Beruflich Dokumente

Kultur Dokumente

R820 Technical Documentation

Hochgeladen von

Zainul Abedin SayedCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

R820 Technical Documentation

Hochgeladen von

Zainul Abedin SayedCopyright:

Verfügbare Formate

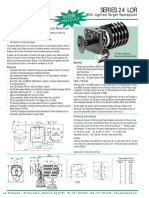

R820 REV2 SERIES

SCR POWER CONTROLS

Product overview

The Viconics R820 series SCR power controls are designed for cost effective, precise

modulation of electric loads for most electric heating applications.

(Applicable on resistive loads only)

The R820 series consists of SCRs power controls, c/w factory assembled heatsink for

surface or in-panel mounting.

Models available

Model No.

Voltage Range

Phase

Max Current

R820-211-REV2

R820-213-REV2

R820-321-REV2

R820-323-REV2

R820-341-REV2

R820-343-REV2

R820-421-REV2

R820-423-REV2

R820-441-REV2

R820-443-REV2

R820-471-REV2

R820-621-REV2

R820-623-REV2

R820-641-REV2

R820-643-REV2

R820-671-REV2

24 - 240 Volts AC

24 - 240 Volts AC

24 - 347 Volts AC

24 - 347 Volts AC

24 - 347 Volts AC

24 - 347 Volts AC

24 - 480 Volts AC

24 - 480 Volts AC

24 - 480 Volts AC

24 - 480 Volts AC

24 - 480 Volts AC

24 - 600 Volts AC

24 - 600 Volts AC

24 - 600 Volts AC

24 - 600 Volts AC

24 - 600 Volts AC

1

3

1

3

1

3

1

3

1

3

1

1

3

1

3

1

10 Amp

10 Amp

25 Amp

25 Amp

45 Amp

45 Amp

25 Amp

25 Amp

45 Amp

45 Amp

75 Amp

25 Amp

25 Amp

45 Amp

45 Amp

75 Amp

Features

Feature

Complete assembly with factory installed heat sink.

Designed for surface or panel mounting

UL Recognized

CSA approved for Canada and USA

Status LED

High quality assembly with 2 year warranty

Full line of matching peripheral temperature

controllers

Benefit

Reduced total installation cost

Covers wider array of application with same

component.

Easily integrated into complete assembly requiring

industry listings.

Trouble free approval process

Quick field troubleshooting.

Reduced field service calls.

Simplified component sourcing and matching for

reliable operation

They are compatible with many industry standard signals. A typical application would be to control a modulating

electric duct heater with a 0 to 10 Vdc control signal from an analog room thermostat. The R820 power controller also

contain four dip switch to adjust to the following control signals:

0 to 10 Vdc control signal ( 2 to 10 Vdc control range )

4 to 20 mA control signal

0 to 135 control signal

LIT-R820_REV2-E03

Power modules installation

Important.

All external safety devices like: contactors, relays, flow switch & thermal protections are to be supplied and

installed by other.

When the SCR is installed inside a panel, the enclosure needs to be adequately louvered for proper ventilation

and heat dissipation. Call the factory for the derating amperage curves for these specific applications.

Electronic controls require special care for wiring and startup. To avoid problems, carefully follow the

procedures below.

Look at the wiring diagrams, and study them carefully. Be sure that you understand how the system is supposed to

work.

A) Location:

1- Can be installed inside a louvered approved cabinet or with the heatsink mounted externally.

2- Must be installed away from excessive heat source.

3- Nothing must restrain air circulation to the heatsink.

B) Installation:

1- If installed completely inside a cabinet, use the mounting tabs on the heatsink to secure the SCR to the back

plate of the panel.

2- If installed with heatsink outside the cabinet, use the proper model mounting template for the cut out

dimensions and to check for mounting obstructions.

3- Respect mounting orientation

( this side up ).

4- Mount the heatsink vertically on the side of the cabinet for proper heat dissipation.

5- Do not relocate the power switching modules on the heatsink.

R820 Installation and Dimensions

Mounting instructions & templates are available from the factory.

The cutout templates include holes position for heatsink attachment to the electrical cabinet

Single phase R820 will have 2 mounting screw, 1 on each side.

Three phase R820 will have 4 mounting screw, 2 on each side.

