Beruflich Dokumente

Kultur Dokumente

D8.1 Box Culvert System

Hochgeladen von

Oby RobiniCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

D8.1 Box Culvert System

Hochgeladen von

Oby RobiniCopyright:

Verfügbare Formate

Hynds Box

Culvert System

Scan for more

information

Technical Guide D8.1

03.15 | DRAINAGE | D8.1 Box Culvert System

Hynds precast concrete box culvert units simplify the construction process,

providing a fast and cost-effective solution that is often more economical than

the in-situ construction option.

Applications

Product Attributes

Quality

Stock underpass for rural

Large range of strengths and opening sizes

ISO 9001:2008 Quality

highway crossings

Optional precast wingwalls and headwalls

Management Standard

Pedestrian tunnels

available to match

Stormwater culverts

Various joint sealing options available

Approvals/Standards

Vertical chambers

Lower fill covers possible, above the

Purpose designed for various load

precast unit

configurations up to HNHO72

NZS 3101, Concrete Structures Standard

NZS3109, Concrete Construction

The go to organisation for civil

and rural water product solutions

Hynds precast concrete box culvert units simplify the

construction process, providing a fast and cost-effective

solution that is often more economical than the in-situ

construction option.

Product Attributes

Customisable for special conditions or shapes

Longer life and smoother surface compared to

steel culverts

Simplifies preparation of site plans for council approval

Design Options

D8.1 Box Culvert System | DRAINAGE | PG 2

Stormwater Culverts: Opening width and height is

determined by the hydraulic requirements of the specific

site. Hydraulic calculations can be performed by referring

to the CPAA Hydraulics of Precast Concrete Conduits

Manual.

Pedestrian Tunnels: Opening size is to be determined by

the tunnel space desired. For Pedestrian Tunnels, this is

usually dependant on the NZ Building Code.

Recommendations for herd sizes:

For a herd size of 450 650 head of cattle, a 2 m x 2 m* box

culvert should be the minimum size opening selected.

For a herd size of 650 head of cattle or more, the recommended

minimum size of the box culvert should be a 3 m x 2 m* structure.

*Please note: The recommendations above are based on the assumption

that the underpass is not too close to buildings on either side. Sizes are

span x depth.

Vertical Chambers: Hynds box culvert units may also be used to form

vertical chambers.

Wingwall Options

Hynds supply wingwall panels with fixing holes, brackets

and dressing sets so that the panels can be fixed to the box

culvert. These panels have reinforcing starter bars

protruding at the bottom of the panel. The bars are fixed to

the base reinforcing mat, and the base is then poured in-situ

on site by the contractor.

Headwall Options

Hynds will supply the end units of the conduit structure with

suitable headwalls as part of the box culvert unit

if requested.

Table 1 Standard box sizes (other sizes made to order)

Height

Width (mm)

(mm)

1500

2000

2500

3000

3500

4000

1000

1500

2000

2500

3000

3500

4000

Larger sizes

made to order

Alternate sizes are available on request Standard unit length is 1550 mm

Culvert Dimensions

Hynds Box Culvert Systems are made to order.

A variety of opening sizes are available to suit most farm

types and stock quantities.

Box culverts dimensions can be customised for specific

site conditions. (e.g. matching existing box culverts.)

Note: Preferred sizes are detailed in Table 1.

Culvert Strength

Culvert strength is dependent on earth loads, highway

loads and cover to the finished culvert.

Hynds Technical Services Department will design the

precast concrete box culverts to suit the specified

highway loading and cover.

Recommended minimum cover over the box culvert is

400 500 mm.

Concrete Surface Finishes

Hynds Box Culverts are generally manufactured to

F3/F4 finish as detailed in NZS3114:1987 Specification

for Concrete Surface Finishes. This finish is typical of

structures which will not be seen or are only going to be

observed from a distance.

Higher classes of finish may be required in elements

subject to frequent observation (F4), subject to frequent

close scrutiny (F5) or elements with painted surfaces.

In these instances the finish required must be advised

at time of quotation and a sample panel will be cast and

approved prior to commencement of manufacture.

