Beruflich Dokumente

Kultur Dokumente

Design Optimization of 2D Steel Frame Structures: 8.1 Objectives

Hochgeladen von

Cesar ManOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Optimization of 2D Steel Frame Structures: 8.1 Objectives

Hochgeladen von

Cesar ManCopyright:

Verfügbare Formate

VIII

DESIGN OPTIMIZATION OF

2D STEEL FRAME STRUCTURES

8.1 Objectives

This chapter presents a genetic algorithm for design optimization of multibay multi

storey steel frameworks according to BS 5950 to achieve four objectives. The first is to

ascertain that the developed GA approach can successfully be incorporated in design

optimization in which framework members are required to be adopted from the

available catalogue of standard steel sections. The design should satisfy a practical

design situation in which the most unfavourable loading cases are considered. The

second is to understand the advantages of applying automated design approaches. The

third is to investigate the effect of the approaches, employed for the determination of the

effective buckling length of a column, on the optimum design. Here, three approaches

are tackled and results are presented. The fourth is to demonstrate the effect of the

complexity of the design problem on the developed algorithm. This involves studying

different examples, each of which have different numbers of design variables

representing the framework members. This chapter starts with describing the design

Design Optimization of 2D Steel Frame Structures

239

procedure for steel frame structures according to BS 5950, then combines this procedure

with the GA to perform design optimization of the steel frame structures.

8.2 Design procedure to BS 5950

In order to correlate between the notations given by BS 5950 and that employed in this

context, the local and global coordinate systems shown in Figure 8.1 are assumed. This

allows us to use the same indices and notations as utilised in BS 5950. Figure 8.2 shows

the coordinate systems combined with a deformed configuration of a framework

X

Figure 8.1. Local and global coordinate systems

Z

Y

X

Y,

mem

nc

N ,1

Ix s

max

N mem

b

X

Y

Y,

mem

nc

N , N b +1

Y

X

Ix s

hN

Y

X

n ,1

I xs

Y

X

max

n mem

b

1, 1

Ix

max

1, n

Ix

ns , N b +1

Ix

1 , N b +1

Ix

hn

h1

Y

X

B1

BN

Figure 8.2. Deformed configuration of a framework combined with coordinate systems

Design Optimization of 2D Steel Frame Structures

240

BS 5950 recommends that the designer selects appropriate standard sections for

the members of a steel framework in order to ensure a sufficient factor of safety is

achieved. This is accomplished by considering ultimate and serviceability limit states.

In elastic design of rigid jointed multistorey frameworks, BS 5950 recommends

that a linear analysis of the whole framework is carried out. This was achieved by

utilising the finite element package ANSYS, followed by a design criteria check. This

can be summarised in the following steps.

Step 1. Preparation of data files and these include framework geometry as well as

loading cases.

Step 2. Classification of the framework into sway or nonsway. This is achieved by

applying the notional horizontal loading case. A framework, analysed without including

the effect of cladding, is classified as nonsway if the difference between the upper

UY ,nmem ( x ) and lower LY ,n mem ( x ) horizontal nodal displacements of each column

c

member ncmem satisfies the following condition:

UY ,n mem ( x ) LY ,n mem ( x )

c

Ln mem

1 , ncmem = 1, 2 , , N cmem . (8.1)

2000

Step 3. Calculation of the effective buckling lengths Leff

and Leff

of columns

X, n mem

Y, n mem

and beams. For columns, Leff

is determined according to one of the following three

X, n mem

c

approaches:

using the charts from BS 5950 as described in Section 2.6.2.2;

Design Optimization of 2D Steel Frame Structures

241

a more accurate method (SCI, 1988) based on finite element analysis as applied in

Section 7.3.1;

selection of the conservative (higher) value out of the two approaches.

The effective buckling length Leff

of a beam equals the unrestrained length of

X, n mem

b

the compression flange that occurs on the underside of a beam (see MacGinley, 1997).

To evaluate Leff

( xi , j ) of beams and columns, It is presupposed that the lateral

Y, n mem

bracing system restrain members from movements out of plane ( X - Z plane) at their

mid spans. Thus, Leff

( xi , j ) equals to the half of the length of the member Lnmem .

Y, n mem

Step 4. Calculation of the slenderness ratios X, nmem ( x ) and Y, nmem ( xi , j ) of the

member n mem using

X, n mem ( x ) =

Leff

( x)

X, n mem

rX, n mem

Y, nmem ( xi , j ) =

Leff

( xi , j )

Y, n mem

rY, n mem

(8.2)

(8.3)

where rX, nmem and rY, nmem are the radius of gyrations of the section about X and Y axes.

Sle

Step 5. Check of the slenderness constraints G s , n mem for each member using

Sle

G s , n mem ( x ) 1 , s = 1, 2

where

Sle

G1 , n mem ( x ) =

Sle

X, nmem ( x )

G 2 , n mem ( xi , j ) =

180

(8.4)

and

Y, nmem ( xi , j )

180

(8.5)

(8.6)

Design Optimization of 2D Steel Frame Structures

242

Step 6. Analysis of the framework under each loading case q to obtain the normal force,

shearing forces and bending moments for each member.

Step 7. Check of the strength requirements for each member n mem under the loading

case q as follows:

a) Determination of the type of the section of the member (e.g. slender, semicompact,

compact or plastic).

b) Evaluation of the design strength py , n mem of the member.

Str , q

c) Check of the strength constraints G r , n mem ( x ) depending on whether the member is

in tension or compression. This stage contains four checks (r = 4) for each member

under each loading case q. The strength constraints, which are local capacity, overall

capacity, shear capacity and the shear buckling capacity, should satisfy

Str , q

G r , n mem ( x ) 1 , r = 1, 2, 3, 4, and q = 1,2, , Q

(8.7)

where the local capacity

F qmem ( x )

n

Ae, nmem ( xi , j ) p y , n mem ( xi , j )

Mq

X, n mem

( x)

M CX , n mem ( xi , j )

for tension

members

Str , q

G1 , n mem ( x ) =

(8.8)

F

n mem

( x)

Ag, n mem ( xi , j ) p y , nmem ( xi , j )

where F qmem ( x ) is the axial force, M q

n

Mq

X, n

mem ( x )

M CX , nmem ( xi , j )

X, n mem

for comprisson

members

( x ) is the moment about the major local

axis (x) at the critical region of the member under consideration, p y, n mem ( xi , j ) is the

design strength of the member and M CX , n mem ( xi , j ) is the moment capacity of the

Design Optimization of 2D Steel Frame Structures

243

member section about its major local axis (X). The effective area and gross area of the

section of the member under consideration Ae, n mem ( xi , j ) and Ag, nmem ( xi , j ) are equal.

Str , q

For each member, the overall capacity G 2 , n mem ( x ) is determined by

m qmem ( x ) M q

X, n mem

( x)

for tension members

M b , n mem ( x )

Str , q

G 2 , n mem ( x ) =

(8.9)

F

n mem

( x)

Ag, n mem ( xi , j ) p C , n mem ( xi , j )

q

n mem

( x) M

q

X, n mem

( x)

for comprisson

members

M b , n mem ( x )

where m qmem ( x ) is the equivalent uniform factor and is calculated as discussed in

n

Chapter 2 for each loading case (q). M b , n mem ( x ) is the buckling resistance moment.

Str , q

The shear capacity G3 , n mem ( x ) is computed by

Fq

Str , q

G3 , n mem ( x ) =

Y, n mem

( x)

(8.10)

PY, n mem ( xi , j )

where PY, n mem ( xi , j ) is the shear capacity of the member, and F q

Y, n mem

( x ) is the critical

shear force under the specified loading case (q).

