Beruflich Dokumente

Kultur Dokumente

Abdel-Hamid Et Al. - 1998 - Fast Amperometric Assay For E. Coli O157H7 Using Partially Immersed Immunoelectrodes

Hochgeladen von

Jimmy SimpsonOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Abdel-Hamid Et Al. - 1998 - Fast Amperometric Assay For E. Coli O157H7 Using Partially Immersed Immunoelectrodes

Hochgeladen von

Jimmy SimpsonCopyright:

Verfügbare Formate

758

Fast Amperometric Assay for E. coli O157:H7 Using Partially

Immersed Immunoelectrodes

Ihab Abdel-Hamid, Dmitri Ivnitski, Plamen Atanasov, and Ebtisam Wilkins*

Chemical and Nuclear Engineering Department, University of New Mexico, Albuquerque, NM 87131

Received: April 3, 1998

Final version: May 14, 1998

Abstract

A novel amperometric immunoelectrode for fast and sensitive assay of E. coli O157:H7 is presented. Antibodies against E. coli O157:H7 were

immobilized on the surface of carbon rods, which acted as both working electrode and sorbent surface. A sandwich scheme of immunoassay was

used and 5-aminosalicylic acid was employed as a redox mediator for the amperometric detection of the enzyme-label (horseradish peroxidase).

The immunoelectrodes were operated while being partly immersed in the detection cell which resulted in the acceleration of the diffusioncontrolled rates of immunological, enzymatic and electrochemical reactions. The amperometric immunoelectrode allows the achievement of

significantly lower detection limits (40 times lower) than that achievable with standard spectrophotometric detection ELISA method using the same

immunochemicals. The immunoelectrode allows determination of E. coli cell concentrations in the range from 200 to 7000 cells/mL with an overall

analysis time of 40 min. This immunoelectrode can be easily adapted for assay of other microorganisms and may be a basis for creating a new class

of highly sensitive and rapid immunosensors.

Keywords: Escherichia coli O157:H7, Bacteria immunoassay, Immunoelectrode, Amperometric detection

1. Introduction

Bacteria, and other microorganisms are among the most common

pathogens in the environment [1, 2]. An average person carries

more than 150 kinds of bacteria which exist both inside and outside

the body [3]. Bacteria can spread easily and rapidly, requiring food,

moisture and a favorable temperature. E. coli O157:H7 is one of the

most dangerous food-borne pathogens [4, 5]. The O157:H7 is a rare

strain of E. coli that produces large quantities of a potent toxin that

can be accumulated in the lining of the intestine and causes severe

damage to it, resulting in hemorrhagic colitis or hemolytic uremic

syndrome and may lead to death especially in children [5, 6]. E. coli

can easily contaminate ground beef, raw milk and poultry,

therefore, careful control of E. coli is extremely important both

for food quality control and food safety. The effective testing of

food products requires methods of analysis that meet a number of

challenging criteria. Very low detection limits are required, since an

infectious dose may be as little as few hundreds of organisms.

Traditional methods for enumerating coliform bacteria (colony

counts) are often slow (from 24 to 72 h are required to obtain

confirmable results [7]) and may vary in reliability. Therefore,

existing techniques are unable to meet modern requirements of

instantaneous food quality control and considerable effort has been

made on the development of rapid, sensitive and accurate analytical

tools and methods for determining microorganisms concentration in

foods [8, 9].

Immunosensors based on highly specific immunological reactions combined with different amplification systems offer an

attractive approach towards solving this problem [9]. Various

types of immunoassay techniques have been developed for E. coli

determination [912]. However, these methods still require

significant time for analysis (several hours) and are greatly lacking

sensitivity. It has been demonstrated that diffusion to the interface

of the solid phase is a rate-limiting step during heterogeneous

electrochemical immunoassays [13]. Due to this diffusion control,

the time for achieving equilibrium of reaction between the

immobilized antibody and the antigen in solution is usually on

the order of several tens of minutes. The result is a fairly lengthy

overall assay. The general way to achieve significantly short

Electroanalysis 1998, 10, No. 11

immunoassay times is to reduce transport limitations across the

unstirred layer of solvent (the layer of immobilized electrolyte) to

the solid surface. The acceleration of the diffusion-controlled rate of

immunological and enzymatic reactions on the solid-solution

interface has been accomplished by: intensive mixing of the

solution (liquid phase) [14]; conducting immunoreactions in an

ultranarrow microcapillary immunoreactor or porous material [15];

the utilization of highly dispersed carbon-based immunosorbents as

electrode materials [16]; or by using an enzyme-channeling

approach which allows in situ generation of the substrates of the

enzyme-label [17].

In this work and for the first time, we present the possibility of

using of partially immersed immunoelectrodes for enhancing the

speed and sensitivity of immunoassays. A schematic of such a

partially immersed immunoelectrode is illustrated in Figure 1. The

fully immersed immunoelectrode (h 0; where h is the length of

the liquid meniscus) is covered by the liquid and thus contacts the

bulk electrolyte with all of its surface; there is no meniscus or thin

film of electrolyte formed around the electrode. As the electrode is

raised from this fully immersed position (h > 0), a liquid meniscus is

formed at the gas/liquid/solid interface. In addition to this meniscus

the hydrophilic protein layer (antibody or enzyme modifying the

electrode surface) facilitates formation of an additional thin liquid

film, the supermeniscus, on the electrode surface (placed above the

meniscus). This supermeniscus is characterized by a thickness of

approximately 0.40.8 mm. The meniscus and supermeniscus play

an important role in providing hydrodynamic conditions of the thin

film in the process of current signal generation.

It has been shown that for capillary systems (including partially

immersed and gas-diffusion electrodes), the magnitude of the

current obtained from a partially immersed electrode is 5 to 10

times greater than that obtained from a fully immersed electrode

[1820]. Since the magnitude of the diffusionally limited current is

inversely proportional to the thickness of the diffusion layer, the

effects observed with the partially immersed electrodes may be

explained by facilitated diffusion of reagents (antigen, conjugate,

substrate and product of enzymatic reaction) to the electrode

surface in the upper part of the meniscus and in the supermeniscus

where the electrode, the electrolyte, and the gas phase meet. Also,

the thickness of the supermeniscus is usually much less than the

q WILEY-VCH Verlag GmbH, D-69469 Weinheim, 1998

1040-0397/98/1109-0758 $ 17.50.50/0

Fast Amperometric Assay for E. coli O157:H7

759

coli O157:H7 (positive control), affinity purified antibody to E. coli

O157:H7 (anti-E. coli antibody, specific to a flagellum protein of

this particular strain of the bacteria), and peroxidase-labeled affinity

purified antibody to E. coli O157:H7 (conjugate) were obtained

from Kirkegaard & Perry Laboratories (KPL, Inc., Gaithersburg,

MD). Mortalyzed bacteria were used for safety reasons and to

ensure a static (nonproliferating) sample population for quantitative

purposes. Reference quantifications of moralyzed bacteria samples

were performed by hemacytometer counts and used to prepare stock

bacterial suspensions in phosphate-buffered saline. All other

chemicals (including buffer solutions components) were of the

highest purity available and were supplied from Sigma.

