Beruflich Dokumente

Kultur Dokumente

Pala Cat 7495 HD

Hochgeladen von

Alexis Pasten CastilloCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pala Cat 7495 HD

Hochgeladen von

Alexis Pasten CastilloCopyright:

Verfügbare Formate

Cat

7495 HD

ELECTRIC ROPE SHOVEL

Specifications

Dimensions

Dipper payload

Dipper capacity

Main Structures (contd)

82 tonnes

27.5-60.4 m3

90 tons

36-79 yd3

Dependent on application and material density.

Weights*

Working weight, with dipper

and standard links

Ballast (furnished by customer)

1 295 777 kg

260 362 kg

2,856,700 lb

574,000 lb

These weights will vary slightly depending upon dipper and optional

equipment selection.

Swing

Two planetary gearboxes, each driven by a vertically mounted motor,

are located on either side of the revolving frame. Dual-output pinion

shafts from each gearbox engage the swing rack.

Hoist

A planetary gearbox with dual-output pinions provides the hoist torque

transfer from the electric motor to the hoist drum gear.

Lube System

*All specifications are based on a 32 m3 (42 yd3) dipper and standard

213.4cm (84 in) treads.

Automatic, single-line system for open gear lubricant andgrease.

6 pumps (4 for open gear lubricant and 2 for grease) located in an

insulated, heated, double-walled lube room.

External fastfill from lower level.

Main Structures

Electrical

Upper works overall width

(including standard walkways)

Crawler Dimensions

Overall width 213.4 cm

(84 in) treads, standard

Overall width 274.3 cm (108 in) treads

Ground Bearing Pressure

Total effective bearing area

213.4 cm (84 in) treads, standard

Total effective bearing area

274.3 cm (108 in) treads

13.5 m

10 m

10.6 m

32.0 m2

400 kPa

41 m2

316 kPa

44 ft 3 in

32 ft 9 in

34 ft 9 in

343 ft2

58 psi

442 ft2

46 psi

Ground bearing pressure is dependent upon many factors.

Planetary Propel

Dual-motor independent drive.

Drive

IGBT Acutrol drive system.

Power Requirements

Voltage

50 Hz

60 Hz

Average power demand

Peak power

3 phase, 50/60 Hz, 7,200V

6,000V, 6,600V,

7,200V, 11,000V

7,200V

832-1165 kW

3330 kW

Other voltage options available to suit customer requirements.

7495 HD Electric Rope Shovel

Front End

Front End (contd)

One piece, forged, seamless tubular dipper handle and wide-spread

boom point sheaves equipped with hoist ropes and dipper padlocks

tostabilize dipper handle.

Crowd

Rope Crowd: the crowd machinery is located at the front center of

the revolvingframe; consisting of a motor, brake, drum and gearing.

Plastic-impregnated crowd and retract ropes are used to move the

dipper handle fore and aft.

Rope Data

No.

Diameter

Hoist

70 mm (2.75 in)

Crowd

64 mm (2.5 in)

Retract

64 mm (2.5 in)

Boom suspension

83 mm (3.25 in)

Dipper trip

16 mm (0.625 in)

High impact ropes available as an option.

Meters

Feet

Ground Line

Meters

Feet

C Rotation

L

Optimal Working Ranges*

1 Dumping height with clearance to open dipper door

9.4 m

30 ft 10 in

2 Cutting height (maximum)

14.9 m

48 ft 9 in

3 Cutting radius (maximum)

22.8 m

74 ft 9 in

4 Radius of level floor

16.0 m

52 ft 4 in

5 Revolving frame tail swing radius

9.3 m

30 ft 8 in

Optimal working ranges based on loading a Cat 793F truck.

*All specifications are based on a 32 m3 (42 yd3) dipper and standard 213.4 cm (84 in) treads.

