Beruflich Dokumente

Kultur Dokumente

Ipir Iso Report

Hochgeladen von

Easwar KumarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ipir Iso Report

Hochgeladen von

Easwar KumarCopyright:

Verfügbare Formate

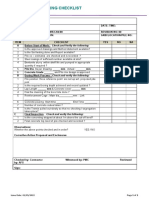

IN-PROCESS INSPECTION REPORT

CENTERLINE MARKING & CHECKING

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-A

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Has the cleaning and levelling of the site been done?

Has the demarcation of the plot and marking of the

actual boundaries been done? (As per Drawing)

Are the grid pillars set out?

Has the check for right angle been done?

Are the locations of footings on the specified grid lines

as per drawing?

Has the allowance for the excavation of footing

shuttering been provided?

Has the marking of structural members been properly

supervised?

Is the reinforecement and shuttering provided as per

marking?

Has the centre line distance between columns and the

verticality been checked?

Yes

NA

Remarks

No. of column and column orientation compare with

Architectural & Structural Drawings

Manual excavation at last one foot of the footing

depth.

Pit bottom compact with the wracker

Check the bore well location while marking the footing

mat

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Supervisor)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

CENTERLINE MARKING & CHECKING

Prepared By:

(Site Supervisor)

Format No: QA-03-A

Issue No: 01

Revision No: 00

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

FOOTING

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-B

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Are the latest "Good for construction"drawings

available with control seal

Are the required number of cement bags available on

site?

Have the Mixer machine & vibrators been checked

before start of the concrete?

Is the necessary shuttering and reinforcement

complete and in place?

Is the dimensional accuracy of shuttering material

correct? (length, Breath, Hight)

Is the test report of cement and steel available at site

office?

Has the diameter and spacing of reinforcement been

checked? (Footing Mat, Column)

Is the concrete been properly compacted with a

vibrator or manually?

*Are the markings on the column dowels done and a

line dori being used to maintain correct concrete level?

10

Check the cover block thickness as per drawing.

11

Measurement Box used for concret mix preparation

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Supervisor)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

COLUMN CONCRETING

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-C

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Are the required number of cement bags available on

site?

Have the Mixer machine & vibrators been checked

before start of the concrete?

Is the dimensional accuracy of shuttering material

correct?

Has markings been made on the column dowels for

concrete level?

Is the test report of cement and steel available at site

office?

Has the aggregate been checked?

Has the diameter and spacing of reinforcement been

checked as per Drawing?

Has the vertically of property supported column box

been checked?

Is the concrete been properly compacted with a

vibrator or manually?

10

Is the concrete been properly compacted with a

vibrator or manually?

11

Has deshuttering been done carefully without

damaging the concrete surface after 24 hours

12

Measurement Box used for concrete mix preparation

13

Is concrete pouring level mark available for all columns

as per drawing.

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Engineer)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

COLUMN CONCRETING

Prepared By:

(Site Engineer)

Format No: QA-03-C

Issue No: 01

Revision No: 00

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

PLINTH BEAM

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-D

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Is the necessary shuttering and reinforcement

completed and in place?

Has the shuttering material been properly aligned

using appropriate equipment?

Has the diameter and spacing of reinforcement been

checked?

Check Cover Block fixing is in propoer size

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Supervisor)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

ROOF

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-E

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Are the latest Good for Construction drawings

available with control seal?

Is the area prepared for starting reinforcement

(shuttering complete, cleaned, oiled, and taped)?

Has the required barricading and safety measured

been taken?

Is the area to be reinforced compatible with the

drawings that are provided?

Are the required tools available at site to ensure

correct work?

Is the reinforcement free from mud, grease and other

forms of contamination?

Is the overlapping ensured and the laps are

staggered?

Are the dowels for column, beams and slab in place

and checked for proper length?

Are the required hooks fixing and is the chair height for

the upper layer of reinforcement correct?

10

Is the reinforcement done ae per specification and

drawing?

11

Are cover blocks provided and fixed in a systematically

correct manner and as per specifications?

12

Have beam and column joints checked for sufficient

cover blocks?

13

Has adequqte lap lengths been provided for all the

column bars?