Respect mounting orientation ( this side up ).

Mount the heatsink vertically on the side of the cabinet for proper heat dissipation.

If mounted on top or bottom of the cabinet, derate maximum usable amperage by 25%.

Do not relocate the power switching modules on the heatsink.

R820 single phase

R820-211-REV2

R820-321-REV2

R820-341-REV2

R820-421-REV2

R820-441-REV2

R820-471-REV2

R820-621-REV2

R820-641-REV2

R820-671-REV2

R820 three phase

R820-213-REV2

R820-323-REV2

R820-343-REV2

R820-423-REV2

R820-443-REV2

R820-623-REV2

R820-643-REV2

A

5.25 "

5.25 "

5.25 "

5.25 "

5.25 "

5.25 "

5.25 "

5.25 "

5.25 "

A

5.25 "

5.25 "

5.25 "

5.25 "

5.25 "

5.25 "

5.25 "

B

4.50 "

4.50 "

6.50 "

4.50 "

6.50 "

10.00 "

4.50 "

6.50 "

10.00 "

C

2.56

2.56

2.56

2.56

2.56

2.56

2.56

2.56

2.56

D

3.00 "

3.00 "

3.00 "

3.00 "

3.00 "

3.00 "

3.00 "

3.00 "

3.00 "

E

3.75 "

3.75 "

3.75 "

3.75 "

3.75 "

3.75 "

3.75 "

3.75 "

3.75 "

Weight

1.80

1.80

2.40

1.80

2.40

3.50

1.80

2.40

3.50

B

6.50 "

6.50 "

10.00 "

6.50 "

10.00 "

6.50 "

10.00 "

C

2.56

2.56

2.56

2.56

2.56

2.56

2.56

D

3.00 "

3.00 "

3.00 "

3.00 "

3.00 "

3.00 "

3.00 "

E

5.75 "

5.75 "

5.75 "

5.75 "

5.75 "

5.75 "

5.75 "

Weight

2.60

3.70

3.70

2.65

3.70

2.65

3.70

LIT-R820_REV2-E03

DIP Switch Adjustments per applications

INPUT SIGNAL

0 to 10 Vdc control signal ( 2 to 10 Vdc control range )

4 to 20 mA control signal

0 to 135 control signal

SWITCH #1

Off

Off

On

SWITCH #2

Off

Off

On

SWITCH #3

Off

On

Off

SWITCH #4

On

Off

Off

Typical applications

0 To 10 Vdc Room Or Duct Thermostat Control

Dip switch position

0 to 10 Vdc control signal

S1

Off

S2

Off

S3

Off

S4

On

2 V dc = 0% capacity

10 V dc = 100% capacity

L1

1

2

Modulating R oom T hermos tat

0 to 10 V dc

C ommon

24 Vac

0 to10 Vdc

output

L2

Modulating S upply A ir C ontrol T hermos tat

0 to 10 V dc

2nd S S R

on 3 phas e

models only

L3

0 To 10 Vdc From a Building Automation System

Dip switch position

0 to 10 Vdc control signal

S1

Off

S2

Off

S3

Off

S4

On

2 V dc = 0% capacity

10 V dc = 100% capacity

L1

1

2

Modulating S ignal F rom B A S S ys tem

0 to 10 V dc

L2

L3

LIT-R820_REV2-E03

2nd S S R

on 3 phas e

models only

0 To 135 Room Or Duct Thermostat Control

Dip switch position

0 to 135 control signal

S1

On

S2

On

S3

Off

S4

Off

0 O hms = 0% capacity

135 Ohms = 100% capacity

L1

1

2

Modulating R oom T hermos tat

50

60

70

80

0 to 135 Ohms

90

R

B

L2

50

60

70

80

90

Modulating S upply A ir C ontrol T hermos tat

0 to 135 Ohms

2nd S S R

on 3 phas e

models only

L3

4 To 20 mA From a Building Automation System

Dip switch position

4 to 20 mA control signal

S1

Off

S2

Off

S3

On

S4

Off

4 mA = 0% capacity

20 mA = 100% capacity

L1

1

2

+

Modulating S ignal F rom B A S S ys tem

4 to 20 mA

L2

L3

LIT-R820_REV2-E03

2nd S S R

on 3 pha se

models only

24 Vac Power& Wiring

It is not necessary to ground any leg of the transformer to earth with the controller card.

