Beruflich Dokumente

Kultur Dokumente

ESE Syllabus ME - Paper 2

Hochgeladen von

TGrey027Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ESE Syllabus ME - Paper 2

Hochgeladen von

TGrey027Copyright:

Verfügbare Formate

1.

Strength of Materials

Stress and strain in two dimensions, Principal stresses and strains, Mohrs construction.

Linear elastic materials, isotropy and anisotropy, stress-strain relations.

Uni-axial loading, thermal stresses.

Beams: Bending moment and shear force diagram, bending stresses and deflection of

beams.

Shear stress distribution, Torsion of shafts, Combined stresses,

Helical springs, Thick-and Thin-walled pressure vessels.

Struts and columns.

Strain energy concepts and theories of failure.

2. Theory of Machines

Kinematic and dynamic analysis of planer mechanisms.

Cams.

Gears and gear trains.

Flywheels.

Governors.

Balancing of rigid rotors and field balancing.

Balancing of single and multi-cylinder engines.

Linear vibration analysis of mechanical systems.

Critical speeds and whirling of shafts, Automatic controls.

3. Machine Design

Design of Joints: cotters, keys, splines, welded joints, threaded fasteners, joints formed

by interference fits.

Design of friction drives: couplings and clutches, belt and chain drives, power screws.

Design of Power transmission systems: gears and gear drives shaft and axle, wire ropes.

Design of bearings: hydrodynamics bearings and rolling element bearings.

4. Engineering Materials

Basic concepts on structure of solids.

Crystalline materials. Defects in crystalline materials.

Alloys and binary phase diagrams.

Structure and properties of common engineering materials.

Heat treatment of steels.

Plastics, Ceramics and composite materials.

Common applications of various materials.

5. Production Engineering

Metal Forming: Basic Principles of forging, drawing and extrusion. High energy rate

forming; Powder metallurgy.

Metal Casting: Die casting, investment casting, Shell Molding, Centrifugal Casting,

Gating & Riser design; melting furnaces.

Fabrication Processes: Principles of Gas, Arc, Shielded arc Welding; Advanced Welding

Processes, Weldability: Metallurgy of Welding.

Metal Cutting: Turning, Methods of Screw Production, Drilling, Boring, Milling, Gear

Manufacturing, Production of flat surfaces, Grinding & Finishing Processes. Computer

Controlled Manufacturing Systems-CNC, DNC, FMS, Automation and Robotics.

Cutting Tools Materials, Tool Geometry, Mechanism of Tool Wear, Tool Life &

Machinability; Measurement of cutting forces. Economics of Machining. Unconventional

Machining Processes. Jigs and Fixtures. Fits and tolerances, Measurement of surface

texture, Comparators Alignment tests and reconditioning of Machine Tools.

6. Industrial Engineering

Production Planning and Control: Forecasting - Moving average, exponential smoothing,

Operations, scheduling; assembly line balancing, Product development, Break-even

analysis, Capacity planning, PERT and CPM.

Control Operations: Inventory control ABC analysis, EOQ model, Materials requirement

planning. Job design, Job standards, Work measurement, Quality Management - Quality

analysis and control.

Operations Research: Linear Programming - Graphical and Simplex methods,

Transportation and assignment models. Single server queuing model.

Value Engineering: Value analysis for cost/value.

7. Elements of Computation

Computer Organization, Flow charting, Features of Common computer Languages FORTRAN, d Base III, Lotus 1-2-3, C and elementary Programming.

Das könnte Ihnen auch gefallen

- TSMBA 1 Getting StartedDokument20 SeitenTSMBA 1 Getting StartedTGrey027Noch keine Bewertungen

- Modeling Chill Down in Cryogenic Transfer LinesDokument30 SeitenModeling Chill Down in Cryogenic Transfer LinesTGrey027Noch keine Bewertungen

- To Say That What Follows Is Pure FictionDokument10 SeitenTo Say That What Follows Is Pure FictionRonakPrajapatiNoch keine Bewertungen

