Beruflich Dokumente

Kultur Dokumente

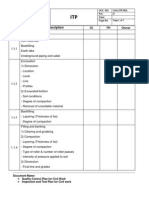

ITP-FW For Civil & Building Works

Hochgeladen von

Rizki KresnaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ITP-FW For Civil & Building Works

Hochgeladen von

Rizki KresnaCopyright:

Verfügbare Formate

PREPARATION OF INSPECTION &

TEST PLANS FOR CIVIL &

STEELWORKS, REV.0

ITEM

ACTIVITY

CONTROL DOCS

1.

DOCUMENTS REQUIRING APPROVAL

1.1

Submission of applicable

Civils Works Procedure(s)

1353043C1

1353043C1

1353043C1

1353043C2

1353042C1

R =

W =

(W) =

I =

PROCEDURE REQUIRED

REPORT FORM/

CHECKLIST

NUMBER

General Earthworks

Works Method

Statement

Piling Method

Statement.

Pile Load Test

1353043C1

Pile Lengthening

Method Statement

HOLD

General Survey

Setting Out

Procedure

Procedure for

Concrete Placement

fore the Large

Review of Inspection & Test Report

Full Witness

Random/Partial Witness

Inspection ,Inspection & Test

1 of 17

RESPONSIBILITY

C

No work to proceed without

approved procedures

General Concrete

Works Method

Statement

General Rebar

Works Method

Statement

General Formworks

Method Statement

1353043C1

1353043C1

FOSTER WHEELER ENERGY LTD

WORK PRACTICE

CONSTRUCTION OPERATIONS

FW

R1

CTCI

COMMENTS

ITEM

ACTIVITY

CONTROL DOCS

1353045C1

Sewer Drainage

Method Statement

1353043C2

Trenches & Duct

Works Method

Statement

Welding Procedures

NDT Procedures

Hydro Test

procedures

Road and Pavement

Method Statement

Steelwork Erection

Method Statement

Concrete Fire

Protection Procedure

Shop Drawings

Bar Cutting &

Bending Schedule

Materials

Submissions List

XF11A000-001

1353045C1

1.2

Preparation and Submission

of Applicable Civil Works

Method Statements

PROCEDURE REQUIRED

Method Statements for Main

Activities

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

Method statements for main

activities to be submitted for

approval prior to Work

Commencement.

FW

CTCI

COMMENTS

ITEM

ACTIVITY

CONTROL DOCS

PROCEDURE REQUIRED

1.3

Weld Procedure

Specifications

1.4

Welder Qualification Test

1353088A1

ASME IX

1.5

Dye Penetrant Procedure

1353088A1

ASME IX

Dye Penetrant Procedure

1.6

Radiographic Procedure

1353088A1

ASME IX

1.7

MPI Procedure

1.8

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

Submission of all weld

procedure specifications,

procedure qualification records

required

FW

CTCI

Radiographic procedure

1353088A1

ASME IX

MPI procedure

UT Procedure

1353088A1

ASME IX

UT procedure

1.9

PMI Procedure

1353080A1

PMI procedure

1.10

PWHT Procedure

1353088C2

PWHT procedure

Procedures and

qualifications to be reviewed

and approved prior to

performing any welding or

NDT work

Procedures and

qualifications to be reviewed

and approved prior to

performing any welding or

NDE work

COMMENTS

ITEM

ACTIVITY

CONTROL DOCS

1.11

Pressure Test Procedure

1.12

Calibration Procedures

1.13

Painting Procedures

1353083A1

1.14

NDT Operator Qualifications

ASNT or

CSWIP

1.15

Materials Approval

1.16

Coating & Wrapping

SURVEY WORKS

2.1

Acceptance of the Survey

Establishment & References

ASME

B31.3

1353088C2

1353083A4

Drawings,

details of

existing

undergroun

d services

PROCEDURE REQUIRED

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

FW

CTCI

Pressure test procedure

Calibration procedures

Painting procedures

Coating & Wrapping Procedure

FM-001

Fm-002

Excavation not to commence

until an agreement of survey

and soils reports and checks

existing U/G services is

reached.