Str, q

Each member should also satisfy the shear buckling constraint G 4 , n mem ( x ) if

d ( xi , j )

t ( xi , j )

63 ( xi, j ) .

(8.11)

Str , q

Hence, G 4 , n mem ( x ) is computed by

Str , q

G 4 , n mem ( x ) =

Fq

Y, n mem

( x)

Vcr, n mem ( xi , j )

(8.12)

Design Optimization of 2D Steel Frame Structures

244

where Vcr, n mem ( xi , j ) is the shear resistance of the member section.

d) For a sway structure, the notional horizontal loading case is considered, this is

termed sway stability criterion.

Step 8. Checks of the horizontal and vertical nodal displacements. These are known as

serviceability criteria

Ser

Gt , n mem ( x ) 1 , t = 1, 2 and 3.

(8.13)

This is performed by:

a) Computing the horizontal nodal displacements due to the unfactored imposed loads

and wind loading cases in order to satisfy the limits on the horizontal displacements,

Ser

G1 , n mem

c

UY , nmem ( x ) LY, n mem ( x )

c

Ln mem

and ncmem= 1, , N cmem (8.14)

300

where Lnmem is the length of the column under consideration. The indexes (U and L)

c

define the position of the twocolumn ends.

b) Imposing the limits on the vertical nodal displacements (maximum value within a

beam) due to the unfactored imposed loading case.

max

Ser

G 2 , n mem ( x ) =

b

nmem ( x )

b

Ln mem

n bmem = 1, 2 , , N bmem

(8.15)

360

where Lnmem is the length of the beam under consideration.

b

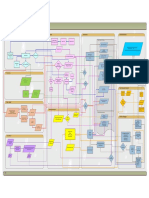

The flowchart given in Figure 8.3 illustrates the design procedure to BS 5950.

Description of the program developed for the design of steel frame structures is given in

Appendix C.

Design Optimization of 2D Steel Frame Structures

245

Start

Apply notional horizontal loading case, compute horizontal nodal

displacements and determine whether the framework is sway or

nonsway using step 2

Compute the effective buckling lengths according the required

approach mentioned in step 3

Apply loading case q = 1, 2 , , Q : if the framework is sway, then

include the notional horizontal loading case

Analyse the framework, compute normal forces, shearing forces

and bending moments for each member

Design of member n

mem

= 1, 2 , , N

mem

Determine the type of the section (slender, semicompact,

compact or plastic) utilising Table 7 of BS 5950

Evaluate the design strength p

y, n mem

( x i , j ) of the member

Check the slenderness criteria employing (8.20) (8.6)

NO

A

A

B

B

Tension

member?

YES

Figure 8.3a. Flowchart of design procedure of structural steelwork

D

D

Design Optimization of 2D Steel Frame Structures

246

Local capacity check

Local capacity check

Overall capacity check

Lateral torsional buckling

check

Carry out the checks of shear applying (8.10) and

shear buckling using (8.12) if necessary

Is n

mem

= N mem ?

NO

YES

NO

Is q = Q?

YES

Compute the horizontal and vertical nodal displacements due to the

specified loading cases

Check of the serviceability criteria using (8.13) (8.15)

End

Figure 8.3b. (cont.) Flowchart of design procedure of structural steelwork

Design Optimization of 2D Steel Frame Structures

247

8.3 Problem formulation and solution technique

The general formulation of the design optimization problem can be expressed by

N mem

Minimize F ( x ) =

n mem = 1

Wn mem Ln mem

Str , q

subject to: G r , n mem ( x ) 1 , r = 1, 2, 3, 4, q = 1,2, , , Q

Sle

G s , n mem ( x ) 1 , s = 1, 2

Ser

Gt , nmem ( x ) 1 , t = 1, 2, 3

I xns , nb

I xns 1 , nb

1 , ns = 1, 2 , , N s , n b = 1, 2 , , N b + 1

(8.16)

x = ( x1T , x T2 , x Tj , , x TJ ) , j = 1, 2, , J

xi , j D j and

Dj

(d

j, 1

,d

j, 2

, , d

j,

where Wn mem is the mass per unit length of the member under consideration and is taken

Str , q

Sle

Ser

from the published catalogue. G r , n mem ( x ) , G s , n mem ( x ) and Gt , n mem ( x ) reflect the

strength, slenderness and serviceability criteria respectively. The vector of design

variables x is divided into J subvectors x J . The components of these subvectors take

values from a corresponding catalogue D j . In the present work, the crosssectional

properties of the structural members, which form the design variables, are chosen from

two separate catalogues (universal beams and columns covered by BS 4).

The flowchart in Figure 8.4 demonstrates the applied solution technique.

Design Optimization of 2D Steel Frame Structures

248

Start

Input data files: GA

parameters, FE model,

loading cases etc.

Randomly generate the initial population

Design set =1, 2, , N p

Decode binary chromosomes to integer values and

select the sections from the appropriate catalogue

according to their corresponding integer values

Apply the design procedure illustrated in flowchart

given in Figure 8.3 to check strength, sway stability

and serviceability criteria to BS 5950

Save the feasibility checks of the design set

NO

Design set = N po ?

New design

YES

Evaluate the objective and penalised functions

Select the best N p individuals out of N p , and impose

them into the first generation of GA algorithm

Figure 8.4a. Flowchart of the solution technique

Design Optimization of 2D Steel Frame Structures

249

Generation 1: Calculate the new penalised objective

function, then carry out crossover and mutation

Design set = 2, 3, , N p

Decode binary chromosomes to integer values and

select the sections from the appropriate catalogue

according to their corresponding integer values

Apply the design procedure illustrated in flowchart

given in Figure 8.3 to check strength, sway stability

and serviceability criteria to BS 5950

Save the feasibility checks of the design set

New generation

Design set = N p ?

NO

New design

YES

Evaluate the objective and penalised functions

Convergence

occurred?

YES

NO

Store the best individuals, and impose them into the next

generation and carry out crossover and mutation

Figure 8.4b. (cont.) Flowchart of the solution technique

Stop

Design Optimization of 2D Steel Frame Structures

250

8.4 Benchmark examples

Having introduced the design procedure according to BS 5950, formulated the problem

and the solution technique, the process of optimization is now carried out.

Three representative frameworks are demonstrated here to illustrate the

effectiveness and benefits of the developed GA technique as well as investigating the

effect of the employed approach for determining the effective buckling lengths on the

optimum design attained. The sectional members are chosen from BS4 as described in

Section 7.2.1.

In the present work, it is assumed that N po and N p are 1000 and 60 respectively.

Onepoint crossover is applied. Probability of crossover Pc and mutation Pm are 70 %

and 1 % respectively. The elite ratio E r is 30 %. The technique described in Section 6.2

is utilised where the simple "exact" penalty function employed is

Minimize F ( x ) =

C - F ( x ) , all constraints satisfied

0,

any of constraints violated.

(8.17)

The convergence criteria and termination conditions detailed in Section 5.6.3.7 are

utilised where C av = 0.001, C cu = 0.001 and gen max = 200 .

8.4.1 Example 1: Twobay twostorey framework

The optimum design of the twobay twostorey framework shown in Figure 8.5 is

investigated. The loading cases described in Section 7.3.2 were considered. The

optimization process was carried out when the number of design variables representing

the framework members is 4 and 6 respectively. The linking of design variables are the

same as those described in Section 7.2.2. The three approaches described in Section 8.2

for the determination of the effective length were also applied.

Design Optimization of 2D Steel Frame Structures

251

8

4

5.00 m

5.00 m

10

9

1

10.00 m

10.00 m

Figure 8.5. Twobay twostorey framework

The problem was run utilising the solution parameters described in Section 8.4.