Installation

Culvert and wingwall units are delivered to site by our

trucks. Off-loading can be arranged if required. Culvert

installation should be done by an experienced contractor

who understands the necessity of jointing, bedding and

backfilling the structure properly as well as the highway

safety requirements applicable to such an installation.

Jointing

Lifting anchor positioning and lifting equipment

specifications can be supplied upon request.

Basic Bedding Preparation

Sufficient foundation support and backfill compaction

is required to prevent settlement of the imported layers

conduit after installation.

Joint sealing can be formed with the use of butyl mastic

sealing strips, epoxy, sand-mortar mix, or silicone

sealant. Contact your local Hynds Sales Branch for

these products.

The bedding must be able to support the full load of

the installed culvert, its contents, and the loads above

the culvert. For this reason the box culvert should be

laid on compacted granular hardfill to the specified line

and gradient.

A box culvert line is usually laid from the downstream

end with the sockets facing upstream to receive the next

culvert to be laid.

The box culvert units should be inspected before laying to

ensure that the jointing surfaces are clean.

The unit is then lowered carefully onto the prepared base,

aligning the spigot with the socket of the unit already laid.

Loose surface bedding material must not enter the joint

space between the units particularly along the bottom

during positioning of the unit.

If any adjustment of level is necessary, remove the box

culvert, adjust the surface layer of the bedding and place

again. Do not use local packers to adjust the level.

Hynds Box Culverts are manufactured with our exclusive

Dog Bone Connector System. The units can then be tied

together on site by a specialist contractor once the units

have been installed. Recommended practise is as follow:

Place first box culvert into required position.

Using the crane, position the second culvert as close as possible to

the previously installed culvert, and whilst being supported by the

crane pull the culverts together with come-alongs attached to the

internal swiftlifts.

Bedding design for a box culvert conduit should be

undertaken by a local consulting engineer as local

knowledge of ground conditions is important to ensure

a successful installation.

Note: DO NOT use the dog-bone connectors to pull the

culverts together.

As a general guide, the compacted thickness of a

basic bedding over the full width of the trench can

vary between 150 to 250 mm (depending on culvert

bearing loads) with compacted layers not exceeding

150 mm thick.

Trench width for most installations should be equal to the

external width of the culvert plus 600 mm.

Local soft spots in the trench must be excavated and

the voids filled with well compacted hardfill to provide

uniform support under the entire structure. This must

provide a bearing capacity of a minimum of 100kPa.

Failure to do so could result in settlement of the units at a

later stage.

Line up two half dog-bone connector recesses.

Place threaded rod connecting set in groove.

Tighten nuts equally at each end using a socket wrench and an

16 set to a maximum torque of 100Nm (standard use).

Fill recess with Sikagrout 212 or equivalent.

See Figures 1-4 for visual steps.

Alternatively Hynds Box Culverts can be manufactured

with a duct in each corner. The units can then be bolted

together or post-tensioned on site. Recommended

practise is to insert the tie rods as the first unit is placed

and push through subseq uent units as they are installed.

D8.1 Box Culvert System | DRAINAGE | PG 3

Box culvert units are normally supplied with swiftlift

anchors cast into the top of each unit. Appropriately rated

chains and lifting beam must be used when handling

the units.

Joint gaps will vary from 5 to 20 mm and in most cases

can be left open.

Laying

Handling

Hynds Box Culverts are manufactured with the quatro

joint which together with the dog bone connector locates

and locks adjacent units together.

Dog Bone Connector Jointing System:

Hynds Box Culverts are manufactured with our exclusive

Dog Bone Connector System, the ideal solution for tying

together culvert sections. This system combined with the

preformed Quatro joint allows a fast and accurate lock of

adjacent units.

Backfilling

Backfilling should commence as soon as possible after

the box culverts have been laid.

Fill the trench to the level of the top of the culvert

working evenly on each side.

Use selected backfill material well compacted in layers

not exceeding 200 mm thickness.

Do not use heavy vibratory equipment.

Continue to fill the culvert conduit in well

compacted layers

Do not run heavy rollers or construction equipment over

the culvert conduit without checking beforehand that the

units are designed to withstand these loads.