The controller uses internally a half wave rectifier bridge. On 0 to 10 Vdc control signal, the reference of the control

signal is the Common of the power supply of the SCR controller card.

Use a Class 1 ( properly fused ) or Class 2, CSA or UL recognized transformer.

High voltage Wiring

General cautions:

High voltages are present on the terminals of these devices. Please read all the instruction in this manual carefully.

The 45 & 75 Amps models need to be wired with the supplied high voltage lugs. Attach the wire to the lug first,

and then screw the lug to the power module.

Have the wiring done by a qualified and skilled professional.

High voltage and amperage can be fatal.

All wiring must conform to national electrical code regulations.

The instrument must be wired before applying power.

Protect circuits with semi conductor fuses.

For in panel installation, derating amperage curves are available from the factory.

Specifications

Operating Conditions:

Thermostatic protection:

Power supply:

0C to 80C ( 32F to 176F ) / 0 % to 95 % R.H. non-condensing

See power derating curves document

Self-resetting. Auto shut off when SCR ambient temp. is above 82C ( 180F )

24 Vac -15%, +10% 50/60 Hz; 2 VA

Use a Class 1 ( properly fused ) or Class 2, CSA or UL recognized transformer.

Troubleshooting

1

2

3

4

5

6

7

8

Check

Check general wiring, as per heater manufacturer diagram

Be sure you understand the system and its normal operation

Verify high voltage power supply wiring

Verify that correct voltage is present at the heater with proper wire size

Verify low voltage 24 Vac power supply wiring

24 Vac is present at terminals 1 & 2 of the R820 SCR

Create or simulate 100 % heating demand Using present control system

R820 Configured for 0 to 10 Vdc input signal

Signal between terminals 1 & 3 is 10 Vdc or superior

Dip switch properly configured: S1=Off, S2=Off, S3=Off & S4=On

Be sure that the polarity is correct and not reversed + to +, - to Red status LED on SCR is on 100 % of the time

R820 Configured for 4 to 20 mA input signal

Signal between terminals 1 & 3 is 20 mA or superior

Dip switch properly configured: S1=Off, S2=Off, S3=On & S4=Off

Be sure that the polarity is correct and not reversed + to +, - to Red status LED on SCR is on 100 % of the time

R820 Configured for 0 to 135 input signal

Signal between terminals 1 & 3 is 135 or superior

Dip switch properly configured: S1=On, S2=On, S3=Off & S4=Off

Red status LED on SCR is on 100 % of the time

Verify amperage consumption of the heater

Red status LED on SCR is on 100 % of the time

Verify & correct 24 Vac power supply to the SCR

Verify low voltage fuses, protections, flow switch, etc

Verify control wiring & control signal

Correct control signal is present at the SCR

Check polarity of control signal

Verify fuses & all protections & contact the heater manufacturer

Viconics Electronics Inc. 9245, Langelier Blvd, St-Leonard, Quebec, Canada H1P 3K9

028-5011

LIT-R820_REV2-E03

Important Notice:

These instruments have

undergone rigorous tests

and verifications prior to

shipment

to

ensure

proper

and

reliable

operation in the field.

However, like other such

products,

they

are

subject to failure. It is

therefore

the

responsibility

of

the

installer / user / electrical

panel

designer

to

incorporate

safety

features and devices

( such as relays, flow

switch,

thermal

protections, etc.. ) to

protect the entire system

from catastrophic failure.

www.viconics.com

sales@viconics.com

5

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Raw 3Dokument31 SeitenRaw 3Apik SubagyaNoch keine Bewertungen

- BELIMO LM24 ActuadorDokument2 SeitenBELIMO LM24 ActuadordcarunchioNoch keine Bewertungen

- 1SCC301020C0201 PDFDokument116 Seiten1SCC301020C0201 PDFlagm54Noch keine Bewertungen

- Altistart 22 ATS22C14QDokument9 SeitenAltistart 22 ATS22C14QJavier SaireNoch keine Bewertungen

- Crompton Protector 250Dokument33 SeitenCrompton Protector 250jishyNoch keine Bewertungen

- BECKETT GeniSys7505 ManualDokument12 SeitenBECKETT GeniSys7505 ManualTommy Castellano100% (1)