COMMENTS

Technicians certificates RT,

UT, MT and PT

Review final copies for final

survey, soil investigation report

etc identify precautions to

protect existing facilities etc.

ITEM

ACTIVITY

CONTROL DOCS

3.

EXCAVATION

3.1

Setting out

3.2

Calibration of instruments

3.3

Classification of materials

13530-43C1

3.4

Disposal of excavated

material

13530-43C1

3.5

Replacement of Over

Excavation or unsuitable

materials revealed.

PROCEDURE REQUIRED

Survey Setting-Out Procedure

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

FM-001

Fm-002

FW

COMMENTS

CTCI

At the beginning Stage of the

Project , References Points

shall be Agreed .

Joint Survey is required.

Prior to Works Commencement

andRegularlyChecks/

Calibrations.

13530-43C1

General Excavation Method

Statement shall be approved

prior to Work Commencement.

Maximum Dry Density &

Optimum Moisture Content

must be obtained as an

indicator to control

compaction in the field.

Suitable excavated material

shall comply to 7.7 Suitable

Excavated Material ,

Specification for Earthworks.

FM-003

No materials to leave site

without permission

Identification of areas for

stockpiling or disposal

FM-003

Gradation of Fill Material shall

be compliance to

Specification for Earth Works

, 13530-43 C2 , Engineering

Standard.

Suitable excavated material

shall comply to 7.7 Suitable

Excavated Material ,

Specification for earth Works .

ITEM

ACTIVITY

CONTROL DOCS

PROCEDURE REQUIRED

4.

PILING

4.1

Pile Load Test & Pile Driving

13530-42C1

Method Statements for Pile

Driving shall be approved prior

to Work Commencement..

4.2

Preparation of pile

lengthening yard

13530-42C1

Design Calculation for Joint

Connection of Piles to be

reviewed prior to confirm

manufacturing.

4.3

Welding Procedures

including Pile Handling

4.4

Welder Qualification

ASME IX

4.5

Weld Maps

Shop Drawings

Method Statement for

Lengthening and Handling shall

be approved prior to Work

Commencement.

REPORT FORM/

CHECKLIST

NUMBER

FM-015

HOLD

RESPONSIBILITY

C

Piling Sequence shall be

approved prior to Piling.

FW

COMMENTS

CTCI

Pile Load Test for the Selected

Piles shall be conducted prior

to piling.

Test Piles shall be agreed by

the Engineer prior to Testing.

The Test shall comply to

General Specification for Piling

Section 6.12 , 7.0 Engineering

Standard.

General Specification for Piling

Section 6.13.3 Engineering

Standard.

FM-014

Approval to be Granted prior

to Work Commencement

Until approval is obtained no

welding is allowed.

FM-014

Certified Welders to be

Submitted Prior to Welding.

Only certified welders are

allowed for the works

Shop Drawings to be

approved prior to Welding

Welding identification for each

weld

ITEM

4.6

ACTIVITY

Set out Piling Positions

CONTROL DOCS

13530-42C1

PROCEDURE REQUIRED

Setting Out Procedure to be

included in Method Statements

for Pile Driving

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

FW

COMMENTS

CTCI

FM-002

FM-015

FM-015

Procedures & Driving Sequence to be

agreed prior to Piling.

Piles Positioning to be reviewed

and agreed by Joint Survey.

4.7

Drive/drill piles including "as

built" Survey

4.8

Reinforcing Steel Materials

Approval

13530-43C1

General Rebar Works Method

Statement shall be approved

prior to Work Commencement.

Material Control for Rebar

Works shall be included in

General Rebar Works

Method Statement shall be

approved prior to Work

Commencement.

Material Certificates Sampling

to be incompliance with 5.3

Reinforcement , Specification

for Concrete Works

Engineering Standard.

