Beruflich Dokumente

Kultur Dokumente

1 s2.0 S0003267012007295 Main

Hochgeladen von

bgl87Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 s2.0 S0003267012007295 Main

Hochgeladen von

bgl87Copyright:

Verfügbare Formate

Analytica Chimica Acta 734 (2012) 3144

Contents lists available at SciVerse ScienceDirect

Analytica Chimica Acta

journal homepage: www.elsevier.com/locate/aca

Review

Recent developments and applications of screen-printed electrodes in

environmental assaysA review

Meng Li, Yuan-Ting Li, Da-Wei Li, Yi-Tao Long

State Key Laboratory of Bioreactor Engineering & Department of Chemistry, East China University of Science and Technology, 130 Meilong Road, Shanghai, 200237, PR China

h i g h l i g h t s

g r a p h i c a l

! Screen-printed electrodes (SPEs) are

economical substrates that attract

interests.

! SPEs have been utilised for the rapid

in situ analysis of environmental pollutants.

! The configuration designs and printing materials of SPEs are developed a

lot.

! Some pretreatment techniques of

surfaces are especially addressed.

The configuration designs and printing materials of screen-printed electrodes (SPEs) are developed ov

the past decades and the applications of SPEs in environmental analysis are reviewed in this article.

a r t i c l e

a b s t r a c t

i n f o

Article history:

Received 9 March 2012

Received in revised form 4 May 2012

Accepted 12 May 2012

Available online 20 May 2012

Keywords:

Screen-printed electrodes

Electrochemistry

Environmental analysis

Recent developments

a b s t r a c t

Screen-printed electrodes (SPEs), which are used as economical electrochemical substrates, have go

through significant improvements over the past few decades with respect to both their format and th

printing materials. Because of their advantageous material properties, such as disposability, simplici

and rapid responses, SPEs have been successfully utilised for the rapid in situ analysis of environmen

pollutants. This critical review describes the basic fabrication principles, the configuration designs

SPEs and the hybrid analytical techniques based on SPEs. We mainly overview the electrochemical app

cations of SPEs in environmental analysis over the past 3 years, including the determination of orga

compounds, heavy metals and gas pollutants.

2012 Elsevier B.V. All rights reserv

Abbreviations: AChE, acetylcholinesterase; AuNPs, gold nanoparticles; ASV, anodic stripping voltammetry; BChE, butyrylcholinesterase; BOD, biochemical oxyg

demand; BiSPEs, bismuth-modified SPEs; !BSPEs, screen-printed microband electrodes; CB, carbon black; CC, catechol; CNTs, carbon nanotubes; CO, carbon monoxid

COD, chemical oxygen demand; CoPC, cobalt-phthalocyanine; CTAB, cetyltrimethylammonium bromide; CTS, Chitosan, poly-["-1-4]-2-amino-2-deoxy-d-glucopyrano

CV, cyclic voltammetry; DAB, 1,2-diaminobenzene; DPV, differential pulse voltammetry; ECL, electrochemiluminescence; FIA, flow injection analysis; Fe3 O4 /Au, Au-collo

coated Fe3 O4 ; GCE, glassy carbon electrode; GO, graphene oxide; HQ, hydroquinone; HRP, horseradish peroxidase; ISEs, ion-selective electrodes; ITO, tin-doped indium oxid

Lac, laccase; LPG, liquefied petroleum gas; LSM, strontium-doped lanthanum manganite; MnOx , manganese oxide; MWCNTs, multi-walled carbon nanotubes; NOx , nitrog

oxide; 1-OHP, 1-hydroxypyrene; Ops, organophosphate pesticides; OPH, OP hydrolase; PAHs, polyaromatic hydrocarbons; PANI, polyaniline; PANI-MB, plyaniline-methyle

blue; PANI-PDTDA, plyaniline-poly(2,2 -dithiodianiline); PAP, polyazetidineprepolymer; PASE, 1-pyrenebutanoic acid, succinimidyl ester; PPO, polyphenol oxidase enzym

SAMs, self-assembled monolayers; SERS, surface-enhanced Raman scattering; SPBE, screen-printed bismuth electrode; SPCE, screen-printed carbon electrode; SPEs, scree

printed electrodes; SPUMEs, screen-printed edge band ultramicroelectrodes; Tyr, tyrosinase; VOCs, volatile organic compounds; YSZ, yttria-stabilised zirconia.

Corresponding author. Tel.: +86 21 642 50032; fax: +86 21 642 50032.

E-mail address: ytlong@ecust.edu.cn (Y.-T. Long).

0003-2670/$ see front matter 2012 Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.aca.2012.05.018

32

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

Contents

1.

2.

3.

4.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fabrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.

Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.

Printing materials and pretreatments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.

Novel designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applications for environmental analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.

Routine water quality tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1.

pH and dissolved oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2.

Nitrite and phosphate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.

Organic compounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1.

Phenolic compounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2.

Pesticides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3.

Herbicides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4.

Polyaromatic hydrocarbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5.

Antibiotic residues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.

Heavy metals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1.

Pb(II) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2.

Cd(II) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3.

Hg(II) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4.

As(III) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.5.

Simultaneous detection of several different metals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.

Gas pollutants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1.

Carbon monoxide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2.

Nitrogen oxide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3.

Volatile organic compounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.

Bacteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.

Radioelements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Concluding remarks and future perspectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acknowledgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Meng Li received the B.S. degree in 2010 from East

China Normal University. She is currently a Ph.D. student under the supervision of Prof. Yi-Tao Long in the

Department of Chemistry at East China University of

Science and Technology, Shanghai, China. Her current

research interests focus on spectroelectrochemistry

and environmental analysis.

Yuan-Ting Li received the B.S. degree in 2009 from

Shanghai University, Shanghai, China. She is currently

working towards the Ph.D. degree in analytical chemistry under the supervision of Prof. Yi-Tao Long at

the East China University of Science and Technology,

Shanghai, China. Her current research interests focus

on biosensor and environmental monitoring technology.

1. Introduction

The advent of screen-printing technology has opened new

exciting opportunity to apply electrochemical techniques for

environmental analyses outside a centralised laboratory. Using

screen-printing technology, the mass production makes screenprinted electrodes (SPEs) with consistent chemical performance.

Besides the need for controlling the chemical nature of the measure

32

33

33

33

33

35

35

35

35

35

35

36

37

37

38

38

38

39

39

40

40

41

41

41

41

42

42

42

43

43

Da-Wei Li received the Ph.D. degree in environmental

science from Dalian University of Technology, Dalian,

China, in 2008. He is currently working as a research

associate in Prof. Yi-Tao Longs group at the East

China University of Science and Technology, Shanghai,

China. His research interests mainly focus on environmental monitoring technology and electroanalytical

chemistry.

Yi-Tao Long received Ph.D. degree (1998) in analytical chemistry under the supervision of Prof. Hongyuan

Chen from Nanjing University. He worked as a

Research Scientist in University of Saskatchewan and

University of Alberta, Canada for 5 years. From 2006

to 2007, he worked as an Associate Specialist in the

Berkeley Sensor and Actuator Center, University of

California, Berkeley. He was appointed as the Professor of ECUST, Shanghai to start his independent

research since 2008. His research interests include

nanopore single molecule detection, biointerface

analysis, biosensors, bioelectrochemistry, impedance

spectroscopy, in situ nano spectroelectrochemistry,

engineered molecular assemble, nanomaterial chemistry, and biomimetic coenzyme Qs.

media, SPEs may be the most appropriate electrochemical sensors for in situ analysis because of their linear output, low power

requirement, quick response, high sensitivity and ability to operate

at room temperature [1,2].