When 4 design variables representing the framework members are taken into account,

the optimization process was carried out using 10 runs for each approach mentioned in

step 3 of Section 8.2. The optimization process was automatically terminated when one

of the termination conditions was satisfied. The solutions are listed in Table 8.1 while

the corresponding design variables of the optimum solution are given in Table 8.2.

Table 8.1. The solutions for the twobay twostorey framework (4 design variables)

Weight (kg)

Run

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

8640

7910

8870

8430

8010

8490

8690

7950

8630

8730

8360

8690

8630

7910

8630

8550

8110

8490

8430

8010

8750

8490

7910

8590

8750

8150

8870

10

8450

8110

8630

Average weight

8579

8043

8664

Minimum weight

8430

7910

8490

Design Optimization of 2D Steel Frame Structures

252

Table 8.2. The optimum solution for the twobay twostorey framework (4 design

variables)

Cross sections

Design

variable

Member

No.

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

1, 2, 5, 6

356 368 177 UC

356 368 129 UC

356 368 153 UC

3, 4

356 368 177 UC

356 368 129 UC

356 368 153 UC

7, 8

457 191 74 UB

610 229 101 UB

610 229 113 UB

9, 10

533 210 82 UB

610 229 101 UB

533 210 82 UB

8430

7910

8490

Weight (kg)

The convergence characteristics of the weight of the framework were then

examined during the optimization process. Figure 8.6 shows the changes of the best

framework design with number of generations performed.

12000

First approach (code)

Second approach (FE)

Best design (kg)

11000

T hird approach (conservative)

10000

9000

8000

7000

0

10

20

30

40

50

Generation number

60

70

Figure 8.6. Twobay twostorey framework (4 design variables):

best design versus generation number

Similarly, the minimum weight design of the same framework under the same

loading cases is investigated when 6 design variables representing the framework

members are considered. The solutions obtained are listed in Table 8.3 while the

Design Optimization of 2D Steel Frame Structures

253

corresponding design variables of the best solution of each approach are also given in

Table 8.4. The convergence history of the best designs are also displayed in Figure 8.7.

Table 8.3. The solutions for the twobay twostorey framework (6 design variables)

Weight (kg)

Run

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

8490

7955

8700

8650

8015

8560

8600

8090

8495

8415

7870

8495

8430

7975

8570

8630

8030

8730

8600

8160

8630

8430

7870

8510

8550

8115

8495

10

8415

8100

8740

Average weight

8521

8018

8592.5

Minimum weight

8415

7870

8495

Table 8.4. The optimum solution for the twobay twostorey framework (6 design

variables)

Cross sections

Design

variable

Member

No.

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

1, 5

356 368 153 UC

356 368 177 UC

356 368 153 UC

2, 6

254 254 73 UC

356 368 129 UC

356 368 153 UC

356 368 153 UC

356 368 177 UC

356 368 202 UC

203 203 86 UC

356 368 129 UC

356 368 153 UC

7, 8

610 229 101 UB

533 210 82 UB

533 210 82 UB

9, 10

762 267 147 UB

533 210 82 UB

610 229 101 UB

8415

7870

8495

Weight (kg)

Design Optimization of 2D Steel Frame Structures

254

12000

First approach (code)

Second approach (FE)

Best design (kg)

11000

T hird approach (conservative)

10000

9000

8000

7000

0

10

20

30

40

50

60

70

80

Generation number

Figure 8.7. Twobay twostorey framework6 design variables:

best design versus generation number

From Tables 8.1 and 8.3, it can be observed that there is more than one solution

available, and the difference in weight between them is small. This could be of benefit

in using an automated design procedure that allows the designer to choose the

appropriate solution depending on the availability of the sections provided by

manufacturer. Moreover, applying design optimization allows the designer to achieve

better solutions when utilising more accurate methods for evaluating the effective

buckling lengths.

It is of interest also to compare the design variables of two solutions having the

same value of the objective function. This could add a new perspective to the

advantages of using automated design. In the first solution presented in Table 8.5, it can

be observed that the cross sections corresponding to the design variables representing

the columns are identical. The design variables corresponding to columns (1, 3 and 5)

are also the same in the second solution. This indicates that it may be economical to use

Design Optimization of 2D Steel Frame Structures

255

the developed algorithm to decide the optimum grouping of the members in a

framework.

Table 8.5. Comparison between the design variables of two solutions having the same

value of the objective function

Cross sections

Design

variable

Member

No.

First solution

Second solution

1, 5

356 368 177 UC

356 368 177 UC

2,6

356 368 177 UC

203 203 46 UC

356 368 177 UC

356 368 177 UC

356 368 177 UC

203 203 71 UC

7,8

457 191 74 UB

610 229 101 UB

9, 10

533 210 82 UB

762 267 147 UB

8430

8430

Weight (kg)

8.4.2 Example 2: Fivebay fivestorey framework

The next example to study is the fivebay fivestorey framework shown in Figure 8.8.

The loading cases described in Section 7.3.3 are taken into account.

2P

5 2P

0.01P

10 4

P

36

2P

0.01P

0.01P

0.01P

2P

51

5.00 m

4P

11

5.00 m

4P

5.00 m

22

54

16

5.00 m

3.00 m

2

P

29

3.00 m

2P

28

3.00 m

2P 27

3.00 m

26

3.00 m

45

4P 23

49

53

52

44

4P 17

2P 30

40

4P 24

4P 18

48

12

7 4P

39

43

4P

47

46

2

13

4P

35

4P 25

4P 19

4P

42

8

2P

14

4P

41

3

38

37

9

34

4P 20

15 4P

2P

33

32

31

0.01P

2P

2P

50

55

21

5.00 m

Figure 8.8. Fivebay fivestorey framework

Design Optimization of 2D Steel Frame Structures

256

The design optimization process was carried out using different numbers of design

variables representing the framework members. Here, 8 and 10 design variables were

considered. Figures 8.9 and 8.10 show the linking of 8 and 10 design variables

respectively. The three approaches described in Section 8.2 for the determination of the

effective lengths were applied (see Toropov et. al., 1999).

7

3

8

2

8

5

7

6

8

1

7

6

7

6

2

8

4

8

1

8

Figure 8.9. Fivebay fivestorey framework showing the arrangement

of 8 design variables

7

3

8

6

9

2

10

5

9

2

10

2

9

4

10

4

10

10

10

4

10

10

10

10

7

6

4

9

10

10

8

6

8

6

1

9

Figure 8.10. Fivebay fivestorey framework showing the arrangement

of 10 design variables

Design Optimization of 2D Steel Frame Structures

257

First, the optimization process was run using 8 design variables representing the

framework members. The solutions over 5 runs are given in Table 8.6. The design

variables corresponding to the optimum design of the three approachs are listed in Table

8.7.

Table 8.6. The solutions for the fivebay fivestorey framework (8 design variables)

Weight (kg)

Run

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

15455

14675

16101

15385

14851

15926

15465

14390

15991

15321

14935

15973

15367

14725

16299

Average weight

15398.6

14715.2

16058

Minimum weight

15321

14390

15926

Table 8.7. The optimum solution for the fivebay fivestorey framework (8 design

variables)

Design

variable

Cross sections

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

356 368 153 UC

305 305 118 UC

305 305 118 UC

356 368 129 UC

305 305 118 UC

305 305 118 UC

356 368 129 UC

305 305 97 UC

254 254 89 UC

356 368 129 UC

356 368 129 UC

356 368 129 UC

254 254 107 UC

305 305 97 UC

305 305 137 UC

203 203 52 UC

203 203 71 UC

254 254 73 UC

406 140 39 UB

305 102 28 UB

254 102 28 UB

406 140 39 UB

305 165 40 UB

406 140 46 UB

Weight (kg)

15321

14390

15926

Design Optimization of 2D Steel Frame Structures

258

It is of interest to note that the optimizer is able to obtain more than one suitable

solution for each approach, and the difference in the weight between them is little. This

can be concluded when comparing the average value of the solutions with each solution

separately. Using the more accurate approach for determining the effective buckling

length may results in achieving better solutions.