2.2. ELISA Procedure

Fig. 1. Schematic of the fully (a) and partially (b) immersed protein-coated

electrodes.

characteristic thickness of the stagnated diffusion layer in the bulk

solution, thus the transport of antigen, conjugate and substrate

molecules through such a film on the electrode surface is facilitated

compared to that through the bulk solution. The effective volume of

the electrolyte participating in the measurement is very small

(concentric cylinder of liquid around the electrode). This may result

in increased local concentration of the product of the enzymatic

reaction due to transport hindrances for the product formed at the

electrode surface to diffuse back to the bulk electrolyte. This

retaining of the product in close proximity of the electrode may

result in higher amperometric signal values. Therefore, the

analytical characteristics of a partially immersed immunoelectrode

are expected to be better than those of a fully immersed one and

result in increasing the signal values and reducing the response

times. This will potentially lead to improvement in the assay

sensitivity and reducing the overall time of analysis. This work

illustrates this approach, while presenting the development of a

heterogeneous enzyme-linked immunoassay for E. coli O157:H7

utilizing a partly immersed immunoelectrode.

2. Experimental

2.1. Materials

Carbon rods used for the fabrication of immunoelectrodes were a

courtesy of DFI Inc. (Erlanger, KY). Horseradish peroxidase (HRP,

E.C.1.11.1.7, activity 90 EU.mg1), its substrates: 5-aminosalicylic

acid (5-ASA), ortho-phenylenediamine (OPD), and hydrogen

peroxide (30 % v/v aqueous solution), as well as: bovine serum

albumin (BSA), N-ethyl-5-phenyl-isoxazolium-30 -sulfonate (Woodwards reagent K), poly-oxyethylene-sorbitan monolaurate (Tween

20) were obtained from Sigma Chem. Co. (St. Louis, MO).

Mortalyzed (by heat treatment) lyophilized pathogenic Escherichia

Sandwich scheme ELISA procedure was performed with

standard polystyrene 96-well plates (Corning Co.). In order to

modify each individual well with the primary antibody, 100 mL of a

10 mg/mL solution of antibody against E. coli O157:H7 diluted in

0.1 M phosphate buffer solution, pH 7.2 (PBS) was passively

adsorbed to the polystyrene cuvettes (wells) at 37 8C for 1 h, and the

cuvettes were rinsed three times (3 min each) with 0.1 M phosphate

buffer solution (pH 7.2) containing 0.5 M NaCl and 0.1 % Tween

20, (washing buffer). Aliquot of 100 mL of E. coli cells suspension

(positive control) was incubated in the cuvettes at room temperature

for 2 h and the cuvettes were rinsed three times (3 min each) with

washing buffer. Then 100 mL of the conjugate solution was added

and incubated for 1 h. The cuvettes were again rinsed as previously

described. For the detection stage 100 mL the enzyme substrate

solution containing 0.66 mg/ml of OPD in 0.1 M citric acidphosphate buffer (pH 5.0), was mixed with 5 mL of 30 % (v/v)

H2O2. The reagents were incubated for 15 min. The enzymatic

reaction was stopped by adding 150 mL of 1 M H2SO4 to each well.

The results of ELISA were measured by an spectrophotometric

ELISA-reader at a wavelength of l 492 nm.

2.3. Immunoelectrode Preparation

Carbon rods (2 mm diameter) were cut into 5 cm pieces. The rods

were insulated by multiple coating with cellulose acetate (from a

45 % w/v acetone solution) except for 1 cm at both ends (one end

designated as a working electrode surface and the other left for

current collecting) and left to dry for 30 min at room temperature.

Then each rod was inserted into a vessel containing 100 mL of

Woodwards reagent K solution (20 mg/mL) and incubated while

being shaken for two hours. This was followed by washing the rods

three times (3 min each) in 20 mM PBS solution (pH 7.4). Then, the

rods were inserted into a vessel containing 100 mL of a solution

containing antibodies against E. coli O157:H7 (0.4 mg/mL) and

shaken for 2 h. This was followed by another washing procedure.

Each rod with immobilized antibody was then inserted into a vessel

containing 200 mL of 1 % w/v BSA in 20 mM PBS (pH 7.8) and

again incubated under shaking conditons for two hours. The

electrodes were then washed and stored at 4 8C until measurement.

Typically 25 to 30 immunoelectrodes were simultaneously prepared.

Some studies of the amperometric assay system were performed

when carbon rod electrodes were unmodified (bare) or modified

directly by horseradish peroxidase by a procedure similar to that

described above, where peroxidase enzyme was immobilized

directly on the electrode surface, instead of incubating the

electrodes with primary antibodies. In this case, carbon rods were

activated by Woodwards reagent K (20 mg/mL) and then

immersed in a 20 mM phosphate buffer solution (pH 7.4) containing peroxidase (1 mg/mL) under shaking conditions for two hours.

Electroanalysis 1998, 10, No. 11

760

I. Abdel-Hamid et al.

Carbon rods with immobilized peroxidase was then incubated in

solution containing 200 mL of 1 % w/v BSA in 20 mM PBS

(pH 7.8) under shaking for two more hours. The electrodes were

washed and stored at 4 8C until measurement. Peroxidase activity

was assayed spectrophotometrically.