Many commercial sources of SPEs in different configurations

exist, and it is very convenient to fabricate homemade ones in small

batches with screen-printing machines. The formats of SPEs are

changeable with respect to the requirements for a specific analyte.

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

In addition, the surface of SPEs can be easily modified to fit multiple

purposes related to different pollutants and to achieve a variety of

improvements. Many kinds of modifiers of SPEs exist for environmental analysis, including noble metals, inorganic nanomaterials,

enzymes, and DNA sequences. SPEs combine ease of use and portability with simple, inexpensive analytical methods. Consequently,

SPEs can be successfully applied to in situ environmental analysis

and achieve improvements in detection, as has been shown over

the past several years.

This review addresses the advances in SPE fabrication and

applications in environmental monitoring from 2009 to 2011.

More published accounts of groundbreaking work with SPEs have

appeared than those covered here. This review is a small sampling

of the available literature and is not intended to cover all advancements reported over the past 3 years. This paper focuses on novel

designs, methods and materials of SPEs as well as their applications

in environmental analysis.

2. Fabrication

2.1. Principles

As a traditional and ancient technique, screen printing was

introduced worldwide over a thousand years ago and exists today in

fields such as art, textiles, and advertising. Researchers have utilised

the screen printing technique to create electrode devices on various substrates to fulfil the demand for reproducible, stable and

disposable devices that are suitable for mass production. Therefore, electrodes manufactured using the screen-printing technique

have attracted wide interest and the related SPEs fabrications have

been reviewed [3]. In addition, the extensive range of modifications to SPEs opens numerous fields of application in environmental

analysis.

The screen-printing technique uses a woven mesh to support

an ink-blocking stencil, and a roller or squeegee is moved across

the screen stencil to force or pump ink or other printable materials

past the threads of the woven mesh in the open areas. In general,

a series of woven meshes is prepared to print the different parts

of the electrode. Between printing two ink layers on a substrate,

the ink needs to first be solidified through a thermal treatment.

Finally, a protective ink coating is used to insulate the conductive

track from the electrodes.

2.2. Printing materials and pretreatments

During the printing process of SPEs, the pastes most commonly

used are silver ink and carbon ink. Silver ink is printed as a conductive track, whereas the working electrodes are mostly printed

using carbon ink or gold ink. Carbon paste is a widespread material

because it is relatively inexpensive, easy to modify and chemically inert. Gold paste is also employed in SPEs but less so than

carbon because of its higher cost. However, the generation of selfassembled monolayers (SAMs) through strong Au S bonds [4] is

creating an increased interest for gold to be employed in SPEs.

The screen-printed gold electrodes are applied as electrochemical

biosensors, including enzymatic, immune-, or genosensors [58].

The printing inks for SPEs contain some mineral binders or

insulating polymers to improve adhesion onto the substrate. The

existence of polymers in inks for working electrodes might shelter the electrochemically active carbon particles and increase the

electron transfer resistance, which would result in slower kinetics of heterogeneous reaction, and quasi-reversible or irreversible

redox processes might therefore occur at the SPEs [9]. To improve

the slow electron transfer of bare SPEs, one can modify the printing

paste with certain materials. Currently, noble metals show the best

overall catalytic performance and play a dominating role as ele

trocatalysts. However, their high cost is a serious impediment

commercial applications, so less expensive materials, such as ma

ganese oxide (MnOx ), are used to replace the noble metal materia

The commercial manganese oxide particles were efficiently mix

into the carbon ink formulation prior to screen printing [10]. As

result, the prepared MnOx SPCE exhibited good performance as

electro-catalyst for the sensing of nitrite ions and ascorbic acid wi

low detection limits. Bismuth oxide [1113] and bismuth nanopa

ticles [14] have also been successfully mixed with the carbon pas

to prepare SPBEs.

Pretreatment is another method to enhance the electrochem

ical properties of SPEs. The main purpose of pretreatment for

SPE is to remove the organic ink constituents and contaminan

and to increase the surface roughness and functionalities. Ther

fore, various researchers have proposed a short electrochemic

pre-anodisation method, a potential cycling method [15], and

two-step pretreatment approach that combines chemical trea

ments (soaked in a high-concentration solution of NaOH) a

electrochemical treatments (anodisation in a mild NaOH solutio

[16]. Moreover, plasma treatment has been introduced to clean a

modify the surface of SPCEs. For example, Ar, O2 , SF6 and CHF3 pla

mas have been used to improve the sensitivity and reproducibil

of SPCEs [1720].

2.3. Novel designs

The forms of the SPEs can vary and could be contrived accor

ing to the demands for analysis where common forms include

disc, a ring, and a band. Compared with common SPEs, the SP

in the micrometre-scale range can exhibit advantageous featur

attributed to microelectrodes, such as improved signal-to-noi

ratios, independence of forced convection, a low ohmic drop [21,2

and a faster mass-transport rate than conventional electrodes [2

However, micrometre-scale SPEs are considered difficult to pr

duce and are not very reproducible. To overcome this obstac

some researchers print the normal-sized working electrodes on t

polymer substrates. After the plate has been cut perpendicular

the conductive track with a scalpel, the formed transversal surfa

could work as a microelectrode [24,25]. Moreover, a carbon-in

based micro-tubular band electrode inside a well was developed v

screen printing [26]. The purpose of the well is to provide a know

volume for enzymatic reactions and other reactions of interest.

create the well-like electrodes, holes were mechanically punch

Fig. 1. Schemes of (a) side view illustrating the method for manufacturing well SP

(b) image of a well electrode strip, and (c) a vertical section cut through the cen

of the well containing the coordinate system used for the well electrode simulati

Adapted with permission from Ref. [26].

2009 Springer.

34

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

Fig. 2. Configurations of electrochemical microarray: (a) photos of a complete 96-well microplate (left) and the printed 96 carbon and Ag/AgCl electrodes with comb-type

connections (right). Reprinted with permission from Ref. [27]. Copyright 2007 Elsevier. (b) Schematic representation of the screen-printed array for direct electro-addressing

of antibodies at the surface of carbon SP microarray. CMA: 4-carboxymethylaniline. Reprinted with permission from Ref. [28]. Copyright 2007 Elsevier. (c) Scheme of assembled

screen-printed electrode array into a holder to produce 16 sealed microwells.

Reprinted with permission from Ref. [29].

2008 American Chemical Society.

or laser-drilled through the four carbon pads to create four well

electrodes on one strip. The fabrication process is shown in Fig. 1.

The application of screen-printed electrode arrays offers

the advantages of rapidity and the possibility to perform the

calibration and the analysis of several unknown samples simultaneously. A disposable sensor array was constructed that consisted

of a 96-well plate whose bottom has been modified with an array

of 96 screen-printed sensors, each of which was composed of a

Fig. 3. Novel design of SPEs: photos of (a) three eight-electrode carbon ink-based arrays stamped on the epidermis and (b) three-electrode contingent on a stress ball. Adapted

with permission from Ref. [31]. Copyright 2012 Royal Society of Chemistry. (c) Photo of SPE on an underwater garment (left) and a red indicative LED (right) when pollutant

content in seawater exceeds a certain level. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of the article.)

Reprinted with permission from Ref. [33].

