetic wave existing.

z There are inflammable materials or gas.

z There is acid or alkaline liquid evaporating.

z Other special conditions.

Installation Order:

z

z

z

z

z

z

Select the location;

Install the indoor unit;

Install the outdoor unit;

Connect the drain pipe;

Wiring;

Test operation.

Installation

21

Accessory

MCAC-KTSM-2008-06

2. Accessory

Name

Shape

Quantity

Function

Installation board

Screw ST3.9x25 for installation board

Plastic expanded tube

Wrapping tape

Drain pipe

Sealing clay

Wall conduit cover

Remote controller (including operation manual)

Frame

Hold the remote controller

Mounting screw(ST2.910-C-H)

Insulation Holder for remote

controller

Alkaline dry batteries (AM4)

Owner's manual

Installation manual

Secure the installation board

3. Inspecting and Handling the unit

At delivery, the package should be checked and any damage should be reported immediately to the carrier

claims agent.

When handling the unit, take into account the following:

1.

Fragile, handle the unit with care.

2.

Keep the unit upright in order to avoid compressor damage.

3. Choose on before hand the path along which the unit is to be brought in.

4. Move this unit as originally package as possible.

5. When lifting the unit, always use protectors to prevent belt damage and pay attention to the position of

the units centre of gravity.

22

Installation

MCAC-KTSM-2008-06

Indoor Unit Installation

4. Indoor Unit Installation

4.1 Installation place

Installation in the following places may cause trouble. If it is unavoidable, please consult with the local

dealer.

A place full of machine oil.

A saline place such as coast.

A place full of sulfide gas such as hot-spring resort.

Places where there are high frequency machines such as wireless equipment, welding

Machine and medical facility.

A place there is no combustive gases and volatile matter.

A place of special environmental conditions.

Installation in the following places:

9 A place where is no obstacle near the inlet and outlet area.

9 A place which can bearf the indoor unit.

9 A place which is convenient to maintenance.

9 A place which provides the space around the indoor unit as required right in the diagram.

9 There is strong electromagnetic wave existing.

9 A place which is far from heat, steam and inflammable gas.

4.2 Drilling A Hole and Mounting Installation Board

Installation Board and Its Direction (unit: mm)

42.5\51\68 type:

85\102 type:

1. Fix the installation board.

Install the installation board horizontally on structural parts in the wall with the spaces provided around

the plate.

In case of brick, concrete or similar type walls, make 5mmdia, holes in the wall. Insert clip anchors for

appropriate mounting screws.

Fix the installation board on the wall.

Installation

23

Indoor Unit Installation

MCAC-KTSM-2008-06

Right installation:

False installation:

2. Drilling a hole.

Determine the pipe hole position using the installation board, and drill the pipe hole (N95mm) so it slants

slightly downward.

Always use a wall hole conduit when piercing metal lath, ply wood or metal plate.

4.3 Connective Pipe and Drainage Installation

1. Drainage

Run the drain hose sloping downward. Do not install the drain hose as illustrated below.

When connection extension drain hose, insulate the connecting part of extension drain hose with a shield

pipe.

24

Installation

MCAC-KTSM-2008-06

Indoor Unit Installation

2. Connection pipe

1)

a)

When install the water pipe of G unit, please following it:

Put down two screws between the pipe holder and unit, and then get down pipe holder. (Refer to the

following fig)

b)

c)

Connect pipe.

Install the pipe holder. (Refer to the following fig)

Installation

25

Indoor Unit Installation

2)

MCAC-KTSM-2008-06

For the left-hand and rear-left-hand piping, install the piping as shown. Bend the connective pipe

to be laid at 43mm height or less from the wall.

3) Fix the end of the connective pipe.

Caution:

z Connect the indoor unit first then the outdoor unit and bend and arrange the pipe carefully.

z Do not allow the piping to let out from the back of the indoor unit.

z Be careful not to let the drain hose slack.

z Insulate both of the auxiliary piping.

z Banding the drain hose under the auxiliary pipe.

z Do not allow the piping to let out from the back of the indoor unit.

3. Piping and bandaging

Wind the connective cable, drain hose and wiring with tape securely, evenly as shown below.

Because the condensed water from rear of the indoor unit is gathered in Pond Box and is piped out of room.

