Beruflich Dokumente

Kultur Dokumente

ME2134

Hochgeladen von

benOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ME2134

Hochgeladen von

benCopyright:

Verfügbare Formate

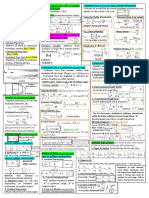

ME2134-2

Darcy-Weisbach Eqn; LOSS in

straight pipe cos of friction

-Using V (average) = Q/A

Analysis of Pipe Flow

Assumptions:

Applies to homogeneous

fluid of constant viscosity

and density; & gases

provided

density

changes are small

Red DETERMINES TYPE

OF FLOW, INTEGRAL

STEP

Laminar Pipe Flow

-Motion

of

fluid

in

layers//to

boundary

surface (Red<2300)

Transitional Pipe Flow

- (Red~2300)

Turbulent

Pipe

Flow

(Red>>2300)

-Random, irregular &

unsteady motion of fluid

particles

-Using energy eqn & momentum eqn

(prev. chapter)

LAMINAR

Flow

in

Circular

Pipe

[SMOOTH/ROUGH]

-Velocity of a real fluid at a fixed boundary is

always zero to satisfy no-slip condn. r=R, u=0.

Velocity Profile (Parabolic)

Drop (+ve value)

Laminar:

Turbulent/V:

(Hagen-Poiseuille Flow)

hf =

Valid for duct flow of

section

&

ANY x-

Laminar:

Turbulent:

Umax (max velocity)

Stress

= 2V (average velocity)

Head Loss, h (Darcy)

Factor, f (Red<2300)

TURBULENT Flow in SMOOTH

Circular Pipe

- Turbulent flow has random eddies

that

dissipate

KE

into

heat.

(Dragturbulent > Draglaminar)

- Turbulent flow (3 regions) is

affected by surface roughness unlike

laminar.

- Wall Layer, Outer Layer &

Overlap Layer

- Friction velocity =

=y

& (R-r)

; f from

eddy losses

with

Minor loss

[Velocity Profile:]

2. Hydraulically Rough Walls:

- protrude into main flow

3. Transitional Roughness:

- Some submerged some protrude

[Velocity Profile:]

B-

Max Velocity, Umax

explaning

TURBULENT Flow in ROUGH Circular

Pipe

- EDDIES can form in rough+turb since

protrusions

*Extent of submersion of roughness

elements into laminar sublayer of

turbulent boundary layer

1. Hydraulically Smooth Walls:

- turbulent flow similar to in smooth pipe

B from

Average Velocity, V:

MINOR LOSSES

graph

*as

Re

increases,

turbulent

sublayer dominates while laminar

sublayer increasingly thins

(hydraulically

smooth

to

rough

transition)

Moody Diagram (Friction Factor)

flaminar=64/Red (Red<2300) ; fsmooth pipe

hydrau smooth

Loss

coeff, K

Loss

in

sudden

Friction

in

expansion:

noncircular pipes

- Replace diameters; d or

D

with

hydraulic

1.

Exit Loss:

diameter,

DH k=1; tank is

big, A2 is v big compared

Loss

in

sudden

contraction:

Frictional

Loss

&

(ge

Factor

neral)

(aft

er venaC)

Not so accurate for laminar flow since V is

not a good approximation of velocity profile

Ac is area of vena contracta;

Cc=Ac/A2,

Friction

[Velocity Profile:]

Velocity Profile:

Darby

Shear

both

Entrance Length: distance

from entrance of pipe flow

travels before fully developed

[Le]

Pressure

(Independent of

Red)

or

Multiple Pipe System [for head

losses, take darcy & minor losses in

each pipe [all networks]

1. Pipes in Series: Q=Q1=Q2=Q3;

MINOR

LOSSES

HL=HL1+HL2+H

L3

explaning eddy losses

Loss

in

sudden

contraction:

2. Gradual Expansion

- KL includes frictional

loss

- >60o, sudden expansion

better

2. Pipes in //:

- Q=Q1+Q2+Q3; HL=HL1=HL2=HL3 (unless got pump

Q1=Q2=Q3)

3. Branching Pipes:

Generally, Head/

energy at a point

3.