For more complete information on Cat products, dealer services, andindustry solutions, visit us on the web atwww.cat.com

2016 Caterpillar

All rights reserved

Materials and specifications are subject to change without notice. Featured machines in photos may include additional

equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, CaterpillarYellow and the Power Edge tradedress, as well

as corporate and product identity used herein, are trademarks ofCaterpillarand may notbeused without permission.

AEHQ6518-02 (03-2016)

Replaces AEHQ6518-01

Das könnte Ihnen auch gefallen

- Catallogo Pala Cable 7495 HFDokument4 SeitenCatallogo Pala Cable 7495 HFmarceloNoch keine Bewertungen

- PC8000-6 A4 InternetDokument8 SeitenPC8000-6 A4 InternetSACHIDHANANDHAM A100% (1)

- Bucyrus 495BII vs. Bucryus 495HR Super 2 (Caterpillar 7495) : Bucyrus 495HR - Side Profile Bucyrus 495HR - Side ProfileDokument4 SeitenBucyrus 495BII vs. Bucryus 495HR Super 2 (Caterpillar 7495) : Bucyrus 495HR - Side Profile Bucyrus 495HR - Side ProfileManuel VargasNoch keine Bewertungen

- Camion Electrico CatDokument30 SeitenCamion Electrico CatYamid ArtetaNoch keine Bewertungen

- Pala O&KRH200Dokument8 SeitenPala O&KRH200mchan1965100% (1)

- Exca enDokument12 SeitenExca enFaruk AtalarNoch keine Bewertungen

- Performance Report: Cat 6050 FS and 6060 FS at La Herradura Gold Mine (Sonora, Mexico)Dokument24 SeitenPerformance Report: Cat 6050 FS and 6060 FS at La Herradura Gold Mine (Sonora, Mexico)EVCY100% (1)

- L1350Dokument4 SeitenL1350RodrigoAndrésMondacaArriazaNoch keine Bewertungen

- Pala O&KRH90CDokument7 SeitenPala O&KRH90Cmchan1965100% (1)

- REHS2516-11 Procedure To Measure Bearing Movement in The Upper and The Lower Articulation HitchDokument11 SeitenREHS2516-11 Procedure To Measure Bearing Movement in The Upper and The Lower Articulation HitchCarlosNoch keine Bewertungen

- Hydraulic Mining Excavator: General Data: FeaturesDokument8 SeitenHydraulic Mining Excavator: General Data: FeaturesIvanNoch keine Bewertungen

- Terex RH200 - Brochure - M 135.0Dokument8 SeitenTerex RH200 - Brochure - M 135.0Relining MineralsNoch keine Bewertungen

- Cartilla Especificaciones Camion 793 PDFDokument32 SeitenCartilla Especificaciones Camion 793 PDFKianna Ospino AlmenarezNoch keine Bewertungen

- Bucyrus 8750 MaquetaDokument12 SeitenBucyrus 8750 MaquetaForomaquinasNoch keine Bewertungen

- DR460 2008 BrochureDokument8 SeitenDR460 2008 Brochuredeath666dark100% (1)

- Generation 2: Wheel Loader Product OverviewDokument7 SeitenGeneration 2: Wheel Loader Product OverviewLetácio OliveiraNoch keine Bewertungen

- Motor Grader Rig Out Catalog: Aftermarket Components and Common Maintenance PartsDokument40 SeitenMotor Grader Rig Out Catalog: Aftermarket Components and Common Maintenance PartsZeena DeamilNoch keine Bewertungen

- Hoist Output Pinion Assembly Featuring An Improved Grease Relief Passage Available On 7495, 7495HD, and 7495HF ERS - ServiceDokument3 SeitenHoist Output Pinion Assembly Featuring An Improved Grease Relief Passage Available On 7495, 7495HD, and 7495HF ERS - ServiceAnonymous ABPUPbKNoch keine Bewertungen

- Loading Profile - 6040 With 785DDokument4 SeitenLoading Profile - 6040 With 785DManuel Vargas100% (1)