Do not put anything else in the box.

4.4 Indoor Unit Installation

26

Pass the piping through the hole in the wall.

Put the claw at the back of the indoor unit on the hook of the installation board, move the Indoor Unit

from side to side to see that it is securely hooked.

Piping can easily be made by lifting the indoor unit with a cushioning material between the indoor unit

and the wall. Get it out after finish piping.

Push the lower part of the Indoor Unit up to the wall, then move the Indoor Unit from side to side, up and

down to check if it is hooked securely.

Installation

MCAC-KTSM-2008-06

Water Pipe Installation

5. Water Pipe Installation

5.1 Material and Size of the Piping

Pipe material

Model

Coil connections (flat plate)

Copper Pipe for Air Conditioner

42.5/51/68

85/102

3/4

3/4

3/4

3/4

5.2 Connection of the Water Pipe

Connection of the water pipe should be done by professionals.

Double-span should be used when connecting pipes of Indoor Unit.

At the first debugging, completely expel air from coils via expelling valve.

Installation

27

Wiring

MCAC-KTSM-2008-06

6. Wiring

Caution:

The reserved function is indicated in broken line table, users can select it when necessary.

1. Take out the faceplate, then dismantle the display cover plate.

2. Individual connects the power cord and signal line, adjusts the dial switch.

6.1 Terminal Board Diagram

Please refer to the indoor unit wiring diagram for the wiring.

Note:

The air-conditioners can connect with Central Control Monitor (CCM). Before operation, please wiring

correctly and set system address and network address of indoor units.

28

Installation

MCAC-KTSM-2008-06

Wiring

Single phase indoor unit:

Please adopt the shielded twisted-pair wire, and connect the shielded layer to E

Installation

29

Wiring

MCAC-KTSM-2008-06

Insert 2 & 3 together is OK

The reserved wire control function is indicated in broken line table, users can purchase the wire controller

when necessary.

6.2 Network address set

Every air-conditioner in network has only one network address to distinguish each other. Address code of

air-conditioner in LAN is set by code switch on Network Interface Module (NIM), and the set range is 0-63.

Functions of cold-air proof and heat-air proof for your select

30

Installation

MCAC-KTSM-2008-06

Wiring

6.3 Trouble-shooting:

Malfunction code

EE

E2

E3

Malfunction

Water-level alarm malfunction

T2 evaporator sensor malfunction

T1 evaporator sensor malfunction

EE: Water-level alarm malfunction

Water-level switch connecting

wire between switch and main

board gets loose

Exist

Reconnect and ensure

that the connection is

reliable.

OK

There is something wrong

with the water-level switch

Exist

Replace switch

OK

Chip fault, or chip foot sheds off, or chip is

inverted (correct mode is semicircular bent

alignment)

OK

Mainboard error:

For example,

getting wet

Installation

Error

Reinstall chip, or install other chip

with same model on the faulty unit,

to check whether there is

something wrong with chip.

OK

Replace

mainboard

31

Wiring

MCAC-KTSM-2008-06

E2: T2 evaporator sensor malfunction

T2 Connecting wire between

sensor and mainboard gets

loose

Exist

Reconnect and ensure

that the connection is

reliable.

OK

Temperature

sensor

is

short-circuited or punctured

Exist

Replace sensor

OK

Chip fault, or chip foot sheds off, or chip is

inverted (correct mode is semicircular bent

alignment)

Error

OK

Reinstall chip, or install other chip

with same model on the faulty unit,

to check whether there is

something wrong with chip.

OK

Mainboard error:

For example,

getting wet

Replace

mainboard

E3: T1 evaporator sensor malfunction

T1 Connecting wire between

sensor and mainboard gets

loose

Exist

Reconnect and ensure

that the connection is

reliable.

OK

Temperature

sensor

is

short-circuited or punctured

Exist

Replace sensor

OK

Chip fault, or chip foot sheds off, or chip is

inverted (correct mode is semicircular bent

alignment)

OK

Mainboard error:

For example,

getting wet

32

Error

Reinstall chip, or install other chip

with same model on the faulty unit,

to check whether there is

something wrong with chip.

