Beruflich Dokumente

Kultur Dokumente

Results and Discussion Expt 4 Specific Heat

Hochgeladen von

cristina_punzalan_2Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Results and Discussion Expt 4 Specific Heat

Hochgeladen von

cristina_punzalan_2Copyright:

Verfügbare Formate

Results and Discussion

Mass of metal

132.60 g

Mass of calorimeter

35.30 g

Mass of calorimeter and water

199.70 g

Mass of water

164.40 g

Specific heat of calorimeter

0.215 cal/C

Initial temperature of the metal

81.7 C

Initial temperature of the water 6.0 C

and calorimeter

Final temperature of the system 11.5 C

Temperature change of the -70.2 C

metal

Temperature change of the 5.5 C

calorimeter and water

Heat gained by the water

904.2 cal

Heat gained by the calorimeter

41.74225 cal

Heat given up by the metal

-945.9425 cal

Specific heat of the metal 0.102 cal/gC

(experimental)

Specific heat of the metal 0.110 cal/gC

(standard)

Absolute error

0.008 cal/gC

Percentage error

7.27 %

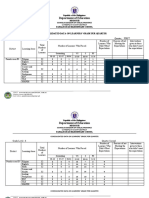

Table 1 below shows all the raw and computed

data recorded from the experiment.

Table 1. Raw and computed data of specific heat of

metals experiment

In this experiment, the masses of the metal, the

calorimeter, and water were first obtained by using the

triple beam balance. The mass of the water was

computed by subtracting the mass of the empty

calorimeter from the mass of the calorimeter and water.

The standard of the specific heat of aluminum is

0.215 cal/C. Given that the calorimeter used in the

experiment is made out of aluminium, hence, it can be

said that the calorimeter used has a specific heat of

0.215 cal/C as well.

After the empty calorimeter was filled with cold

water, its initial temperature was measured before

dropping the metal inside it. The initial temperature of

the metal was measured as well by placing the

thermometer inside the beaker while it was still on the

hot plate, making sure that the thermometer hits the

surface of the metal. On the other hand, the final

temperature of the system was obtained by measuring

the temperature of the metal as soon as it was placed

inside the calorimeter filled with cold water. It is now

called temperature of the system because the

temperature of the metal, water, and calorimeter is

being measured wherein it is assumed that the three

now have the same temperature as each other.

The change in the temperature of the metal was

calculated by subtracting its initial temperature from

the final temperature of the system. The change in

temperature of the calorimeter and water, on other

hand, was computed by subtracting its initial

temperature from the final temperature of the system.

To compute for the heat gained by the water, the

following formula was used :

Qwater = (mCT)water

Where:

m = mass of the water

C = specific heat of water

T = temperature change of calorimeter and water

By substituting the equation with the values

above, the heat gained by the water can be computed.

Qwater = (164.40g)(1cal/gC)(5.5C)

= 904.2 cal

The formula below was used to compute for the

heat gained by the calorimeter:

Qcalorimeter = (mCT)calorimeter

Where

m = mass of the calorimeter

C = specific heat of calorimeter

T = temperature change of calorimeter and water

The heat gained by the calorimeter was computed

as shown below:

Qcalorimeter =

(35.30g)(0.215cal/gC)(5.5C)

= 41.74225 cal

The heat given up by the metal can be expressed

as the negative value of the sum of the heat gained by

the water and the heat gained by the calorimeter, thus

giving us the equation, (Qwater + Qcalorimeter).

Hence, to compute for the heat given up by the

metal the following formula is used:

Q metal =(Q water + Q calorimeter )

Qmetal =(904.2 cal+ 41.7225 cal)

= 945.9425 cal

As soon as all the variables are obtained and the

heat given up by the metal, which is denoted by Qmetal,

is correctly computed, the experimental specific heat of

the metal can now be solved by using the formula

below.

Cmetal =

(Qwater +Qcalorimeter )

Q

Cmetal = metal

m T

mT

Wherein

error =

0.008 cal/gC

x 100

0.110 cal/ gC

error =7.27

Cmetal = Specific heat of the metal

Qmetal or (Qwater + Qcalorimeter) = Heat given up by the

metal

m = mass of the metal

T = change in temperature of the metal

The specific heat of the metal was computed as

shown below.