2.4. Amperometric Immunoassay Protocol

A sandwich scheme of immunoassay was employed and the

measurement procedure was carried out according to the following

steps. The immunoelectrodes (carbon rods with immobilized antiE. coli antibodies) were incubated for 26 min in 1 mL of 20 mM

acetate buffer (pH 5.0, 1 % w/v BSA) containing the desired

concentration of cells (first stage incubation). Immediately after the

incubation with the bacteria suspension (sample), the immunoelectrodes were washed 2 times (1 min each) in 1 mL of 20 mM acetate

buffer (pH 5.0, 1 % w/v BSA). The next step was incubating the

immunoelectrodes for 7 min in 0.3 mL of 20 mM acetate buffer

(pH 5.0, 1 % w/v BSA) containing 10 mL of 50 mg/mL of

peroxidase conjugated anti-E. coli antibodies (second stage

incubation). Then, the immunoelectrodes were washed, as before,

2 times (1 min each) in 1 mL of 20 mM acetate buffer (pH 5.0, 1 %

w/v BSA). The last step was the electrochemical measurement

which was carried out in a three-electrode cell (volume 0.3 mL)

with the immunoelectrode connected as a working electrode, a

carbon rod auxiliary electrode, and a standard Ag/AgCl reference

electrode. The electrolyte was 20 mM acetate buffer solution,

pH 5.0, containing 0.15 M NaCl. This electrolyte contained

0.6 mM of 5-aminosalicylic acid (5-ASA) and a polarization

potential of 0.0 V (vs. Ag/AgCl) was applied between the working

and reference electrodes using a bipotentiostat AFCBP1 (Pine

Instruments Co., Grove City, PA). The mixing of the electrolyte

was achieved by rotating of the immunoelectrode at a controlled

speed (usually at 300 rpm) by the Pine Instr. rotor/controller unit. In

the case of fully immersed electrode, the working electrode was

introduced in the cell so the electrolyte/air interface was in the

insulated zone of the carbon rod. Partially immersed state was

achieved, starting from the fully immersed condition, by gradually

elevating the electrode (using the rotor/controller unit lifting

mechanism). The length of the liquid meniscus formed was

estimated by observation (under a magnifying glass) and visual

comparison of it to a millimeter graduated standard. Immunoassay

steps: incubation, washing and electrochemical measurements were

performed utilizing both positions of the electrode: the fully

immersed position and the partially immersed position.

The background signal was measured while establishing its

steady-state value for 2 min. At this point 10 mL of 9 mM solution of

H2O2 was added to the cell and the amperometric signal was

monitored continuously employing an analog XY recorder

Ominigraphic 100 (Houston Instruments, Austin, TX). The time

for the amperometric signal to reach a steady-state value never

exceeded 3 minutes. Negative control experiments were carried out

when the first incubation stage was performed with no E. coli cells

in the sample. All experiments were carried out at room temperature

(approximately 20 8C).

Fig. 2. Mechanism of oxidation of 5-aminosalicylic acid in the presence of

hydrogen peroxide and peroxidase.

substrate (5-ASA) is widely used as a chromogenic noncarcinogenic substrate for horseradish peroxidase in enzyme immunoassay

with optical [21, 22] and potentiometric detection [23]. The reaction

scheme of the oxidation of 5-ASA in the presence of horseradish

peroxidase is shown in Figure 2 [24]. The oxidation of 5-ASA is a

two-electron process and is accompanied by the formation of the

electrochemically active species: 5-ASA-quinoneimine (5-ASA-QI).

The quinoneimine can further hydrolyze to benzoquinone which

forms a quinone/ hydroquinone redox couple. Cyclic voltammetry

of 5-ASA on the carbon rod electrodes indicated presence of the

5-ASA-QI form at potentials close to 0.0 V (vs. Ag/AgCl). Constant

potential amperometry experiments in the potential range from

0.1 to 0.1 V were conducted and it was found that for 5-ASAQI, an electro-reduction potential of 0.0 V (vs. Ag/AgCl) was

optimal from the point of view of signal-to-noise ratio and

sensitivity of peroxidase assay. At this potential a minimal (close

to zero) background current was observed.

The effect of pH on the rate of the peroxidase oxidation of 5-ASA

was also investigated. Figure 3 presents the steady-state values of

the amperometric response of a fully immersed carbon rod

electrode to the addition of 60 ng/mL peroxidase (in the solution)

at different pH. It can be seen that the activity of peroxidase was

highest between pH 4 and 5, and it gradually decreased in neutral

solutions (for pH greater than 5). Hence, a pH of 5 was selected as

standard for subsequent experiments of amperometric detection of

the peroxidase catalyzed reaction in the immunoassay.

Figure 4 shows typical response and a comparison of a fully

(h 0) and partially immersed (h > 0) peroxidase modified carbon

electrode in the presence of 0.15 mM hydrogen peroxide and

3. Results and Discussion

The amperometric immunoassay of E. coli was based on using

5-aminosalicylic acid (5-ASA) as a mediator for the measurement

of the activity of peroxidase-label in the immunocomplex

(sandwich) formed on the electrode surface. This peroxidase

Electroanalysis 1998, 10, No. 11

Fig. 3. Effect of pH on the response of the immersed carbon rod electrode to

addition of 60 ng/mL peroxidase. Conditions: potential applied 0.0 V (vs. Ag/

AgCl); 0.6 mM 5-ASA in 0.15 M NaCl; room temperature of 20 8C; rotating

speed 300 rpm. Points are means of three independent determinations.

Fast Amperometric Assay for E. coli O157:H7

761

Fig. 4. The response of the peroxidase modified electrode in 20 mM acetate buffer solution (pH 5) containing 0.15 mM H2O2, 0.6 mM 5-ASA and 0.15 M NaCl

as a function of the electrode position when raising from h 0 mm: current transients after injection of H2O2 in the solution (a) and dependence of the steady

state value of the signal on the electrode raising height (b).

0.6 mM 5-ASA. A constant potential of 0.0 V (vs. Ag/AgCl) was

applied to the electrode and the current transients were measured

following the introduction of H2O2 into the measuring cell at a

constant rotating speed of the cylindrical rod electrode. Figure 4a

presents the current transients obtained with the peroxidase

modified carbon rod electrode at different raising heights. It can

be seen that a fully immersed electrode (h 0) yields the lowest

amperometric response. Raising the electrode from the initial

totally immersed position (h 0) in the electrolyte solution results

in an increase in the amperometric response, reaching a maximum

at h 5 mm. Further raising of the electrode (h > 5) did not result in

further increase of the amperometric response. Figure 4b presents

the steady state signal values (plotted as means of three independent

measurements) vs. the raising height of the rod electrode. It can be

seen that the sensitivity of the partially immersed electrode

(h $ 5 mm) to hydrogen peroxide was 6 folds higher than for the

fully immersed one. The time required to reach 95 % of the steadystate current (after addition of the H2O2 sample) was less than 10 s

for this partially immersed electrode. Under the same conditions,

the response time of the fully immersed electrode is significantly

longer combined with a lower sensitivity. It can be hypothesized,

that the reason for the fast response and high sensitivity of the

partially immersed electrode are due to the attractive features of

the ultrathin electrolyte film in the supermeniscus region on the

electrode surface (see Fig. 1). The transport conditions for

electrochemically active species across the supermeniscus to the

electrode surface permit a rapid enzyme-substrate interaction and

therefore significantly reduce the assay time. This can be explained

by an effect of a small volume effective measuring cell formed by

the thin liquid film. One can think that the product of peroxidase

catalyzed reaction is retained in close proximity of the electrode,

thus resulting in higher values of amperometric response. On the

other hand, concentration of the electrochemically active species in

the supermeniscus might be increased by their surfactant properties,

which may lead to enhancement in the electrode sensitivity.