- DWYER - RHP-3D-11.instruções PDFDokument4 SeitenDWYER - RHP-3D-11.instruções PDFMarcio Issao WatanabeNoch keine Bewertungen

- Lecture by P.Ranga Rao Chief Manager / KolarDokument69 SeitenLecture by P.Ranga Rao Chief Manager / KolarabhilashNoch keine Bewertungen

- Guide SSHV2Dokument4 SeitenGuide SSHV2vinhson65-1Noch keine Bewertungen

- Manual Icm 450Dokument8 SeitenManual Icm 450CoolSolutions ElSalvadorNoch keine Bewertungen

- Datasheet Flatpack2 48-60-2000 HEDokument4 SeitenDatasheet Flatpack2 48-60-2000 HEnahuan_mataNoch keine Bewertungen

- Delcon RelayDokument11 SeitenDelcon RelayamanurrahmanNoch keine Bewertungen

- PT-76 Series Temperature Controller Operation Manual - B0Dokument2 SeitenPT-76 Series Temperature Controller Operation Manual - B0jowegNoch keine Bewertungen

- 2.33. - Electroswitch 7803gDokument6 Seiten2.33. - Electroswitch 7803gHubert Maraza JaliriNoch keine Bewertungen

- Rele Control NivelDokument76 SeitenRele Control NivelIngenieria Electrónica UnapNoch keine Bewertungen

- Electronic RelaysDokument21 SeitenElectronic Relayslopablito24Noch keine Bewertungen

- PC8AHXS Buyers GuideDokument6 SeitenPC8AHXS Buyers GuidekkrishnamoorthyNoch keine Bewertungen

- ATS22C59QDokument9 SeitenATS22C59QthavaselvanNoch keine Bewertungen

- Features: SCR Power ControllerDokument2 SeitenFeatures: SCR Power Controllerpradeepchennai10_959Noch keine Bewertungen

- LM3404Dokument28 SeitenLM3404Radu CaramaliuNoch keine Bewertungen

- Contactors Regul - Modif.Dokument2 SeitenContactors Regul - Modif.Momir Cokorilo100% (1)

- System Sensor PR-1 Data SheetDokument2 SeitenSystem Sensor PR-1 Data SheetJMAC SupplyNoch keine Bewertungen

- ATS22D88QDokument10 SeitenATS22D88QSurendra PatamsettyNoch keine Bewertungen

- Mcdonnell & Miller: WarningDokument8 SeitenMcdonnell & Miller: WarningALEXANDER VARELANoch keine Bewertungen

- Manual Version 3.4Dokument8 SeitenManual Version 3.4pjvansandwykNoch keine Bewertungen

- AD780Dokument10 SeitenAD780game___overNoch keine Bewertungen

- ATS22C11Q: Product Data SheetDokument9 SeitenATS22C11Q: Product Data SheetMuneeb ImtiazNoch keine Bewertungen

- Furnace Replace Carrier 302075 304 Board Ig LIAF044 1Dokument2 SeitenFurnace Replace Carrier 302075 304 Board Ig LIAF044 1topogigio240Noch keine Bewertungen

- Max 16841 Ev KitDokument16 SeitenMax 16841 Ev KitjorojoroNoch keine Bewertungen

- Data SheetDokument6 SeitenData SheetArthur CarvalhoNoch keine Bewertungen

- Schneider RelaysDokument12 SeitenSchneider Relaysrajpre1213Noch keine Bewertungen

- Diagrama de Asfaltadora ADP100Dokument23 SeitenDiagrama de Asfaltadora ADP100Gabino Ubilio MurilloNoch keine Bewertungen

- Under & Over Current RelayDokument2 SeitenUnder & Over Current RelayRenghat RumahorboNoch keine Bewertungen

- Catalogo RWGDokument8 SeitenCatalogo RWGFolpoNoch keine Bewertungen

- MODEL PC-414R Transformer Temperature Indicator: 1. ApplicationDokument4 SeitenMODEL PC-414R Transformer Temperature Indicator: 1. ApplicationMKNoch keine Bewertungen

- Telemecanique PDFDokument60 SeitenTelemecanique PDFMario PerezNoch keine Bewertungen