14

Centering gaps covered with G.I Sheets.

15

Ensure all beam bottoms and all slab bottom are in

same level

16

Check with elevation darwing if any extra centering or

steel work required.

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Supervisor)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

ROOF

Prepared By:

(Site Supervisor)

Format No: QA-03-E

Issue No: 01

Revision No: 00

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

CEILING PLASTERING

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-F

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Is the concrete surface hacked?

Are button marks plased at appropriate intervals?

Is the electrical conducting works completed?

Is the kind of finishing required been achived?

Normal sponge finish?

Use measuring box for mortor mixing

Write curing date in the wall surface

Yes

NA

Remarks

check right angle (squareness) for the beam plastering

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Supervisor)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

BRICK WORK

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-G

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Are there any specific requirements of the client?

Has signature of the Client obtained

Is the brickwork checked in vertical and horizontal

directions?

Has the check for diagonals & dimensions been done

as per drawing?

Has the thickness for joints been done?

Has the brick work being erected to give specifications

to plum and in line?

Are the bricks soaked in water before laying

Check the location of door & Windows opening as per

drawing

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Engineer)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

INTERNAL PLASTERING

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-H

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Is the concrete surface beam/column hacked?

Are button marks plased at appropriate intervals?

Has the GI mesh been nailed between all RCC &

masonry members?

Are the openings of doors frames fixed at the same

level?

Is the electrical conducting works completed (pipe

laying & Box fixing?

Is the PHE piping works in toilets & kitchen

completed?

Is the height of switch boxes fixed correctly?

Use measuring box for mortor mixing

Are the windows corner are to the right angles, beam

& column?

10

Check loft bottom are at same level?

11

Cut the plaster surface properly for skirting

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Engineer)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

EXTERNAL PLASTERING

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-I

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Is the concrete surface beam/column hacked?

Are button marks plased at appropriate intervals?

Has the GI mesh been nailed between all RCC &

masonry members?

Has the scaffolding arrangement been made?

Is the plaster in proper line & verticality?

Is the wall being plastered to given specifications, to

plumb and even?

Is plastering done above & below platforms and

sunshades?

Are the switch boxes in position and properly finished?

Is the plaster surface cut properly for skirting?

10

Has the kind of finishing required been achieved?

Yes

NA

Remarks

- Normal Sponge finish

- Rough finish

- Smooth even finish

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Engineer)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

EXTERNAL PLASTERING

Prepared By:

(Site Engineer)

Format No: QA-03-I

Issue No: 01

Revision No: 00

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

WALL TILES

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-J

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Are the joints properly aligned?

No hollow sound on the tile when tapped?

Have the edges been checked for straightness?

Are all the laid floor tiles properly covered?

Has the grouting been done?

Is the tiles surface plumb?

Have the setting of joints been done only after a

minimum of 24 hours?

check the tiles laying pattern with the client work order

if any change requested?

Check the Tiles brand & Size requested?

10

Check proper cutting of tiles at water pipe line out

lets?

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Engineer)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

FLOOR TILES

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-K

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Has slop been provided wherever required?

Has the laying procedure been followed?

Have the joints been cleaned to remove loos mortar?

Are the joints properly aligned?

No hollow sound on the tile when tapped?

Is the finished floor level?

Are all the laid floor tiles properly covered?

Has it been ensured that grouting is only done after 24

hours of laying of tiles?

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Engineer)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

GRANITE / MARBLE WORK

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-L

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Have the joints been cleaned to remove loose mortar?

Are the joints properly aligned?

Is work carried out to plump and horizontally to line?

Is the finished floor level?

Are all the laid floor tiles properly covered?

Has it been ensured that grouting is only done after

24hrs of laying of tiles?

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Supervisor)

Reviewed By:

(Project Manager)

IN-PROCESS INSPECTION REPORT

PAINTING

Project Code & Name:

Report. No / Date:

Location:

Stage of Inspection:

Site Engineer Name:

Floor No / Flat No:

Format No: QA-03-M

Issue No: 01

Revision No: 00

Project Manager Name:

S.No

Description

Is the primer application done?

Has the putty been applied after the 1st coat has

completely dried?

Have all undulation been covered using putty?