During the optimization process, the solutions are monitored to examine their

convergence history. Then, the graphical representation of changes of the best design

with the number of generations performed achieved to reach the optimum design is

shown in Figure 8.11. It is worth observing that the solution convergence is achieved in

90 generations using a population size of only 70.

24000

First approach (code)

Second approach (FE)

Best design (kg)

22000

T hird approach (conservative)

20000

18000

16000

14000

12000

0

10

20

30

40

50

60

70

80

90

Generation number

Figure 8.11. Fivebay fivestorey framework (8 design variables):

best design versus generation number

Second, the problem was similarly analysed when utilising 10 design variables

representing the framework members. The solutions obtained are given in Table 8.8

while the design variables corresponding to the optimum design of each approach are

listed in Table 8.9.

Design Optimization of 2D Steel Frame Structures

259

Table 8.8. The solutions for the fivebay fivestorey framework (10 design variables)

Weight (kg)

Run

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

15391

14723

16309

15571

14461

16239

15371

14195

16941

15753

14809

15819

15679

14455

16469

Average weight

15553

14528.6

16355.4

Minimum weight

15371

14195

15819

Table 8.9. The optimum solution for the fivebay fivestorey framework (10 design

variables)

Design

variable

Cross sections

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

305 305 97 UC

305 305 137 UC

305 305 137 UC

305 305 97 UC

305 305 137 UC

305 305 97 UC

254 254 107 UC

203 203 52 UC

254 254 89 UC

356 368 129 UC

356 368 129 UC

356 368 129 UC

254 254 107 UC

254 254 73 UC

356 368 129 UC

203 203 46 UC

203 203 46 UC

203 203 60 UC

533 210 92 UB

533 210 92 UB

356 171 51 UB

254 146 31 UB

254 102 25 UB

254 146 37 UB

356 171 51 UB

356 127 39 UB

406 178 54 UB

10

406 140 46 UB

406 140 39 UB

406 140 39 UB

Weight (kg)

15371

14195

15819

Figure 8.12 demonstrates the convergence history of the optimum designs during

the optimization process. It can be observed that the convergence has been achieved in

80 generations due to the termination conditions described in Section 8.4.

Design Optimization of 2D Steel Frame Structures

260

24000

First approach (code)

Second approach (FE)

Best design (kg)

22000

T hird approach (conservative)

20000

18000

16000

14000

12000

0

10

20

30

40

50

60

70

80

Generation number

Figure 8.12. Fivebay fivestorey framework (10 design variables):

best design versus generation number

8.4.3 Example 3: Fourbay tenstorey framework

The final example is the fourbay tenstorey framework shown in Figure 8.13. In this

figure, the loading pattern for the stability analysis and member numbering are shown

where = 0.01 . The problem formulated in Section 8.4.1 utilising 8 design variables

representing the framework members are considered and the linking is given in Figure

8.13. It is assumed that the spacing between successive frameworks is 6.00 m. The

framework will be used for offices and computer equipment purposes. The following

eight loading cases were considered.

1. The beams are subjected to the vertical loads P v = 1.4 DL + 1.6 LL .

2. The beams are subjected to the vertical loads P v = 1.4 DL + 1.6 LL , and the left hand

side of the framework is subjected to the notional horizontal loads.

Design Optimization of 2D Steel Frame Structures

51

53

54

30

40

50

2P

4P

4P

4P

2P

55

56

57

19

29

39

49

2P

4P

4P

4P

2P

59

60

61

18

28

38

48

2P

4P

4P

4P

2P

64

65

17

27

37

47

2P

4P

4P

4P

2P

68

69

16

26

36

46

4P

4P

4P

2P

72

73

15

25

35

45

2P

4P

4P

4P

2P

76

77

14

24

34

44

2P

4P

4P

4P

2P

80

81

13

23

33

43

2P

4P

4P

4P

2P

2

2P

84

85

12

4P

87

22

4P

88

4.00 m

32

4P

21

4.00 m

42

2P

3.00 m

41

5.00 m

90

31

4.00 m

3.00 m

86

89

11

3.00 m

82

83

3.00 m

78

79

3.00 m

74

75

3.00 m

70

2P

71

3.00 m

66

67

3.00 m

62

63

3.00 m

58

52

2P

20

2P

10

2P

32.00 m

261

4.00 m

16.00 m

Figure 8.13. Fourbay tenstorey framework: dimensions, member numbering

and loading pattern for the stability analysis

Design Optimization of 2D Steel Frame Structures

262

3. The beams of the first bay (counting from the left) are exposed to the vertical loads

P v = 1.4 DL + 1.6 LL while the rest of the beams are subjected to the vertical loads

P v = 1.4 DL .

4. The beams of the first two bays (counting from the left) are subjected to the vertical

loads P v = 1.4 DL + 1.6 LL while the rest of the beams are subjected to the vertical

loads P v = 1.4 DL .

5. P v = 1.4 DL + 1.6 LL and P v = 1.4 DL are distributed in a staggered way. This

means that the loads applied to the top left storey are P v = 1.4 DL + 1.6 LL while the

adjacent beams either in the same storey level or the storey beneath carry vertical

loads P v = 1.4 DL .

6. The beams are subjected to vertical loads P v = 1.2 DL + 1.2 LL and the left hand side

of the framework is subjected to the factored wind loads P h = 1.2WL .

7. The beams are subjected to the vertical loads P v = 1.0 LL and the left hand side of

the framework is subjected to unfactored wind loads P h = 1.0WL . This loading

pattern is considered to check horizontal displacements at the nodes.

8. The beams are subjected to vertical loads P v = 1.0 LL . This loading pattern is taken

into account to check vertical displacements at nodes.

Figure 8.14 shows a loading pattern in which the values of the nodal loads of each

loading case, stated above, can be identified from Table 8.10.

Design Optimization of 2D Steel Frame Structures

P1

P4

H1

P7

P10

7

3

P2

H2

P6

H3

P2

P5

H4

P8

8

2

P3

H5

8

2

P2

5

P8

P5

H6

8

2

P3

P6

P9

8

2

P2

5

P8

P5

H8

4

P9

P6

H9

P2

H10

P8

8

P24

P27

5

P20

P23

2

P26

P24

1

P27

P18

4

P21

8

4

P14

P17

P20

P21

P23

2

P26

P11

2

P27

P24

8

P17

4

P15

P5

P17

5

P20

P18

5

P14

P12

8

1

5

P21

P26

P15

P11

8

1

P3

P18

P23

8

P12

P24

3

P27

P20

P14

H7

P17

P11

3

P26

P23

5

P15

P12

6

P21

8

5

P9

P6

P18

P14

P2

P11

6

P20

8

6

P17

P15

P2

P12

P19

8

6

P9

P16

6

P14

P11

8

3

P3

P13

7

6

P8

P5

263

P23

P26

Figure 8.14. Fourbay tenstorey framework

Design Optimization of 2D Steel Frame Structures

264

Table 8.10. Loads applied on the fourbay tenstorey framework (in kN)