Figure 5 presents the dependence of the steady-state amperometric signal on increasing concentrations of horseradish peroxidase (varied from 10 to 100 ng/mL) for two 5-ASA concentrations

(0.6 mM and 1.3 mM) at a constant H2O2 concentration of 0.15 mM

for the partially immersed unmodified carbon rod electrode. All

measurements were conducted in a dynamic mode, while recording

the transient amperometric response of the electrode until reaching

the steady-state current plateau. It can be seen from Figure 5 that

for both 5-ASA concentrations, the amperometric signal magnitude

increases with increasing peroxidase concentrations and that

nanogram quantities (in the order of 1012 M) of peroxidase

enzyme can be detected in terms of current transients. It can also be

seen that the amperometric signal value is relatively higher at

0.6 mM 5-ASA concentration and decreases with increasing 5-ASA

concentrations to 1.3 mM. The signal value decreases further when

high concentrations of 5-ASA (> 1.3 mM) were used (not shown in

the figure). This can be explained by the fact that at high

concentration of 5-ASA the direction of the peroxidase oxidation

of 5-ASA changes (see Fig. 2). A polymer film is formed on the

electrode surface as a result of polymerization of the free radicals

formed during the enzymatic oxidation of 5-ASA at high

concentrations of this substrate [24]. This results in fouling of the

electrode surface. Therefore, all subsequent experiments were

performed with 0.6 mM 5-ASA.

3.1. ELISA of E. coli O157:H7

The E. coli samples were assayed by a standard sandwich ELISA

method with spectrophotometric detection in order to compare

ELISA performance with the electrochemical method of assay.

Polystyrene wells were coated with three dilutions of anti-E. coli

antibodies: 1/100, 1/1000, and 1/5000. The calibration plots for

E. coli obtained with the ELISA reader are shown in Figure 6. It

can be seen that the plots obtained with 1/100 and 1/1000 dilution of

Fig. 5. Calibration plots for peroxidase determination obtained with partially

immersed electrode in 20 mM acetate buffer solution (pH 5) containing

0.15 mM H2O2, 0.6 mM 5-ASA and 0.15 M NaCl.

Electroanalysis 1998, 10, No. 11

762

Fig. 6. Calibration plots of an Enzyme-linked Immunosorbent Assay

(ELISA) for determination of E. coli O157:H7 in phosphate buffer solution

with different dilutions of anti-E. coli antibodies (semilogarithmic plot).

Curves: 1) dilution 1:100; 2) dilution 1:1000; 3) dilution 1:5000.

the primary anti-E. coli antibodies practically coincide. When the

primary antibody dilution was increased to 1/5000, a significantly

lower response was obtained. Figure 6 shows that the standard

ELISA technique was able to detect E. coli O157:H7 in the range of

suspension concentrations from 104 to 107 cells/mL. The dynamic

range of the calibration plot (the fraction with a higher sensitivity)

lies within 105 107 cells/mL and the lower detection limit was

approximately 104 cells/mL. Thus, the sensitivity of this standard

ELISA assay is inadequate for practical application in direct assay

of food samples. The overall duration of this assay procedure is

approximately 4 h. The limiting factors of a heterogenic enzyme

immunoassay are diffusion transport conditions and the problem of

nonspecific binding of the conjugate to the solid surface.

3.2. Amperometric Immunoassay

Nonspecific binding of the conjugate to the solid surfaces is

among the most important factors influencing the achievable low

detection limit in immunoassays [25]. Nonspecific binding of antiE. coli-peroxidase conjugate in the format of the immunoelectrode

assay was studied using different blocking reagents: 0.1 M glycine,

1 % w/v BSA, and Tween-20. It was found that addition of 1 % w/v

BSA to the 20 mM acetate buffer (pH 5) markedly decreased

nonspecific adsorption of conjugate without altering the specific

binding. Low nonspecific binding of conjugate to the electrode

surface was observed when 1 % w/v BSA was used in all the steps

of immunoassay, including washing and measurement.

Figure 7 presents the calibration plots obtained for the assay of

E. coli O157:H7 cells using a fully (Fig. 7a) and partly immersed

(Fig. 7b) immunoelectrodes. It can be see from Figure 7a that the

lower detection limit of a fully immersed immunoelectrode was

7000 cells/mL and the dynamic range this calibration plot was

7 103 7 107 cells/mL. These characteristics of the calibration

plot of the fully immersed immunoelectrode were advantageous

while still comparable with that of the standard ELISA assay (see

Fig. 6). A significantly lower detection limit of 200 cells/mL was

obtained when using partially immersed immunoelectrodes

(Fig. 7b). The dynamic range of the calibration plot obtained

with partially immersed electrode was from 150 to 7000 cells/mL

(Fig. 7b). At bacteria suspension concentrations higher than 7 103

cells/mL the calibration plot reaches saturation. Along with the

Electroanalysis 1998, 10, No. 11

I. Abdel-Hamid et al.

Fig. 7. Calibration plots for determination of E. coli O157:H7 by means of a

sandwich scheme immunoassay using the fully (a) and partially (b) immersed

immunoelectrodes (semilogarithmic plot). Background signal level is shown

by a dashed line.

possible effect of concentration of the product of the enzymatic

reaction in the thin film, it can be hypothesized that the lowering of

the detection limit in the case of partially immersed immunoelectrode is associated also with some concentrating of the target

analytes (bacteria) and probably the immunoconjugate in the

meniscus and supermeniscus areas. This is probably due to their

surfactant properties. The presumption of such preconcentration

can explain the significantly lower saturation limit of the calibration

plot. On the other hand absolute signal values (steady-state current)

on both calibration plots, Fig. 7a and Fig. 7b can not be adequately

compared. Current densities are probably quite different, because

the experimental set-up did not allow exact determination of the wet

electrode area in the case of partially immersed electrode.