2011 Royal Society of Chemistry.

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

carbon working electrode and an Ag/AgCl pseudo-reference electrode (shown in Fig. 2a below). The array, which was connected

to a multichannel readout, could perform virtually simultaneous

determinations [27]. There are several different types of screenprinted microarrays, such as a biochip composed of eight working

electrodes, one ring-shaped pseudo-reference electrode and one

central auxiliary electrode (shown in Fig. 2b) [28]. Another type

of array was sandwiched between insulating layers to produce

microwells, as shown in Fig. 2c. Each array consisted of 16 working

electrodes and rested on a foam pad stabilised by a Teflon block

[29].

In spite of the attractive merits of SPEs, one limitation of

fabrication methodology still hampers its incompatibility with

non-planar substrates. Therefore, particular attention is paid to the

SPEs directly printed on some rigid and flexible substrates (shown

in Fig. 3a and b) [30,31]. Recently, first example of wearable screenprinted electrochemical sensor was reported (shown in Fig. 3c)

[32]. By printing the electrodes on neoprene substrates, this sensorpotentiostat microsystem could provide a visual indication and

real-time monitor the levels of marine contaminants if they have

exceeded a pre-defined threshold.

3. Applications for environmental analysis

SPEs have been used as a support to produce portable electrochemical sensors that offer exciting opportunities to perform

environmental analyses, such as routine water quality tests for

organic contaminants and heavy metals, amongst other species.

3.1. Routine water quality tests

3.1.1. pH and dissolved oxygen

An increasing need exists for reliable sensors to monitor the

variation in pH in harsh environments. The concept of screen printing is interesting because it can simplify the electronic sensing

components for in-the-field testing and replace the traditional

glass electrode that requires frequent re-calibration and is unstable. pH sensors with one electrode (with both the reference and

the measurement electrode) were attempted to be printed based

on this concept [33]. This research resulted in one printing process being capable of printing pH sensors with different pastes onto

one substrate. Almost simultaneously, a three-electrode integrated

system was successfully fabricated for pH sensing, which simplified the electronic components and increased the sensitivity vs.

the two-electrode system [34] (which has also been expanded for

the electroanalytical sensing of hydroxide ions using a nickel oxide

bulk modified SPE [35]).

The dissolved oxygen concentration is also an important parameter to evaluate water quality. A disposable CdS-modified SPE has

been utilised to determine the dissolved oxygen concentration in

water by a hot electron-induced cathodic electrochemiluminescence (ECL) method [36]. The excellent luminescent properties of

semiconductor nanocrystals allow CdS-modified SPEs to be operated at a lower potential without a dramatic evolution of hydrogen

due to the electrolysis of water. Moreover, because the common

thin film in an Al/Al2 O3 electrode is unstable in strongly acidic or

basic media, CdS-modified SPEs could be used as an alternative

because some insulating polymers or mineral binders in carbon

paste could form a thin insulating layer for cathodic ECL. This developed method has the potential to detect chemical oxygen demand

(COD) and biochemical oxygen demand (BOD).

3.1.2. Nitrite and phosphate

A sensitive and simplified method for the determination of

nitrite and phosphate ions at low levels is critically important

because of their ubiquitous nature and toxicity. Some designs based

on the advantages of SPEs have been fabricated and are feasible f

the sensing of nitrate. Because nitrite is difficult to detect on co

ventional electrodes by direct electrochemical oxidation becau

of the required large overpotential, a MnO2 SPE was fabricat

to lower the operating potentials for nitrite sensing [10]. Micr

electrodes combined with screen-printing technology have be

utilised to fabricate sensitive sensors for nitrite, which has adva

tages that include the minimisation of the iR drop (even witho

a supporting electrolyte), an increased mass transport to the ele

trode surface, and the facilitation of a rapid response with a stea

current potential [37]. A screen-printed shallow recessed graph

microelectrode array was designed without modification, whi

permitted the sensing of nitrite at low micromolar levels in riv

water samples [38]. Furthermore, a low-cost electrochemical c

was specifically designed for screen-printed edge band ultramicr

electrodes (SPUMEs) for the detection of nitrite by flow injecti

analysis (FIA) [37]. The SPUMEs were built in a three-electro

pattern, where the edge of the films could serve as a band-ty

ultramicroelectrode. The SPUMEs combined with FIA were su

cessfully applied in the determination of nitrite in the absence o

supporting electrolyte in ground and lake waters, which drama

cally simplified the detection process.

Ion-selective electrodes (ISEs) are often used for routine wat

analysis, especially because they have the ability to measure va

ous species in turbid or coloured samples. For phosphate ions, th

strongly hydrophilic character makes them challenging to dete

mine. Therefore, three types of electrodes (screen-printed, carb

paste and the conventional PVC membrane electrodes) were co

structed as the substrates for phosphate ion-selective electrod

[39]. Among them, the SPE-based ISEs worked satisfactorily with

detection limit of 4.0 !mol L1 for phosphate ion and showed a fa

response of approximately 2 s.

3.2. Organic compounds

3.2.1. Phenolic compounds

The rapid in situ determination of phenolic compounds and th

derivatives is an important environmental challenge because

the easy penetration of such species through membranes or ski

of plants, animals and humans, with toxic side effects [15]. SP

based electrochemical biosensors have led to a low-cost, simp

and sensitive analytical method for phenolic compounds.

The direct electrochemical behaviour of individual pheno

compounds at non-pretreated SPEs has been previously discusse

thereby simplifying the procedures for electrode treatment [40,4

In certain cases, the electro-oxidation products of phenol wou

passivate the surface of SPEs and hinder the electron transf

process. The use of surfactants with antifouling properties in co

junction with preconcentration is an effective way to solve t

problem. One research studied the usage of SPEs in the presence

a cationic surfactant, cetyltrimethylammonium bromide (CTAB),

determine bisphenol A in river water and sewage samples [41].

Phenolic isomers usually coexist in environmental sample

therefore, methodologies to spontaneously determine pheno

isomers are of great interest. The challenge in isomer analy

is the overlapping peak potentials in untreated SPEs that ex

as a result of similar structures and properties. Electrochemic

pretreatment has been used because of its simplicity. After pr

treatment, the organic binder within the surfaces of SPEs w

removed, and graphite particles in the micrometre-size range we

exposed, which increased the specific surface area of the SP

A simultaneous method for the determination of hydroquino

(HQ) and catechol (CC) was applied at anodically pretreated SP

in river water samples and yielded a good peak separation of H

and CC [42]. Another study reported that an electrochemically pr

treated SPE was employed for the simultaneous determination

36

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

aminophenol isomers in river water [15]. Three well-defined oxidation peaks of aminophenol in the isomer mixture could be achieved

using derivative techniques.

Further studies have been performed at chemically modified

SPEs, especially nanomaterial-modified SPEs, because the modifying substances can dramatically increase the sensitivity and

selectivity of detection because of their unique electronic, catalytic and chemical properties [43]. A nanocomposite-modified

SPE coated with multi-walled carbon nanotubes (MWCNTs) and

electrodeposited gold nanoparticles (AuNPs) was fabricated to

determine the three types of dihydroxybenzene isomers in water

samples [44]. Compared with a nontreated SPE, the fabricated

SPE displayed significantly greater electrocatalytic activity for

the oxidation of dihydroxybenzenes because AuNPs supported

on the conducting MWCNTs enhanced the sensitivity remarkably. Using differential pulse voltammetry (DPV), the authors

simultaneously determined three kinds of isomers at the modified SPE. In addition, multielectrode arrays have recently received

considerable attention because of their ability to provide multicomponent, simultaneous and high-throughput analyses. For example,

an MWCNT-modified screen-printed multielectrode array was

designed for the determination of dihydroxybenzene isomers [45].