- TC9102 ManualDokument16 SeitenTC9102 Manualأياام زمانNoch keine Bewertungen

- 45zelio RM17 35Dokument96 Seiten45zelio RM17 35Dauceanu Ciprian100% (1)

- Rca ctc179cm Chassis (ET)Dokument32 SeitenRca ctc179cm Chassis (ET)titoritomex100% (1)

- 2 Guide SSHV2Dokument3 Seiten2 Guide SSHV2Calsonic CMGNoch keine Bewertungen

- 156 pp002 - en PDokument2 Seiten156 pp002 - en PMarino VillalbaNoch keine Bewertungen

- PID Temp. ControllerDokument8 SeitenPID Temp. ControllerHowardgfNoch keine Bewertungen

- Type VHXM: Under / Over Voltage RelayDokument6 SeitenType VHXM: Under / Over Voltage RelayAmit KumarNoch keine Bewertungen

- 95C 10939efsDokument40 Seiten95C 10939efsBobNoch keine Bewertungen

- AEGPS Protect RCS EN PDFDokument4 SeitenAEGPS Protect RCS EN PDFIrfan AshrafNoch keine Bewertungen

- Panel Accessories Catalogue R1Dokument184 SeitenPanel Accessories Catalogue R1supermannon0% (1)

- Airpax PDFDokument46 SeitenAirpax PDFvjNoch keine Bewertungen

- AV1000 + Assembly + ManualDokument22 SeitenAV1000 + Assembly + ManualAnonymous V1NW1Cm3w4100% (3)

- Selection Guide: Altistart 22 Open-Style Soft StartDokument4 SeitenSelection Guide: Altistart 22 Open-Style Soft StartJenny TamayoNoch keine Bewertungen

- Electronic Pressure Switch & Transmitter: General SpecificationDokument4 SeitenElectronic Pressure Switch & Transmitter: General Specificationhuu thanh nguyenNoch keine Bewertungen

- 06 Pomocni Sklopnici I RelejiDokument55 Seiten06 Pomocni Sklopnici I Relejiaksiom007Noch keine Bewertungen

- Temperature Controller Using 89c51project of E.CDokument15 SeitenTemperature Controller Using 89c51project of E.Csri kanthNoch keine Bewertungen

- Series 142 RetrofitDokument54 SeitenSeries 142 RetrofitVasanth KumarNoch keine Bewertungen

- Notes: Cam Operated Rotary Switches Cam Operated Rotary SwitchesDokument16 SeitenNotes: Cam Operated Rotary Switches Cam Operated Rotary Switchesatanumaster1987Noch keine Bewertungen

- Delta DVP-ES2 I MUL 20121031Dokument20 SeitenDelta DVP-ES2 I MUL 20121031Rafael BispoNoch keine Bewertungen

- AD694Dokument12 SeitenAD694Asghar AliNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- York Start-Up Check List - Air Handling UnitsDokument2 SeitenYork Start-Up Check List - Air Handling UnitsBen MusimaneNoch keine Bewertungen

- Training Courses 2021 - 5Dokument1 SeiteTraining Courses 2021 - 5Zainul Abedin SayedNoch keine Bewertungen

- Air Handling Units: Pre Start-UpDokument2 SeitenAir Handling Units: Pre Start-Upshant_mNoch keine Bewertungen

- Model YK Centrifugal Liquid Chillers Design Level F: FORM 160.73-EG1Dokument78 SeitenModel YK Centrifugal Liquid Chillers Design Level F: FORM 160.73-EG1Zainul Abedin SayedNoch keine Bewertungen

- Operation Check List / Start-Up Report: Axijet High Plume Exhaust SystemDokument2 SeitenOperation Check List / Start-Up Report: Axijet High Plume Exhaust SystemZainul Abedin SayedNoch keine Bewertungen

- Method Statement & Risk Assessment: Project Name: Location of The Works: Title of Method Statement: Scope of WorksDokument17 SeitenMethod Statement & Risk Assessment: Project Name: Location of The Works: Title of Method Statement: Scope of WorksSiti Noor Rahimah IbarahimNoch keine Bewertungen

- NEBB Discipline - Testing, Adjusting and Balancing (TAB) - NEBBDokument1 SeiteNEBB Discipline - Testing, Adjusting and Balancing (TAB) - NEBBZainul Abedin SayedNoch keine Bewertungen