- Hydraulic Mining Excavators Tripower The Magic TriangleDokument17 SeitenHydraulic Mining Excavators Tripower The Magic TriangleMiguel Angel Rodriguez100% (1)

- Fa 980e-5 A5003-Up Ceaw009702-190-205Dokument16 SeitenFa 980e-5 A5003-Up Ceaw009702-190-205EDSON JONATHAN SALINAS AYALANoch keine Bewertungen

- KG 850,650 LB: Maximum GVWDokument4 SeitenKG 850,650 LB: Maximum GVWRohmanNoch keine Bewertungen

- Electric Mining Shovel - DC Drive Product OverviewDokument5 SeitenElectric Mining Shovel - DC Drive Product OverviewmohanNoch keine Bewertungen

- Palas Hidraulicas Sobre Orugas Cat 6060Dokument12 SeitenPalas Hidraulicas Sobre Orugas Cat 6060thavo220% (1)

- KeyFeature TriPowerDokument17 SeitenKeyFeature TriPowerCesar Ochoa Aranguez100% (2)

- Smartroc D65: DTH Surface Drill Rig For Quarrying and MiningDokument5 SeitenSmartroc D65: DTH Surface Drill Rig For Quarrying and MiningVictor ArceNoch keine Bewertungen

- R9800Dokument12 SeitenR9800tugu_tgNoch keine Bewertungen

- Armado 784 y 785c InglésDokument349 SeitenArmado 784 y 785c InglésFelipeNicolasSilvaNoch keine Bewertungen

- 5110B Performance Report I (PR00263)Dokument5 Seiten5110B Performance Report I (PR00263)suwarjitechnicNoch keine Bewertungen

- Liebherr T262 GB NTBDokument8 SeitenLiebherr T262 GB NTBJulioNoch keine Bewertungen

- Shipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671ADokument4 SeitenShipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671Aait mimouneNoch keine Bewertungen

- Hydraulic Mining Excavator: General Data: FeaturesDokument8 SeitenHydraulic Mining Excavator: General Data: FeaturesIvan100% (1)

- Earthmovers in Scotland: Mining, Quarries, Roads & ForestryVon EverandEarthmovers in Scotland: Mining, Quarries, Roads & ForestryNoch keine Bewertungen

- Truck Body and Canopy - RemoveDokument5 SeitenTruck Body and Canopy - RemoveBelimar CostaNoch keine Bewertungen

- PC5500 SN 15032 Operation and Maintenance ManualDokument527 SeitenPC5500 SN 15032 Operation and Maintenance ManualFernando Pérez Sarria100% (1)

- All The Right Choices Large Track Type Undercarriage-PEDJ0201-05Dokument12 SeitenAll The Right Choices Large Track Type Undercarriage-PEDJ0201-05Carlos Indigoyen LimaymantaNoch keine Bewertungen

- Hydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionDokument24 SeitenHydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionMiguel Angel RodriguezNoch keine Bewertungen

- Hydraulic Mining Excavator CAT 6050: 00. ContentsDokument2 SeitenHydraulic Mining Excavator CAT 6050: 00. ContentsJorby CuadrosNoch keine Bewertungen

- CAT - BucyrusPresentation. (Before and After Acquisition)Dokument20 SeitenCAT - BucyrusPresentation. (Before and After Acquisition)MirnesNoch keine Bewertungen

- 365B L Your Working Advantage (AEDC0603-01)Dokument16 Seiten365B L Your Working Advantage (AEDC0603-01)suwarjitechnic100% (1)

- KS En240 PDFDokument11 SeitenKS En240 PDFWilliam Alberto Angulo OrdinolaNoch keine Bewertungen