Losses

in

Bends =

- if R/d=0, K~1.1

K

includes

Regardless

of

pipe

network, must satisfy:

Continuity,

only

one

energy

(Q&H&Hloss

=HL) level (head) at

given point & friction eqn

must be satisfied for

each pipe. (Diff in head =

Das könnte Ihnen auch gefallen

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterVon EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNoch keine Bewertungen

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedVon EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNoch keine Bewertungen

- Me2134 PDFDokument1 SeiteMe2134 PDFbenNoch keine Bewertungen

- ME2134cheatsheet PDFDokument1 SeiteME2134cheatsheet PDFbenNoch keine Bewertungen

- Hydraulics - Chapter 3Dokument8 SeitenHydraulics - Chapter 3thuaiyaalhinaiNoch keine Bewertungen

- Pipe FlowDokument10 SeitenPipe Flowproghosh7Noch keine Bewertungen

- Friction Losses in A Series of PipesDokument19 SeitenFriction Losses in A Series of PipesJohn Paul CordovaNoch keine Bewertungen

- Steady Conduit FlowDokument13 SeitenSteady Conduit FlowEyuelAdamNoch keine Bewertungen

- Flow in Pipes Faculty - Washington.eduDokument18 SeitenFlow in Pipes Faculty - Washington.eduils411Noch keine Bewertungen

- Air-Condtioning: Course No. ME40107Dokument34 SeitenAir-Condtioning: Course No. ME40107bhalchandrapatilNoch keine Bewertungen

- Jayam College of Engineering & Technology Fluid Mechanics & Machinery Me1202Dokument17 SeitenJayam College of Engineering & Technology Fluid Mechanics & Machinery Me1202Muthuvel MNoch keine Bewertungen

- Chapter 8 Turbulent Flow in Circular PipesDokument29 SeitenChapter 8 Turbulent Flow in Circular PipesSiti Nurshahira100% (1)

- Chapter 9 Flow in Open ChannelDokument28 SeitenChapter 9 Flow in Open ChannelolescootNoch keine Bewertungen

- Fluid MechanicsDokument52 SeitenFluid Mechanicsmanneli talpagiriNoch keine Bewertungen

- FM Minor Losses 1Dokument14 SeitenFM Minor Losses 1mahesh100% (1)

- Unit-6 Flow Through PipesDokument54 SeitenUnit-6 Flow Through PipesS PrathebaNoch keine Bewertungen

- Module 3-Part3-FM&FMC - Pipe FlowDokument42 SeitenModule 3-Part3-FM&FMC - Pipe FlowASHITA K BNoch keine Bewertungen

- 48 - 25795 - ME362 - 2020 - 1 - 2 - 1 - Lecture 11 - Fluid 1 - Flow Through Pipes - Part IDokument20 Seiten48 - 25795 - ME362 - 2020 - 1 - 2 - 1 - Lecture 11 - Fluid 1 - Flow Through Pipes - Part IHussien El-masryNoch keine Bewertungen

- FMHM Unit-Iii Part 2 Class NotesDokument73 SeitenFMHM Unit-Iii Part 2 Class Notes203C310 ChandanNoch keine Bewertungen

- EAT259 Chapter 1 IntroductionDokument34 SeitenEAT259 Chapter 1 IntroductionAbdullahi Dirie AbdiNoch keine Bewertungen

- Major & Minor Energy LossDokument5 SeitenMajor & Minor Energy LossHaris jugnoo0% (1)

- Chapter 8-Flow in Pipes02Dokument76 SeitenChapter 8-Flow in Pipes02Emmanuel Gómez Losada100% (1)

- Guide 1 (19.10.2022)Dokument5 SeitenGuide 1 (19.10.2022)Iyad AboissaNoch keine Bewertungen

- Flow of Incompressible Fluids Through PipesDokument28 SeitenFlow of Incompressible Fluids Through PipesN Khadija BathoolNoch keine Bewertungen

- Fluid Mechanics: Handout Lectures For Year Two Chapter Five/ Flow I N PipesDokument11 SeitenFluid Mechanics: Handout Lectures For Year Two Chapter Five/ Flow I N PipesEggrollmanNoch keine Bewertungen

- Chapter 4Dokument106 SeitenChapter 4lockas222Noch keine Bewertungen

- Open Channel Flows - Fluid MechanicsDokument47 SeitenOpen Channel Flows - Fluid Mechanicsnaeema_58Noch keine Bewertungen

- Chapt4 Edited RBMDokument130 SeitenChapt4 Edited RBMIfa IsmailNoch keine Bewertungen

- Experiment 1 - Friction Losses in Pipes-ReportDokument41 SeitenExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram68% (53)