This strategy was also demonstrated to have the potential for

detecting other organic isomers.

SPE-based electrochemical biosensors appear to be an attractive

and suitable option for the more sensitive and selective determinations of phenolic compounds. Enzymes have been widely used

in the preparation of biosensors for the analysis of phenolic compounds and have allowed the measurement to be performed at

a low applied potential to significantly reduce the interference

[46]. Two important types of polyphenol oxidase enzyme (PPO),

tyrosinase (Tyr) and laccase (Lac), can catalyse the oxidation of benzenediols and phenols to quinones or to radical species by reaction

with oxygen in solution [47].

One of the most important aspects that affects the performances

of enzymatic biosensors is their effective immobilisation on the

electrode surface. Hence, most research in this area has focused on

the development of approaches that retain the biochemical activity of an enzyme whilst minimising the enzymes denaturation and

leakage into solution. One approach is to immobilise the enzyme

through the entrapment method. As immobilising agents, polyazetidineprepolymer (PAP) and polyvinyl alcohol photopolymer have

been successfully used to immobilise Lac on surfaces of SPEs. The

efficiency of the constructed SPEs was confirmed using phenolic

analysis [4850].

Electrodeposition is another simple method to immobilise an

enzyme onto an electrode surface. One biosensor for phenol detection was achieved through the electrodeposition of PPO with the aid

of a Bi3+ precursor onto the MWCNT-modified SPE without the use

of any matrix or binder [51]. Other research reported a biosensor

for the detection of 1,2-diaminobenzene (DAB) by electropolymerisation of PPO, DAB and a mediator complex on a screen-printed Pt

electrode [52]. The analytical results for DAB demonstrated that the

mediator-modified enzymes displayed improved electron-transfer

rates compared to that of the native enzyme.

Other efficient immobilisation methods have been recently

developed. The combination of magnetic nanoparticles with bioimmobilisation, separation and detection could provide unique

capabilities and improve the performance of biosensors. Magnetic

nickel nanoparticles were utilised as an immobilisation platform

to construct disposable biosensors, with the highest performance

for determination of bisphenol A compared with biosensors based

on Fe3 O4 and AuNPs [53]. Moreover, some simple and versatile

noncovalent methods through supermolecular interactions could

also be utilised to construct biosensors. One biosensor based on

the immobilisation of Tyr-protected AuNPs onto 1-pyrenebutanoic

acid, succinimidyl ester (PASE) functional graphene oxide (GO)

modified SPE was fabricated for the determination of CC [54]. PASE

is a bi-functional molecule that was assembled onto GO sheets

through noncovalent ## interactions. Using this approach, Tyr

could be assembled onto SPEs with a high degree of control and

specificity, which led to good stability and a high sensitivity for the

determination of CC. Silver-electrodeposited screen-printed electrodes (Ag-SPEs) were introduced as portable surface-enhanced

Raman scattering (SERS) substrates to detect phenolic compounds

[55]. These SERS-active substrates are easily prepared and stored,

and they are better suited for in situ determinations than silver colloids. Combing with the electrostatic preconcentration technique,

Ag-SPEs based SERS sensors could be qualitatively and quantitatively to analyse polar organic pollutants with detection limits of

0.1 nmol L1 .

3.2.2. Pesticides

Pesticides, especially organophosphate pesticides (OPs), can

lead to cholinergic dysfunction, which disrupts the health of

both humans and animals. Monitoring the amount of pesticides

in water and soil is an effective way to detect the abuse of

pesticides in agriculture [56]. Because pesticides can inhibit the

activity of many enzymes, such as acetylcholinesterase (AChE),

butyrylcholinesterase (BChE), OP hydrolase (OPH), and Tyr, various inhibition biosensor systems based on SPEs have emerged in

recent years as promising alternatives for in-the-field detection

of pesticides (Table 1). When an enzyme immobilised on an SPE

interacts with the substrate, the electroactive species are produced.

After the enzyme is exposed to the inhibitor, the decreased enzyme

activity leads to a decrease in the current intensity. Hence, the general quantitative principle of pesticides is primarily based on the

amperometric measurement of the decreased enzyme activity [57].

The performance of biosensors depends considerably on the

method used to immobilise the enzymes. Cross-linking [5759],

physical entrapment [60] and solgel [61] approaches are the traditional chosen strategies. However, the utilisation of these types of

immobilisation methods, the non-renewability of the sensing surface and the aggressive detection environment, which could lead

to enzyme denaturation, are problems that need to be addressed.

Recently, enzyme immobilisation using magnetic materials has

been explored for the construction of biosensors for pesticides.

The magnetic feature of magnetic materials enables enzymatic

reactions to occur close to the transducer, a rapid separation of

the immobilised enzyme in the magnetic field for the renewability of the sensitive surface, and a good microenvironment for

retaining the bioactivity of the enzyme. Hybrid core/shell biomagnetic glasses, which consist of a Fe3 O4 inorganic core and a

mesoporous silica shell, were synthesised as a platform for AChE

immobilisation [61]. SPEs with AChE-biomagnetic glasses were

employed to construct a paraoxon biosensor with a detection limit

in the nanomolar range. Another magnetic nanoparticle species,

Au-colloid-coated Fe3 O4 (Fe3 O4 /Au), where Au improves the stability of magnetic Fe3 O4 cores, was selected for the immobilisation

of AChE on composite membrane-based SPEs using an external

magnetic field [62]. When the magnet is removed, the SPE surface

can be easily renewed. In addition, to eliminate the mass-transfer

problems commonly associated with immobilisation, whole cells

could be directly used for immobilisation without permeabilisation. Whole cells of Escherichia coli were successfully immobilised

on SPEs through a cross-linking agent for methyl parathion analysis, and only a small sample volume was required for detection

[63].

During the amperometric measurement, the modification of

SPEs with mediators is necessary to reduce the relatively high

working potential, which causes interference from other electroactive compounds. Prussian blue [57,62], carbon nanotubes [59,62],

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

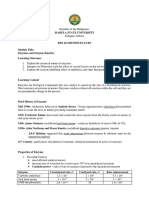

Table 1

Pesticide sensors based on SPEs dedicated to environmental analysis applications.

SPE configuration

Analyte

Sensor characteristic

LOD (ppb)

Reference

Nanometre-sized titania/SPE

BChE-based Prussian Blue/SPE

0.63

2

0.5

12

25

10b

19b

5b

6b

4

1.3

[60]

[61]

AChE-based MWCNT-cellulose/SPE

AChE-based PEDOT:PSSa /SPE

Dichlofenthion

Paraoxon

Chlorpyrifos-methyl oxon

Aldicarb

Carbaryl

Carbaryl

Diazinon

Carbofuran

Methyl parathion

Carbaryl

Chlorpyrifosoxon

AChE-biomagnetic glasses/SPE

AChE-based magnetic composite/SPE

recombinant Escherichia coli/SPE

Molecularly imprinted polymer/SPE

Paraoxon

Dimethoate

Methylparathion

Fenitrothion

14

5.6 104

131.6

222

[65]

[66]

[67]

[69]

AChE-based Prussian Blue/SPE

Tyr-based CoPc-cellulose-graphite/SPE

a

b

[62]

[63]

[64]

PEDOT:PSS-poly(3,4-ethylenedioxythiophene):poly(styrenesulphonate).

The minimum value of the linear range.

cobalt-phthalocyanine (CoPC) [64] and conductive polymer [60]

have been successfully used to lower the working potential of pesticide biosensors. These electronic mediators are typically deposited

on the surface of SPEs using a drop-coating method or screenprinting technology using a conductive paste.