Loading case

Load

symbol

P1

45.0

45.0

45.0

45.0

45.0

35.0

15.0

15.0

P2

90.0

90.0

90.0

90.0

45.0

65.0

40.0

40.0

P3

90.0

90.0

90.0

90.0

90.0

65.0

40.0

40.0

P4

90.0

90.0

90.0

90.0

90.0

70.0

30.0

30.0

P5

180.0

180.0

180.0

180.0

60.0

130.0

80.0

80.0

P6

180.0

180.0

180.0

180.0

180.0

130.0

80.0

80.0

P7

90.0

90.0

70.0

90.0

70.0

70.0

30.0

30.0

P8

180.0

180.0

120.0

180.0

120.0

130.0

80.0

80.0

P9

180.0

180.0

120.0

180.0

120.0

130.0

80.0

80.0

P10

90.0

90.0

45.0

90.0

45.0

70.0

30.0

30.0

P11

180.0

180.0

60.0

180.0

180.0

130.0

80.0

80.0

P12

180.0

180.0

60.0

180.0

60.0

130.0

80.0

80.0

P13

90.0

90.0

60.0

70.0

70.0

70.0

30.0

30.0

P14

180.0

180.0

60.0

120.0

120.0

130.0

80.0

80.0

P15

180.0

180.0

60.0

120.0

120.0

130.0

80.0

80.0

P16

90.0

90.0

60.0

45.0

90.0

70.0

30.0

30.0

P17

180.0

180.0

60.0

60.0

60.0

130.0

80.0

80.0

P18

180.0

180.0

60.0

60.0

60.0

130.0

80.0

80.0

P19

90.0

90.0

60.0

60.0

70.0

70.0

30.0

30.0

P20

180.0

180.0

60.0

60.0

120.0

130.0

80.0

80.0

P21

180.0

180.0

60.0

60.0

120.0

130.0

80.0

80.0

P22

90.0

90.0

60.0

60.0

45.0

70.0

30.0

30.0

P23

180.0

180.0

60.0

60.0

180.0

130.0

80.0

80.0

P24

180.0

180.0

60.0

60.0

180.0

130.0

80.0

80.0

P25

45.0

45.0

25.0

25.0

70.0

35.0

30.0

30.0

P26

90.0

90.0

45.0

45.0

90.0

65.0

80.0

80.0

P27

90.0

90.0

45.0

45.0

45.0

65.0

80.0

80.0

H1

0.0

3.5

0.0

0.0

0.0

11.0

9.2

0.0

H2

0.0

7.0

0.0

0.0

0.0

16.7

14.0

0.0

H3

0.0

7.0

0.0

0.0

0.0

15.6

13.0

0.0

H4

0.0

7.0

0.0

0.0

0.0

14.5

12.0

0.0

H5

0.0

7.0

0.0

0.0

0.0

13.4

11.2

0.0

H6

0.0

7.0

0.0

0.0

0.0

12.2

10.2

0.0

H7

0.0

7.0

0.0

0.0

0.0

11.1

9.25

0.0

H8

0.0

7.0

0.0

0.0

0.0

10.0

8.35

0.0

H9

0.0

7.0

0.0

0.0

0.0

8.9

7.5

0.0

H10

0.0

7.0

0.0

0.0

0.0

7.5

6.25

0.0

Design Optimization of 2D Steel Frame Structures

265

The problem was analysed employing the solution parameters mentioned in

Section 8.4. The optimization process was carried out using 5 runs for each approach for

determining the effective buckling lengths. The optimization process was automatically

terminated when one of the termination conditions, stated in Section 8.4, is satisfied.

The solutions achieved are listed in Table 8.11 while the corresponding design variables

of the optimum solution of each approach are given in Table 8.12.

Table 8.11. The solutions for the fourbay tenstorey framework

Weight (kg)

Run

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

34421

30835

35125

34400

30649

35393

34424

29301

35649

34337

30904

34934

34406

30727

36992

Average weight

34397.6

30483.2

35618.6

Minimum weight

34337

29301

34934

Table 8.12. The optimum solution for the fourbay tenstorey framework

Design

variable

Cross sections

First approach

(code)

Second approach

(FE)

Third approach

(conservative)

356 406 235 UC

356 368 177 UC

356 406 235 UC

356 368 153 UC

305 305 118 UC

356 368 153 UC

356 368 129 UC

203 203 71 UC

356 368 129 UC

356 406 235 UC

356 368 202 UC

356 406 235 UC

305 305 118 UC

356 368 129 UC

356 368 129 UC

305 305 118 UC

254 254 73 UC

356 368 129 UC

254 146 31 UB

305 102 33 UB

305 102 25 UB

457 152 52 UB

457 152 52 UB

457 152 52 UB

Weight (kg)

34337

29301

34934

Design Optimization of 2D Steel Frame Structures

266

It can be observed that there is little difference in the values of the solution for

each approach, listed in Table 8.11. This indicates the developed algorithm can be

successfully applied to reach a good solution. It is also interesting to note that the

column members, belonging to group 1 and 4 were grouped separately, but the same

universal column (356 406 235 UC) was adopted for both groups when using either

the first or third approach. Similarly, the cross sections, corresponding to the third, fifth

and sixth design variable of the optimum design of the third approach, are also the same.

This indicates that it may be more economical to use the developed algorithm to decide

the best grouping of the framework members.

During the optimization process, the convergence characteristics of each solution

were examined. Figure 8.15 shows the changes of the best design with the number of

generations performed to reach the optimum design.

60000

Best design (kg)

First approach (code)

Second approach (FE)

T hird approach (conservative)

50000

40000

30000

20000

0

10

20

30

40

50

60

70

80

Generation number

Figure 8.15. Fourbay tenstorey framework: best design versus

generation number

It is worth noting that the optimum solutions were reached within 50 generations,

and the rest of the computations were carried out to satisfy the convergence criteria.

Design Optimization of 2D Steel Frame Structures

267

8.5 Validation of the optimum design

This section shows that the values of the constraints obtained by applying the developed

FORTRAN code for the design of steel frame structures to BS 5950 are in a good

agreement with those obtained by CSC software.

Since 1975, CSC UK Ltd. (1998) has specialised in developing PCbased

software for structural engineering design. The product SFRAME was introduced to

analyse a framework under specified loading cases, then by switching to the product S

STEEL the framework members can be checked for compliance with BS 5950 design

criteria. Due to the innovative use of graphics, both SFRAME and SSTEEL have a

user interface facility. The user interface facility provides the designer to visualise the

orientation of the sections of the members, coordinate system, member numbering and

the design results. The following steps can summarise the used procedure.

1) In SFRAME, the framework geometry, member sections and loading cases are

defined. Then, the bending moments, shear forces, displacements are calculated

applying the linear analysis facility.

2) Starting to SSTEEL program. This automatically detects the framework geometry,

loading cases, bending moments, shear forces and displacements and member

sections. The design checks are then carried out. Here, the effective length factors

( LeX,ffnmem ( x ) Ln mem and LeY,ffnmem ( xi , j ) Ln mem ) and the equivalent uniform factor

m qmem ( x ) are user defined. The default value for each is unity. At this stage, it is

n

worth noting that m qmem ( x ) is computed in the developed FORTRAN code as given

n

in clause 4.3.7.6 of BS 5950 (technique 1) for each member at each loading case.

3) The design results are then visualised in a separate window as shown later.

Design Optimization of 2D Steel Frame Structures

268

To validate the applied FORTRAN code, the problem described in Section 8.3

should be first run when m qmem ( x ) for each member equals 1. This is named as

n

technique 2. Then, CSC software is used to check the obtained results.

