Beruflich Dokumente

Kultur Dokumente

Eaton Overcenter Valve 1CPBD300 - PCT - 274201

Hochgeladen von

snsnagarajanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Eaton Overcenter Valve 1CPBD300 - PCT - 274201

Hochgeladen von

snsnagarajanCopyright:

Verfügbare Formate

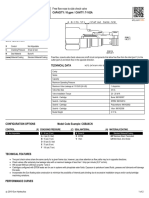

1CPBD300 - Overcenter Valve

Zero differential with check

300 L/min (80 USgpm) 400 bar (5800 psi)

Operation

Sectional View

Features

The check section allows free

flow into the actuator then

holds and locks the load against

movement. By the application

of pilot pressure to the pilot port

the poppet moves back against

the main spring opening the

cylinder port to the valve port.

The metering characteristic of

the valve is controlled by the rate

The cartridge fits a simple cavity

allowing quick, easy field service

reducing down time. Hardened

poppet and seat provide for long

leak free performance..

of the spring, the seat angle and

the pilot pressure applied.

Due to the balanced poppet

design load induced pressure

will not open the valve and once

open valve port pressure will

not increase the pilot pressure

required to keep the valve open.

Performance Data

Ratings and Specifications

Drain (4)

Pilot (3)

Valve (2)

Cyl (1)

300 L/min (80 USgpm)

400 bar (5800 psi)

Working parts hardened and ground steel.

External surfaces zinc plated.

Unrestricted

A13098 (See Section M)

150 Nm (110 lbs ft)

0.91 kg (2.00 lbs)

SK971

(Nitrile)

SK971V

(Viton)

SK971P (Polyurethane/Nitrile)

BS5540/4 Class 18/13 (25 micron nominal)

-30 to +90C (-22 to +194F)

4 milliliters/min nominal (60 dpm)

5 bar

Viton is a registered trademark of E.I. DuPont

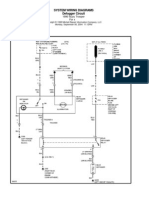

Pressure Drop

Zero differential overcenter

valves give static and dynamic

control of loads by supplying

a restriction to flow related

to the opening of the valve

created by the pilot pressure.

The valve is used in

conjunction with a remote

pilot source to provide hose

failure protection, load control

and load holding functions.

If over-pressure or shock

pressure protection is required

then a separate relief valve

should be used.

The drain line allows the

valve to be used in corrosive

atmospheres preventing

the ingress of atmospheric

contaminant.

352

308

264

220

176

132

88

44

0

50

Flow - L/min

100 150 200 250 300 350 400

Free flow

Pilot open

0

25

50

Flow - US gpm

75

100

24

21

18

15

12

9

6

3

0

Pressure - bar

Description

Pressure - psi

Figures based on: Oil Temp = 40C Viscosity = 32 cSt (150 SUS)

Rated flow

Max working pressure

Cartridge material

Mounting position

Cavity

Torque cartridge into cavity

Weight cartridge only

Seal kit

Filtration

Temperature range

Internal leakage

Nominal viscosity range

5 to 500 cSt

Bar per turn

Where measurements are critical request certified drawings. We reserve the right to change specifications without notice.

F-340.A

EATON Screw-In Cartridge Valves E-VLSC-MC001-E December 2009

An Eaton Brand

1CPBD300 - Overcenter Valve

Zero differential with check

300 L/min (80 USgpm) 400 bar (5800 psi)

Model Code

1CPBD300

Function

1CEBD300 - Cartridge only

Adjustment

F - Screw adjustment

Pilot Adjust Range

Note: Code based on pressure

in bar.

2 - 5-20 bar. Std setting 10 bar

Std setting made at 4.8 L/min

4 Seal Material

S - Nitrile (For use with

most industrial

hydraulic oils)

SV - Viton (For high

temperature and most

special fluid applications)

P - Polyurethane/Nitrile

(For arduous applications)

Dimensions

mm (inch)

Cartridge Only

Basic Code

1CPBD300

F

Hex Socket Adjust

6.0 A/F

22.0 A/F

63.0

(2.48)

MAX

46.0 A/F

Drain (4)

1-5/8-12 UN-2A

Pilot (3)

75.5

(2.97)

Valve (2)

Cyl (1)

Note: Tightening torque

of F adjuster locknut 20 to 25 Nm.