D8.1 Box Culvert System | DRAINAGE | PG 4

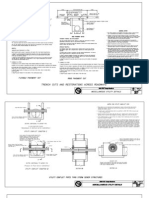

Installation:

Fig. 1 Place first culvert into required position

Fig. 2 Place the next culvert as close as possible to desired position

and then pull into correct position with a come-along, connected to the

swiftlifts in the culvert. Line up two half dog-bone connector recesses.

Fig. 3 Place threaded rod connecting set in groove. Tighten nuts equally

at each end, using a socket wrench to a maximum torque of:

16 set: 100 Nm; 20 set: 125 Nm; 24 set: 150 Nm

Fig. 4 Fill recess with Sikagrout 212 or equivalent.

Branches Nationwide Support Office & Technical Services 09 274 0316

Disclaimer: While every effort has been made to ensure that the information in this document is correct and accurate, users of Hynds product or information within this document must make their own assessment

of suitability for their particular application. Product dimensions are nominal only, and should be verified if critical to a particular installation. No warranty is either expressed, implied, or statutory made by Hynds

unless expressly stated in any sale and purchase agreement entered into between Hynds and the user.

Das könnte Ihnen auch gefallen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Humes PDFDokument6 SeitenHumes PDFBrian BlankenshipNoch keine Bewertungen

- Method of Statement Column and Access With Water MarkDokument11 SeitenMethod of Statement Column and Access With Water MarkManu MohanNoch keine Bewertungen

- Layher Scaffolding CatalogueDokument10 SeitenLayher Scaffolding CataloguefresitoNoch keine Bewertungen

- Method Statement For Under Floor Trunkingt For Cables-1Dokument14 SeitenMethod Statement For Under Floor Trunkingt For Cables-1shareyhou0% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Von EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Bewertung: 5 von 5 Sternen5/5 (2)

- How to Build a Global Model Earthship Operation II: Concrete WorkVon EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNoch keine Bewertungen

- Elastic Settlement Shallow Foundations - A Critical Review 2 PDFDokument35 SeitenElastic Settlement Shallow Foundations - A Critical Review 2 PDFmohdpat05100% (2)

- Katalog Gunung Garuda NewDokument36 SeitenKatalog Gunung Garuda Newabduh81Noch keine Bewertungen

- Soilmec Sr-40 Brochure PDFDokument12 SeitenSoilmec Sr-40 Brochure PDFOby RobiniNoch keine Bewertungen

- Elastic Settlement Shallow Foundations - A Critical Review 2 PDFDokument35 SeitenElastic Settlement Shallow Foundations - A Critical Review 2 PDFmohdpat05100% (2)

- Meet The Profesor 2021Dokument398 SeitenMeet The Profesor 2021Raúl AssadNoch keine Bewertungen

- RMHE08Dokument2.112 SeitenRMHE08Elizde GómezNoch keine Bewertungen

- Prawn ProcessingDokument21 SeitenPrawn ProcessingKrishnaNoch keine Bewertungen

- D8.1 Box Culvert SystemDokument4 SeitenD8.1 Box Culvert Systemsattar12345Noch keine Bewertungen

- Installation Guidance For Cable Troughs and Service Ducts PD84Dokument7 SeitenInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020Noch keine Bewertungen

- Installation Guidance For Cable Troughs and Service Ducts PD84Dokument7 SeitenInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020Noch keine Bewertungen

- Installation Guidance For Cable Troughs and Service Ducts PD84Dokument7 SeitenInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020Noch keine Bewertungen

- 05 Box CulvertsDokument9 Seiten05 Box CulvertsAllan James Anticamara FernandezNoch keine Bewertungen

- Box Culvert Brochure Web VersionDokument8 SeitenBox Culvert Brochure Web Versionsiva_civil4051Noch keine Bewertungen

- Box Culverts HumesDokument12 SeitenBox Culverts HumesawwalnafiNoch keine Bewertungen

- Box Culverts HumesDokument12 SeitenBox Culverts Humespete0980Noch keine Bewertungen

- Lintel Bro 2011web 70Dokument5 SeitenLintel Bro 2011web 70iestyn williamsNoch keine Bewertungen

- Trench Install Guide1Dokument4 SeitenTrench Install Guide1Fatholla Salehi100% (1)

- Sheet PilingDokument12 SeitenSheet PilingTanvi Rane100% (1)