The optimum design of twobay twostorey framework is investigated when 4

design variables representing the framework members are considered. The framework is

shown in Figure 8.5. The framework is subjected to the same loads as mentioned in

Section 7.3.2. The optimization process was carried out utilising the design procedure

discussed in Section 8.2 while the solution parameters and the convergence criteria are

considered as those given in Section 8.4. Five runs were carried out when applying the

first approach for determining the effective buckling lengths. The design variables

corresponding to the optimum solution were then tabulated in Table 8.13. It is worth

comparing the best solution obtained with that achieved in section 8.4.1 (technique 1)

when a more accurate equation for determining m qmem ( x ) was applied. This comparison

n

is also presented in Table 8.13.

Table 8.13. The best solution for the twobay twostorey framework (4 design

variables)

Cross sections

Design

variable

Member

No.

Technique 1

Technique 2

1, 2, 5, 6

356 368 177 UC

305 305 118 UC

3, 4

356 368 177 UC

305 305 118 UC

7, 8

457 191 74 UB

610 229 101 UB

9, 10

533 210 82 UB

762 267 147 UB

8430

8500

Weight (kg)

It is known from clause 4.3.7.6 of BS 5950 that the upper limit of m qmem ( x ) is 1.

n

Therefore, the cross sections of beams, obtained when applying technique 2, have more

Design Optimization of 2D Steel Frame Structures

269

strength than those achieved by employing technique 1. This allows the optimizer to

obtain solution (8500 kg), which has column sections (305 305 118 UC) having

strength less than those (356 368 177 UC) of technique 1.

The graphical representation of changes of the best design with the number of

generations performed for each trial is shown in Figure 8.16.

Best design (kg)

12000

First run

Second run

T hird run

Fourth run

Fifth run

11000

10000

9000

8000

0

10

20

30

40

50

60

70

Generation number

Figure 8.16. Twobay twostorey framework: best design versus

generation number.

At this stage, the framework weight is optimized and the section of each member

is known. The optimizer is also modified to indicate whether the framework is sway or

nonsway. Here, the optimizer identifies the framework as a nonsway framework. This

is also successfully examined when using SFRAME.

Following the three steps stated at the beginning of this section, the obtained

results are validated and the design results from SSTEEL are displayed in Figure 8.17.

Figure 8.17. The design results of twobay twostorey framework (captured from SSTEEL)

Design Optimization of 2D Steel Frame Structures

271

In this figure, the numbering of the framework members, type of cross section of

each member and node are shown. The design checks are indicated in colour in which

the code utilisation menu gives the range for of each colour. It is worth noting that the

design results vary between 0.8 and 1.0. Among the strength constraints, the overall

buckling constraints have the largest value.

8.6 Concluding remarks

Optimization technique based on GA was applied for design optimization of steel frame

structures. Multiple loading cases were considered. The design method obtained a steel

frame structure with the least weight by selecting appropriate sections for beams and

columns from BS 4. The following concluding remarks can be made.

1) It has been proven that the developed GA approach can be successfully incorporated

in design optimization in which framework members have to be selected from the

available sections taken from BS 4 while the design satisfies the design criteria

according to BS 5950.

2) It is also worth noting that different numbers of design variables are considered for

each framework and the optimizer is able to obtain a good solution in a reasonable

number of generations. This indicates that the developed approach can be utilised by

a practising designer.

3) The optimizer is successfully linked to a finite element package for a more accurate

treatment of the determination of the effective buckling length that leads to

achieving a more economical design.

4) In the present chapter, the constraints imposed on the second moment of area of two

adjacent columns in two adjacent storey levels are chosen to reflect the designers

experience. Other constraints, such as sectional dimensions, sectional area, etc., can

Design Optimization of 2D Steel Frame Structures

272

also formulated. This indicates that the optimizer is able to treat different practical

constraints depending on the skills and experience of the designer.

5) It can be observed that the optimizer helps to identify the best arrangement of

grouping to obtain economical design. This illustrates that it may be economical to

use the developed algorithm to decide the optimum grouping of the members in a

framework using multiobjective functions.

6) It can also be concluded that the developed optimizer is able to obtain more than one

suitable solution, and the difference between them is small. This adds a benefit of

using an automated design that allows the designer to choose the appropriate

solution depending on the availability of the sections provided by manufacturer.

7) It is interesting to note that even some of the powerful computer software packages

available today for the design of steel frameworks such as CSC and STAADIII

require the structural designer to input the effective buckling length factor as a

parameter. In this study, computation of the effective buckling length is automated

and included in the developed algorithm. This is achieved by employing three

different approaches as discussed in Section 8.2.

Two questions arise. The first is whether or not the developed optimizer can

obtain a solution of minimum weight design of threedimensional steelwork. This is a

more complex problem and the formulation of the problem includes more constraints.

The bracing members, which take discrete values from BS 4848 have to be incorporated

in the design problem. The second is what difference could be achieved in the optimum

design when using either of these approaches for evaluating the effective buckling

length. These questions will be answered in the next chapter.

Das könnte Ihnen auch gefallen

- Automatic Verified Shear Force Design of Reinforced Concrete BeamsDokument14 SeitenAutomatic Verified Shear Force Design of Reinforced Concrete BeamsMyron OikonomakisNoch keine Bewertungen

- Analysis Procedure for Earthquake Resistant StructuresVon EverandAnalysis Procedure for Earthquake Resistant StructuresNoch keine Bewertungen

- Bracing Design To Eurocode 3Dokument13 SeitenBracing Design To Eurocode 3Greg Rabulan100% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Advance Design - Bracing Members Design According To Eurocode 3Dokument8 SeitenAdvance Design - Bracing Members Design According To Eurocode 3gemo_n_fabrice69Noch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Multi-Objective Optimization of Reinforced Concrete Frames: Matěj LepšDokument8 SeitenMulti-Objective Optimization of Reinforced Concrete Frames: Matěj LepšxelmerxNoch keine Bewertungen

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Sp208-04ex 6Dokument22 SeitenSp208-04ex 6Žarko LazićNoch keine Bewertungen

- Grillage Analysis of Structures Consist of Steel I-BeamsDokument17 SeitenGrillage Analysis of Structures Consist of Steel I-Beamsjust_u_prettyNoch keine Bewertungen

- Robot Manipulators: Modeling, Performance Analysis and ControlVon EverandRobot Manipulators: Modeling, Performance Analysis and ControlNoch keine Bewertungen

- Bracing Design To Eurocode 3Dokument13 SeitenBracing Design To Eurocode 3B.A H100% (1)

- Design of Reinforced Concrete ColumnsDokument25 SeitenDesign of Reinforced Concrete Columnsmedodo100% (1)

- Mace 60035Dokument7 SeitenMace 60035eng_ayman_H_MNoch keine Bewertungen

- Example 6: Prestressed Beam: Adolfo Matamoros Julio RamirezDokument19 SeitenExample 6: Prestressed Beam: Adolfo Matamoros Julio RamirezTùng HìNoch keine Bewertungen

- Steel FramesDokument14 SeitenSteel FramesClaudia Alina IovanNoch keine Bewertungen

- Reliability Investigation of Steel Cased ColumnsDokument10 SeitenReliability Investigation of Steel Cased ColumnsvoobyNoch keine Bewertungen

- Design of Reinforced Concrete Columns PDFDokument26 SeitenDesign of Reinforced Concrete Columns PDFMa Gh100% (1)

- Etapa IIGrinda PrincipalaDokument7 SeitenEtapa IIGrinda PrincipalaMacovei AlinNoch keine Bewertungen

- Optimum Geometry Design of Nonlinear Braced Domes Using Genetic AlgorithmDokument9 SeitenOptimum Geometry Design of Nonlinear Braced Domes Using Genetic AlgorithmFrancisco Javier Torres AlvaradoNoch keine Bewertungen

- Stiffness Optimization Technique For 3D Tall Steel Building Frameworks Under Multiple Lateral LoadingsDokument7 SeitenStiffness Optimization Technique For 3D Tall Steel Building Frameworks Under Multiple Lateral LoadingskarolNoch keine Bewertungen