Contributions to the signal value of both immuno-interaction and

enzymatic reaction may be complex and are not well separated in

this system. By all means the physical chemistry behind the

phenomenon needs further investigation. From a practical analytical point of view, however, the system with fully/partially

immersed immunoelectrodes can be successfully applied for

detection of very low bacterial suspension concentrations (in a

partially immersed format) as well as for quantification of sufficiently

high concentrations (while using the totally immersed electrode). The

immunoassay detection stage demonstrates a fast response time of

20 s and an overall analysis time (including incubation and washing

stages) that does not exceed 40 min. All the assay procedures can be

automated and integrated in a dedicated immunoassay system for

detection of bacterial contamination in aqueous samples.

Immunoelectrodes demonstrated good reproducibility of their

analytical characteristics. In this format of the assay the carbon rod

electrodes were used as disposable sensing elements. Immunoelectrode response to each individual cell suspension concentrations

(presented in Fig. 7) was obtained as an average of four

measurements. Thus, sets of 20 to 30 individual electrodes were

used for obtaining the calibration plots (Fig. 7a and b).

4. Conclusions

This work shows that a partially immersed immunoelectrode can

find application in a rapid immunoassay of low concentrations of

Fast Amperometric Assay for E. coli O157:H7

aqueous suspensions of E. coli. Possible role of the conditions

formed with the partially immersed immunoelectrode in acceleration of the diffusion-controlled rates of immunological, enzymatic

and electrochemical reactions is yet to be studied in detail. The

capillary phenomena which are probably associated with the

observed effects could be explored also in other system formats

such as porous electrodes or hollow capillary tubes. This technique

employs surface reactions and therefore is not strictly dependent

on the reaction volume so that small sample volumes may be used.

E. coli concentrations could be detected in the range of 200 to 7000

cells/mL with an overall analysis time of 40 min. This immunoassay

approach can be easily extended to the detection of other bacterial

cells and may be a basis for creating a new type of highly sensitive

and rapid immunosensors.

5. Acknowledgements

This research was supported in part by a grant from the WasteManagement Education and Research Consortium of New Mexico.

Dr. Dmitri Ivnitski is thankful to the University of New Mexico,

School of Engineering for financial support.

6. References

[1] N.H. Bean, P.M. Griffin, J.S. Goulding, C.B. Ivey, J. Food Protection 1990,

53, 711.

763

[2] G.W. Beran, H.P. Shoeman, K.F. Anderson. Dairy Food Environ. Sci. 1991,

11, 189.

[3] C.W. Kaspar, C. Tartera, Methods Microbiol. 1990, 22, 497.

[4] R.L. Buchanan, M.P. Doly, Food Technol. 1997, 51, 69.

[5] P.M. Griffin, R.V. Tauxe, Epidemiol. Rev. 1991, 13, 60.

[6] P.C. Rowe, E. Orrbine, G.A. Wells, J. Pediatr. 1991, 119, 218.

[7] K. Helrich (ed.), Official Methods of Analysis of the Association of Official

Analytical Chemists, Vol. 2, 15th ed. (Ed: K. Helrich) AOAC Inc., Arlington,

VA 1990, pp. 425497.

[8] B.M. Paddle, Biosens. Bioelectron. 1996, 11, 1079.

[9] S. Oh, Trends Food Sci. Technol. 1993, 4, 98.

[10] F.J. He, Q. Geng, W. Zhu, L.H. Nie, S.Z. Yao, C. Meifeng, Anal.Chim. Acta

1994, 289, 313.

[11] E.J. Fricker, C.R. Fricker, Water Res. 1996, 30, 2226.

[12] R. Szabo, E. Todd, J. McKenzie, L. Parrington, A. Armstrong, Appl. Env.

Microbiol. 1990, 56, 3546.

[13] B.M. Gorovits, A.P. Osipov, A.M. Egorov, J. Immunol. Methods 1993, 157,

11.

[14] D. Huet, C. Gyss, C. Bourdillon, J. Immunol. Methods 1990, 135, 33.

[15] M. Frutos, S.K. Paliwal, F.E. Regnier, Anal. Chem. 1993, 65, 2159.

[16] R. Krishnan, A.L. Ghindilis, P. Atanasov, E. Wilkins, J. Montoa, F.T. Koster,

Electroanalysis 1996, 8, 1131.

[17] D. Ivnitski, J. Rishpon, Biosens. Bioelectron. 1996, 11, 409.

[18] K. Ogura, H. Watanabe, J. Chem. Soc., Faraday Trans. 1985, 81, 1569.

[19] I. Iliev, A. Kaisheva, F. Scheller, D. Pfeiffer, Electroanalysis 1995, 7, 542.

[20] J. Wang, P.V.A. Pamidi, C.L. Renschler, C. White, J. Electroanal. Chem.

1996, 404, 137.

[21] A.P. Bogoyavlenksy, I.E. Digel, V.E. Berezin, Biochemistry (Russ) 1997, 62,

870.

[22] D.I. Metelitsa, N.V. Girina, E.I. Karaseva, M.I. Savenkova, Appl. Biochem.

Microbiol. 1995, 31, 526.

[23] B.B. Dzantiev, A.V. Zherdev, M.F. Yulaev, R.A. Sitdikov, N.M. Dmitrieva,

I.Y. Moreva, Biosens. Bioelectron. 1996, 11, 179.

[24] R.K. Palsmeier, D.M. Radzik, C.E. Lunte, Pharm. Res. 1992, 9, 933.

[25] S.H. Jenkins, W.R. Heineman, H.B. Halsall, Anal. Biochem. 1988, 168,

292.