4.9

Reinforcement cutting

bending and fixing

13530-43C1

General Rebar Works Method

Statement shall be approved

prior to Work Commencement

Bending schedule

Bar List Schedule to be

Approved prior to Cutting and

Bending.

4.10

Approval of Cement

13530-43C1

Manufacturer Certificate

required for each delivery

Comply with ASTM C94. All

The trial mixes proposed are in

compliance with the

requirement stated in clause

6.4 Concrete Mixes

,Specification for Concrete

Works.

4.11

Sampling and Approval of

Aggregates

13530-43C1

Approval of Sources

including Tests prior to use

Sampling will be regularly done

to ensure its conformance still

maintained

ITEM

ACTIVITY

CONTROL DOCS

REPORT FORM/

CHECKLIST

NUMBER

PROCEDURE REQUIRED

4.12

Approval of Water for

Concrete Mixes

13530-43C1

4.13

Approval of Admixture

4.14

Design Mixes

4.15

Concrete mixing batching

and transportation

General Concrete Works

Method Statement shall be

approved prior to placing order.

4.16

Concrete placing,

compaction and vibration

General Concrete Works

Method Statement shall be

approved prior to placing order.

HOLD

RESPONSIBILITY

C

FW

COMMENTS

CTCI

Water Test for its Properties

shall be submitted for

approval prior to use

To be incompliance with ACI

318 and Specification for

Concrete Works , Engineering

Standard.

13530-43C1

Certificate Required from

Independent Laboratory

To be incompliance with ASTM

C494

13530-43C1

Trial Mixes to be performed

prior to use.

To comply with ASTM C94. All

The trial mixes proposed are in

compliance with the

requirement stated in clause

6.4 Concrete Mixes

,Specification for Concrete

Works.

Approval of batching plant

prior to use

Tools & Apparatus etc to be

calibrated/certified

Final inspection of pile and

rebar. Vibration equipment

during placing

Slump test each load, cubes in

accordance with specification

FM-006

FM-007

FM-008

FM-009

ITEM

ACTIVITY

CONTROL DOCS

4.17

Protection and Curing

13530-42C1

5.

FILL, BACKFILL & COMPACTION

5.1

Selection of Fill Material

13530-43C2

5.2

Placement and Compaction

13530-43C2

CONCRETE WORKS

6.1

Formwork Design

13530-43C1

PROCEDURE REQUIRED

Method Statements for Pile

Driving shall be approved prior

to Work Commencement

REPORT FORM/

CHECKLIST

NUMBER

FM-008

FM-009

FM-004

HOLD

RESPONSIBILITY

C

FW

COMMENTS

CTCI

To comply with ASTM C94. All

trial mixes proposed to be in

compliance with the

requirement stated in clause

6.8 , Specification for Piling ,

Engineering Standard.

Gradation , Maximum Dry

Density and Optimum Moisture

Content shall comply to

Section 13.2 , Specification for

Earthworks , Engineering

Standard.

shall comply to Section 13.5,

13.6,13.7,13.8,13.9,13.10,13.1

1,13.12,13.13,13.14

Specification for Earthworks ,

Engineering Standard.

Shall be incompliance with the

requirement stated in Section

8.0 , Specification for Concrete

Works , Engineering Standard.

ITEM

ACTIVITY

CONTROL DOCS

PROCEDURE REQUIRED

6.2

Formwork Construction

13530-43C1

General Formwork Method

Statement shall be approved

prior to Work Commencement.

6.3

Reinforcing Steel

13530-43C1

General Rebar Works Method

Statement shall be approved

prior to Work Commencement

6.4

Bar Cutting & Bending

13530-43C1

6.5

Approval of Cement

6.6

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

FW

COMMENTS

CTCI

Check dimensions, datums and

benchmarks, shape, profile and

ties prior to concrete pour.

Shall be incompliance with the

requirement stated in Section

8.0 , Specification for Concrete

Works , Engineering Standard.