OK

Replace

mainboard

Installation

MCAC-KTSM-2008-06

Control

Part 4

Control

1. Wireless remote controller R51/E..............................34

2. Optional Controller .....................................................36

Control

33

Wireless remote controller R51/E

MCAC-KTSM-2008-06

1. Wireless remote controller R51/E

Remote Controller Specifications

Model

R51/E

Rated Voltage

3.0V

Lowest Voltage of CPU Emitting Signal

2.0V

Reaching Distance

8m (when using 3.0 voltage, it can get 11m)

Environment Temperature Range

-560

Introduction of Function Buttons on the Remote Controller

1. TEMP DOWN Button: Push the TEMP DOWN button to decrease the indoor temperature setting or to

adjust the timer in a counter-clockwise direction.

2. MODLE SELECT Button: Each time you push the button, a mode is selected in a sequence that goes

from AUTO, COOL, DRY, HEAT and FAN as the following figure indicates:

3. SWING Button: Push this switch button to change the louver angle.

4. RESET Button: When the RESET button is pushed, all of the current settings are cancelled and the

control will return to the initial settings.

5.

6.

7.

8.

34

ECONOMIC RUNNING Button: Push this button to go into the Energy-Saving operation mode.

LOCK Button: Push this button to lock in all the current settings. To release settings, push again.

CANCEL Button: Push this button to cancel the TIMER settings.

TIMER Button: This button is used to preset the time ON (start to operate) and the time OFF (turn off

the operation)

Control

MCAC-KTSM-2008-06

Wireless remote controller R51/E

9. ON/OFF Button: Push this button to start the unit operation. Push the button again to stop the unit

operation.

10. FAN SPEED Button: This button is used for setting fan speed in the sequence that goes from AUTO,

LOW, MED to HIGH, and then back to Auto.

11. TEMP UP Button: Push this button to increase the indoor temperature setting or to adjust the timer in a

counter-clockwise direction.

12. VENT Button: Push this button to set the ventilating mode. The ventilating mode will operate in the

following sequence:

Control

35

Optional Controller

MCAC-KTSM-2008-06

2. Optional Controller

2.1 The below is KJR-10B wired remote controller

NAME AND FUNCTION OF LCD ON THE WIRE CONTROLLER

1. Mode select button (MODE):

Press MODE button to select COOL, DRY , "HEAT", or "FAN ONLY" mode.(HEAT is invalid for

COOL ONLY wire controller.)

2. Fan speed button (FAN SPEED)

Press FAN SPEED to select fan speed from "AUTO", "LOW"," MED" , and "HIGH. NOTE: some air

conditioners have no MED fan speed, and then the MED is regarded as HIGH.

3. Economical operation displays:

Press ECONOMICAL to display economical operation, if press ECONOMICAL again then the display

disappears

36

Control

MCAC-KTSM-2008-06

Optional Controller

4. Lock display

Press LOCK to display the icon of LOCK. Press the button again then the icon of LOCK disappears. In

the mode of LOCK, all the buttons are invalid except for LOCK button.

5. CLOCK display

Usually display the clock set currently. Press the button CLOCK for 4 seconds, the HOUR part will flash,

press button and to adjust HOUR. Press the button CLOCK again, the minute part flash, press

button or to adjust MINUTE. After clock set or clock operation, it must press CONFIRM to complete

the set.

6. TIMER ON/OFF display:

Display ON at the state of TIMER ON adjustment or after only set the TIMER ON; Display OFF at the

state of TIMER OFF adjustment or after only set the TIMER OFF; Display ON/OFF if simultaneously set

the mode of TIMER ON and TIMER OFF.

7. Temperature display area:

Usually display the set temperature. Press the buttons of and to set temperature, at the mode of FAN,

there is no figure display in the area.

NAME AND FUNCTIONS OF BUTTONS ON WIRE CONTROLLER

1. mode selection button:

It is used to select mode, push the button one time, then the operation modes will change in turn as

follows:

AUTO COOLING DEHUMIDIFY HEATING FAN

Remark: no heating mode if wire controller is set as the cool only.

2. timer on button:

Push the button to set TIMER ON, each time you push the button the time moves forward by o.5 hours.