Electroanalysis 1998, 10, No. 11

Das könnte Ihnen auch gefallen

- Application and Evaluation of Loop Mediated IsotheDokument22 SeitenApplication and Evaluation of Loop Mediated IsotheAliyi HassenNoch keine Bewertungen

- Full Text 01Dokument70 SeitenFull Text 01anuj1166100% (1)

- 1 s2.0 S2405844023040288 MainDokument9 Seiten1 s2.0 S2405844023040288 MainHà NgọcNoch keine Bewertungen

- ElisaDokument13 SeitenElisaSHOBHIT KUMAR MUNANoch keine Bewertungen

- A Rapid Lateral - Ow Immunoassay For Phytosanitary Detection of Erwinia Amylovora and On-Site Re Blight DiagnosisDokument9 SeitenA Rapid Lateral - Ow Immunoassay For Phytosanitary Detection of Erwinia Amylovora and On-Site Re Blight DiagnosisDimitrius00Noch keine Bewertungen

- Chen 2014Dokument9 SeitenChen 2014RAJAN GARGNoch keine Bewertungen

- Antimicrobial Resistance Patterns of Escherichia Coli O157:H7 From Nigerian Fermented Milk Samples in Nasarawa State, NigeriaDokument7 SeitenAntimicrobial Resistance Patterns of Escherichia Coli O157:H7 From Nigerian Fermented Milk Samples in Nasarawa State, NigeriaWida YantiNoch keine Bewertungen

- Jurnal BiomedikDokument10 SeitenJurnal BiomedikneaNoch keine Bewertungen

- Biosensors 10 00054 v2Dokument18 SeitenBiosensors 10 00054 v2Krishna ChalamNoch keine Bewertungen

- Detection of Escherichia Coli O 157:H7 and O104:H4 in Patients With Diarrhea in Northern Lebanon and Characterization of Fecal E. Coli Producing ESBL and Carbapenemase GenesDokument8 SeitenDetection of Escherichia Coli O 157:H7 and O104:H4 in Patients With Diarrhea in Northern Lebanon and Characterization of Fecal E. Coli Producing ESBL and Carbapenemase GenesInternational Medical PublisherNoch keine Bewertungen

- ELISA ProtocolDokument29 SeitenELISA Protocolmelg16Noch keine Bewertungen

- Enzyme Linked Immunosorbent AssayDokument5 SeitenEnzyme Linked Immunosorbent AssayDesriwanAnggaMedicaNoch keine Bewertungen

- Full Report ELISA LatestDokument8 SeitenFull Report ELISA LatestBilal TahirNoch keine Bewertungen

- Assur EHEC 996.10 8-HourDokument8 SeitenAssur EHEC 996.10 8-Hourapi-3697331Noch keine Bewertungen

- Full Report - ELISA LatestDokument8 SeitenFull Report - ELISA LatestNik AmirNoch keine Bewertungen

- Asam PeroksideDokument6 SeitenAsam PeroksideAsa Étudier La-DienNoch keine Bewertungen

- Jurnal E.coliDokument6 SeitenJurnal E.coliShintia Cristin Min DalaNoch keine Bewertungen

- Techniques EverolimusDokument5 SeitenTechniques EverolimusJonatan David Escalante ORtizNoch keine Bewertungen

- DIRECT Elisa (Theory) - Immunology Virtual Lab I - Biotechnology and Biomedical Engineering - Amrita Vishwa Vidyapeetham Virtual LabDokument3 SeitenDIRECT Elisa (Theory) - Immunology Virtual Lab I - Biotechnology and Biomedical Engineering - Amrita Vishwa Vidyapeetham Virtual LabsantonuNoch keine Bewertungen

- Role of Weil Felix Test For Rickettsial InfectionsDokument3 SeitenRole of Weil Felix Test For Rickettsial InfectionsIOSRjournal100% (1)

- Elisa TestDokument9 SeitenElisa Testbrkica2011Noch keine Bewertungen

- Diagnosis and Treatment of Typhoid Fever and Associated PrevailingDokument7 SeitenDiagnosis and Treatment of Typhoid Fever and Associated Prevailing073090Noch keine Bewertungen

- Sobre Ação Do EDC NHSDokument6 SeitenSobre Ação Do EDC NHSAlberto Galdino SparrowNoch keine Bewertungen

- A Potentiometric Microbial Biosensor For Direct Determination of Organophosphate Nerve AgentsDokument5 SeitenA Potentiometric Microbial Biosensor For Direct Determination of Organophosphate Nerve AgentsBeaaaaNoch keine Bewertungen

- Rapid Detection of Escherichia Coli O157:H7 in Food Using Enrichment and Real-Time Polymerase Chain ReactionDokument7 SeitenRapid Detection of Escherichia Coli O157:H7 in Food Using Enrichment and Real-Time Polymerase Chain ReactionPhạm Bền ChíNoch keine Bewertungen

- Anomalous Adsorptive Properties of HIV ProteaseDokument5 SeitenAnomalous Adsorptive Properties of HIV ProteasePetr CiglerNoch keine Bewertungen

- Cytokine ELISADokument5 SeitenCytokine ELISAbelabelawNoch keine Bewertungen

- Research Article: Sesame Oil Attenuates Ovalbumin-Induced Pulmonary Edema and Bronchial Neutrophilic Inflammation in MiceDokument8 SeitenResearch Article: Sesame Oil Attenuates Ovalbumin-Induced Pulmonary Edema and Bronchial Neutrophilic Inflammation in MiceSri Nurliana BasryNoch keine Bewertungen

- Antigen-Antibody Reaction-Basic Immunological TechniquesDokument16 SeitenAntigen-Antibody Reaction-Basic Immunological TechniquesJesuhovie Solomon OkpobrisiNoch keine Bewertungen

- Bullwho00453 0009 PDFDokument11 SeitenBullwho00453 0009 PDFRonal WinterNoch keine Bewertungen

- J Sichuan Univ 2021 Doi: 10.12182/20210760104Dokument6 SeitenJ Sichuan Univ 2021 Doi: 10.12182/20210760104Lina WinartiNoch keine Bewertungen

- Jurnal HibridisasiDokument12 SeitenJurnal HibridisasiNurfanida Natasya mNoch keine Bewertungen

- Experimental Treatment of Recurrent Otitis Externa: Open Veterinary Journal, (2015), Vol. 5 (1) : 38-41Dokument4 SeitenExperimental Treatment of Recurrent Otitis Externa: Open Veterinary Journal, (2015), Vol. 5 (1) : 38-41Christian ThamNoch keine Bewertungen

- JadiDokument3 SeitenJadiAliefyo JetbushdNoch keine Bewertungen

- Polymeric Nanoparticles As Delivery System For Influenza Virus GlycoproteinsDokument13 SeitenPolymeric Nanoparticles As Delivery System For Influenza Virus GlycoproteinsПолина ТелегееваNoch keine Bewertungen