- Lect#2 Pipes Flow-1Dokument31 SeitenLect#2 Pipes Flow-1Kamran AliNoch keine Bewertungen

- CH 3 2020Dokument62 SeitenCH 3 2020Emmanuel LazoNoch keine Bewertungen

- Fluid Mechanics Unit - 6Dokument15 SeitenFluid Mechanics Unit - 6Prem T RajuNoch keine Bewertungen

- Pipe Flow: Major and Minor Losses: Puja Upadhyay Florida Center For Advanced Aero - PropulsionDokument35 SeitenPipe Flow: Major and Minor Losses: Puja Upadhyay Florida Center For Advanced Aero - PropulsionJohn Ceasar PascoNoch keine Bewertungen

- Internal Flows (Pipe Flow) Internal Flows (Pipe Flow)Dokument58 SeitenInternal Flows (Pipe Flow) Internal Flows (Pipe Flow)Theødřøš ÄbNoch keine Bewertungen

- Flow Through PipesDokument31 SeitenFlow Through PipesShyam Pandey50% (2)

- T 2Dokument31 SeitenT 2Vinay Gupta100% (1)

- Gradually Varied FlowDokument47 SeitenGradually Varied FlowGonzalo ÁlvarezNoch keine Bewertungen

- Cve341lecturenotes1 220921133246 9aa9c294Dokument61 SeitenCve341lecturenotes1 220921133246 9aa9c294Krishna P. YadavNoch keine Bewertungen

- Topic 4c Minor Losses Turbulent Flow in Circular Pipes 2021Dokument23 SeitenTopic 4c Minor Losses Turbulent Flow in Circular Pipes 2021Nor SyamimiNoch keine Bewertungen

- Lec 1 Pipe Flow UpdatedDokument45 SeitenLec 1 Pipe Flow Updatedrajpoot aliNoch keine Bewertungen

- Open Channel FlowDokument75 SeitenOpen Channel FlowPrince VinceNoch keine Bewertungen

- Experiment On Friction in PipesDokument15 SeitenExperiment On Friction in PipesVijay ShetNoch keine Bewertungen

- Internal FlowDokument41 SeitenInternal FlowTusanita MapuolaNoch keine Bewertungen

- Fluid Mechanics and Pressure DropDokument48 SeitenFluid Mechanics and Pressure DroppraSHANT2331Noch keine Bewertungen

- Pipe Flow - Upadhyay 2017Dokument35 SeitenPipe Flow - Upadhyay 2017John Ceasar PascoNoch keine Bewertungen

- FALLSEM2018-19 - MEE1004 - ETH - MB309 - VL2018191003741 - Reference Material I - Fluid Mechanics-3 PDFDokument69 SeitenFALLSEM2018-19 - MEE1004 - ETH - MB309 - VL2018191003741 - Reference Material I - Fluid Mechanics-3 PDFSivaram PeramNoch keine Bewertungen

- Chapter 08 - Flow in PipesDokument92 SeitenChapter 08 - Flow in Pipessalkan_rahmanovic810100% (1)

- Experiment 1 - Friction Losses in Pipes-ReportDokument41 SeitenExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram67% (3)

- SCIA1402Dokument74 SeitenSCIA1402godofdevil434Noch keine Bewertungen

- Minor Losses in PipesDokument9 SeitenMinor Losses in PipesRam Krishna Singh60% (5)

- Flow in Conduits: Fluid Mechanics, Spring Term 2009Dokument44 SeitenFlow in Conduits: Fluid Mechanics, Spring Term 2009Remoremo RemoNoch keine Bewertungen

- WK - 13Dokument26 SeitenWK - 13shanza678Noch keine Bewertungen

- Jooned Hendrarsakti, PH.D, IPM: Internal FlowDokument26 SeitenJooned Hendrarsakti, PH.D, IPM: Internal FlowLativa Putry AFiznaNoch keine Bewertungen

- I. Oe4625 Chapter06 PDFDokument20 SeitenI. Oe4625 Chapter06 PDFAnonymous K3FaYFlNoch keine Bewertungen

- Internal Flow: Hasan HacişevkiDokument103 SeitenInternal Flow: Hasan HacişevkiMukaram AliNoch keine Bewertungen

- Hydraulics II Unit 3Dokument62 SeitenHydraulics II Unit 3Eyob Light WorkuNoch keine Bewertungen

- Open Channel Head Loss: H L C Q HDokument51 SeitenOpen Channel Head Loss: H L C Q HKolos Char YiuNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen