Beruflich Dokumente

Kultur Dokumente

Ball Drop Inspection

Hochgeladen von

ravichandraCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ball Drop Inspection

Hochgeladen von

ravichandraCopyright:

Verfügbare Formate

Ball drop test for ensuring annulus gap in TN-RAM/TN-LC

Background:

Based on the radiometry results of TN-RAM conducted as per L&T/TN-RAM/15/GSP

R8, several areas of the cask were found to have a thickness reduction in lead w.r.t

design thickness. The thickness reduction areas as categorized in to three colour

codes in the report 20241/annular/01 R1 depending upon the magnitude of

thickness loss. The pink areas were the ones with greater than 2mm loss, green

ones with 1-2mm, blue ones with <1mm. Close observation of the location of blue

and green zones indicate clear polarization of their existence towards one half of

the cask. Further, it is observed that in the opposite half of the cask, thickness is

greater than design minima, i.e. 146 mm. This leads to the suspicion if the inner

and outer shells were concentric to each other before pouring or not.

Radiometry results:

The radiometry results

Inspection reports:

A dimensional inspection of cask assembly was done prior to lead pouring ( Report:

0200-01/D1/5.1/01 ). In this inspection, the annulus gap was calculated by

measuring the ID of inner shell and OD of outer shell and subtracting the

thicknesses of the shells. However, doing so would not give information about the

actual annulus gap present at that location, instead we end up with the average

annulus gap of two points located 1800 to each other.

Proposed Inspection:

To acquire meaningful information regarding the annulus gap present, there is need

for an inspection technique which physically ensures the gap. It can be achieved in

several ways. One way of doing it would be to make a sphere of diameter exactly

equal to required annulus gap and drop it into the annulus at various orientations.

This will ensure the presence of annular gap at every point along the particular

orientation.

Annulus

Sphere/ball

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Astm D16Dokument8 SeitenAstm D16ravichandra100% (1)

- EMATDokument28 SeitenEMATravichandraNoch keine Bewertungen

- DHDSDokument36 SeitenDHDSravichandraNoch keine Bewertungen

- Vpci-337 (1-6-11)Dokument5 SeitenVpci-337 (1-6-11)ravichandraNoch keine Bewertungen

- Hotel Booking FormDokument2 SeitenHotel Booking FormravichandraNoch keine Bewertungen

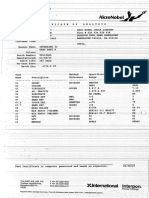

- AkzoDokument10 SeitenAkzoravichandra0% (1)

- PQR NewDokument2 SeitenPQR NewravichandraNoch keine Bewertungen

- Sonstest GelDokument2 SeitenSonstest GelravichandraNoch keine Bewertungen

- FORM-13 - Transfer of EPFDokument2 SeitenFORM-13 - Transfer of EPFravichandraNoch keine Bewertungen

- National Institute of Technology: M. Tech. Degree IN Non - Destructive TestingDokument36 SeitenNational Institute of Technology: M. Tech. Degree IN Non - Destructive TestingravichandraNoch keine Bewertungen

- Stages of Inspection and CTQ For The Pyrogel Installation in S0400058Dokument1 SeiteStages of Inspection and CTQ For The Pyrogel Installation in S0400058ravichandraNoch keine Bewertungen

- Fitz's Atlas of Coating DefectsDokument16 SeitenFitz's Atlas of Coating DefectsravichandraNoch keine Bewertungen

- RwoDokument6 SeitenRworavichandraNoch keine Bewertungen

- Until We Extend The Circle of Our Compassion To All Living Things, Humanity Will Not Know Peace.Dokument1 SeiteUntil We Extend The Circle of Our Compassion To All Living Things, Humanity Will Not Know Peace.ravichandraNoch keine Bewertungen

- Vino TH AbstractDokument1 SeiteVino TH AbstractravichandraNoch keine Bewertungen

- Regulations: Operative From June 2014Dokument20 SeitenRegulations: Operative From June 2014ravichandraNoch keine Bewertungen

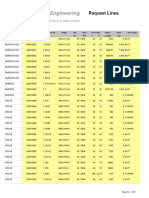

- Request LinesDokument8 SeitenRequest LinesravichandraNoch keine Bewertungen

- Specific Exam QuestionsDokument2 SeitenSpecific Exam QuestionsravichandraNoch keine Bewertungen

- Accoustic Emmission Testing PresentationDokument25 SeitenAccoustic Emmission Testing PresentationravichandraNoch keine Bewertungen

- PQRDokument2 SeitenPQRravichandraNoch keine Bewertungen

- Scanning in Corner Areas - RadiometryDokument3 SeitenScanning in Corner Areas - RadiometryravichandraNoch keine Bewertungen

- 1.0 Introduction To Ultrasonic Thickness GagingDokument2 Seiten1.0 Introduction To Ultrasonic Thickness GagingravichandraNoch keine Bewertungen

- Copy of 45802-1 Rescan StatusDokument3 SeitenCopy of 45802-1 Rescan StatusravichandraNoch keine Bewertungen