- (Pure and Applied Chemistry) Trends and Challenges in Biochemical Sensors For Clinical and Environmental MonitoringDokument18 Seiten(Pure and Applied Chemistry) Trends and Challenges in Biochemical Sensors For Clinical and Environmental Monitoringabdelhadi eljaouhariNoch keine Bewertungen

- Concerted Inhibitory Activities of Phyllanthus Amarus On HIV Replication in Vitro and Ex VivoDokument10 SeitenConcerted Inhibitory Activities of Phyllanthus Amarus On HIV Replication in Vitro and Ex Vivoapi-198310771Noch keine Bewertungen

- Activation Human Granulocyte by IvigDokument9 SeitenActivation Human Granulocyte by IvigIwan kustiawanNoch keine Bewertungen

- Baldelli 2004Dokument7 SeitenBaldelli 2004davidlaglaNoch keine Bewertungen

- J Bios 2004 07 021Dokument6 SeitenJ Bios 2004 07 021PACIJA, MARIA GERALDENNoch keine Bewertungen

- tmp3C58 TMPDokument9 Seitentmp3C58 TMPFrontiersNoch keine Bewertungen

- One-Step Antibody Immobilization-Based Sandeep VasistDokument8 SeitenOne-Step Antibody Immobilization-Based Sandeep VasistTanhajiGhodkeNoch keine Bewertungen

- Sensors and Actuators B: Chemical: Jin Wang, Hiroaki Suzuki, Takaaki SatakeDokument5 SeitenSensors and Actuators B: Chemical: Jin Wang, Hiroaki Suzuki, Takaaki SatakeMELISSA VERONICA TUDELANO OSPINANoch keine Bewertungen

- Important NotesDokument8 SeitenImportant NotesARYSSA BINTI AZRINoch keine Bewertungen

- Serological Test For Viral DetectionDokument3 SeitenSerological Test For Viral DetectionDibyakNoch keine Bewertungen

- 07-Detection of E. Coli O157H7 and Other Verocytotoxin-Producing E. ColiDokument15 Seiten07-Detection of E. Coli O157H7 and Other Verocytotoxin-Producing E. ColiNguyễn Hữu ToànNoch keine Bewertungen

- Setting Up A Laboratory For Radioimmunoassay (RIA)Dokument6 SeitenSetting Up A Laboratory For Radioimmunoassay (RIA)aemc786Noch keine Bewertungen

- Semi-Automated Fluorogenic PCR Assays (TaqMan) Forrapid Detection of Escherichia Coli O157H7 and Other Shiga Toxigenic E. Coli 1999Dokument12 SeitenSemi-Automated Fluorogenic PCR Assays (TaqMan) Forrapid Detection of Escherichia Coli O157H7 and Other Shiga Toxigenic E. Coli 1999Ahmed BelhadriNoch keine Bewertungen

- Tlili2011 PDFDokument5 SeitenTlili2011 PDFManju ManoharNoch keine Bewertungen

- 2022 Serogroups and Genetic Diversity of Diarrheagenic Strains of Escherichia Coli A Retrospective StudyDokument8 Seiten2022 Serogroups and Genetic Diversity of Diarrheagenic Strains of Escherichia Coli A Retrospective StudyAnca MareNoch keine Bewertungen

- Bacteria-Triggered Release of Antimicrobial AgentsDokument3 SeitenBacteria-Triggered Release of Antimicrobial Agentsbunny9669Noch keine Bewertungen

- Tavana 2012Dokument6 SeitenTavana 2012selia destianingrumNoch keine Bewertungen

- The Action of Three Antiseptics/disinfectants Against Enveloped and Non-Enveloped VirusesDokument13 SeitenThe Action of Three Antiseptics/disinfectants Against Enveloped and Non-Enveloped VirusesTrần Minh TríNoch keine Bewertungen

- Development of Enzyme Biosensor Based On Ph-Sensitive Field-Effect Transistors For Detection of Phenolic CompoundsDokument3 SeitenDevelopment of Enzyme Biosensor Based On Ph-Sensitive Field-Effect Transistors For Detection of Phenolic CompoundsMurugesan EswaranNoch keine Bewertungen

- Sensors: Label-Free Aptasensor For Lysozyme Detection Using Electrochemical Impedance SpectrosDokument11 SeitenSensors: Label-Free Aptasensor For Lysozyme Detection Using Electrochemical Impedance SpectrosLakshmipriya GopinathNoch keine Bewertungen

- Zoonotic PathogensDokument8 SeitenZoonotic PathogensSaghirAurakxaiNoch keine Bewertungen

- Wang 2013Dokument8 SeitenWang 2013César Luciano Otárola RuizNoch keine Bewertungen

- Elisa: From A ZDokument66 SeitenElisa: From A ZMaria JozilynNoch keine Bewertungen

- Comparison of Chemiluminescence Enzyme ImmunoassayDokument7 SeitenComparison of Chemiluminescence Enzyme ImmunoassayDewi ArisandyNoch keine Bewertungen

- Alcohols As Surface Disinfectants in Healthcare Settings: ReviewarticleDokument6 SeitenAlcohols As Surface Disinfectants in Healthcare Settings: ReviewarticleJimmy SimpsonNoch keine Bewertungen

- Urban Solid Waste Generation and Disposal in Mexico: A Case StudyDokument8 SeitenUrban Solid Waste Generation and Disposal in Mexico: A Case StudyJimmy SimpsonNoch keine Bewertungen

- Dokumen - Tips Numerical Methods Using Matlab 4ed Solution ManualDokument172 SeitenDokumen - Tips Numerical Methods Using Matlab 4ed Solution ManualJimmy SimpsonNoch keine Bewertungen

- Begon, Garcìa - 2002 - Metal-Nanoparticles Based ElectroanalysisDokument11 SeitenBegon, Garcìa - 2002 - Metal-Nanoparticles Based ElectroanalysisJimmy SimpsonNoch keine Bewertungen

- Amarillas Et Al. - 2013 - Complete Genome Sequence of Escherichia Coli O157H7 Bacteriophage PhiJLA23 Isolated in MexicoDokument2 SeitenAmarillas Et Al. - 2013 - Complete Genome Sequence of Escherichia Coli O157H7 Bacteriophage PhiJLA23 Isolated in MexicoJimmy SimpsonNoch keine Bewertungen

- Alvarez - 2004 - Integrated Approaches For Detection of Plant Pathogenic Bacteria and Diagnosis of Bacterial DiseasesDokument30 SeitenAlvarez - 2004 - Integrated Approaches For Detection of Plant Pathogenic Bacteria and Diagnosis of Bacterial DiseasesJimmy SimpsonNoch keine Bewertungen