- TL 5 X 10Dokument10 SeitenTL 5 X 10number_25Noch keine Bewertungen

- Box Culverts - Humes BookletDokument17 SeitenBox Culverts - Humes BookletScott Downs100% (3)

- Supreme Beam and Block FloorDokument8 SeitenSupreme Beam and Block FloorDoralba V NolanNoch keine Bewertungen

- Guide To Site - Box CulvertDokument4 SeitenGuide To Site - Box Culvertjs kalyana ramaNoch keine Bewertungen

- 5447 - Concrete Box CulvertsDokument6 Seiten5447 - Concrete Box CulvertssdewssNoch keine Bewertungen

- Studliner Installation GuidelinesDokument10 SeitenStudliner Installation GuidelinesJULIONoch keine Bewertungen

- L-861 FatoDokument15 SeitenL-861 FatoSebastiánNoch keine Bewertungen

- Tank Manual2 Of2Dokument195 SeitenTank Manual2 Of2AlbertNoch keine Bewertungen

- Lifting and FIxing PrecastDokument25 SeitenLifting and FIxing Precastdandee451100% (2)

- General Installation Smart DitchDokument8 SeitenGeneral Installation Smart Ditchanon_49687612Noch keine Bewertungen

- Box Culvert Handling and Jointing Instructions 2020 PDFDokument3 SeitenBox Culvert Handling and Jointing Instructions 2020 PDFHpeso EmohseNoch keine Bewertungen

- Box Culvert, VUP & Minor BridgeDokument22 SeitenBox Culvert, VUP & Minor BridgeĐărsĥąna RanasingheNoch keine Bewertungen

- Casting Box Girder Segments - tcm45-342871Dokument3 SeitenCasting Box Girder Segments - tcm45-342871AuYongTheanSengNoch keine Bewertungen

- Pile Foundations: Driven Piles of Ductile Cast IronDokument8 SeitenPile Foundations: Driven Piles of Ductile Cast IronqawsderNoch keine Bewertungen

- HyJOIST Brochure (Jul 2008)Dokument28 SeitenHyJOIST Brochure (Jul 2008)GPNoch keine Bewertungen

- IG de Reno Mattresses InstallationDokument2 SeitenIG de Reno Mattresses InstallationSílvio GonçalvesNoch keine Bewertungen

- N Stress Floor SlabDokument4 SeitenN Stress Floor SlabBen Sim NitroNoch keine Bewertungen

- Roof Truss Installation GuideDokument12 SeitenRoof Truss Installation GuideAwang Mahardy67% (3)

- Backhoe Boxes: User GuideDokument6 SeitenBackhoe Boxes: User GuideSundar KandasamyNoch keine Bewertungen

- L9 - Construction Methodology - 1Dokument20 SeitenL9 - Construction Methodology - 1J. Kumar Infraprojects LtdNoch keine Bewertungen

- Hollow Core Planks Application and Design GuideDokument46 SeitenHollow Core Planks Application and Design Guidemixi1978100% (1)

- Perfect Manhole System Installation Manual: Precast Concrete Manholes With Load Bearing Elastomeric JointsDokument9 SeitenPerfect Manhole System Installation Manual: Precast Concrete Manholes With Load Bearing Elastomeric Jointschienthan21Noch keine Bewertungen

- Perform With Precision: Box Culvert TravelerDokument14 SeitenPerform With Precision: Box Culvert Traveler魏雨辰Noch keine Bewertungen

- 8 Scaffolding SafetyDokument12 Seiten8 Scaffolding SafetygbogboiweNoch keine Bewertungen

- Methodology of PSC Girder StressingDokument8 SeitenMethodology of PSC Girder StressingRavikant TyagiNoch keine Bewertungen

- Tehnologia Posi StrutDokument35 SeitenTehnologia Posi Strutdanut_docNoch keine Bewertungen

- Installation Instructions: Landscaping Civils Sport Aq UaDokument84 SeitenInstallation Instructions: Landscaping Civils Sport Aq UaIrinel GrăjdeanuNoch keine Bewertungen

- Standing Seam Installation-23-11-21Dokument35 SeitenStanding Seam Installation-23-11-21Gokulnath TgNoch keine Bewertungen