Cmetal =

945.9425 cal

=0.102 cal/ gC

( 132.60 g )(70.2 C )

This computation gives us the experimental

specific heat of the metal, which is to be compared to

the standard specific heat of the metal. It is necessary

to compare these two as it is critical in assessing

whether there were drastic, minimal, or no errors that

occurred or were involved in performing the

experiment. The comparison of these two quantities is

done by computing for the absolute error and the

percentage error.

The absolute error is computed by simply

subtracting the experimental specific heat of the metal

from the standard specific heat of the metal. The

percentage error, on the other hand, is the absolute

error divided by the standard value. Apparently, the

metal block that our group got was made out of steel.

Hence, we are to compare the value of our computed

experimental specific heat to the standard specific heat

of steel, which has the value 0.110 cal/gC.

The computation for absolute error is done as

follows:

Absolute error

= Standard specific heat of the metal Experimental

specific heat of the metal

= 0.110 cal/gC 0.102 cal/gC

Absolute error = 0.008 cal/gC

The percentage error was computed by using

the formula below.

error =

Absolute error

x 100

Standard value

Based on the computations done above, it can

be said that our percentage error, having the value of

7.27%, is considerably small as our lab instructor gave

us a percentage error range with 20% being the

maximum percentage error. 7.27% is definitely a

considerably small value compared to 20%.

Although our percentage error is considerably

small, having said that it is far from the maximum

percentage error which is 20%, it still seems to be a

little bit far from zero which indicates that we may

have made some errors during the execution of the

experiment. There may have been some systematic

errors upon performing the experiment which include

faulty calibration of measuring instruments such as the

triple beam balance, as it is poorly maintained. This

may have affected the measurements obtained by the

researchers. This may have made caused the

researchers to make some mistakes in measuring the

weight of the metal block, water, and calorimeter,

which definitely affects all computations involved in

obtaining the results. If the errors made were not

caused by defects in the instruments, it can be said that

the errors may have been due to the faulty reading of

instruments by the researchers. This includes parallax

error, which is caused by the user reading an

instrument at an angle, resulting in a reading which is

either too high or too low compared to the correct

value. Other errors may include random errors.

Common sources of random errors are problems in

estimating a quantity that lies between the graduations

of an instrument and the inability to read an instrument

because the reading fluctuates during the measurement.

The researchers encountered these problems in using

the thermometer. In measuring the temperature of the

metal while it was inside the beaker which was placed

on the hot plate, the readings were fluctuating, which

caused confusion in reading the measurement.

Moreover, some of the temperature measurements were

in between the graduations of the thermometer which

caused us to estimate some values. The errors stated

above may possibly be the reason why we obtained a

value of 7.27% in computing for our percentage error.

But overall, a 7.27% percentage error is not so bad.

The results we obtained were reasonably close to the

standard value.

Das könnte Ihnen auch gefallen

- Lab Experiment: Specific Heat of MetalDokument13 SeitenLab Experiment: Specific Heat of MetalHafiz Mohd Basir100% (2)

- Experiment No1 (Calibration of Thermometers)Dokument17 SeitenExperiment No1 (Calibration of Thermometers)justinndonn80% (5)

- Lab Report Heat of ReactionDokument8 SeitenLab Report Heat of ReactionLera May BenavidezNoch keine Bewertungen

- Gravimetry Analysis Lab ReportDokument9 SeitenGravimetry Analysis Lab ReportLolie SaidNoch keine Bewertungen

- Lab Report (Spectroscopy)Dokument6 SeitenLab Report (Spectroscopy)Levison Kasenga100% (2)

- Phy Chem Experiment 3Dokument20 SeitenPhy Chem Experiment 3eiddnew0% (1)

- Experiment 4 CombustionDokument8 SeitenExperiment 4 CombustionJof RomanNoch keine Bewertungen

- Expt2 Partially Miscible LiquidsDokument5 SeitenExpt2 Partially Miscible LiquidsJean Criste Cainila100% (3)

- Analytical Chemistry 1-Recitation 2Dokument18 SeitenAnalytical Chemistry 1-Recitation 2Gia HoàngNoch keine Bewertungen

- Experiment 3 Lab ReportDokument10 SeitenExperiment 3 Lab ReportVanessa Denise AguilarNoch keine Bewertungen

- Lab Report CHM674 Experiment 1 - Galvanic CellDokument12 SeitenLab Report CHM674 Experiment 1 - Galvanic CellWellonicaOlga0% (1)