Has the dust from the surface been thoroughly wiped

off after sanding the puttied surface?

Has it been ensured that the final coat of paint is

applied and finished with roller?

Has it been ensured that the first coat is applied after

6 hours or more of first coat?

Yes

NA

Remarks

Draw / Write note on part being inspected & Mark the Actual readings

Prepared By:

(Site Engineer)

Reviewed By:

(Project Manager)

Das könnte Ihnen auch gefallen

- Check List - 2D Drawing ReviewDokument18 SeitenCheck List - 2D Drawing ReviewNikhil ChaundkarNoch keine Bewertungen

- Mold Design ChecklistDokument10 SeitenMold Design ChecklistRamesh RaoNoch keine Bewertungen

- Checklist - HRSG Inlet Duct - Non Pressure Parts Drgs.Dokument2 SeitenChecklist - HRSG Inlet Duct - Non Pressure Parts Drgs.Ramalingam PrabhakaranNoch keine Bewertungen

- Check List For Piping GADokument2 SeitenCheck List For Piping GAmksk_23Noch keine Bewertungen

- Inspection Test PlanDokument3 SeitenInspection Test Planfabin100% (3)

- S.No Description Format No Rev RemarksDokument23 SeitenS.No Description Format No Rev RemarksGulam Mujtaba KhanNoch keine Bewertungen

- Logo of Client Logo of EngineerDokument3 SeitenLogo of Client Logo of EngineerDawood Shaik Abdul CadarNoch keine Bewertungen

- Checklist For Site WorksDokument18 SeitenChecklist For Site Worksgkkeyen83% (40)

- Aluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and MarkingDokument4 SeitenAluminium Form Work (Mivan) : Sl. No Description YES NO N/A Remarks Layout and Markinganbunilavan50% (2)

- FootingDokument3 SeitenFootingUday Kumar DasNoch keine Bewertungen

- Checklist Pre-Tender Civil ProjectsDokument8 SeitenChecklist Pre-Tender Civil Projectssarathirv6Noch keine Bewertungen

- Inspection Check ListDokument6 SeitenInspection Check ListNagesh RaoNoch keine Bewertungen

- C-04 - PilingDokument1 SeiteC-04 - PilingKamal KksNoch keine Bewertungen

- Check List - IfADokument1 SeiteCheck List - IfAsaadashfaqNoch keine Bewertungen

- Block - Brick MasonryDokument1 SeiteBlock - Brick MasonryGabriel GabeNoch keine Bewertungen

- Checklist For Piping GA DrawingDokument2 SeitenChecklist For Piping GA DrawingRamalingam PrabhakaranNoch keine Bewertungen

- Quality Check List FormatDokument28 SeitenQuality Check List Formatjagadeesh_kumar_20100% (1)

- Iso Checklist Rev02Dokument4 SeitenIso Checklist Rev02Hemant Shinde100% (1)

- Reinforced Concrete Inspection Checklist 2015Dokument1 SeiteReinforced Concrete Inspection Checklist 2015khinwah88100% (3)

- A-2.2!10!20-01 - Checklist For Plumbing and Fire-Fighting WorksDokument25 SeitenA-2.2!10!20-01 - Checklist For Plumbing and Fire-Fighting WorksUnna Malai50% (2)

- CONQUAS Ver 2editDokument3 SeitenCONQUAS Ver 2editbyleekkNoch keine Bewertungen

- Concrete Pouring and Form Closure RequestDokument2 SeitenConcrete Pouring and Form Closure RequestJefferson Fontanilla Ganado50% (2)

- Upf Pipe Support Inspection RecordDokument2 SeitenUpf Pipe Support Inspection RecordaryopnNoch keine Bewertungen

- Checklist - Civil WorksDokument25 SeitenChecklist - Civil WorksJagoan Neon0% (1)

- Quality Assurance in Buillding WorksDokument8 SeitenQuality Assurance in Buillding WorksAtish KumarNoch keine Bewertungen

- Building Completion Inspection CRITERIA TRAKHEESDokument12 SeitenBuilding Completion Inspection CRITERIA TRAKHEESAdnan JadoonNoch keine Bewertungen