- 3 Section2Dokument14 Seiten3 Section2Zainul Abedin SayedNoch keine Bewertungen

- 5 IndexDokument3 Seiten5 IndexZainul Abedin SayedNoch keine Bewertungen

- Part 1 - Standards: Foreword NEBB Testing and Balancing Committee ofDokument6 SeitenPart 1 - Standards: Foreword NEBB Testing and Balancing Committee ofZainul Abedin SayedNoch keine Bewertungen

- Part 1 - Standards: Section 1 DefinitionsDokument4 SeitenPart 1 - Standards: Section 1 DefinitionsZainul Abedin SayedNoch keine Bewertungen

- Welding Process PDFDokument1 SeiteWelding Process PDFZainul Abedin SayedNoch keine Bewertungen

- 4 AppendicesDokument12 Seiten4 AppendicesZainul Abedin SayedNoch keine Bewertungen

- Testing, Adjusting and Balancing Certification Requirements - NEBBDokument1 SeiteTesting, Adjusting and Balancing Certification Requirements - NEBBZainul Abedin SayedNoch keine Bewertungen

- Duct Liner StandardDokument31 SeitenDuct Liner StandardEshref AlemdarNoch keine Bewertungen

- NEBB's Certification Program - NEBBDokument1 SeiteNEBB's Certification Program - NEBBZainul Abedin SayedNoch keine Bewertungen

- Individual Certification - NEBBDokument1 SeiteIndividual Certification - NEBBZainul Abedin SayedNoch keine Bewertungen

- Ansi Ahri Standard 220 2014Dokument19 SeitenAnsi Ahri Standard 220 2014prattie4uNoch keine Bewertungen

- ANSI - AHRI Standard 880 (I-P) - 2011Dokument17 SeitenANSI - AHRI Standard 880 (I-P) - 2011Zainul Abedin SayedNoch keine Bewertungen

- Duct Leakage Tester PDFDokument8 SeitenDuct Leakage Tester PDFZainul Abedin SayedNoch keine Bewertungen

- Safety Data Sheet: Chemical Name Cas # Percent Classification NoteDokument6 SeitenSafety Data Sheet: Chemical Name Cas # Percent Classification NoteZainul Abedin SayedNoch keine Bewertungen

- Case Studies HVACRDokument7 SeitenCase Studies HVACRZainul Abedin SayedNoch keine Bewertungen

- Mechartes - Brochure - 2019 - Building & ConstructionDokument19 SeitenMechartes - Brochure - 2019 - Building & ConstructionZainul Abedin SayedNoch keine Bewertungen

- Ahri General Operations ManualDokument69 SeitenAhri General Operations ManualZainul Abedin SayedNoch keine Bewertungen

- Noise Control With Concrete MasonryDokument24 SeitenNoise Control With Concrete MasonryZainul Abedin SayedNoch keine Bewertungen

- Xuv 500Dokument6 SeitenXuv 500Zainul Abedin SayedNoch keine Bewertungen

- Silencer Placement - ASHRAE ReferenceDokument1 SeiteSilencer Placement - ASHRAE ReferenceZainul Abedin SayedNoch keine Bewertungen

- Suzuki - Annual ReportDokument68 SeitenSuzuki - Annual ReportZainul Abedin SayedNoch keine Bewertungen

- Belimo Actuator - FSAF24Dokument4 SeitenBelimo Actuator - FSAF24Zainul Abedin SayedNoch keine Bewertungen

- Medium Voltage, 27KV and 38KV, Metal-Clad Switchgear Spec SDokument14 SeitenMedium Voltage, 27KV and 38KV, Metal-Clad Switchgear Spec SJuvencio MolinaNoch keine Bewertungen

- Low Impedance Bus Differential System: Grid SolutionsDokument522 SeitenLow Impedance Bus Differential System: Grid SolutionsLuiz Augusto Reis e FreitasNoch keine Bewertungen

- Ligo System Installation Guide V3 Newestpage 1 of 14Dokument14 SeitenLigo System Installation Guide V3 Newestpage 1 of 14ZzzdddNoch keine Bewertungen