Material Certificate and Sample

Test is required to confirm its

conformance.

Schedules for installation,

bending or welding required

before use

Bar Cutting & Bending Shall be

submitted for approval prior to

Work Commencement.

13530-43C1

Manufacturer Certificate

required for each delivery

comply with ASTM C94. All

The trial mixes proposed are in

compliance with the

requirement stated in clause

6.4 Concrete Mixes

,Specification for Concrete

Works.

Sampling and Approval of

Aggregates

13530-43C1

Approval of Sources

including Tests prior to use

Sampling will be regularly done

to ensure its conformance still

maintained

6.7

Approval of water for

concrete mixes

13530-43C1

Approval of sources including

testing prior to use in

concrete mixes

6.8

Approval of Admixture

13530-43C1

Certificate Required from

Independent Laboratory

FM-006

Mill Certificates shall

arrive with each lot

of delivery.

Water analysis

report

To be incompliance with ASTM

C494

ITEM

ACTIVITY

CONTROL DOCS

PROCEDURE REQUIRED

6.9

Design Mixes

13530-43C1

6.10

Concrete Mixing Batching

and Transportation

13530-43C1

General Concrete Works

Method Statement shall be

approved prior to placing order.

6.11

Concrete Placing,

Compaction and Vibration

13530-43C1

General Concrete Works

Method Statement shall be

approved prior to placing order.

REPORT FORM/

CHECKLIST

NUMBER

FM-006

FM-007

FM-008

FM-009

HOLD

RESPONSIBILITY

C

FW

COMMENTS

CTCI

Trial Mixes to be performed

prior to use.

To comply with ASTM C94. All

The trial mixes proposed are in

compliance with the

requirement stated in clause

6.4 Concrete Mixes

,Specification for Concrete

Works.

Batching Plant to be

approved prior to use

Tools & Apparatus etc to be

calibrated/certified.

Final inspection of formwork

and rebar, weather

conditions.,

To comply with ASTM C94. All

trial mixes proposed to be in

compliance with the

requirement stated in clause

6.8 , Specification for Piling ,

Engineering Standard.

To follow General Concrete

Works Method Statement

Concrete sampling & Slum

test before pour,

Vibration during placement

6.12

Protection and Curing

13530-43C1

8.13

Cube Testing

13530-43C1

Method Statements for Pile

Driving shall be approved prior

to Work Commencement

Concrete Test results.

Random Test by

Independent Laboratory

ITEM

ACTIVITY

CONTROL DOCS

6.14

Embedded Items

TRENCHES & DUCTWORK

7.1

Setting out

Layout

drawings

7.2

Installation of underground

duct banks, pull pits, conduits

and manholes

Layout

drawings

PROCEDURE REQUIRED

13530-43C1

Method Statement for Trenches

& Ductwork

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

FW

CTCI

FM-006

Setting out Procedure

FM-002

Agreed setting out points

FM-002

FM-003

1353043C2

7.3

Trench excavation

Layout

drawings

1353043C22

FM-002

FM-003

Compaction Test at the

bottom is accepted.

COMMENTS

Check of templates and bolt

settings.

Cross check shall be done

regularly.

ITEM

7.4

ACTIVITY

CONTROL DOCS

Backfill and compaction

PROCEDURE REQUIRED

REPORT FORM/

CHECKLIST

NUMBER

Layout

drawings

HOLD

RESPONSIBILITY

C

FM-004

FW

CTCI

1353043C22

8.

STEELWORK

8.1

Welding procedures

8.2

Welder qualification

ASME IX

8.3

Welder performance

Welders daily

performance record

8.4

Weld maps

Construction drawings

8.5

NDT

Construction drawings

8.6

Erection marking

46C1

8.7

Erection and setting out

46C1

FM-014

Approved welding

procedures

Welders identification for

each weld

COMMENTS

ITEM

ACTIVITY

CONTROL DOCS

8.8

Painting

8.9

Steelwork inspection and

acceptance

9.