- Design Charts For Channel Shaped Reinforced Concrete Short Columns Subjected To Axial Compressive Load and Uniaxial BendingDokument11 SeitenDesign Charts For Channel Shaped Reinforced Concrete Short Columns Subjected To Axial Compressive Load and Uniaxial BendingP.Sang-GeoNoch keine Bewertungen

- Dos II - Lecture NotesDokument71 SeitenDos II - Lecture NotesSajee SweetNoch keine Bewertungen

- r891 PDFDokument16 Seitenr891 PDFlyeshiunNoch keine Bewertungen

- Design of Zipper Column in Inverted V Braced Steel FramesDokument7 SeitenDesign of Zipper Column in Inverted V Braced Steel FramesMohammad AshrafyNoch keine Bewertungen

- CIV 4235 ExamDokument9 SeitenCIV 4235 Exammalumius100% (2)

- Mechanics of MaterialDokument3 SeitenMechanics of MaterialChhaya Sharma100% (1)

- Han 2011Dokument4 SeitenHan 2011amirbakhtiary97Noch keine Bewertungen

- 4.3 Moment Magnification PDFDokument13 Seiten4.3 Moment Magnification PDFChetan ChaudhariNoch keine Bewertungen

- Mom Sem 1 (09-10)Dokument12 SeitenMom Sem 1 (09-10)Jenylex KumilNoch keine Bewertungen

- Lateral Support For Tier Building FramesDokument4 SeitenLateral Support For Tier Building Framesuhu_plus6482Noch keine Bewertungen

- Rao 1973Dokument6 SeitenRao 1973karolNoch keine Bewertungen

- Review of Lateral-Torsional Buckling Design ProvisionsDokument16 SeitenReview of Lateral-Torsional Buckling Design ProvisionsDhimas ZakariaNoch keine Bewertungen

- Seismic Design StorageTanks Ed2010Dokument39 SeitenSeismic Design StorageTanks Ed2010VladSimionNoch keine Bewertungen

- Rbs-Reduced Beam SectionsDokument8 SeitenRbs-Reduced Beam Sectionswayne1925Noch keine Bewertungen

- Analysis and Design of Compression Steel MembersDokument55 SeitenAnalysis and Design of Compression Steel MembersWulandita Prihandini SagarmathaNoch keine Bewertungen

- Discrete Optimum Design of Cable-Stayed BridgesDokument9 SeitenDiscrete Optimum Design of Cable-Stayed BridgesspoorthissNoch keine Bewertungen

- Ch3 FrameDokument51 SeitenCh3 Framengkt722Noch keine Bewertungen

- Buckling Analysis Design of Steel FramesDokument0 SeitenBuckling Analysis Design of Steel FramestangkokhongNoch keine Bewertungen

- Design of Columns To EurocodeDokument19 SeitenDesign of Columns To EurocodeKasun Karunaratne92% (13)

- Xiaoyang Lu, Yaru Wang, Xiaoxiao Wang, Hao Zhang, Silu XieDokument5 SeitenXiaoyang Lu, Yaru Wang, Xiaoxiao Wang, Hao Zhang, Silu Xiesawmag123Noch keine Bewertungen

- Reinforced Concrete Lecture Notes University of HongKongDokument32 SeitenReinforced Concrete Lecture Notes University of HongKongApril Ingram100% (4)

- Medhekar & Kennedy - Displacement-Based Seismic Design of Buildings-ApplicationDokument12 SeitenMedhekar & Kennedy - Displacement-Based Seismic Design of Buildings-ApplicationBiţă MihaiNoch keine Bewertungen

- A Structured Approach To The Design and PDFDokument12 SeitenA Structured Approach To The Design and PDFmocker1987Noch keine Bewertungen

- RC Assignment 1 - 9septDokument6 SeitenRC Assignment 1 - 9septBa Thanh Dinh100% (1)

- Mechanical Design of A Power SystemDokument34 SeitenMechanical Design of A Power Systemapi-312541429Noch keine Bewertungen

- Chapter 6 Design of Axially Loaded ColumnsDokument18 SeitenChapter 6 Design of Axially Loaded Columnsكريم حمدNoch keine Bewertungen

- Joist SlabDokument13 SeitenJoist SlabAhmed Nabil80% (5)

- Optimal Design of Axially Loaded RC ColumnsDokument4 SeitenOptimal Design of Axially Loaded RC ColumnsBONFRING100% (1)

- Pedestrian Cable-Stayed Bridge Project: Ce 491C - Senior Design SPRING 2000Dokument35 SeitenPedestrian Cable-Stayed Bridge Project: Ce 491C - Senior Design SPRING 2000Ing Manolo HernandezNoch keine Bewertungen

- Self Supporting Cone Roof DesignDokument5 SeitenSelf Supporting Cone Roof DesignBerk KoçNoch keine Bewertungen

- ACKROYD - Simplified Frame Design of Type PR ConstructionDokument6 SeitenACKROYD - Simplified Frame Design of Type PR ConstructionValentin Vergara GonsagaNoch keine Bewertungen

- 2004 Behaviour ICJDokument8 Seiten2004 Behaviour ICJshilp88Noch keine Bewertungen

- Analysis of Straight and Skewed Box Girder Bridge by Finite Strip MethodDokument8 SeitenAnalysis of Straight and Skewed Box Girder Bridge by Finite Strip MethodBharat SharmaNoch keine Bewertungen

- Built Up ColumnsDokument22 SeitenBuilt Up Columnsfinn.crown100% (1)

- Design of FootingDokument24 SeitenDesign of FootingAnonymous ux7KlgruqgNoch keine Bewertungen

- Box Girder Design CraneDokument8 SeitenBox Girder Design CraneSomi Khan100% (2)

- Structure No LinealDokument10 SeitenStructure No LinealArte MachacaNoch keine Bewertungen

- Miscellaneous Heroism: Abelaard of NidusDokument12 SeitenMiscellaneous Heroism: Abelaard of NidusCesar ManNoch keine Bewertungen

- Folder Pagina Induscon - São Paulo - Nov 11th To 14th 2018Dokument3 SeitenFolder Pagina Induscon - São Paulo - Nov 11th To 14th 2018Cesar ManNoch keine Bewertungen

- Aspect RatioDokument1 SeiteAspect RatioCesar ManNoch keine Bewertungen

- Hayward 1997-AirCoupledNDE ConfDokument9 SeitenHayward 1997-AirCoupledNDE ConfCesar ManNoch keine Bewertungen

- Ogres and Their KinDokument4 SeitenOgres and Their KinCesar ManNoch keine Bewertungen

- Figuras para Convergencia Dos DeslocDokument3 SeitenFiguras para Convergencia Dos DeslocCesar ManNoch keine Bewertungen

- Sara Dunstan, Founder of The Legion of SteelDokument1 SeiteSara Dunstan, Founder of The Legion of SteelCesar ManNoch keine Bewertungen

- Miscellaneous Heroism: Abelaard of NidusDokument12 SeitenMiscellaneous Heroism: Abelaard of NidusCesar ManNoch keine Bewertungen

- Miscellaneous Heroism: Abelaard of NidusDokument12 SeitenMiscellaneous Heroism: Abelaard of NidusCesar ManNoch keine Bewertungen

- Masters of The ConclaveDokument1 SeiteMasters of The ConclaveCesar ManNoch keine Bewertungen

- Legion of SteelDokument1 SeiteLegion of SteelCesar ManNoch keine Bewertungen

- Gallego-Juárez Et Al. - 2010Dokument12 SeitenGallego-Juárez Et Al. - 2010Cesar ManNoch keine Bewertungen