Where measurements are critical request certified drawings. We reserve the right to change specifications without notice.

An Eaton Brand

EATON Screw-In Cartridge Valves E-VLSC-MC001-E December 2009

F-341.A

Das könnte Ihnen auch gefallen

- Grove TMS540Dokument24 SeitenGrove TMS540soporte tecnicoNoch keine Bewertungen

- Technical Data SheetDokument10 SeitenTechnical Data SheetErvinMayorcaPizarroNoch keine Bewertungen

- POWER STEERING Ø58. 0,96 MMDokument70 SeitenPOWER STEERING Ø58. 0,96 MMDavid AltarribaNoch keine Bewertungen

- SCOUT 700: Technical DescriptionDokument4 SeitenSCOUT 700: Technical DescriptionGerko Berrios GarcíaNoch keine Bewertungen

- Kenwood SW301 501 MANUALDokument8 SeitenKenwood SW301 501 MANUALjb68Noch keine Bewertungen

- Aspire Music Group v. Cash Money RecordsDokument8 SeitenAspire Music Group v. Cash Money RecordsPitchfork News100% (1)

- SP en Esquema Hidraulico 1Dokument21 SeitenSP en Esquema Hidraulico 1SANTANDER GARCIANoch keine Bewertungen

- Atlas Copco Blasthole Drills Dm45-SeriesDokument4 SeitenAtlas Copco Blasthole Drills Dm45-SeriesfelipeNoch keine Bewertungen

- MONTABERT HC112 Tech Spec 1 PDFDokument1 SeiteMONTABERT HC112 Tech Spec 1 PDFSaid TouhamiNoch keine Bewertungen

- Drilling Solutions Brochure PDFDokument5 SeitenDrilling Solutions Brochure PDFEstyNoch keine Bewertungen

- PERFORADORA ConversionMontabertDokument15 SeitenPERFORADORA ConversionMontabertmarcos abalNoch keine Bewertungen

- Immay 2007 CDokument9 SeitenImmay 2007 CMarkusMakuAldoNoch keine Bewertungen

- Roc 442PCDokument5 SeitenRoc 442PCluizpmrNoch keine Bewertungen

- LF 700 Cylinder Rope FeedDokument2 SeitenLF 700 Cylinder Rope FeedMax RojasNoch keine Bewertungen

- Spare Parts List: Hydraulic BreakersDokument40 SeitenSpare Parts List: Hydraulic BreakersomertiryakimakineNoch keine Bewertungen

- Atlas Copco Drilling Solutions: Part List Model: Dm50/Lp S/N: US009240Dokument790 SeitenAtlas Copco Drilling Solutions: Part List Model: Dm50/Lp S/N: US009240Nasrul arul100% (1)

- UGM GET V1.0xDokument13 SeitenUGM GET V1.0xGustavo Fierro MendozaNoch keine Bewertungen

- Technical Specification Simba w6 C - 9851 2635 01 - tcm835-1537599Dokument4 SeitenTechnical Specification Simba w6 C - 9851 2635 01 - tcm835-1537599Cecitafex2014Noch keine Bewertungen

- Proportional Valve Group PVG 32Dokument76 SeitenProportional Valve Group PVG 32Nippur de LagashNoch keine Bewertungen

- Impact valve block sections and functionsDokument11 SeitenImpact valve block sections and functionsApeksNoch keine Bewertungen

- EN NM TD 50HzDokument72 SeitenEN NM TD 50Hzlee marvin BilongNoch keine Bewertungen

- Manual de Ensamble 1200-6Dokument224 SeitenManual de Ensamble 1200-6RonyRafaelAgamezMoreno100% (1)