CONCRETE FIRE PROTECTION

9.1

Concrete Fire Protection

Application

10

ROADWAYS & PAVING

10.1

Setting Out

PROCEDURE REQUIRED

REPORT FORM/

CHECKLIST

NUMBER

HOLD

C

Surface preparation, Dry film

thickness

46C1

1353043C3

Layout

drawings

RESPONSIBILITY

FW

CTCI

FM-002

Agreed setting out reference

FM-003

FM-007

Agreed for Maximum Dry

Density & Optimum Moisture

Results to control Field

Compaction

1353043C2

10.2

Compaction Inspection

Layout

drawings

1353043C2

11.

GROUTING MATERIALS & WORKMANSHIP

COMMENTS

ITEM

ACTIVITY

CONTROL DOCS

11.1

Preparation curing and

placement

12.

EARTHING CABLES & RODS

12.1

Installation and Testing

13.

UNDERGROUND PIPING (CARBON STEEL)

13.1

Piping fabrication

1353088C2

13.2

Existing services

13.3

PROCEDURE REQUIRED

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

CTCI

Visual fit-up

As-built

drawings

Approval before excavating

Welding procedures (carbon

steel)

1353088C2

Approved welding

procedures

13.4

Welder qualification

ASME IX

Approved welders

13.5

Welder performance

Welders

daily

performanc

e record

13.6

Weld maps

Isometric

Drawings

1353043C1

1353043C8

Supplier to be Approved prior

to use.

FW

Welders identification for

each weld

COMMENTS

Material approval if contractor supplied

ITEM

ACTIVITY

CONTROL DOCS

13.7

NDT

Isometric

Drawings

13.8

Piping erection

Isometric

Drawings

13.9

Pre-hydrotest inspection

13.10

Hydrotesting

Test packs

13.11

Coating and wrapping

1353083A4

13.12

Air and water tests (nonpressurised drainage and

sewer systems)

14.

UNDERGROUND PIPING (NON METALLIC)

14.1

Setting Out

14.2

Excavation

14.3

PROCEDURE REQUIRED

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

FW

COMMENTS

CTCI

Hold until release for

connection

Completed isometric

fabrication packs

Hydsrotest procedure

Pre-test inspection and

approval to test

Coating/wrapping procedure

Holiday test

Pretest inspection

Layout Drawings

13530-45C1

Formation of trench

14.4

Check invert levels of trench

14.5

Installation of concrete/nonmetallic pipe to

manufacturers instructions

13530-45C1

14.6

Check connections are

aligned and tight

13530-45C1

Material to be approval prior to use.

Manholes and catchbasins included

Random inspection

Materials approval if contractor supplied

ITEM

ACTIVITY

CONTROL DOCS

PROCEDURE REQUIRED

REPORT FORM/

CHECKLIST

NUMBER

HOLD

RESPONSIBILITY

C

FW

14.7

Hydrotest on closed systems

13530-45C1

14.8

Flushing of open systems

13530-45C1

14.9

Backfill and compaction

13530-45C1

14.10

Visual inspection for

obstructions

13530-45C1

14.11

Manholes fitted and sealed

as appropriate

13530-45C1

14.12

Gratings fitted as appropriate

13530-45C1

COMMENTS

CTCI

Hydrotest of manholes and catchbasins

included

Das könnte Ihnen auch gefallen

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionVon EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionBewertung: 4.5 von 5 Sternen4.5/5 (16)

- Project Earthwork ProcedureDokument6 SeitenProject Earthwork ProcedureJitesh SahiNoch keine Bewertungen

- ItpDokument7 SeitenItpJose Sherin100% (1)

- Field Inspection - Test PlanDokument59 SeitenField Inspection - Test PlansswahyudiNoch keine Bewertungen

- Project Execution Plan PDFDokument14 SeitenProject Execution Plan PDFAnonymous nbWDHCv100% (1)

- National Water Supply Building Works Method StatementDokument16 SeitenNational Water Supply Building Works Method StatementPROJECT MANAGERNoch keine Bewertungen