- TD of Electrochemical Cells Lab ReportDokument6 SeitenTD of Electrochemical Cells Lab ReportDebalina Dass50% (2)

- Calorimetry LabReportDokument4 SeitenCalorimetry LabReportVinz GonzagaNoch keine Bewertungen

- Ideal Solutions Homework SolutionsDokument28 SeitenIdeal Solutions Homework SolutionsFiqa Success89% (9)

- Lab Report Phy 3Dokument4 SeitenLab Report Phy 3Eri SkcNoch keine Bewertungen

- The Vernier and Micrometer Calipers Physics Formal ReportDokument4 SeitenThe Vernier and Micrometer Calipers Physics Formal ReportJim Asenci100% (1)

- Chapter 1 Lab ReportDokument5 SeitenChapter 1 Lab ReportJabin Sta. TeresaNoch keine Bewertungen

- Lab Report Specific Heat PDFDokument5 SeitenLab Report Specific Heat PDFAhmad Shahir ShakriNoch keine Bewertungen

- Experimental Determination of The Gas ConstantDokument3 SeitenExperimental Determination of The Gas ConstantJaniel Arlan OmboyNoch keine Bewertungen

- Lab 3 - Newton's Law of CoolingDokument5 SeitenLab 3 - Newton's Law of Coolingbilly100% (4)

- Physics Lab Report 1.0 Vernier and Micrometer ScalesDokument5 SeitenPhysics Lab Report 1.0 Vernier and Micrometer ScalesIan Garcia100% (2)

- Experiment 2 Lab ReportDokument11 SeitenExperiment 2 Lab ReportVanessa Denise Aguilar50% (2)

- Determination of Iron With 1,10-PhenanthrolineDokument5 SeitenDetermination of Iron With 1,10-PhenanthrolineOmSilence26510% (1)

- Sample Lab ReportDokument3 SeitenSample Lab Reportmamazookeepr63% (8)

- Chem 20024 - Lab No. 6 GRP ReportDokument4 SeitenChem 20024 - Lab No. 6 GRP ReportOrangeIsLemonNoch keine Bewertungen

- The Preparation and Standardization of EdtaDokument5 SeitenThe Preparation and Standardization of Edtaapi-281104735Noch keine Bewertungen

- The Specific Heat of A Metal LabDokument3 SeitenThe Specific Heat of A Metal LabSelena Seay-ReynoldsNoch keine Bewertungen

- Experiment 4 Preparation of Standardized SolutionsDokument10 SeitenExperiment 4 Preparation of Standardized SolutionsJohn Dy100% (1)

- Module 1 - ElectrochemistryDokument31 SeitenModule 1 - ElectrochemistryjeniferNoch keine Bewertungen

- Laboratory Report #2 (Molar Mass of A Volatile Liquid)Dokument3 SeitenLaboratory Report #2 (Molar Mass of A Volatile Liquid)Immanuel De Los ReyesNoch keine Bewertungen

- Corrosion of Iron Experiment-StudentDokument6 SeitenCorrosion of Iron Experiment-StudentKunal Ramnatsing100% (1)

- My Final Report On Viscosity of A LiquidDokument8 SeitenMy Final Report On Viscosity of A LiquidKuo Sarong100% (1)

- Experiment 2 Topic: Heat of Combustion Objectives: 1. To Determine The Calorimeter Constant Using Benzoic AcidDokument9 SeitenExperiment 2 Topic: Heat of Combustion Objectives: 1. To Determine The Calorimeter Constant Using Benzoic AcidAliz FadzillahNoch keine Bewertungen

- Lab Report Level MeasurementDokument18 SeitenLab Report Level MeasurementNur Ainin SofiaNoch keine Bewertungen

- StoichDokument3 SeitenStoichMichael Robert Gatdula SamarNoch keine Bewertungen

- Experiment 8 Series and Parallel Circuits Physics LabDokument7 SeitenExperiment 8 Series and Parallel Circuits Physics LabGrace UrbanoNoch keine Bewertungen

- Experiment: Ultra Violet-Visible (Uv-Vis) Spectroscopy For Quantitative AnalysisDokument5 SeitenExperiment: Ultra Violet-Visible (Uv-Vis) Spectroscopy For Quantitative AnalysisAin SyuhadaNoch keine Bewertungen