- FP McCann Precast Concrete Headwalls InstallationDokument4 SeitenFP McCann Precast Concrete Headwalls InstallationgemotorresNoch keine Bewertungen

- Bracing System Table of ContentsDokument10 SeitenBracing System Table of ContentsNyein ZawNoch keine Bewertungen

- Trench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutDokument3 SeitenTrench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutIqueline JacqelineNoch keine Bewertungen

- Cable Tray SOPDokument21 SeitenCable Tray SOPHasnain NiazNoch keine Bewertungen

- Free Standing Jib CranesDokument7 SeitenFree Standing Jib CranesJean Grey ValerNoch keine Bewertungen

- ScaffoldDokument17 SeitenScaffoldAnwar ShaikNoch keine Bewertungen

- Culvert SlipliningDokument8 SeitenCulvert SlipliningbetopagoadaNoch keine Bewertungen

- Installation of Hollow Core Floor Slabs 786687Dokument24 SeitenInstallation of Hollow Core Floor Slabs 786687Vishant ChandraNoch keine Bewertungen

- Spec 451 Reinforced Portland Cement Concrete PavementDokument6 SeitenSpec 451 Reinforced Portland Cement Concrete PavementCharan ReddyNoch keine Bewertungen

- Bored Cast-In Situ PilesDokument7 SeitenBored Cast-In Situ PilesPathankot MandiNoch keine Bewertungen

- How to Build a Simple Three Bedroom Shipping Container HouseVon EverandHow to Build a Simple Three Bedroom Shipping Container HouseBewertung: 4 von 5 Sternen4/5 (2)

- Sewage Disposal Works: Their Design and ConstructionVon EverandSewage Disposal Works: Their Design and ConstructionNoch keine Bewertungen

- ST 21Dokument9 SeitenST 21amarnath_jbbNoch keine Bewertungen

- Analisis Injeksi Epoxy Pada Perbaikan Retak Beton Terhadap Beban LenturDokument9 SeitenAnalisis Injeksi Epoxy Pada Perbaikan Retak Beton Terhadap Beban LenturOby RobiniNoch keine Bewertungen

- Segmental Box Culvert 14 24 Span Type 3 d2415Dokument1 SeiteSegmental Box Culvert 14 24 Span Type 3 d2415Oby RobiniNoch keine Bewertungen

- Ultrasonic TestingDokument29 SeitenUltrasonic TestingOby RobiniNoch keine Bewertungen

- Computer Mouse Concept PowerPoint TemplateDokument34 SeitenComputer Mouse Concept PowerPoint TemplateMahasariNoch keine Bewertungen

- LisaConcreteIndonesiaBrochure PDFDokument7 SeitenLisaConcreteIndonesiaBrochure PDFOby RobiniNoch keine Bewertungen

- OE TechnicalArticle ControllingGeneratorVibration 2013Dokument5 SeitenOE TechnicalArticle ControllingGeneratorVibration 2013Pankaj KambleNoch keine Bewertungen

- HC SR04 PDFDokument3 SeitenHC SR04 PDFVipan Sharma100% (1)

- USIRR (Manual)Dokument25 SeitenUSIRR (Manual)a_riantikaNoch keine Bewertungen

- File 25580625132137 SCG Pipe BrosurDokument12 SeitenFile 25580625132137 SCG Pipe BrosurOby RobiniNoch keine Bewertungen

- Tabel HoneycombDokument2 SeitenTabel HoneycombAzwar HalimNoch keine Bewertungen

- Pra UTSDokument1 SeitePra UTSOby RobiniNoch keine Bewertungen

- Vibration Measurement-Based Simple Technique For Damage Detection of Truss Bridges (Siriwardane, S. 2015)Dokument9 SeitenVibration Measurement-Based Simple Technique For Damage Detection of Truss Bridges (Siriwardane, S. 2015)Jose ManuelNoch keine Bewertungen

- Concrete Mix Design (ACI)Dokument8 SeitenConcrete Mix Design (ACI)Oby RobiniNoch keine Bewertungen

- Shell Gadus: Designed To Do More. Just Like Our Greases - Shell GadusDokument2 SeitenShell Gadus: Designed To Do More. Just Like Our Greases - Shell Gadusperi irawanNoch keine Bewertungen