- Albareda-Sirvent, Merkoçi, Alegret - 2000 - Configurations Used in The Design of Screen-Printed Enzymatic Biosensors. A RDokument11 SeitenAlbareda-Sirvent, Merkoçi, Alegret - 2000 - Configurations Used in The Design of Screen-Printed Enzymatic Biosensors. A RJimmy SimpsonNoch keine Bewertungen

- Banu, Marcu, Cristian - 2007 - New Uses of Nanocomposit E Materials With Polymeric Matrix For Environmental MonitorisationDokument4 SeitenBanu, Marcu, Cristian - 2007 - New Uses of Nanocomposit E Materials With Polymeric Matrix For Environmental MonitorisationJimmy SimpsonNoch keine Bewertungen

- (Eds.) Brajter-Toth A., Chambers J.Q., Electroanalytical Methods For Biological Materials (Dekker, 2002)Dokument553 Seiten(Eds.) Brajter-Toth A., Chambers J.Q., Electroanalytical Methods For Biological Materials (Dekker, 2002)Jimmy SimpsonNoch keine Bewertungen

- (Eds.) Conway B.E., Et Al., Modern Aspects of Electrochemistry v.32 (Kluwer, 2002) PDFDokument437 Seiten(Eds.) Conway B.E., Et Al., Modern Aspects of Electrochemistry v.32 (Kluwer, 2002) PDFJimmy SimpsonNoch keine Bewertungen

- Rail Vehicle DynamicsDokument55 SeitenRail Vehicle DynamicsdfNoch keine Bewertungen

- Esteem 1999 2000 1.3L 1.6LDokument45 SeitenEsteem 1999 2000 1.3L 1.6LArnold Hernández CarvajalNoch keine Bewertungen

- Shawal 1431 AH Prayer ScheduleDokument2 SeitenShawal 1431 AH Prayer SchedulemasjidibrahimNoch keine Bewertungen

- From Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesDokument15 SeitenFrom Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesKayra MoslemNoch keine Bewertungen

- Keiilf: Training ManualDokument53 SeitenKeiilf: Training ManualGary GouveiaNoch keine Bewertungen

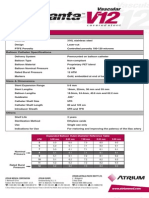

- Advanta V12 Data SheetDokument2 SeitenAdvanta V12 Data SheetJuliana MiyagiNoch keine Bewertungen

- Cynosure Starlux 500 Palomar Technical Service ManualDokument47 SeitenCynosure Starlux 500 Palomar Technical Service ManualJF SilvaNoch keine Bewertungen

- WPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFDokument88 SeitenWPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFbabuzducNoch keine Bewertungen

- Sales 20: Years Advertising Expense (Millions) X Sales (Thousands) yDokument8 SeitenSales 20: Years Advertising Expense (Millions) X Sales (Thousands) ybangNoch keine Bewertungen

- Eng DS Epp-2314 1410Dokument2 SeitenEng DS Epp-2314 1410MarkusAldoMaquNoch keine Bewertungen

- Basic Geriatric Nursing 6th Edition Williams Test BankDokument10 SeitenBasic Geriatric Nursing 6th Edition Williams Test Bankmaryrodriguezxsntrogkwd100% (49)

- LG250CDokument2 SeitenLG250CCarlosNoch keine Bewertungen

- Lesson Plan in Science 9: I. ObjectivesDokument8 SeitenLesson Plan in Science 9: I. ObjectivesmarichuNoch keine Bewertungen

- Arbor APS STT Unit 01 Design Basics 25 Jan2018Dokument31 SeitenArbor APS STT Unit 01 Design Basics 25 Jan2018masterlinh2008Noch keine Bewertungen

- PIX4D Simply PowerfulDokument43 SeitenPIX4D Simply PowerfulJUAN BAQUERONoch keine Bewertungen

- Malvinas Gas Plant Operator Training: Paragon Engineering Services, Inc. Houston, TexasDokument71 SeitenMalvinas Gas Plant Operator Training: Paragon Engineering Services, Inc. Houston, TexasMary Cruz Meza CahuanaNoch keine Bewertungen

- PPT DIARHEA IN CHILDRENDokument31 SeitenPPT DIARHEA IN CHILDRENRifka AnisaNoch keine Bewertungen

- Murata High Voltage CeramicDokument38 SeitenMurata High Voltage CeramictycristinaNoch keine Bewertungen

- Module 1 Notes The White Bird Reading The Image Painting Analysis PDFDokument4 SeitenModule 1 Notes The White Bird Reading The Image Painting Analysis PDFMelbely Rose Apigo BaduaNoch keine Bewertungen

- Training Report On Self Contained Breathing ApparatusDokument4 SeitenTraining Report On Self Contained Breathing ApparatusHiren MahetaNoch keine Bewertungen

- Shandong Baoshida Cable Co, LTD.: Technical ParameterDokument3 SeitenShandong Baoshida Cable Co, LTD.: Technical ParameterkmiqdNoch keine Bewertungen

- Tugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiDokument4 SeitenTugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiFebry SugiantaraNoch keine Bewertungen

- AKI in ChildrenDokument43 SeitenAKI in ChildrenYonas AwgichewNoch keine Bewertungen

- SPL Lab Report3Dokument49 SeitenSPL Lab Report3nadif hasan purnoNoch keine Bewertungen

- Innerwear Industry Pitch PresentationDokument19 SeitenInnerwear Industry Pitch PresentationRupeshKumarNoch keine Bewertungen

- The Acceptability of Rubber Tree Sap (A As An Alternative Roof SealantDokument7 SeitenThe Acceptability of Rubber Tree Sap (A As An Alternative Roof SealantHannilyn Caldeo100% (2)

- Main Girders: CrossDokument3 SeitenMain Girders: Crossmn4webNoch keine Bewertungen

- Digging Deeper: Can Hot Air Provide Sustainable Source of Electricity?Dokument2 SeitenDigging Deeper: Can Hot Air Provide Sustainable Source of Electricity?Рустам ХаджаевNoch keine Bewertungen

- ZF-FreedomLine TransmissionDokument21 SeitenZF-FreedomLine TransmissionHerbert M. Zayco100% (1)

- Math AA SL P 1 Marks SchemeDokument6 SeitenMath AA SL P 1 Marks SchemeMrin GhoshNoch keine Bewertungen