- Ranger 6802 Technical SpecificationDokument3 SeitenRanger 6802 Technical Specificationnaruto04042014Noch keine Bewertungen

- ST7 Battery - Technical SpecificationDokument8 SeitenST7 Battery - Technical SpecificationpowermanagerNoch keine Bewertungen

- 3344 f2440Dokument4 Seiten3344 f2440Darwin AjomadoNoch keine Bewertungen

- Espec DL310 PDFDokument4 SeitenEspec DL310 PDFFranklin LabbeNoch keine Bewertungen

- HKS (M-Da-H-F10 200 360º) Manual de PartesDokument17 SeitenHKS (M-Da-H-F10 200 360º) Manual de Partescesar franz napaico perezNoch keine Bewertungen

- GMK 5175Dokument21 SeitenGMK 5175cornel_lupu100% (1)

- Planos Hidraulicos Troidon 66 - jmc-516Dokument12 SeitenPlanos Hidraulicos Troidon 66 - jmc-516Maria Isabel Alzate RamirezNoch keine Bewertungen

- Cat. HY15-3502CPCDokument56 SeitenCat. HY15-3502CPCMaximiliano Dreyer100% (1)

- 9852 0918 01a Setting COP 1238ME 07 Bench DrillingDokument1 Seite9852 0918 01a Setting COP 1238ME 07 Bench DrillingJehuty88Noch keine Bewertungen

- RCS4 Test Manual 2658453227 - 012Dokument146 SeitenRCS4 Test Manual 2658453227 - 012Edson Rodriguez100% (1)

- 03 Simbas Rango-EpirocDokument108 Seiten03 Simbas Rango-Epiroccristian nahuelcuraNoch keine Bewertungen

- CT20 Performace Specifications - v0.1Dokument2 SeitenCT20 Performace Specifications - v0.1gustavo caicedoNoch keine Bewertungen

- ScopTramp 1030Dokument89 SeitenScopTramp 1030Nelson GonzalezNoch keine Bewertungen

- Relief Cartridge ValvesDokument16 SeitenRelief Cartridge Valvesvivek_11111987Noch keine Bewertungen

- R954 Crawler Excavator Offers Powerful Digging & DemolitionDokument12 SeitenR954 Crawler Excavator Offers Powerful Digging & Demolitionequipment9278Noch keine Bewertungen

- Spec ST2D 9851 2251 01f - tcm795-1539250 PDFDokument4 SeitenSpec ST2D 9851 2251 01f - tcm795-1539250 PDFRizky AsharyNoch keine Bewertungen

- ProductBrochure A35F A40F en 30A1006561Dokument24 SeitenProductBrochure A35F A40F en 30A1006561Ji UvexNoch keine Bewertungen

- DD 311 DS 311 DL 311: SandvikDokument1 SeiteDD 311 DS 311 DL 311: SandvikBernabe Ruben Alayo RamosNoch keine Bewertungen

- Senr1343senr1343 01 SisDokument2 SeitenSenr1343senr1343 01 SisJaime Ventura ZenaNoch keine Bewertungen

- Vane Motor M5a m5b UkDokument16 SeitenVane Motor M5a m5b UkUtku KepcenNoch keine Bewertungen

- Insumbi Montabert CPADokument4 SeitenInsumbi Montabert CPAMoodNoch keine Bewertungen

- 13.atlas Copco ROCKET BOOMER E1-E2 SerijaDokument8 Seiten13.atlas Copco ROCKET BOOMER E1-E2 Serijaadamajaks1985Noch keine Bewertungen

- 6Dokument6 Seiten6juan carlos zavalaNoch keine Bewertungen

- Tiempo Geologico PDFDokument2 SeitenTiempo Geologico PDFRoy SupaNoch keine Bewertungen

- Mine TruckDokument2 SeitenMine TruckyesNoch keine Bewertungen

- Pve27 2 ParteDokument4 SeitenPve27 2 ParteEdgar Rojas EspejoNoch keine Bewertungen

- Product Range Overview RexrothDokument21 SeitenProduct Range Overview RexrothEustahije BrzicNoch keine Bewertungen

- Item - List - View (2) 52Dokument631 SeitenItem - List - View (2) 52dbbony 00990% (1)

- Drive and control systems for excavatorsDokument16 SeitenDrive and control systems for excavatorsEdwin Uceda AlvaNoch keine Bewertungen

- 08 ST1030 Dump and Hoist - enDokument25 Seiten08 ST1030 Dump and Hoist - enGerardo HuertaNoch keine Bewertungen

- ELITE40 Parts Manual 1007Dokument15 SeitenELITE40 Parts Manual 1007Edgar Castañeda100% (1)

- Toro50 SpecDokument3 SeitenToro50 SpecAli Narváez quispeNoch keine Bewertungen

- MT 5020/6020 TRAINING: Brake SystemDokument48 SeitenMT 5020/6020 TRAINING: Brake SystemFrancisco RojasNoch keine Bewertungen

- Series Check Valve: Check, Manually Operated 5.5-15 L/Min (1.5-4 Usgpm) - 210 Bar (3000 Psi)Dokument2 SeitenSeries Check Valve: Check, Manually Operated 5.5-15 L/Min (1.5-4 Usgpm) - 210 Bar (3000 Psi)Daniel CringusNoch keine Bewertungen

- Valv Y AscoDokument12 SeitenValv Y Ascojoticamario123Noch keine Bewertungen

- Bomba Rexroth A4SGCDokument32 SeitenBomba Rexroth A4SGCEdgarRetuertoNoch keine Bewertungen

- High Pressure Filters for Hydraulic ApplicationsDokument12 SeitenHigh Pressure Filters for Hydraulic ApplicationsIgor Alberto MarkovNoch keine Bewertungen

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- PBVP 10 - 520 P 061120 enDokument2 SeitenPBVP 10 - 520 P 061120 ensnsnagarajanNoch keine Bewertungen

- Dkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpenDokument2 SeitenDkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpensnsnagarajanNoch keine Bewertungen

- Free-flow nose-to-side check valve technical detailsDokument2 SeitenFree-flow nose-to-side check valve technical detailssnsnagarajanNoch keine Bewertungen

- Proportional Pressure Reducing Valve, Direct Operated, Increasing Characteristic Curve FTDRE 2 KDokument12 SeitenProportional Pressure Reducing Valve, Direct Operated, Increasing Characteristic Curve FTDRE 2 KsnsnagarajanNoch keine Bewertungen

- Model CSZN Series Z Shuttle Valve 4 L/min Technical DataDokument2 SeitenModel CSZN Series Z Shuttle Valve 4 L/min Technical DatasnsnagarajanNoch keine Bewertungen

- Hydraulic Excavator: - 5G - 5G - 5G - 5G - 5G - 5GDokument15 SeitenHydraulic Excavator: - 5G - 5G - 5G - 5G - 5G - 5GDt NamdinhNoch keine Bewertungen

- Adding Prefix in Excel CellDokument1 SeiteAdding Prefix in Excel CellsnsnagarajanNoch keine Bewertungen

- Hydraulic Oil RENOLIN CLP enDokument11 SeitenHydraulic Oil RENOLIN CLP ensnsnagarajanNoch keine Bewertungen

- Loan CalculatorDokument73 SeitenLoan CalculatorSide Al RifatNoch keine Bewertungen

- Comparison of Low Budget CarDokument9 SeitenComparison of Low Budget CarsnsnagarajanNoch keine Bewertungen

- Oriental Fine Arts Academy of London International Examination 2004Dokument4 SeitenOriental Fine Arts Academy of London International Examination 2004suganthsuthaNoch keine Bewertungen

- Professional Practice 1 REVIEWERDokument3 SeitenProfessional Practice 1 REVIEWERAki OlleroNoch keine Bewertungen

- Laddie A True Blue Story by Stratton-Porter, Gene, 1863-1924Dokument302 SeitenLaddie A True Blue Story by Stratton-Porter, Gene, 1863-1924Gutenberg.orgNoch keine Bewertungen

- v1.0 Rishabh Engineering Case Study 25 Piping Stress Analysis For Vacuum Heater Ver23Dec15Dokument4 Seitenv1.0 Rishabh Engineering Case Study 25 Piping Stress Analysis For Vacuum Heater Ver23Dec15JasonChong212Noch keine Bewertungen

- New Application - eTMFile Instructions From IPODokument3 SeitenNew Application - eTMFile Instructions From IPOmarkinfinitysportNoch keine Bewertungen

- Xmlparser LicenseDokument5 SeitenXmlparser LicenseJona OttoNoch keine Bewertungen

- Sharp Ar 5320eDokument10 SeitenSharp Ar 5320ePega SuzeNoch keine Bewertungen

- GC CatalogDokument30 SeitenGC Catalogjchristoe2613Noch keine Bewertungen

- Stepan Formulation 840Dokument2 SeitenStepan Formulation 840mohamed AdelNoch keine Bewertungen

- Music Piracy in NepalDokument7 SeitenMusic Piracy in NepalRozez ShresthaNoch keine Bewertungen

- Singapore Air Lines 9GSIA19J03: InstructionsDokument5 SeitenSingapore Air Lines 9GSIA19J03: InstructionsTrịnh Xuân BáchNoch keine Bewertungen

- Isuzu Trooper 1990Dokument20 SeitenIsuzu Trooper 1990toktor toktor100% (5)

- Witcher 3 Wild Hunt, The - Papertoy YenneferDokument2 SeitenWitcher 3 Wild Hunt, The - Papertoy YenneferBogdan NicaNoch keine Bewertungen

- F1044 1479757-1Dokument5 SeitenF1044 1479757-1Thaweekarn ChangthongNoch keine Bewertungen

- Mass Media - Laws and JurisprudenceDokument38 SeitenMass Media - Laws and JurisprudenceJustice Hugo67% (3)

- Configuration Oracle HTTP Server For FlexcubeDokument5 SeitenConfiguration Oracle HTTP Server For FlexcubecuonglunNoch keine Bewertungen

- English - Stage 8 - 02 - INS - RP - AFP - tcm143-639963Dokument4 SeitenEnglish - Stage 8 - 02 - INS - RP - AFP - tcm143-639963Danny AdeNoch keine Bewertungen

- Conditionals Type 1 Esl Multiple Choice Quiz For KidsDokument3 SeitenConditionals Type 1 Esl Multiple Choice Quiz For KidsPaula CalvoNoch keine Bewertungen

- Capitulo 11 SolucionarioDokument28 SeitenCapitulo 11 SolucionarioElizabeth MeraNoch keine Bewertungen

- Offered ProductsDokument29 SeitenOffered ProductsJade Marie CoronadoNoch keine Bewertungen

- LATICRETEDokument164 SeitenLATICRETEnap_carino100% (1)

- Round Timber Piles: Standard Specification ForDokument7 SeitenRound Timber Piles: Standard Specification ForJosé Ramón GutierrezNoch keine Bewertungen

- How To Efficiently Prune SAP NetWeaver BW QueriesDokument19 SeitenHow To Efficiently Prune SAP NetWeaver BW QueriesShahid_ONNoch keine Bewertungen

- Merrill's Pocket Guide To Radiography (PDFDrive)Dokument349 SeitenMerrill's Pocket Guide To Radiography (PDFDrive)A Seul100% (1)

- C1403 15Dokument5 SeitenC1403 15Lorena JimenezNoch keine Bewertungen

- Oh, Susanna: American Folk SongDokument1 SeiteOh, Susanna: American Folk SongDiego Smith SmithNoch keine Bewertungen

- Crown SHRDokument4 SeitenCrown SHRAbdulrahman EL-GammalNoch keine Bewertungen

- Motorola Cm360Dokument184 SeitenMotorola Cm360marcelgarrigaNoch keine Bewertungen