When the set time is over 10 hours, each time you push the button the time moves forward by 1 hour. If

want to cancel the TIMER ON, then adjust the time of TIMER ON as 0.0

3. timer off button:

Push the button to set TIMER OFF, each time you push the button the time moves forward by o.5 hours.

When the set time is over 10 hours, each time you push the button the time moves forward by 1 hour. If

want to cancel the TIMER OFF, then adjust the time of TIMER OFF as 0.0

4. CLOCK button:

Normally display the clock set currently (display 12:00 for the first electrifying or resetting). When push

the button for 4 seconds, the hour part on the clock display flashes every 0.5 seconds, then push button

and to adjust hour; push the button CLOCK again, the minute part flashes every 0.5 seconds, then push

and button to adjust minute. When set clock or alter clock setting, must push the confirm button to

complete the setting

Control

37

Optional Controller

MCAC-KTSM-2008-06

Installation

Installation Notice:

When the air conditioner needs the constant frequency wire Controller, be sure adding a Wire Joint with 5

terminal named

A, B, C, D, E in indoor unit, and fixing a infrared emitter whose anode and cathode connecting with A and B

near the receiver

in the Indoor Unit Switch Board, then connecting the terminal +5v, GND, Run in the Switch Board to C,D,E

respectively.

NOTE

Never turn screws too tightly, or else the cover would be dented or the Liquid Crystal breaks.

Please leave enough long cable for maintenance of the Wire Controller Board.

38

Control

MCAC-KTSM-2008-06

Optional Controller

2.2 The below is MD-CCM03 indoor CCM

Control

39

Optional Controller

40

MCAC-KTSM-2008-06

Control

MCAC-KTSM-2008-06

Optional Controller

Liquid crystal matrix display description:

1.

2.

3.

The liquid crystal matrix is composed of 4*64 grids, and each grid is composed of two blocks of different

sizes (as shown in the above figure).

The matrix includes horizontal coordinates 00-15 on the upper side and vertical coordinates 00+, 16+,

32+ and 48+ on the left

Side, which indicate the address of the indoor unit. The sum of the horizontal coordinate and the vertical

coordinate of the grid is the address of the grid. Each grid corresponds to an indoor unit of this address.

One grid is composed of two blocks of different sizes. The status

Indication table is as follows:

Status

Object

Big black block

Small black block

Constantly on

Slow blink

In-service

Selected

Power on

Fast blink

Out of service

Fault of indoor unit

Power off

LCD display description

1. Description of the standby page

1) The LCD displays the standby page, 60 air conditioners are in service, of which 28 are powered on and

32 off.

2) In the matrix, the big dots of (00, 16+) and (15,32+) are luminous, and the small dots are not luminous. It

indicates the 32 air conditioners with the addresses from 16 to 47 are powered off.

3) In the matrix, the big and small dots of (09, 48+) and (12, 48+) are not luminous. It indicates the four air

conditioners with the addresses from 57 to 60 are outside the network.

4) All other big and small dots in the matrix are luminous. It indicates all other air conditioners are in the

network and powered on.

5) The address of the air conditioner is sum of the coordinates. For example, the address of (09, 48+) is

09+48=57.

6) The centralized controller keypad is locked, and the centralized controller communicates with the

computer normally.

Control

41

Optional Controller

2.

1)

2)

3)

MCAC-KTSM-2008-06

Description of the query page

The LCD displays the query page, and the air conditioner with the address of 08 is being queried. Mode

of the air conditioner with the address 01 is: Cooling, strong air, swing on, indoor temperature 22C, set

temperature 20C, cooling mode lock.

In the matrix, only the big and small black dots at (00, 00+) and (01, 00+) are luminous. It indicates the

in-service and power-on status of the air conditioners with the addresses of 00 and 01.

The centralized controller communicates with the computer normally.

Description of the setting page

1) The LCD displays the setting page, and queries the air conditioner with the address of 08. The mode of

the air conditioner with the address 08 is: Cooling, strong air, swing on, indoor temperature 28C, set

temperature 22C, cooling.

2) In the matrix, only the big black dots from (08, 00+) to (16, 00+) are luminous. It indicates the air

conditioners with the addresses from 08 to 16 are in service.

3) The centralized controller communicates with the computer normally.