- Lab Report Sample For Spiral Spring MassDokument20 SeitenLab Report Sample For Spiral Spring MassBEN100% (5)

- LAB 3 Radiation Heat TrasferDokument16 SeitenLAB 3 Radiation Heat TrasferMastura Ahmad Termizi89% (19)

- (FR) Photochemical Synthesis of Benzopinacol and Acid-Catalyzed Rearrangement Product BenzopinacoloneDokument3 Seiten(FR) Photochemical Synthesis of Benzopinacol and Acid-Catalyzed Rearrangement Product Benzopinacoloneyugimotuo100% (2)

- Experiment 1 - Use of The Analytical BalanceDokument11 SeitenExperiment 1 - Use of The Analytical BalanceJoemer Absalon Adorna100% (1)

- Thin Layer Chromatography and Column Chromatography Results and DiscussionDokument2 SeitenThin Layer Chromatography and Column Chromatography Results and DiscussionJennifer Heredia67% (3)

- Title:Determination of The Equilibrium Constant For The Formation of Tri-Iodide IonDokument6 SeitenTitle:Determination of The Equilibrium Constant For The Formation of Tri-Iodide IonKojo Eghan100% (5)

- Chem. 14.1 - Expt. 9 Chem Lab Report - Chemical EquilibriumDokument3 SeitenChem. 14.1 - Expt. 9 Chem Lab Report - Chemical EquilibriumRomi Necq S. Abuel40% (5)

- Experiment 5: Simple Distillation ObjectiveDokument7 SeitenExperiment 5: Simple Distillation Objectiveshark eye67% (3)

- Want Chemistry Games, Drills, Tests and More? You Need To Become An !Dokument18 SeitenWant Chemistry Games, Drills, Tests and More? You Need To Become An !Liezl ValienteNoch keine Bewertungen

- Experiment 2: Vector AdditionDokument5 SeitenExperiment 2: Vector AdditionLina Lou BerdijoNoch keine Bewertungen

- SKU 3023 Lab Report 4 - Galvanic CellDokument9 SeitenSKU 3023 Lab Report 4 - Galvanic CellAbdulRahim059100% (24)

- Experiment 2: G From Simple PendulumDokument15 SeitenExperiment 2: G From Simple Pendulumsyaf100% (1)

- Experiment 1 Determination of Enthalpy of Reactions FinalDokument10 SeitenExperiment 1 Determination of Enthalpy of Reactions Finalcreate foxesNoch keine Bewertungen

- In A Quality Control TestDokument5 SeitenIn A Quality Control TestHarry Frianota IDNoch keine Bewertungen

- Chapter 04 The Second Law of Thermodynamics (PP 82-99)Dokument18 SeitenChapter 04 The Second Law of Thermodynamics (PP 82-99)Muhammad Ashfaq Ahmed71% (7)

- Flame Test PracDokument2 SeitenFlame Test PracJimBeanz75% (12)

- Discussion Uv VisDokument4 SeitenDiscussion Uv VisFatin ArisyaNoch keine Bewertungen

- Lab ReportDokument7 SeitenLab ReportAristotle LeventidisNoch keine Bewertungen

- Experiment 2 Calorimetry and Specific HeatDokument8 SeitenExperiment 2 Calorimetry and Specific HeatGodfrey SitholeNoch keine Bewertungen

- CH 10 Lab WriteupDokument3 SeitenCH 10 Lab Writeupmickmuffinx100% (1)

- Thermodynamic Lab 7 (Group7) (Formal)Dokument11 SeitenThermodynamic Lab 7 (Group7) (Formal)Remmey KiraNoch keine Bewertungen

- 1 Energy-12Dokument4 Seiten1 Energy-12Mae TadaNoch keine Bewertungen

- Sheet-Metal Forming Processes: Group 9 PresentationDokument90 SeitenSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyNoch keine Bewertungen

- Week 3 Lab Arado, Patrick James M.Dokument2 SeitenWeek 3 Lab Arado, Patrick James M.Jeffry AradoNoch keine Bewertungen

- A Project Report ON Strategic Purchasing Procedure, Systems and Policies (Hospital Industry)Dokument20 SeitenA Project Report ON Strategic Purchasing Procedure, Systems and Policies (Hospital Industry)amitwin1983Noch keine Bewertungen