- Kedarnath Yatra Route Map 2018 - Road Map From Delhi To KedarnathDokument2 SeitenKedarnath Yatra Route Map 2018 - Road Map From Delhi To KedarnathTGrey027Noch keine Bewertungen

- Acceptance Tests For AMS Radiocarbon MeasurementDokument7 SeitenAcceptance Tests For AMS Radiocarbon MeasurementTGrey027Noch keine Bewertungen

- TBL Paper Final PDFDokument52 SeitenTBL Paper Final PDFTGrey027Noch keine Bewertungen

- Advt 02 19 ORA Engl 0Dokument35 SeitenAdvt 02 19 ORA Engl 0Anonymous FSjpYTcNoch keine Bewertungen

- Modeling Chill Down in Cryogenic Transfer LinesDokument30 SeitenModeling Chill Down in Cryogenic Transfer LinesTGrey027Noch keine Bewertungen

- Physics Proceedia Vol. 90Dokument3 SeitenPhysics Proceedia Vol. 90TGrey027Noch keine Bewertungen

- FR CSME 2018 Engl1Dokument18 SeitenFR CSME 2018 Engl1NDTVNoch keine Bewertungen

- Delhi RishikeshDokument1 SeiteDelhi RishikeshTGrey027Noch keine Bewertungen

- Route Map Sukd PDFDokument1 SeiteRoute Map Sukd PDFTGrey027Noch keine Bewertungen

- UPSC Exam Schedule 2017Dokument1 SeiteUPSC Exam Schedule 2017kaifiahmedNoch keine Bewertungen

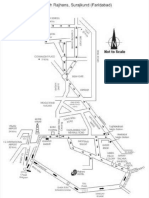

- Route Map SurajkundDokument1 SeiteRoute Map SurajkundTGrey027Noch keine Bewertungen

- Social DevelopmentDokument34 SeitenSocial DevelopmentTGrey027Noch keine Bewertungen

- NEWTON FORWARD INTERPOLATIONDokument27 SeitenNEWTON FORWARD INTERPOLATIONkrkqualityNoch keine Bewertungen

- Fluid MechanicsDokument15 SeitenFluid MechanicsTGrey027Noch keine Bewertungen

- Code of Ethics For EngineersDokument2 SeitenCode of Ethics For EngineersSyed RaziuddinNoch keine Bewertungen

- 1 2Dokument18 Seiten1 2Kaaya GodfreyNoch keine Bewertungen

- ICT Skills Full Book PDFDokument411 SeitenICT Skills Full Book PDFTGrey02783% (47)

- UPSC Engineering Exam NoticeDokument25 SeitenUPSC Engineering Exam NoticeMohitSinhaNoch keine Bewertungen

- Reduces The Risk of A Driver Losing Control. Different Manufacturers Call ESC by Different Names, Some Include: - Esp - DSC - VDC - VSC - DSTC - AstcDokument6 SeitenReduces The Risk of A Driver Losing Control. Different Manufacturers Call ESC by Different Names, Some Include: - Esp - DSC - VDC - VSC - DSTC - AstcTGrey027Noch keine Bewertungen

- Induction MotorDokument37 SeitenInduction MotorTGrey027Noch keine Bewertungen

- Thermodynamics, Cycles, IC Engines and Heat TransferDokument1 SeiteThermodynamics, Cycles, IC Engines and Heat TransfersharathbabuvNoch keine Bewertungen

- 1 - 6 Nptel Design NotesDokument9 Seiten1 - 6 Nptel Design NotesgirishnnaikNoch keine Bewertungen

- IES General Ability 2013Dokument20 SeitenIES General Ability 2013Amit KarmakarNoch keine Bewertungen

- HTS MotorsDokument18 SeitenHTS MotorsTGrey027100% (1)

- Nptel Design NotesDokument18 SeitenNptel Design NotesgirishnnaikNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 31 10 00 10-P6000CFP-000-PV - ADokument6 Seiten31 10 00 10-P6000CFP-000-PV - Aprasenjit pandit100% (1)

- Welding Symbols 2Dokument19 SeitenWelding Symbols 2SastrawanNoch keine Bewertungen