- Masters of The ConclaveDokument1 SeiteMasters of The ConclaveCesar ManNoch keine Bewertungen

- Mankind: AbanasinianDokument9 SeitenMankind: AbanasinianCesar ManNoch keine Bewertungen

- GnomesDokument1 SeiteGnomesCesar ManNoch keine Bewertungen

- ElvesDokument3 SeitenElvesCesar ManNoch keine Bewertungen

- Knights of The Divine HammerDokument1 SeiteKnights of The Divine HammerCesar ManNoch keine Bewertungen

- Knights of SolamniaDokument3 SeitenKnights of SolamniaCesar ManNoch keine Bewertungen

- Ariakan, Head of The Knights of TakhisisDokument2 SeitenAriakan, Head of The Knights of TakhisisCesar ManNoch keine Bewertungen

- KenderDokument2 SeitenKenderCesar ManNoch keine Bewertungen

- ElvesDokument3 SeitenElvesCesar ManNoch keine Bewertungen

- Antal Kizm (Geographical Feature)Dokument21 SeitenAntal Kizm (Geographical Feature)Cesar Man100% (1)

- KenderDokument2 SeitenKenderCesar ManNoch keine Bewertungen

- Ariakan, Head of The Knights of TakhisisDokument2 SeitenAriakan, Head of The Knights of TakhisisCesar ManNoch keine Bewertungen

- Gallego Juarez 1994Dokument10 SeitenGallego Juarez 1994Cesar ManNoch keine Bewertungen

- Arthur Ray Love, Nutley Et Al. - 2010 - (19) United States (12) Patent Application Publication (10) Pub .Dokument20 SeitenArthur Ray Love, Nutley Et Al. - 2010 - (19) United States (12) Patent Application Publication (10) Pub .Cesar ManNoch keine Bewertungen

- 03 Yaralioglu 02 PDFDokument4 Seiten03 Yaralioglu 02 PDFCesar ManNoch keine Bewertungen

- 47435Dokument23 Seiten47435Cesar ManNoch keine Bewertungen

- 03 Yaralioglu 02 PDFDokument4 Seiten03 Yaralioglu 02 PDFCesar ManNoch keine Bewertungen

- Levin Chapter 1Dokument4 SeitenLevin Chapter 1Vibhav MathurNoch keine Bewertungen

- Tia Portal Vs Studio 5000Dokument76 SeitenTia Portal Vs Studio 5000onyekaNoch keine Bewertungen

- Future Outlook of HBLDokument5 SeitenFuture Outlook of HBLAmbreen AlamNoch keine Bewertungen

- Sonic RDokument26 SeitenSonic RaddinfoNoch keine Bewertungen

- Railway Reservation System Er DiagramDokument4 SeitenRailway Reservation System Er DiagramPenki Sarath67% (3)

- Barbara Liskov, Programming With Abstract Data TypesDokument10 SeitenBarbara Liskov, Programming With Abstract Data TypesJehu ShalomNoch keine Bewertungen

- Brkarc 2749Dokument97 SeitenBrkarc 2749Edi WibowoNoch keine Bewertungen

- Murach SQL Server 2008 Examples Installation GuideDokument4 SeitenMurach SQL Server 2008 Examples Installation Guidegeko1Noch keine Bewertungen

- Blockchain's Smart Contracts: Driving The Next Wave of Innovation Across Manufacturing Value ChainsDokument10 SeitenBlockchain's Smart Contracts: Driving The Next Wave of Innovation Across Manufacturing Value ChainsCognizant50% (2)

- MIMIX Reference PDFDokument747 SeitenMIMIX Reference PDFRahul JaiswalNoch keine Bewertungen

- Brouchure Eng SG5000 9910Dokument8 SeitenBrouchure Eng SG5000 9910rhomadonaNoch keine Bewertungen

- Student Database Management SystemDokument23 SeitenStudent Database Management SystemAnonymous ra8J8qlyVNoch keine Bewertungen

- Programming Concepts in JavaDokument12 SeitenProgramming Concepts in Javarishabhindoria57Noch keine Bewertungen

- Paper Template For Iumrs Ica 2018Dokument4 SeitenPaper Template For Iumrs Ica 2018BravNoch keine Bewertungen

- 10 Obscure Excel Tricks That Can Expedite Common ChoresDokument8 Seiten10 Obscure Excel Tricks That Can Expedite Common ChoresHamza IslamNoch keine Bewertungen

- 300-115 by Aditya Gaur v-6Dokument5 Seiten300-115 by Aditya Gaur v-6chetan666123Noch keine Bewertungen

- Feature Selection in Machine LearningDokument34 SeitenFeature Selection in Machine LearningShivam PandeyNoch keine Bewertungen

- Strategy Management AssignmentDokument7 SeitenStrategy Management AssignmentAftab Khan SuriNoch keine Bewertungen

- Queen Problem - Allegro 5Dokument3 SeitenQueen Problem - Allegro 5Alexandru Gabriel StoicaNoch keine Bewertungen

- Researcher (Economic & Business Analyst)Dokument2 SeitenResearcher (Economic & Business Analyst)TTNoch keine Bewertungen

- Exploration Flowchart DataDokument1 SeiteExploration Flowchart Datasesbasar sitohangNoch keine Bewertungen

- S0 HandoutDokument4 SeitenS0 HandoutJ Reach (JR3ach)Noch keine Bewertungen

- Oracle LogMiner Viewer and Flashback TransactionDokument21 SeitenOracle LogMiner Viewer and Flashback TransactionMohammad ZaheerNoch keine Bewertungen

- Citronix Ci5000 Labeltec - SeDokument6 SeitenCitronix Ci5000 Labeltec - SeJosemar M. FerreiraNoch keine Bewertungen

- 8086 Development ToolsDokument7 Seiten8086 Development ToolsJashuva Chukka0% (1)

- Career Climber CV TemplateDokument2 SeitenCareer Climber CV TemplatesagarNoch keine Bewertungen

- Old Question Papers of PGDCA 1 Semester H.K. Hi-Tech (College of IT & Management) H.K. Hi-TechDokument9 SeitenOld Question Papers of PGDCA 1 Semester H.K. Hi-Tech (College of IT & Management) H.K. Hi-TechPrince KatiyarNoch keine Bewertungen

- Mmultimedia 3Dokument45 SeitenMmultimedia 3iyasu ayenekulu100% (2)

- Installing MySQL Cluster 7.0 - OpenSolarisDokument7 SeitenInstalling MySQL Cluster 7.0 - OpenSolarismysql_clustering3251Noch keine Bewertungen

- Syntax and SemanticsDokument59 SeitenSyntax and SemanticsRej ChandlerNoch keine Bewertungen

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchVon EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchBewertung: 4 von 5 Sternen4/5 (10)

- SketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyVon EverandSketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyBewertung: 1.5 von 5 Sternen1.5/5 (2)

- Certified Solidworks Professional Advanced Weldments Exam PreparationVon EverandCertified Solidworks Professional Advanced Weldments Exam PreparationBewertung: 5 von 5 Sternen5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsVon EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsBewertung: 5 von 5 Sternen5/5 (1)

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesVon EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesBewertung: 4 von 5 Sternen4/5 (4)

- Beginning AutoCAD® 2020 Exercise WorkbookVon EverandBeginning AutoCAD® 2020 Exercise WorkbookBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersVon EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersNoch keine Bewertungen

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Von EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Bewertung: 5 von 5 Sternen5/5 (2)

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®Von EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Noch keine Bewertungen

- Up and Running with AutoCAD 2020: 2D Drafting and DesignVon EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignNoch keine Bewertungen