- Checklist Ref: No Activity Horizontal, Vertical LocationDokument1 SeiteChecklist Ref: No Activity Horizontal, Vertical LocationMohamed GamalNoch keine Bewertungen

- Checklist For Boomi Pooja: Project: Doc. No.: QA/CL-EXC/01 Client: Project LocationDokument28 SeitenChecklist For Boomi Pooja: Project: Doc. No.: QA/CL-EXC/01 Client: Project LocationThang Tran VietNoch keine Bewertungen

- QF-DES-03 R03 DSC-ChecklistDokument4 SeitenQF-DES-03 R03 DSC-ChecklistvudinhnambrNoch keine Bewertungen

- ColumnDokument2 SeitenColumnUday Kumar Das100% (1)

- Sanitary Check ListDokument36 SeitenSanitary Check ListankurNoch keine Bewertungen

- Sanitary Check ListDokument52 SeitenSanitary Check ListankurNoch keine Bewertungen

- Checklist For Site WorksDokument54 SeitenChecklist For Site WorkskhajaimadNoch keine Bewertungen

- Format For Accredited Checker'S Report: Title PageDokument2 SeitenFormat For Accredited Checker'S Report: Title PagerowatersNoch keine Bewertungen

- ................................. DIVISION OFFICE 1999 Inspection Guide (Metric Version) Major Structures - Steel ErectionDokument4 Seiten................................. DIVISION OFFICE 1999 Inspection Guide (Metric Version) Major Structures - Steel ErectionYohannes GebreNoch keine Bewertungen

- In-Process Inspection Checklist: SL Check Points Observations Checked I Fabricated Cubicle / in House FabricationDokument3 SeitenIn-Process Inspection Checklist: SL Check Points Observations Checked I Fabricated Cubicle / in House FabricationViswa Bhuvan0% (1)

- Footing - ChecklistDokument2 SeitenFooting - ChecklistbsudhareddyNoch keine Bewertungen

- Checklist For Transformer Yard LayoutDokument2 SeitenChecklist For Transformer Yard LayoutRahulNoch keine Bewertungen

- Drawing Checking Sheet DuctingDokument2 SeitenDrawing Checking Sheet DuctingswatkoolNoch keine Bewertungen

- Design Development ChecklistDokument5 SeitenDesign Development Checklistgilbert cruzNoch keine Bewertungen

- Erection Checklist Tank Vol0Dokument4 SeitenErection Checklist Tank Vol0Oladimeji Taiwo100% (1)

- False Celling Check ListDokument2 SeitenFalse Celling Check Listjohn paulNoch keine Bewertungen

- Construction Documents ChecklistDokument2 SeitenConstruction Documents ChecklistRalph SapitulaNoch keine Bewertungen

- Engineering DiaryDokument146 SeitenEngineering Diarynicmarsode100% (1)

- Vardhman Projects Operation ManualDokument76 SeitenVardhman Projects Operation ManualShankey BafnaNoch keine Bewertungen

- Check List For Plastering - M & E Co-Ordination: Company NameDokument1 SeiteCheck List For Plastering - M & E Co-Ordination: Company NameSayed WafiNoch keine Bewertungen

- Acceptance of Works Inspection ChecklistDokument6 SeitenAcceptance of Works Inspection ChecklistJulius Mak'Oderoh100% (1)

- Check List For Fire Protection InstallationDokument2 SeitenCheck List For Fire Protection InstallationAnas El BalghiNoch keine Bewertungen

- Checklist Bypass Line SizingDokument5 SeitenChecklist Bypass Line Sizingsrinivas_gowthamNoch keine Bewertungen

- QC Tower ErectionDokument4 SeitenQC Tower ErectionAnonymous ExWAN2xjFJNoch keine Bewertungen

- Piling FormatsDokument21 SeitenPiling FormatsSangamesh Kotarki50% (2)

- Readycheck For Bridge PlanDokument8 SeitenReadycheck For Bridge PlanMichael DixonNoch keine Bewertungen

- Preliminary Drawing ChecklistDokument14 SeitenPreliminary Drawing ChecklistDodi IsnandarNoch keine Bewertungen

- Check List For Piping Unit Plot PlanDokument5 SeitenCheck List For Piping Unit Plot PlanVijay GaikwadNoch keine Bewertungen

- Checklists ExternalWorksInfrastructure PipelayingandRoad 03032020Dokument73 SeitenChecklists ExternalWorksInfrastructure PipelayingandRoad 03032020LUKMANNoch keine Bewertungen

- QC - DBFO - 005 CIP Portl Cement Concrete Deck SuperstructureDokument1 SeiteQC - DBFO - 005 CIP Portl Cement Concrete Deck SuperstructureMuhammad Shakil JanNoch keine Bewertungen

- Preheater Installation Check List: PlantDokument11 SeitenPreheater Installation Check List: PlantJCSNoch keine Bewertungen

- Managing Measurement Risk in Building and Civil EngineeringVon EverandManaging Measurement Risk in Building and Civil EngineeringNoch keine Bewertungen

- Sikafloor®-264: Product Data SheetDokument5 SeitenSikafloor®-264: Product Data SheetEaswar KumarNoch keine Bewertungen

- Sikafloor 261hs PDFDokument7 SeitenSikafloor 261hs PDFEaswar KumarNoch keine Bewertungen

- Sikafloor - M: 2-Part Epoxy Line Marking Coating For Cardeck FlooringDokument4 SeitenSikafloor - M: 2-Part Epoxy Line Marking Coating For Cardeck FlooringEaswar KumarNoch keine Bewertungen

- Hand Sanitizer Market Share, Growth Factors and Forecast Analysis To 2026Dokument3 SeitenHand Sanitizer Market Share, Growth Factors and Forecast Analysis To 2026Easwar KumarNoch keine Bewertungen

- Sikafloor - 89: 2-Part Water Based Epoxy CoatingDokument4 SeitenSikafloor - 89: 2-Part Water Based Epoxy CoatingEaswar KumarNoch keine Bewertungen

- Msds XyleneDokument6 SeitenMsds XyleneEaswar KumarNoch keine Bewertungen

- Safety Data Sheet (SDS) Xylene 1. Identification: GHS Classification Hazard Class Hazard CategoryDokument8 SeitenSafety Data Sheet (SDS) Xylene 1. Identification: GHS Classification Hazard Class Hazard CategoryEaswar KumarNoch keine Bewertungen

- 1 Introduction To Statistics - HandoutsDokument43 Seiten1 Introduction To Statistics - HandoutsEaswar KumarNoch keine Bewertungen

- Moore's Procedure & Johnson's Procedure: Session 12Dokument16 SeitenMoore's Procedure & Johnson's Procedure: Session 12Easwar KumarNoch keine Bewertungen

- Built-Up Area Calculation NormsDokument3 SeitenBuilt-Up Area Calculation NormsEaswar KumarNoch keine Bewertungen

- Unit 1 Structural Analysis IIDokument51 SeitenUnit 1 Structural Analysis IIEaswar KumarNoch keine Bewertungen

- Jackie Chan International Fan Club Tour 2014 Celebrating JC's 60 Birthday in Beijing and Shanghai Application FormDokument1 SeiteJackie Chan International Fan Club Tour 2014 Celebrating JC's 60 Birthday in Beijing and Shanghai Application FormEaswar KumarNoch keine Bewertungen

- CE2254 Surveying 2 QBDokument22 SeitenCE2254 Surveying 2 QBEaswar KumarNoch keine Bewertungen

- Question BankDokument12 SeitenQuestion BankEaswar KumarNoch keine Bewertungen

- A Great Green DayDokument1 SeiteA Great Green DayEaswar KumarNoch keine Bewertungen

- Calinawan Re - Ed.NOT DONEDokument5 SeitenCalinawan Re - Ed.NOT DONERichard Jr CalinawanNoch keine Bewertungen

- Tell Me Another StoryThe Book of Story Programs by Bailey, Carolyn Sherwin, 1875-1961Dokument140 SeitenTell Me Another StoryThe Book of Story Programs by Bailey, Carolyn Sherwin, 1875-1961Gutenberg.orgNoch keine Bewertungen