- Megawin M135CDokument16 SeitenMegawin M135Cvlaxis cncNoch keine Bewertungen

- Signal Output Module (51250-18)Dokument52 SeitenSignal Output Module (51250-18)Fadjar rinantoNoch keine Bewertungen

- Aljotronic Control 2 PDFDokument30 SeitenAljotronic Control 2 PDFjhfbtyNoch keine Bewertungen

- Bottom Mount Refrigerators ServiceDokument77 SeitenBottom Mount Refrigerators ServiceaderlochNoch keine Bewertungen

- Electrical DataDokument43 SeitenElectrical DataSidra QasimNoch keine Bewertungen

- Manual Tecnico de Instalaciones ElectricasDokument15 SeitenManual Tecnico de Instalaciones ElectricasJose MimbelaNoch keine Bewertungen

- Wizard 900/900E Digital Readout Operations ManualDokument198 SeitenWizard 900/900E Digital Readout Operations ManualnorbertNoch keine Bewertungen

- Electrical Engineering Multiple Choice Questions: SF6 Free SwitchgearDokument32 SeitenElectrical Engineering Multiple Choice Questions: SF6 Free SwitchgearVikash SinghNoch keine Bewertungen

- Manual Service LG MicroondasDokument37 SeitenManual Service LG MicroondascarlosNoch keine Bewertungen

- Copeland Screw Compressors Semi-Hermetic Compact Operating InstructionsDokument12 SeitenCopeland Screw Compressors Semi-Hermetic Compact Operating Instructionsugas666999Noch keine Bewertungen

- 3900 Chair ManualDokument44 Seiten3900 Chair ManualAyham DarwichNoch keine Bewertungen

- 160.54-m1 - Optiview Control Center - Service InstructionsDokument240 Seiten160.54-m1 - Optiview Control Center - Service InstructionsPaulo Alves de Santana77% (22)

- User Manual: DCSF-C Series Servo MotorDokument46 SeitenUser Manual: DCSF-C Series Servo MotorTuan Ngoc100% (1)

- Smart Liquid Level Controller Using Arduino With SMS AlertDokument4 SeitenSmart Liquid Level Controller Using Arduino With SMS AlertInternational Journal of Innovations in Engineering and Science0% (1)

- Chapter 3 - Protection SystemDokument97 SeitenChapter 3 - Protection SystemSyafiq MuhamadNoch keine Bewertungen

- Fuse Box Diagram Mercedes-Benz C-Class (W203 2000-2007) MiniDokument6 SeitenFuse Box Diagram Mercedes-Benz C-Class (W203 2000-2007) Minimitoloj410Noch keine Bewertungen

- Cover PDFDokument3 SeitenCover PDFТатьяна ГарецNoch keine Bewertungen

- Paradox DG-85Dokument2 SeitenParadox DG-85Gabriel BanuNoch keine Bewertungen

- Sperre Instrument Air CompressorDokument51 SeitenSperre Instrument Air CompressorTalha Mairaj0% (1)

- HIMEL Low VoltageDokument40 SeitenHIMEL Low VoltageheruNoch keine Bewertungen

- r201 000 3Dokument1 Seiter201 000 3Anand KumarNoch keine Bewertungen

- 2 Simple Application ControllerDokument826 Seiten2 Simple Application ControllerJanNoch keine Bewertungen

- MK 9054 Ac 0,5-5V Uh Ac 230V 1SDokument6 SeitenMK 9054 Ac 0,5-5V Uh Ac 230V 1SHamza ChenakerNoch keine Bewertungen

- Types of Electrical Protection Relays or Protective Relays - Electrical Engineering PDFDokument6 SeitenTypes of Electrical Protection Relays or Protective Relays - Electrical Engineering PDFRohan RustagiNoch keine Bewertungen

- 18 Sensor Proximity SwitchDokument88 Seiten18 Sensor Proximity SwitchPrince Rao MuaazNoch keine Bewertungen

- CAT-4001 B200 Series Mounting BasesDokument2 SeitenCAT-4001 B200 Series Mounting BasesJuan Perez SubicuetaNoch keine Bewertungen

- 4.5" Dial Temperature Swichgage SPL and 45TE SeriesDokument4 Seiten4.5" Dial Temperature Swichgage SPL and 45TE SeriesAlejandroMuñozNoch keine Bewertungen