Furthermore, to provide a rapid response and signal for the

existence of complex pesticides within samples, a screen-printed,

amperometric biosensor array that consisted of 12 CoPC-modified

SPEs was used for the simultaneous determination of OPs [64]. Six

different AChE enzymes were immobilised on different SPE surfaces

to achieve the inhibition data in a sample solution.

Enzyme-based biosensors can only provide the total toxicity

of a mixed sample without the possibility of selectively quantifying different pesticides. To avoid the utilisation of enzymes,

molecular imprint and photoelectrochemical technologies with

high selectivities towards specific pesticide species have been used

to analyse pesticides in environmental samples (Table 1). A molecularly imprinted polymer was obtained by the electropolymerisation

of Ni(II)-p as an SPE coating for the selective and in-the-field

determination of fenitrothion through cyclic voltammetry [65].

Another group has described a simple photoelectrochemical

SPE sensor for dichlofenthion based on a nanometre-sized TiO2

photocatalytic degradation mechanism [56]. This sensor creates

new opportunities for the monitoring of other non-electroactive

pesticides.

3.2.3. Herbicides

The increasing use of herbicides impacts drinking water and

affects crop safety, resulting in contamination of the water and

soil system. One common approach for the selective detection

of herbicides is the immunoassay method. Combined with SPEs,

the immunoassay approach allows for a single shot determination

of herbicides, thereby avoiding the cleaning and reuse of active

components. An enzyme-linked screen-printed immunoassay was

fabricated for isoproturon based on a horseradish peroxidase

(HRP)-labelled polyclonal antibody [66]. This sensing platform

incorporated a membrane into the working electrode allowing

for the covalent immobilisation of assay reagents and fast signal transduction. With respect to the simplification of procedures

and improvements in sensitivity, an AuNPs-assisted ultra-sensitive

non-enzyme electrochemical immunoassay has been reported [67].

The sensitivity detection achieved sub-nanomole levels for chlorsulphuron using anodic stripping voltammetry. This strategy could

also be readily utilised for the simultaneous screening of different

analyte arrays of environmental importance.

However, the immunoassay procedure faces some drawbac

such as the time-consuming antibody generation process a

the possibility of cross-reactivity of the antibody with simi

compounds [68]. Hence, many researchers have focused th

investigations on the development of biosensors for alternati

uses. The use of photosynthesis biosensors for this purpose th

employ natural photosynthesis machinery has been well doc

mented. The entrapment of photosynthetic materials is challengi

with respect to the construction of photosynthesis biosenso

Screen-printing and self-assembly technologies are common

utilised to immobilise photosynthetic materials. A screen-print

algal biosensor was fabricated by mixing unicellular microal

cells into an algal ink for evaluation of the toxicity of herbicid

which yielded a shorter assay time [69]. Another example report

recently is the immobilisation of photosynthetic-reaction reporte

onto gold SPEs using a self-assembled monolayer for the develo

ment of a unique biointerface [68]. The biosensor displayed go

performance with respect to achieving effective mediator tran

fer to the SPEs, with a detection limit of 1.15 nmol L1 for atrazin

Moreover, the development of whole-cell biosensors has draw

attention because the living cells can function as bioreporters th

offer a fast and effective assessment of the overall toxicity of a wat

system. A whole-cell triazine herbicide biosensor based on ma

netic nanoparticles functionalised living cells has been report

(Fig. 4) [70]. This methodology allowed for efficient cell immobi

sation and did not affect the cellular metabolism.

3.2.4. Polyaromatic hydrocarbons

Polyaromatic hydrocarbons (PAHs), which contain two or mo

fused aromatic rings, often require complex preconcentration pr

cedures during detection because of their low solubility in wat

Therefore, SPEs could be an effective extraction and absorpti

tool for PAHs because aromatic compounds could interact with t

graphite walls and stack onto carbon materials through noncov

lent bonding [71].

The electrochemical oxidation behaviour and the oxidati

mechanism for 1-hydroxypyrene (1-OHP) has been investigat

at a disposable SPE [72]. In particular, PAHs are always found

a mixture of individual compounds with similar molecular stru

ture, similar electron density and a lack of side groups. Therefo

an immunosensor based on SPEs was developed for PAH detecti

using a co-exposure competition assay. The immunosensor d

played cross-reactivities of varying degrees towards 16 importa

PAH compounds [73]. Nevertheless, the production of antibodi

specific for only one PAH is difficult. Future approaches may invol

38

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

Fig. 4. A sketch of the biosensor setup based on a screen-printed electrode, a

tetrafluoroethylene support with the embedded permanent magnet and magnetically functionalised microalgae cells. The arrow indicates the order of assembly.

The inset shows a typical optical microscopy image of the MNP-functionalised C.

pyrenoidosa cells.

Reprinted with permission from Ref. [70].

2011 Royal Society of Chemistry.

the use of various antibodies within a single sensor to produce

different signals and deliver more information regarding the PAH

mixture.

Fig. 5. (a) Schematic representation of a disposable screen-printed array based

on eight graphite round-shaped working electrodes, each one with a silver

pseudo-reference electrode and a graphite counter electrode. (b) A disposable

screen-printed array, the magnet holding block, and the two components assembled

in the proper position.

3.2.5. Antibiotic residues

The detection of antibiotic residues in environmental samples

through the combination of disposable electrochemical sensors

has achieved significant attention for fast, low-cost and sensitive detection. Tetracyclines, as an important class of antibiotics,

were investigated on gold SPEs using cyclic voltammetry and FIA

[74]. A screen-printed eight-electrode-based immunoarray for the

detection of sulfonamide antibiotics was developed using magnetic

beads as a solid phase, which allowed the rapid extraction of sulfonamides in complex matrices (Fig. 5) [75]. The combination of

the antibody-based assays, magnetic bead separation and screenprinted array transduction is an attractive aspect of this research

that has the potential to be used in the development of a highsample-throughput screening system.

Reprinted with permission from Ref. [75].

2010 John Wiley and Sons.

3.3. Heavy metals

In developing countries, rapid economic development often

occurs at the expense of the environment. The environmental damage from heavy metals has only begun to be remedied. Therefore,

simple and inexpensive sensing devices are needed for in situ monitoring. In recent decades, heavy metals have been persistently

monitored all over the world because of their toxicity, even at low

concentrations [76]. Common toxic metal ions, such as Pb(II), Cd(II),

Hg(II), and As(III), are especially important because they are neurotoxic (e.g., Pb(II) [77] and Hg(II)), easily absorbed by the human

body and accumulate within the environment and living organisms

[78]. Historically, electrochemical stripping analysis, commonly

using anodic stripping voltammetry (ASV), has been widely recognised as a powerful technique for heavy-metal detection because

of the simplicity of the instrument as well as its moderate cost and

portability. Moreover, the ASV technique combined with SPEs can

handle all scenarios that require rapid, inexpensive, sensitive and

accurate determination [79] in the field of environmental monitoring. Most studies of heavy-metal determination using SPEs show

that mercury, gold, silver, bismuth or other materials modified on

the surface of SPEs can improve selectivity or sensitivity [24,7983].

A number of reviews have provided an in-depth analysis of specific areas. Therefore, we have reviewed and listed the recent

developments in heavy-metal-ion detection using different modified SPEs with some optimised analytical parameters in Table 2.