Fault page display description

42

Control

MCAC-KTSM-2008-06

1)

2)

3)

Optional Controller

Query the air conditioner with the address of 08 in the query page. The air conditioner with the address

of 08 is faulty, and the fault code is 08. The big black dot below (08, 0+) blinks.

In the matrix, only the big and small black dots from (00, 00+) to (16, 15+) illuminate. It indicates the

in-service status of the air conditioners with the addresses of 00 and 01.

The centralized controller communicates with the computer normally.

2.3 The below is MD-CCM04 weekly schedule timer

Control

43

Optional Controller

MCAC-KTSM-2008-06

Name and Function of Indicators on the controller

1.

Operation mode indication: When press "MODE and "ADD" or "REDUCE" button, the following

mode can be selected

in circle: Cool Heat Off.

For cooling only model, heat mode should be skipped.

2. Fan speed indication: There are four fan modes: low, middle, high, auto. For some models, no

middle fan then the middle fan is seen as high speed.

3. Fault indication.

4. Temperature indication.

5. Weekly Schedule Controller switch indication.

6. Date indication.

7. Time indication.

8. Period indication.

9. Lock indication.

10. Week indication.

NAME AND OPERATION OF THE BUTTON ON THE WIRE CONTROLLER

1.

44

Mode button: When press this button and

ADD or REDUCE button to select Heat or Cool or off, press Confirm to save and back.

Remark: For the cooling only model, the heating mode should be skipped.

Control

MCAC-KTSM-2008-06

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Optional Controller

Fan speed button: press this button and ADD or REDUCE Button to select of High or Middle or Low

or Auto, press

Confirm to save and back.

Edit button: When press this button, can setup Week and Date and Period.

Day button: press this button and ADD or REDUCE button to select of High or Middle or Low or

Auto, press Confirm to save and back.

Timer on/off button: Press this button, can turn off the weekly timer function.

Reset button: When press this button, all of the display part of LCD will be light last 2 second when

weekly timer has been electrified or reset. Following the lamp will be closed and last 1 second. So

the system will come into normal display state and need to carry out initial setting.

Lock button: press this button, weekly timer come into lock mode, Press LOCK again, lock mode is

unchained at once. Weekly timer lock mode state can not be canceled when weekly timer has

come back to supply power after interruption of power supply.

Cancel button: It is for not saving and retreating, or to cancel the lock.

Query button: Press Query Select query present temperature value press Cancel to back,

press Confirm time section parameters' setting :press Add or reduce to select several days

from Sun to Sat 7 days, press Confirm 1 ~8 time section selection beginning from No.1 time

section , setting modefan's velocitystarting time and end time, till 8 time sections are finished

press Confirm to save press Cancel to retreat.

Reduce button: It is for reducing to numbers and moving left or up to the other.

Add button: It is for adding to numbers, and moving right or down to the other.

Confirm button: It is for confirm selection.

Time button: When press button, and press Add or Reduce to adjust the hours value , press

Confirm adjust minutes: press Add or Reduce to adjust the minutes value, press Confirm to

save and back.

Installation

Control

45

Optional Controller

MCAC-KTSM-2008-06

Instruction for installing:

When a weekly schedule controller is needed, a small 2-cores wire and 3-cores wire should be added.

Connect with the same color.

Note

z The connecting wire should be a little longer as to take away the switch board easily for maintenance.

z The connecting wire should be a little longer as to take away the controller easily for maintenance.

46

Control

Das könnte Ihnen auch gefallen

- Saudi Aramco Radiation Protection Guidelines Unsealed Sources ContaminationDokument8 SeitenSaudi Aramco Radiation Protection Guidelines Unsealed Sources ContaminationbryanNoch keine Bewertungen

- A11-019 Toshiba R410Dokument241 SeitenA11-019 Toshiba R410list16947Noch keine Bewertungen

- Exertus Circa Operation Manual MKT - OM - CIRCA (Rev.01) - enDokument32 SeitenExertus Circa Operation Manual MKT - OM - CIRCA (Rev.01) - enmuni fatuzzahrohNoch keine Bewertungen

- Air Receiver Tank Hazard ChecklistDokument2 SeitenAir Receiver Tank Hazard ChecklistJade JavierNoch keine Bewertungen