- Construction Solutions: Maximize Productivity. Optimize Weld Quality. Improve Your Bottom LineDokument12 SeitenConstruction Solutions: Maximize Productivity. Optimize Weld Quality. Improve Your Bottom LineAlberto LobonesNoch keine Bewertungen

- E1416-96 Radioscopic Exam of WeldmentsDokument5 SeitenE1416-96 Radioscopic Exam of WeldmentssanthakumarNoch keine Bewertungen

- Double Wall Ammonia Storage Tank Design and Engineering DocumentsDokument33 SeitenDouble Wall Ammonia Storage Tank Design and Engineering DocumentsErol DAĞ100% (1)

- R057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpoolDokument16 SeitenR057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpooldharwinNoch keine Bewertungen

- QCR W 2001Dokument4 SeitenQCR W 2001Madhan KannanNoch keine Bewertungen

- Bridge Fatigue GuideDokument65 SeitenBridge Fatigue Guideaapennsylvania100% (1)

- Final SS Specification 18 12 2020Dokument10 SeitenFinal SS Specification 18 12 2020Amit NG AmitNoch keine Bewertungen

- Feature Based Cost and Carbon Emission Modelling For WAAMDokument128 SeitenFeature Based Cost and Carbon Emission Modelling For WAAMMark BacklerNoch keine Bewertungen

- PTFE Sliding Bearing CatalogueDokument5 SeitenPTFE Sliding Bearing Cataloguenght7942Noch keine Bewertungen

- Method of Statement For Wrapping and Coating of Underground PipingDokument4 SeitenMethod of Statement For Wrapping and Coating of Underground PipingKarthikNoch keine Bewertungen

- Loctite Adhesive SourcebookDokument212 SeitenLoctite Adhesive Sourcebookechobravo1Noch keine Bewertungen

- Erection of DPC Clinker Silo Extraction-2Dokument7 SeitenErection of DPC Clinker Silo Extraction-2RajuNoch keine Bewertungen

- B2.1 8 025 2001PVDokument4 SeitenB2.1 8 025 2001PVJaimeNoch keine Bewertungen

- Sandvik WeldingDokument3 SeitenSandvik WeldingRam KadamNoch keine Bewertungen

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDokument1 SeiteOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNoch keine Bewertungen

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDokument1 SeiteEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeNoch keine Bewertungen

- 17 Weldability of SteelsDokument40 Seiten17 Weldability of SteelsJawed Akhter100% (1)

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Dokument28 Seiten2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValenteNoch keine Bewertungen

- E1418-10 Standard Practice For Visible Penetrant Testing Using The Water-Washable ProcessDokument6 SeitenE1418-10 Standard Practice For Visible Penetrant Testing Using The Water-Washable ProcessRodrigo JeldesNoch keine Bewertungen

- Outback 185: Operator S ManualDokument34 SeitenOutback 185: Operator S ManualHenry Diaz VelasquezNoch keine Bewertungen

- API 571 DamageDokument111 SeitenAPI 571 DamageNatraji100% (16)

- HQSM12-Q13-103-001-A4 ITP E-101 AB - HQSM Commented 21.02.2020 PDFDokument11 SeitenHQSM12-Q13-103-001-A4 ITP E-101 AB - HQSM Commented 21.02.2020 PDFfdfazfzNoch keine Bewertungen

- Ansi-Aws d1.2 PDFDokument208 SeitenAnsi-Aws d1.2 PDFzokytoNoch keine Bewertungen

- List Applicable WPS StructureDokument7 SeitenList Applicable WPS StructureFerdie OSNoch keine Bewertungen

- Welding Part 2Dokument38 SeitenWelding Part 2Balqees Al RiyamiNoch keine Bewertungen

- R 392Dokument19 SeitenR 392Ucok666Noch keine Bewertungen

- Manufacturing Impellers for TurbocompressorsDokument16 SeitenManufacturing Impellers for TurbocompressorsWillian Tavares de CarvalhoNoch keine Bewertungen

- Final Report - KisanDokument71 SeitenFinal Report - KisanSavinai VangalaNoch keine Bewertungen