- IPA Smith Osborne21632Dokument28 SeitenIPA Smith Osborne21632johnrobertbilo.bertilloNoch keine Bewertungen

- Life and Works of Jose Rizal Modified ModuleDokument96 SeitenLife and Works of Jose Rizal Modified ModuleRamos, Queencie R.Noch keine Bewertungen

- Approvals Management Responsibilities and Setups in AME.B PDFDokument20 SeitenApprovals Management Responsibilities and Setups in AME.B PDFAli LoganNoch keine Bewertungen

- Inverter 2 chiềuDokument2 SeitenInverter 2 chiềuKhánh Nguyễn MinhNoch keine Bewertungen

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDokument4 SeitenDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaNoch keine Bewertungen

- str-w6754 Ds enDokument8 Seitenstr-w6754 Ds enAdah BumbonNoch keine Bewertungen

- English For Academic and Professional Purposes - ExamDokument3 SeitenEnglish For Academic and Professional Purposes - ExamEddie Padilla LugoNoch keine Bewertungen

- BECED S4 Motivational Techniques PDFDokument11 SeitenBECED S4 Motivational Techniques PDFAmeil OrindayNoch keine Bewertungen

- Hyundai SL760Dokument203 SeitenHyundai SL760Anonymous yjK3peI7100% (3)

- English Test For Grade 7 (Term 2)Dokument6 SeitenEnglish Test For Grade 7 (Term 2)UyenPhuonggNoch keine Bewertungen

- 53 English Work Book XDokument292 Seiten53 English Work Book XArun DhawanNoch keine Bewertungen

- FIR FliterDokument10 SeitenFIR FliterasfsfsafsafasNoch keine Bewertungen

- Meta100 AP Brochure WebDokument15 SeitenMeta100 AP Brochure WebFirman RamdhaniNoch keine Bewertungen

- Đề Tuyển Sinh Lớp 10 Môn Tiếng AnhDokument11 SeitenĐề Tuyển Sinh Lớp 10 Môn Tiếng AnhTrangNoch keine Bewertungen

- .CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADODokument782 Seiten.CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADOMarcelo JesusNoch keine Bewertungen

- Principled Instructions Are All You Need For Questioning LLaMA-1/2, GPT-3.5/4Dokument24 SeitenPrincipled Instructions Are All You Need For Questioning LLaMA-1/2, GPT-3.5/4Jeremias GordonNoch keine Bewertungen

- National Interest Waiver Software EngineerDokument15 SeitenNational Interest Waiver Software EngineerFaha JavedNoch keine Bewertungen

- Title: Smart Monitoring & Control of Electrical Distribution System Using IOTDokument27 SeitenTitle: Smart Monitoring & Control of Electrical Distribution System Using IOTwaleed HaroonNoch keine Bewertungen

- Pearson R CorrelationDokument2 SeitenPearson R CorrelationAira VillarinNoch keine Bewertungen

- Aristotle - OCR - AS Revision NotesDokument3 SeitenAristotle - OCR - AS Revision NotesAmelia Dovelle0% (1)

- Community Profile and Baseline DataDokument7 SeitenCommunity Profile and Baseline DataEJ RaveloNoch keine Bewertungen

- G.Devendiran: Career ObjectiveDokument2 SeitenG.Devendiran: Career ObjectiveSadha SivamNoch keine Bewertungen

- Internal Resistance To Corrosion in SHS - To Go On WebsiteDokument48 SeitenInternal Resistance To Corrosion in SHS - To Go On WebsitetheodorebayuNoch keine Bewertungen

- MATM1534 Main Exam 2022 PDFDokument7 SeitenMATM1534 Main Exam 2022 PDFGiftNoch keine Bewertungen

- Building Material Supplier in GurgaonDokument12 SeitenBuilding Material Supplier in GurgaonRodidustNoch keine Bewertungen

- CE EVALUATION EXAM No. 4 - MGT, Fluid Properties, Hydrostatic Force (Answer Key)Dokument6 SeitenCE EVALUATION EXAM No. 4 - MGT, Fluid Properties, Hydrostatic Force (Answer Key)Angelice Alliah De la CruzNoch keine Bewertungen

- Halloween EssayDokument2 SeitenHalloween EssayJonathan LamNoch keine Bewertungen