- Tracer MP580/581 Programmable ControllersDokument16 SeitenTracer MP580/581 Programmable ControllersArthit MeanphayukNoch keine Bewertungen

- Ammonia Machinery Room Ventilation Requirements Dtc-Engineering-bulletin-4Dokument11 SeitenAmmonia Machinery Room Ventilation Requirements Dtc-Engineering-bulletin-4Sergio GarciaNoch keine Bewertungen

- 1 Heat Exchanger VDFDokument26 Seiten1 Heat Exchanger VDFPablo TorresNoch keine Bewertungen

- Penberthy Liquid Level Gage Gagecock AEDokument35 SeitenPenberthy Liquid Level Gage Gagecock AEDamon AlfaroNoch keine Bewertungen

- Ventilation Plan TemplateDokument11 SeitenVentilation Plan TemplatePlank89Noch keine Bewertungen

- Automobile Air Condition System Using Exahust GasDokument19 SeitenAutomobile Air Condition System Using Exahust GasEr. Ramji TripathiNoch keine Bewertungen

- Operation Manual: Air ConditionersDokument10 SeitenOperation Manual: Air ConditionersTechbhushanNoch keine Bewertungen

- AGZ026BDokument106 SeitenAGZ026Bciperu55Noch keine Bewertungen

- Ashrae Dammam 2017Dokument2 SeitenAshrae Dammam 2017habeebNoch keine Bewertungen

- Fire Protection Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanDokument21 SeitenFire Protection Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanmarvinNoch keine Bewertungen

- Magnochem: Installation/Operating ManualDokument110 SeitenMagnochem: Installation/Operating Manualjaelani sidikNoch keine Bewertungen

- Scaffold TowerDokument20 SeitenScaffold TowerAndhika HerdiawanNoch keine Bewertungen

- TNEGCDokument76 SeitenTNEGCAjit Kumar0% (1)

- SK Assoicates Authorized DealerDokument1 SeiteSK Assoicates Authorized DealerKamalesh KumarNoch keine Bewertungen

- Orbisphere 410 Quick GuideDokument12 SeitenOrbisphere 410 Quick GuiderafaelotreNoch keine Bewertungen

- EHS Approved Agencies for Fire Equipment TestingDokument8 SeitenEHS Approved Agencies for Fire Equipment Testingtp101267Noch keine Bewertungen

- Hot Work Pre-Inspection ChecklistDokument2 SeitenHot Work Pre-Inspection Checklistஹரிஹரசுதன்Noch keine Bewertungen

- Atex Guide PDFDokument6 SeitenAtex Guide PDFSELVARAJNoch keine Bewertungen

- Third Party Equipment ChecklistDokument5 SeitenThird Party Equipment ChecklistMARIO LEALNoch keine Bewertungen

- Common Terms Used in Instrument Calibration: Calibration RangeDokument4 SeitenCommon Terms Used in Instrument Calibration: Calibration RangeChidiebere Samuel OkogwuNoch keine Bewertungen

- Tae Evo 015 - 351 EnglDokument39 SeitenTae Evo 015 - 351 EnglMantenimientoValdezGutierrezNoch keine Bewertungen

- Vapour Absorption Chiller (VAM) - Working Principle in DetailDokument14 SeitenVapour Absorption Chiller (VAM) - Working Principle in DetailUPENNoch keine Bewertungen

- 09 WMI-Policy For Opening Ammonia Refrigeration SystemsDokument10 Seiten09 WMI-Policy For Opening Ammonia Refrigeration SystemsDave CNoch keine Bewertungen

- HSEQ - Calibration KitdddeeDokument4 SeitenHSEQ - Calibration KitdddeeSalim MuftahNoch keine Bewertungen

- Maintenance Schedule For Fire Alarm Addressable SystemDokument2 SeitenMaintenance Schedule For Fire Alarm Addressable SystemRobert LuggardNoch keine Bewertungen

- Installation Manual (PR215 216 517 03)Dokument36 SeitenInstallation Manual (PR215 216 517 03)Jkevin John Capada DardoNoch keine Bewertungen

- Name: SignDokument1 SeiteName: SignAdel AlKhedawyNoch keine Bewertungen

- LUFT AHU Installation Startup MaintananceDokument38 SeitenLUFT AHU Installation Startup MaintananceUğur DarcanNoch keine Bewertungen