- Table 1 Minimum Separation DistancesDokument123 SeitenTable 1 Minimum Separation DistancesjhonNoch keine Bewertungen

- Communication Models in Internet of Things: A SurveyDokument5 SeitenCommunication Models in Internet of Things: A SurveyIJSTENoch keine Bewertungen

- Germania Agenturinfo enDokument4 SeitenGermania Agenturinfo enДушан СтепановићNoch keine Bewertungen

- Solid Modeling Techniques: Constructive Solid Geometry (CSG)Dokument22 SeitenSolid Modeling Techniques: Constructive Solid Geometry (CSG)amolNoch keine Bewertungen

- SAT Biochar Ethylene Poster 10 - 10b PDFDokument1 SeiteSAT Biochar Ethylene Poster 10 - 10b PDFsherifalharamNoch keine Bewertungen

- BTK Implant Guide SurgeryDokument48 SeitenBTK Implant Guide SurgeryMaria VolvinaNoch keine Bewertungen

- Drug Study LidocaineDokument15 SeitenDrug Study LidocaineFrancym R. BatengaNoch keine Bewertungen

- Inform LetterDokument2 SeitenInform LetterMc Suan75% (4)

- By This Axe I Rule!Dokument15 SeitenBy This Axe I Rule!storm0% (1)

- CAC Bubble DiagramsDokument12 SeitenCAC Bubble Diagramsangst6250Noch keine Bewertungen

- Firestone & Scholl - Cognition Does Not Affect Perception, Evaluating Evidence For Top-Down EffectsDokument77 SeitenFirestone & Scholl - Cognition Does Not Affect Perception, Evaluating Evidence For Top-Down EffectsRed JohnNoch keine Bewertungen

- Final Thesis - Aris PotliopoulosDokument94 SeitenFinal Thesis - Aris PotliopoulosCristinaNoch keine Bewertungen

- St. John's Wort: Clinical OverviewDokument14 SeitenSt. John's Wort: Clinical OverviewTrismegisteNoch keine Bewertungen

- Bio (RocessDokument14 SeitenBio (RocessVijay SansanwalNoch keine Bewertungen

- Bahir Dar University BIT: Faculity of Mechanical and Industrial EngineeringDokument13 SeitenBahir Dar University BIT: Faculity of Mechanical and Industrial Engineeringfraol girmaNoch keine Bewertungen

- HMT RM65 Radial DrillDokument2 SeitenHMT RM65 Radial Drillsomnath213Noch keine Bewertungen

- Design Documentation ChecklistDokument8 SeitenDesign Documentation ChecklistGlenn Stanton100% (1)

- PEDokument12 SeitenPEMae Ann Base RicafortNoch keine Bewertungen

- Earth Sciences Notes Csir-Ugc Net JRFDokument57 SeitenEarth Sciences Notes Csir-Ugc Net JRFmanas773Noch keine Bewertungen

- Engineering Structures: C.X. Dong, A.K.H. Kwan, J.C.M. HoDokument14 SeitenEngineering Structures: C.X. Dong, A.K.H. Kwan, J.C.M. HoElieser SinagaNoch keine Bewertungen

- Sample Dilapidation ReportDokument8 SeitenSample Dilapidation ReportczarusNoch keine Bewertungen

- Science Involved in Floating Paper Clip Science Experiment GuidelinesDokument4 SeitenScience Involved in Floating Paper Clip Science Experiment GuidelinesSHIELA RUBIONoch keine Bewertungen

- Eliminating Oscillation Between Parallel MnosfetsDokument6 SeitenEliminating Oscillation Between Parallel MnosfetsCiprian BirisNoch keine Bewertungen

- Sheet Metal Manufacturing Companies NoidaDokument9 SeitenSheet Metal Manufacturing Companies NoidaAmanda HoldenNoch keine Bewertungen

- AR BuildingDokument819 SeitenAR BuildingShithin KrishnanNoch keine Bewertungen

- Marketing Management 4th Edition Winer Test BankDokument35 SeitenMarketing Management 4th Edition Winer Test Bankapneaocheryzxs3ua100% (24)