- rh90c BDokument8 Seitenrh90c BDino AlajbegovicNoch keine Bewertungen

- Mtt20 For Cat 777 Mega Rigid Frame Truck Conversion: Specialty Haulage Solutions For Construction & MiningDokument3 SeitenMtt20 For Cat 777 Mega Rigid Frame Truck Conversion: Specialty Haulage Solutions For Construction & MiningjulioNoch keine Bewertungen

- MT 3000 Mining Truck: 120 Ton (109 T) Payload CapacityDokument8 SeitenMT 3000 Mining Truck: 120 Ton (109 T) Payload Capacitybayu enasoraNoch keine Bewertungen

- 830e Sales Brochure Aess565-01 (2001) PDFDokument4 Seiten830e Sales Brochure Aess565-01 (2001) PDFfernando chinchazoNoch keine Bewertungen

- Sis 2.0 PDFDokument4 SeitenSis 2.0 PDFDahi Med100% (1)

- PC5500-6 Sales Brochure (2009) PDFDokument8 SeitenPC5500-6 Sales Brochure (2009) PDFBenjamin Arnold CFNoch keine Bewertungen

- Ex5500 PDFDokument7 SeitenEx5500 PDFRoberto Chang PalmaNoch keine Bewertungen

- Catalog Mining Truck 793f CaterpillarDokument28 SeitenCatalog Mining Truck 793f CaterpillardiegoNoch keine Bewertungen

- Reusable Gear Guide HTT - GG1 - 0711Dokument18 SeitenReusable Gear Guide HTT - GG1 - 0711sphiri600100% (1)

- Bucket BrochureDokument13 SeitenBucket BrochureIván ColomaNoch keine Bewertungen

- Bi644940 00 enDokument2 SeitenBi644940 00 enJhulyñoTuziquiñooLokiioNoch keine Bewertungen

- PH-Electric-Rope-Shovel-Components (Splited)Dokument3 SeitenPH-Electric-Rope-Shovel-Components (Splited)Oscar JimenezNoch keine Bewertungen

- L 2350 2Dokument4 SeitenL 2350 2Rodrigo MendozaNoch keine Bewertungen

- Hydraulic Shovel: Engine Bucket Operating SpecificationsDokument32 SeitenHydraulic Shovel: Engine Bucket Operating SpecificationserallatuasanNoch keine Bewertungen

- Modular Mining Systems The Ultimate Step-By-Step GuideVon EverandModular Mining Systems The Ultimate Step-By-Step GuideNoch keine Bewertungen

- Brochure Pala CatDokument2 SeitenBrochure Pala CatWilder Dianderas MandujanoNoch keine Bewertungen

- Cat 7395Dokument2 SeitenCat 7395Erick Yamir Abril ValdiviaNoch keine Bewertungen

- Specifications: Lectric Ope HovelDokument2 SeitenSpecifications: Lectric Ope HovelJosimar MachadoNoch keine Bewertungen

- Aquila Specs-125Dokument4 SeitenAquila Specs-125Fernandes LatoxNoch keine Bewertungen

- Nutritional Recommendations and Guidelines For Women in Gymnastics Current Aspects and Critical InterventionsDokument14 SeitenNutritional Recommendations and Guidelines For Women in Gymnastics Current Aspects and Critical InterventionsInez Davega100% (1)

- Case Study - K2 Crawley Leisure CentreDokument4 SeitenCase Study - K2 Crawley Leisure Centreedzudyzaibidin100% (1)

- Medial Collateral Ligament InjuriesDokument14 SeitenMedial Collateral Ligament InjuriesosamadrNoch keine Bewertungen

- Dana 60-F Dana 60 Dana 70Dokument2 SeitenDana 60-F Dana 60 Dana 70Zé MirtoNoch keine Bewertungen

- The Durability Code Prime Week 1, Day 1 - Lower BodyDokument4 SeitenThe Durability Code Prime Week 1, Day 1 - Lower BodyTomNoch keine Bewertungen