- Generator Emission Test ResultsDokument2 SeitenGenerator Emission Test ResultsTaz UddinNoch keine Bewertungen

- Safety in Pressure TestingDokument12 SeitenSafety in Pressure TestingrodofgodNoch keine Bewertungen

- Flammability: A Safety Guide For Users: Best Practice Guidelines N°Dokument48 SeitenFlammability: A Safety Guide For Users: Best Practice Guidelines N°Anonymous smFxIR07Noch keine Bewertungen

- HSE-OCP-042 SRL - Access Control ProcedureDokument5 SeitenHSE-OCP-042 SRL - Access Control ProcedureibrahimNoch keine Bewertungen

- Safety Bulletin # 023: Confined Space Entry (Part 2)Dokument3 SeitenSafety Bulletin # 023: Confined Space Entry (Part 2)Al DubNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstDokument3 SeitenSaudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstAdel KlkNoch keine Bewertungen

- Positive Isolation StandardDokument21 SeitenPositive Isolation Standardmadhulika100% (2)

- 1-Piece Instrumentation, 40G and 40 Series: Part NoDokument2 Seiten1-Piece Instrumentation, 40G and 40 Series: Part Nozidanejason8Noch keine Bewertungen

- Oil and Gas Activity Operations ManualDokument208 SeitenOil and Gas Activity Operations Manualkhalil_ahmedinNoch keine Bewertungen

- 048 Pat LimitsDokument4 Seiten048 Pat LimitstorrespacNoch keine Bewertungen

- (ED) DMS502B51 (BACnet Gateway) EngDokument14 Seiten(ED) DMS502B51 (BACnet Gateway) EngTuongnhu DinhNoch keine Bewertungen

- Emergency PreparednessDokument16 SeitenEmergency PreparednessMuntaj AnsariNoch keine Bewertungen

- Wind Turbine Braking Systems SeminarDokument12 SeitenWind Turbine Braking Systems SeminarAkhil GuliaNoch keine Bewertungen

- Project: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Dokument14 SeitenProject: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Mohamed Wasim ShaikhNoch keine Bewertungen

- Fcu York Ysk SelectionDokument11 SeitenFcu York Ysk Selectionamo3330Noch keine Bewertungen

- Series 380 Impeller Btu SystemDokument14 SeitenSeries 380 Impeller Btu SystemJosimar AquijeNoch keine Bewertungen

- Specifications and diagrams for Daikin Deck Unit USDN~H Series condenserDokument1 SeiteSpecifications and diagrams for Daikin Deck Unit USDN~H Series condenserairlanggaputraNoch keine Bewertungen

- Installation ManualDokument64 SeitenInstallation ManualBùi LinhNoch keine Bewertungen

- F 1090 - 87 R97 - Rjewota - PDFDokument4 SeitenF 1090 - 87 R97 - Rjewota - PDFFreddy AlmeidaNoch keine Bewertungen

- Copeland Compresor 2019 ECT2014DS78 PDFDokument166 SeitenCopeland Compresor 2019 ECT2014DS78 PDFFrancisco Sanchez RNoch keine Bewertungen

- Ac MaintenanaceDokument22 SeitenAc Maintenanacenafis2uNoch keine Bewertungen

- CDM 2015 Simplified - What You Need To KnowDokument118 SeitenCDM 2015 Simplified - What You Need To KnowAchilleas21Noch keine Bewertungen

- OHS PROC 113 BarricadesDokument9 SeitenOHS PROC 113 BarricadesPhillip L100% (1)

- 360 CDE Atlas Copco Air Dryers ManualDokument38 Seiten360 CDE Atlas Copco Air Dryers Manualshamil130798100% (1)

- Isolation and Lockout - IEDokument25 SeitenIsolation and Lockout - IEyuwantoniNoch keine Bewertungen

- Pramac Portable Generator E5000Dokument15 SeitenPramac Portable Generator E5000Filipe HortaNoch keine Bewertungen

- Infineon SiGe LNA BFP760 Rev - 1Dokument27 SeitenInfineon SiGe LNA BFP760 Rev - 1tarpinoNoch keine Bewertungen