3.3.1. Pb(II)

According to a recent review [84], sensors for Pb(II) detection are

usually modified with carbon, bismuth, gold or other materials to

improve sensitivity. These modifiers can be transplanted onto the

surface of SPEs to allow detection to be more convenient. The most

widely used modifier of SPEs for electroanalysis is bismuth because

of its good analytical performance and its environment-friendly

characteristics. Since the pioneering report in 2000 [81], bismuthmodified SPEs (BiSPEs) have been broadly applied to the field of

environmental [85] monitoring. Advantages, such as not requiring the removal of dissolved oxygen during stripping analysis and

characterisation over a wide negative-potential window [8587],

make testing convenient. Moreover, the bismuth-modified SPEs

can improve sensitivity; for example, the detection limits of Pb(II)

can reach the ppb level or lower [88].

In general, bismuth is in situ or ex situ electroplated onto the

surface of working electrodes to form a Bi film on SPEs. Based on

this observation, a novel sensor was developed for the one-step

sensing of Pb(II) [82,89] by covering a paper disk impregnated with

buffer and reagents (including an internal standard of Zn(II) and

a plating solution of Bi(III)) on a screen-printed carbon electrode.

After the sample was added to the surface of the electrode, it could

be applied to run a single-step assay for Pb(II) detection (Table 2).

The performance of the electrode was satisfactory (550 ppb Pb(II)

detected), and only a final, small volume of the sample (10 !L) was

needed to be placed on the surface of the paper for running one

assay. In addition, an internal standard with a known concentration

was added to improve the accuracy and precision [90,91]. Hg-free

screen-printed microband electrodes (!BSPEs), which are easily

manufactured with the option to renew the electrode surface, was

used to detect Pb(II) and a theoretical detection limit of 2.3 ng mL1

was calculated based on a signal-to-noise ratio of three [92].

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

Table 2

Application examples of SPEs for metal ion detection.

Metal ion

Modification

Stripping

technique

Limit of

detection

(LOD) (ppb)

Time (s)

Potential (vs. Ag/AgCl)

Pb(II)

None/!BSPEs

Bi

LSASV

SWASV

2.3 ng mL1

<5

1500

120

Hg thin film/micro-well

SWASV

ex situ deposited Hg (5 !g)

AuNPs amalgam

Microelectrode array/Hg

SWASV

DPASV

SWASV

2 109 mol L1

(0.2 ppb)

0.2

2.6

1.3

Hg(II)

SPGEs

Thiol compound

SPCE/PANI + PDTDA

SPCE/PANI + MB

SWASV

it

DPASV

DPASV

As(III)

PtNPs

AuNPs

AcH

Cd(II)

Practical application

Reference

1.3 V

1.4 V

Surface water

[99]

[89]

60

1.0 V

Soil solution

[103]

60

100

300

1.0 V

1.1 V

1 V

River water

River/tap water

River water

[100]

[102]

[90]

1.1

1

56

54

60

120

120

+0.3 V

0.3 V

0.3 V

Waste water

Drinking water

Ultra pure water

[112]

[113]

[116]

[117]

CV

LSV

it

5.68

0.4

0.8

160

0.4 V (vs. SCE)

Tap water

Canal water

Tap water

[120]

[121]

[125]

BiNPs

SWASV

Pb(II): 0.9

Cd(II): 1.2

Zn(II): 2.6

120

1.4 V

Waste water

Tap water

[18]

Au film

SWASV

1.0 V

+0.3 V

1.0 V

+0.3 V

[133]

SWASV

120

120

120

120

Tap water

Preconcentrated with

thiol-modified Fe3 O4

Pb(II): 0.5

Hg(II): 1.5

Pb(II): 0.02

Hg(II): 0.08

Tap water

[133]

Crown-ether/Hg film

LSASV

Pb(II): 1.65

Cd(II): 0.67

120

1.0 V

River water

Soil solution

[134]

CTS/SPCE

DPASV

Pb(II): 3.4

Cu(II): 5

Cd(II): 5

Hg(II): 2

30

1.0 V

Tap water

[137]

Hg/MWCNTs-CTS/SPE

SWASV

Pb(II): 4.8

Cd(II): 1.3

Cu(II): 1.3

300

1.3 V

River water

[138]

Pb(II), Cd(II), Zn(II)

Pb(II), Hg(II)

Pb(II)

Cd(II)

Pb(II), Cu(II), Cd(II),

Hg(II)

Pb(II), Cd(II), Cu(II)

Deposition

SWASV, square wave anodic stripping voltammetry; DPASV, differential pulse anodic stripping voltammetry; LSASV, linear sweep anodic stripping voltammetry; CV, cy

voltammetry; LSV, linear sweep voltammetry.

3.3.2. Cd(II)

Although bismuth is widely used to modify SPEs for the detection of heavy metals, this approach exhibits shortcomings. For

example, acidic or highly alkaline working media may be necessary for in situ plating of Bi film, because of the Bi(III) hydrolysis in

neutral and alkaline media [86]. In contrast, the quasi-noble-metal

behaviour of mercury allows analyses over a wide pH range [93].

Because of the high affinity of mercury for metals associated with

the analytical performance of stripping voltammetry, low detection

limits can be achieved with relatively short analysis times without degassing [94]. Mercury is therefore still used as the modifier

for trace metal detection [93,95]. However, because of the toxicity

of mercury, researchers are actively pursuing ways to reduce the

amount that is needed for modification of SPEs.

A thin-film mercury screen-printed working electrode was combined with a micro-well to detect Cd (II) (see Fig. 6) [96]. The use of

a micro-well reduced the volume of the sample to 200 !L without stirring, which minimised the loss of sensitivity. Moreover,

this working electrode was used for direct analysis in raw samples of soil solution without pretreatment, which provides a useful

method for the in situ determination of heavy metals.

Some researchers have also printed auxiliary electrodes with

the working electrode on the same polymer plates [93]. This

screen-printed sensor was ex situ electrodeposited with a small

quantity (approximately 5 !g) of mercury at 0.1 V (vs. Ag/AgCl).

However, when this sensor was used, an additional commercial

reference electrode or counter electrode was needed to compose

a 3-electrode system for detection. Therefore, a screen-printed

electrode system on the same substrate would be more convenie

A 3-electrode device with a standard USB port conveniently co

nected to a PC or laptop computer was designed [95].

Microelectrodes provide new tools for environmental analys

however, the difficulty of recording very low currents using micr

electrodes needs to be overcome [97]. Therefore, microelectro

arrays have been consequently developed to obtain a higher cu

rent output [98]. Based on femtosecond laser ablation technologi

square arrays of 64 microelectrodes (8 8) were made in a pol

mer substrate and then screen-printed carbon ink (see Fig. 7) [8

Because of the small overall surface of SP!EA, only a low quant

of mercury (less than 1 !g) was ex situ deposited, and the devic

were sufficient to perform a trace analysis of river water close to

zinc mine.

3.3.3. Hg(II)

Mercury is also one of the most problematic heavy-me

pollutants in environmental monitoring and its organic form

bioaccumulative and toxic. Moreover, the accumulation of mercu

in the human body can cause severe disease, such as kidney a

respiratory failure, and damage to the gastrointestinal and nervo

systems [99].

Bare gold electrodes or modified gold electrodes are usually ch

sen for inorganic Hg(II) detection because the high affinity for Hg(

enhances preconcentration [100]. However, the major drawbac

of the use of a gold electrode are structural changes at the surfa

40

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

Fig. 6. Schemes of (a) a screen-printed sensor and (b) a screen-printed sensor adds with a microwell.

Adapted with permission from Ref. [96].