- Holowchak - Stoics - A Guide For The PerplexedDokument249 SeitenHolowchak - Stoics - A Guide For The Perplexedthiago_a1979Noch keine Bewertungen

- Sherlock Holmes and The DukeDokument3 SeitenSherlock Holmes and The DukeWill KeyNoch keine Bewertungen

- Grd. 8 Mapeh 4TH Quarter ExamDokument1 SeiteGrd. 8 Mapeh 4TH Quarter ExamEl TisoyNoch keine Bewertungen

- Medieval Concept of GodDokument13 SeitenMedieval Concept of GodEJ JoseNoch keine Bewertungen

- Goan Social StudyDokument37 SeitenGoan Social StudyKushal RaoNoch keine Bewertungen

- Curtain Wall Installation Instructions - Rev 05-04-11Dokument36 SeitenCurtain Wall Installation Instructions - Rev 05-04-11rmdarisaNoch keine Bewertungen

- Future Player's Companion - Tomorrows' Foundation PDFDokument44 SeitenFuture Player's Companion - Tomorrows' Foundation PDFKevin Lee Elam100% (3)

- Team TextDokument6 SeitenTeam TextkensicoNoch keine Bewertungen

- 50 TAHUN LAGI - PartsDokument6 Seiten50 TAHUN LAGI - PartsPak Gibio SiraitNoch keine Bewertungen

- Lissa PaulDokument28 SeitenLissa PaulApril Lei IrincoNoch keine Bewertungen

- Amazing Bella by Crochet GarageDokument20 SeitenAmazing Bella by Crochet GarageKADIKIZI100% (5)

- S. Rangarajan Etc Vs P. Jagjivan Ram On 30 March, 1989Dokument21 SeitenS. Rangarajan Etc Vs P. Jagjivan Ram On 30 March, 1989aarohanNoch keine Bewertungen

- Harris Broadcasting Accessories 1982Dokument200 SeitenHarris Broadcasting Accessories 1982João Pedro AlmeidaNoch keine Bewertungen

- Philippine Possession and PoltergeistDokument12 SeitenPhilippine Possession and PoltergeistYan Quiachon BeanNoch keine Bewertungen

- 21 Prayer Points For PromotionDokument1 Seite21 Prayer Points For PromotionVincent Kalule92% (13)

- Apocalypse World - NPC PromptsDokument4 SeitenApocalypse World - NPC Promptsnomad79Noch keine Bewertungen

- Difficult One PieceDokument7 SeitenDifficult One PieceXarhs KalimanisNoch keine Bewertungen

- Yatin S PanditDokument1 SeiteYatin S PanditShivani MaratheNoch keine Bewertungen

- DSR PuneDokument7 SeitenDSR PunedigvijayjagatapNoch keine Bewertungen

- BC SplitTopRouboNotes Nov12Dokument28 SeitenBC SplitTopRouboNotes Nov12Noemi GonzálezNoch keine Bewertungen

- Final Written Exam Course: Intermediate One (I01) Book: World Link 3 / 3 Edition (Units 1Dokument3 SeitenFinal Written Exam Course: Intermediate One (I01) Book: World Link 3 / 3 Edition (Units 1b100% (1)

- Cartas de TolkienDokument493 SeitenCartas de TolkienPc Funciona CollipulliNoch keine Bewertungen

- Aisi Type p20 Mold Steel (Uns t51620)Dokument2 SeitenAisi Type p20 Mold Steel (Uns t51620)doan anh TuanNoch keine Bewertungen

- Imperial Tiger Kung FuDokument3 SeitenImperial Tiger Kung FuEule100Noch keine Bewertungen

- Tugas Bahasa Inggris: Adjective ClauseDokument7 SeitenTugas Bahasa Inggris: Adjective Clauseanon_323638500Noch keine Bewertungen

- LKPD 3.1Dokument3 SeitenLKPD 3.1Rahim100% (1)

- Alphabet Song Classic LyricDokument1 SeiteAlphabet Song Classic LyricMaíta Medeiros e SilvaNoch keine Bewertungen

- 07 Story of Samson and Delilah - Judges 13Dokument9 Seiten07 Story of Samson and Delilah - Judges 13vivianstevenNoch keine Bewertungen