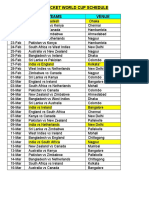

- 2011 Cricket World Cup ScheduleDokument2 Seiten2011 Cricket World Cup ScheduleVishnu RamNoch keine Bewertungen

- KONERDokument100 SeitenKONERLenin InlagoNoch keine Bewertungen

- AAA Eastern: Norview High School Is A Public High School in CentralDokument8 SeitenAAA Eastern: Norview High School Is A Public High School in CentraldakotapalmNoch keine Bewertungen

- Ryobi: 18 Volt Circular Saw Model No. P508 Repair SheetDokument4 SeitenRyobi: 18 Volt Circular Saw Model No. P508 Repair SheetVictor Perez100% (1)

- Tournament PDFDokument6 SeitenTournament PDFS. KanishkaNoch keine Bewertungen

- A Cold Night in Klettwitz PDFDokument5 SeitenA Cold Night in Klettwitz PDFMichael MerlinNoch keine Bewertungen

- Marieb ch3dDokument20 SeitenMarieb ch3dapi-229554503Noch keine Bewertungen

- List of Prime Ministers of Britain and The United KingdomDokument3 SeitenList of Prime Ministers of Britain and The United KingdomrifaldiNoch keine Bewertungen

- Mark Dvoretsky, Arthur Yusupov, Artur Iusupov, Vladimir Vulfson-Technique For The Tournament Player (Batsford Chess Library) (1995) PDFDokument241 SeitenMark Dvoretsky, Arthur Yusupov, Artur Iusupov, Vladimir Vulfson-Technique For The Tournament Player (Batsford Chess Library) (1995) PDFMukul Kumar Roy80% (5)

- Problems On String - CompressedDokument34 SeitenProblems On String - CompressedMd Jobayer HossainNoch keine Bewertungen

- Ultimate Secrets of Card Magic Table of ContentsDokument2 SeitenUltimate Secrets of Card Magic Table of Contentsscribdman1Noch keine Bewertungen

- Mapeh: Physical EducationDokument5 SeitenMapeh: Physical EducationSariah B. BaquinquitoNoch keine Bewertungen

- 1000 Baladas RomanceDokument3 Seiten1000 Baladas RomanceSE CarlosNoch keine Bewertungen

- Da Annex 2021-04-02Dokument11 SeitenDa Annex 2021-04-02Trump WonNoch keine Bewertungen

- Chain Saw PDFDokument2 SeitenChain Saw PDFcityofdarwingisNoch keine Bewertungen

- Manon MelisDokument2 SeitenManon MelisMarvelous VillafaniaNoch keine Bewertungen

- RTR 160 PDFDokument74 SeitenRTR 160 PDFLukesh Kumar100% (2)

- Gunslinger PDFDokument36 SeitenGunslinger PDFscott100% (2)

- Look at The Pictures and Then Match The PairsDokument2 SeitenLook at The Pictures and Then Match The PairsAmiraNoch keine Bewertungen

- DECATHLONDokument35 SeitenDECATHLONHanna Relator Dolor100% (2)

- Converting 5th Edition To C&CDokument7 SeitenConverting 5th Edition To C&CSendral OrokNoch keine Bewertungen

- Amigurumi White Rabbit Free Crochet Pattern - AmigurumiDokument18 SeitenAmigurumi White Rabbit Free Crochet Pattern - AmigurumiBegoña Martinez0% (1)

- Camelot Game Rulesgeekfile - ViewDokument7 SeitenCamelot Game Rulesgeekfile - ViewnoneNoch keine Bewertungen

- HuffnCuffs Huff+'n+Cuffs+Carissa+Clutch+V2 251513Dokument18 SeitenHuffnCuffs Huff+'n+Cuffs+Carissa+Clutch+V2 251513him by himNoch keine Bewertungen

- Modulo 6Dokument6 SeitenModulo 6janet71% (7)