2007 John Wiley and Sons.

caused by amalgam formation. For this reason, time-consuming

cleaning treatments are necessary to achieve reproducibility [101].

Alternatively, commercial screen-printed gold electrodes make

routine measurements of Hg(II) in water samples simpler and more

attractive because preplating steps are unnecessary. Commercial

screen-printed gold electrodes (SPGEs, DropSens, Spain) have been

successfully used for the measurement of Hg(II) in ambient water

[102].

Some researchers have detected Hg(II) using SPEs based on the

electrochemical behaviour of a Hg-complex. A thiol-probe based

on SPEs modified with a film of nanostructured carbon black (CB)

is highly sensitive to thiocholine and cysteine. After the Hg(II) is

added, a non-electroactive complex is formed, which leads to a

diminished signal [103]. This sensor is a promising replacement for

the traditional gold electrode. The application of polyaniline (PANI)

has been investigated for the preconcentration and speciation of

inorganic Hg(II) and methyl mercury, [CH3 Hg]+ , in various water

samples [104,105]. Other researchers have modified bare SPCEs

with a conducting polymer layer of PANI, polyanilinepoly(2,2 dithiodianiline) (PANI-PDTDA) [106] or polyaniline-methylene

blue (PANI-MB) [107], and these SPCE/polymer sensors could be

used as alternative transducers for the voltammetric stripping and

analysis of inorganic Hg(II). Moreover, this electrochemical sensor has been utilised for the simultaneous determination of Hg(II),

Pb(II), Ni(II) and Cd(II) [108,109].

3.3.4. As(III)

Arsenic, also a kind of toxic element, can dissolve from minerals

to contaminate groundwater under certain geochemical conditions

and upon microbiological activity. Drinking water rich in arsenic

over a long period of time leads to arsenic poisoning or arsenicosis.

Some researchers have prepared PtNPs/SPCEs by electrochemically depositing K2 PtCl6 to detect As(III) [110]. PtNPs/SPCEs makes

no interference from Cu(II) towards the oxidation of As(III) during detection. Usually, the sensitivity of CV is lower than that of

ASV, which includes a preconcentration step under the same conditions. With the use of SPCEs modified with citrate-capped AuNPs,

As(III) was determined with no interference from Cu(II) [111].

These metallic nanomaterials provided a new means for multiple

modifications of SPEs and the replacement of traditional preciousmetal electrodes.

Recently, enzymatic biosensors have also been used for the

determination of hazardous metals because some metals can act as

enzyme inhibitors, which lead to sensitive and specific detection

[112,113]. For this reason, acetylcholinesterase (AchE) was immobilised by covalent linkage on the surface of SPCEs to detect As (III)

[114]. However, the interference of Hg(II), Ni(II) and Cu(II) species

cannot be neglected. Thus, an enzyme that is more specific and

sensitive to As(III) might be selected for future detection.

3.3.5. Simultaneous detection of several different metals

SPEs designed for the simultaneous determination of different metals are more interesting for time and cost reasons. SPEs

modified with Hg and Bi, either in situ [115] or ex situ [116,117],

are commonly used to determine Pb(II) and Cd(II) concentrations. Otherwise, Bi could be deposited on SPEs in many forms,

such as bismuth oxide [1113], bismuth nanoparticles [14], bismuth co-deposited with metal ions in solution [118] and bismuth

pre-deposited as a film [119]. As far as we can determine, Bi

nanoparticles plated on SPEs using the SWASV technique exhibited the lowest detection limits of Pb(II), Cd(II) and Zn(II). When

combined with a flow cell, the detection limits could be lower [14].

Fig. 7. Side and top views of different steps for microelectrode array fabrication: (a) membrane of mylar, (b) membrane after laser ablation; (c) ablated membrane after

screen-printing; and (d) side of the screen-printed membrane after the application of the insulation.

Reprinted with permission from Ref. [83].

2009 Elsevier.

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

The normal Au-film-coated SPEs displayed excellent linear

behaviour. Moreover, the researchers improved the preconcentration technique by modifying the magnetic particles (superparamagnetic iron oxide (Fe3 O4 ) nanoparticles [120,121]) with thiols to

preconcentrate heavy metals from samples whose concentrations

were lower than 1 !g L1 [122].

Because crown-ethers can form complexes by fitting metal

cations into the cage of the crown structure, some researchers

have modified crown-ether-based membranes on a thin-film of Hgcoated SPCE to achieve a selective uptake of Pb(II) and Cd(II) [123].

In addition, the crown-ethers can protect the working surface from

interferences during analysis. Without deoxygenation and stirring,

this device was successfully used to detect Pb(II) and Cd(II) Also,

this device was utilised in raw samples and in the semicontinuous

monitoring of Pb(II) and Cd(II) for 42 h in tap water [94].

Chitosan,

poly-["-1-4]-2-amino-2-deoxy-d-glucopyranose

(CTS), can form stable chelates with many transition-metal ions

through hydroxyl and amino groups. CTS and its derivatives have

been used for the electrochemical determination of metal ions with

glassy carbon electrode (GCE) [124]. Some researchers modified

CTS on the surface of SPCEs for the simultaneous determination of

Pb(II), Cu(II), Cd(II) and Hg(II) with preconcentration time of only

30 s [125]. In addition, CTS could be used for the homogeneous

dispersion of MWCNTs [126] and the CTS-MWCNTs composite

film exhibited significant improvements in tensile modulus and

strength [127]. A small amount of mercury was subsequently

deposited in situ, and a random array of mercury nano-droplets

formed on the surface of the MWCNTs-CHIT/SPE. This sensor

was used for the simultaneous determination of Pb(II), Cd(II) and

Cu(II). Moreover, a hybrid analytical method, which combined

electrochemical adsorptiondesorption with colourimetric

analyses, was developed to detect heavy-metal ions [128]. The

electrochemical adsorptiondesorption procedure, which is more

convenient and less time-consuming, was used as a pretreatment

process for the colourimetric analysis. The colourimetric approach

used for quantitative analysis may avoid errors that arise from the

instability of the electroanalytical method.

3.4. Gas pollutants

Many analytical instruments, such as those based on colour

reactions, chemical luminescence, or IR absorption, have been used

for measuring the concentration levels of toxic gases. Comparing

with these instruments, the electrochemical gas sensors prepared

using a screen-printing method were low in cost, simple in construction, and small in size. Such screen-printed gas sensors have

gradually been applied in environmental analysis.

3.4.1. Carbon monoxide

Carbon monoxide (CO) is a colourless, odourless, tasteless and

poisonous gas that is commonly produced by the incomplete combustion of fossil fuels. It combines with haemoglobin to produce

carboxyhaemoglobin, which is ineffective for delivering oxygen to

body tissues, and a level of 50% carboxyhaemoglobin may result in

seizure, coma, or death.

Because of its excellent stability and ion-conducting behaviour

over a wide range of oxygen partial pressures and temperatures,

yttria-stabilised zirconia (YSZ) was utilised as an electrolyte to

detect CO. Whereas strontium-doped lanthanum manganite (LSM)

was used as the counter electrode, and Au was used as the sensing electrode [129]. This film was fabricated by the screen-printing

technique, which allowed the implementation of a compact planar

device in an easy, fast and highly economical manner. The excellent

performance and fast response time to CO molecules were corroborated at relatively low temperatures without a cross-sensitivity to

NO2 . Otherwise, the sensor signal showed long-term stability.

Another CO sensor was based on the deposition of Pt nanopar

cles on a SPUME with Nafion as the solid polymer electrolyte (Fig.