- 52 ServiceManual-R410AFixSpeedDokument213 Seiten52 ServiceManual-R410AFixSpeedFerenc SchmidtNoch keine Bewertungen

- Control Daigram BmsDokument1 SeiteControl Daigram Bmssaw1511985Noch keine Bewertungen

- Glazing Specification For RefDokument1 SeiteGlazing Specification For Refsaw1511985Noch keine Bewertungen

- Heat Recovery Technical GuideDokument50 SeitenHeat Recovery Technical Guidesaw1511985Noch keine Bewertungen

- Test LoadDokument1 SeiteTest Loadsaw1511985Noch keine Bewertungen

- Test LoadDokument1 SeiteTest Loadsaw1511985Noch keine Bewertungen

- Noise Conrol On Constructin & Demolition 1998Dokument8 SeitenNoise Conrol On Constructin & Demolition 1998saw1511985Noch keine Bewertungen

- Test LoadDokument1 SeiteTest Loadsaw1511985Noch keine Bewertungen

- Test Test Test For UploadDokument1 SeiteTest Test Test For Uploadsaw1511985Noch keine Bewertungen

- Electrical System Design Standard for Industrial InstallationsDokument185 SeitenElectrical System Design Standard for Industrial InstallationstavoliNoch keine Bewertungen

- Supervision GUide For Mechanical Engineering WorksDokument34 SeitenSupervision GUide For Mechanical Engineering Workssaw1511985Noch keine Bewertungen

- Test For UploadDokument1 SeiteTest For Uploadsaw1511985Noch keine Bewertungen

- Electrical System Design Standard for Industrial InstallationsDokument185 SeitenElectrical System Design Standard for Industrial InstallationstavoliNoch keine Bewertungen

- Econovent Sales BrochureDokument8 SeitenEconovent Sales Brochuresaw1511985Noch keine Bewertungen

- Df-0214 01 Daikin VRV AhuDokument2 SeitenDf-0214 01 Daikin VRV Ahusaw1511985Noch keine Bewertungen

- 70E PresentationDokument60 Seiten70E PresentationAdilson Leite ProençaNoch keine Bewertungen

- Appendix CDokument8 SeitenAppendix CMac ShaikNoch keine Bewertungen

- Assembly InstructionDokument20 SeitenAssembly Instructionsaw1511985Noch keine Bewertungen

- MIEEIDokument408 SeitenMIEEIsaw1511985Noch keine Bewertungen

- How To PassDokument5 SeitenHow To PassHasen BebbaNoch keine Bewertungen

- Motor Load and Lighting Ballast Ref PDFDokument5 SeitenMotor Load and Lighting Ballast Ref PDFsaw1511985Noch keine Bewertungen

- Pump FormulaDokument3 SeitenPump FormulaViwek MertiyaNoch keine Bewertungen

- Psychrometric ChartDokument2 SeitenPsychrometric Chartsaw1511985Noch keine Bewertungen

- RSE Part 1 Morning PDFDokument5 SeitenRSE Part 1 Morning PDFsaw1511985Noch keine Bewertungen

- Cable SizingDokument1 SeiteCable Sizingsaw1511985Noch keine Bewertungen

- Appendix CDokument8 SeitenAppendix CMac ShaikNoch keine Bewertungen

- RSE Part 2 - Evening P&S Solution PDFDokument7 SeitenRSE Part 2 - Evening P&S Solution PDFsaw1511985Noch keine Bewertungen

- RSE Part 1 Morning PDFDokument5 SeitenRSE Part 1 Morning PDFsaw1511985Noch keine Bewertungen

- FE Exam Info HandoutDokument3 SeitenFE Exam Info Handoutsaw1511985Noch keine Bewertungen

- BookDokument458 SeitenBookramoradoNoch keine Bewertungen

- Ae53 Ac53 At53Dokument4 SeitenAe53 Ac53 At53M Taher BamyaniNoch keine Bewertungen

- ContentServer PDFDokument16 SeitenContentServer PDFdaniel leon marinNoch keine Bewertungen

- Tower 3300 Instruction ManualDokument23 SeitenTower 3300 Instruction ManualMark RobertsNoch keine Bewertungen