[130]. The sensor scheme requires no supporting electrolyte, a

the catalytic activity is enhanced substantially because of the

nanoparticles deposited homogeneously on the electrode. In th

study, Pt is employed as the working electrode because it is high

catalytic to CO oxidation and is chemically stable [131]. The Nafi

thin-film solid polymer electrolyte is hygroscopic, which allow

the conduction of protons and permits the gases to access t

electrodes [132]. The developed gas sensor has a good cataly

oxidative activity regarding the determination of CO or gaseo

formaldehyde [133]. This device could be used for in situ measur

ments and for continuous monitoring.

A CO gas sensor has been reported that was based on a scree

printed SnO2 film on an alumina substrate [134]. SnO2 is an n-ty

semiconductor, and a screen-printed porous SnO2 thin film cou

interact with oxygen by transferring electrons from the condu

tion band to adsorbed oxygen atoms, which would result in t

formation of ionic species such as O2 or O . When the SnO2 fi

is exposed to a reducing gas, such as CO, the adsorbed oxygen

removed by oxidation of the gas, and the captured electrons a

injected into the conduction band. The screen-printed SnO2 fi

exhibited excellent selectivity towards CO gas against LPG (li

uefied petroleum gas), CH4 and H2 , high sensitivity and reliab

correlation over the range of 2575 ppm.

3.4.2. Nitrogen oxide

Nitrogen oxide (NOx ) refers to NO and NO2 that are produc

during combustion, especially at high temperatures. NO in the

may convert to nitric acid, which has been implicated in the form

tion of acid rain. NO2 , a reddish-brown toxic gas, has a characteris

sharp, biting odour and is a prominent air pollutant; symptoms

poisoning (lung edema) may appear several hours after inhalati

of a low but potentially fatal dose. Also, low concentrations (4 ppm

will anesthetise the nose, thus creating a potential for overexp

sure. Furthermore, both NO and NO2 participate in depletion of t

ozone layer.

Various types of solid-state NOx sensors have been dev

oped, as reviewed previously [135]. Sensors that incorpora

solid electrolytes can operate at high temperatures and are t

most promising sensors for monitoring NOx in high-temperatu

combustion exhausts or in the environment. A decade aft

that, solid-electrolyte-based sensors were developed [136]. Som

researchers fabricated screen-printed tin-doped indium oxi

(ITO) thin films on glass substrates to detect NOx gases [137]. T

transparent and conductive ITO thin films were obtained from

organometallic-based paste fired in an infrared furnace. Moreov

the specific morphology of the screen-printed ITO film (granu

and porous) was highly suitable for the development of stable a

efficient NOx gas sensors.

3.4.3. Volatile organic compounds

Volatile organic compounds (VOCs), which are numerou

varied, and ubiquitous, are organic chemicals with a hi

vapour pressure under ambient conditions. Many VOCs, inclu

ing formaldehyde, acetone, and methanol, are dangerous to hum

health or cause harm to the environment. VOCs are present in ne

furnishings, wall coverings, and office equipment such as phot

copy machines, which can off-gas VOCs into the air and result

long-term health problems.

A gas sensor based on WO3 thick films, which have good ele

trical and optical properties, exhibited excellent acetone vapo

sensing properties. The sensitivity of this sensor could reach abo

456% at 300 C with fast response and recovery times [138]. In add

tion, the conductivity of the carbon nanotubes (CNTs) has be

found to be sensitive to various gases, and CNT-based gas senso

42

M. Li et al. / Analytica Chimica Acta 734 (2012) 3144

Fig. 8. Schemes of (a) the structure of the screen printed edge band ultramicroelectrodes (SPUME) assembly with a built-in three-electrode configuration, (b) an SEM image

of Pt nanoparticles deposited on the surface of a carbon working electrode and (c) a representation of the electrode structure.

Reprinted with permission from Ref. [130].

2009 John Wiley and Sons.

have been reported [139,140]. Thus, a screen-printed nanocomposite film composed of MWCNTs and a silicon dioxide binder has

been reported to detect organic gases, including acetone, ethanol,

formaldehyde and methanol. The conductivity of the film decreases

when the film is exposed to organic gases. The existence of micropores in the composite provides channels for gas molecules to

absorb onto CNTs and increase the resistance of the CNT composite.

3.5. Bacteria

SPEs provide excellent platforms for the rapid detection of

bacteria to lower the risks of infection and prevent enteric diseases and economic losses. An indirect sandwich enzyme-linked

immunosensing strip was fabricated for the specific detection of

E. coli O157:H7 because of the use of double-specific antibodies

[141]. Another example of the selective detection of E. coli was

based on an impedimetric immunosensor developed using selfassembled monolayer-modified gold SPEs [142]. It was used for

the rapid analysis of E. coli in river and tap water samples without preconcentration steps. It is noteworthy that the SPEs involved

in these research efforts act primarily as functional components.

Thus, a screen-printed integrated microsystem for the detection of

pathogens was developed in which the SPEs served as both functional and structural components, which improved the simplicity

and ease of fabrication [143]. This research intends to be an outline

for a series of methodological procedures, immobilisation, lysis and

detection, integrated within a low-cost microsystem. In addition,

the study of bacteria species immobilised or adsorbed on electrode

surfaces is interesting for sensor applications. A simple method

with the application of a disposable SPE was used to study the

direct electron-transfer reaction at Shewanella sp. bacteria without the aid of a redox mediator [144]. The SPE was modified with

bacteria using an easy drop-coating procedure, which avoided the

laborious and time-consuming step of growing a bacterial biofilm

on the electrode.

3.6. Radioelements

Radioelements are radiologically and chemically toxic, and the

application of SPEs has contributed to the monitoring of trace

radioelements in the aquatic ecosystem. Dedicated efforts to monitor uranium (U) have been reported. Among these efforts, the

electroanalytical strategy appears to be one of the most promising

methods because of the low power requirement and the utility of

portable instrumentation. Recently, a 4-carboxyphenyl-grafted SPE

has been reported for sub-nanomolar U(VI) analysis using squarewave voltammetry [145]. This approach increased the electrode

selectivity, and Cd(II), Pb(II) and Zn(II) caused no significant interference. Another sensor for U(VI) detection in aqueous solutions

was based on electrochemically induced, non-modified SPEs, with

a detection limit of 4.5 nmol L1 [146].

4. Concluding remarks and future perspectives

Screen-printed electrodes provide a crucial analytical tool to satisfy the increasing demand for the rapid, sensitive and selective

determination of environmental pollutants. The SPEs can be easily

adapted to detect a wide range of analytes and are inexpensive. In

addition, they can be easily combined with other techniques to fit

particular applications.

In this review, we summarised the published novel designs

of SPEs and their application in environmental analysis over

the past 3 years. Two branches of SPE development are underway: devices with specificity and devices capable of simultaneous

determinations. Various materials used to modify the working system, including nanomaterials, enzymes, and noble metals, were

discussed. Moreover, the changeable format of SPEs and screenprinted electrode arrays can be applied for the simultaneous

detection of environmental pollutants. Certain hybrid techniques

based on SPEs are introduced herein for more sensitive and rapid

determinations.

Considerable selective and sensitive SPEs have already been

developed for environmental analysis, which provides a variety of

tools that may be utilised for in situ determinations. This review

may provide the appropriate background for the development of

novel analytical tools for the determination of environment pollutants. The field of SPEs, however, continues to grow and find

new areas of application. We believe that this field will focus

more on unique materials and multiple analytical methods over