- 03 Rebar InspectionDokument1 Seite03 Rebar InspectionDawit SolomonNoch keine Bewertungen

- Method Statement For Carbon Steel U G Piping Fabrication ErectionDokument28 SeitenMethod Statement For Carbon Steel U G Piping Fabrication ErectionAriel Anasco100% (1)

- 026-Itp For Structural Steel PDFDokument18 Seiten026-Itp For Structural Steel PDFKöksal Patan100% (11)

- ITP Plan - FF PDFDokument7 SeitenITP Plan - FF PDFAltaf KhanNoch keine Bewertungen

- Land Preparation Plan for 12 Ha Revetment ProjectDokument12 SeitenLand Preparation Plan for 12 Ha Revetment ProjectBerry UmpolaNoch keine Bewertungen

- Structural Steel ErectionDokument7 SeitenStructural Steel Erectionzaki fadlNoch keine Bewertungen

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDokument18 Seiten012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanNoch keine Bewertungen

- Procedure Installation of Grounding & Lightning System - LABUAN BAJO PDFDokument9 SeitenProcedure Installation of Grounding & Lightning System - LABUAN BAJO PDFWika Djoko ONoch keine Bewertungen

- Method Statement Trial TrenchDokument6 SeitenMethod Statement Trial TrenchSasi KumarNoch keine Bewertungen

- Work Plan: Schedule Activity Start Date Finish DateDokument4 SeitenWork Plan: Schedule Activity Start Date Finish DateIbrahim MohammedNoch keine Bewertungen

- Request For Inspection of MaterialDokument3 SeitenRequest For Inspection of MaterialSopi Labu100% (1)

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDokument53 SeitenA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNoch keine Bewertungen

- Method Statement Fo UG Sewer UPVC PipingDokument7 SeitenMethod Statement Fo UG Sewer UPVC PipingUgurNoch keine Bewertungen

- Itp PipingDokument40 SeitenItp PipingBUDAPESNoch keine Bewertungen

- SA04C2-T-MET-AAG-00037 Hydrotest Method StatementDokument25 SeitenSA04C2-T-MET-AAG-00037 Hydrotest Method StatementABAID ULLAH100% (2)

- Fire Hose Rack & Reel Testing ProcedureDokument2 SeitenFire Hose Rack & Reel Testing ProcedureDong VanraNoch keine Bewertungen

- 8.steel Structure WorkDokument15 Seiten8.steel Structure Workibal_farhan100% (4)

- 039-Itp For Embedded Plate PDFDokument7 Seiten039-Itp For Embedded Plate PDFKöksal PatanNoch keine Bewertungen

- Al Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation & Termination of Cables & WiresDokument5 SeitenAl Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation & Termination of Cables & Wiresmidhun muraliNoch keine Bewertungen

- ITP FormatDokument3 SeitenITP FormatyousifNoch keine Bewertungen

- Summary of Test On Steel ReinforcementDokument1 SeiteSummary of Test On Steel ReinforcementalfredoNoch keine Bewertungen

- Above Ceiling Work PermitDokument1 SeiteAbove Ceiling Work Permitmark lester caluzaNoch keine Bewertungen

- Method Statement for Excavation WorksDokument12 SeitenMethod Statement for Excavation WorksBasem DoniaNoch keine Bewertungen

- Method Statement Piping WorksDokument11 SeitenMethod Statement Piping WorksAtty Atty100% (1)

- 5.ITP For Excavation and Back FillingDokument19 Seiten5.ITP For Excavation and Back FillingDaniel Sinaga100% (5)

- ITP AllDokument1 SeiteITP AllMuhammadIqbalMughalNoch keine Bewertungen

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDokument1 SeiteAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairNoch keine Bewertungen

- Daily site diary construction backup facilitiesDokument2 SeitenDaily site diary construction backup facilitiesMahibul HasanNoch keine Bewertungen

- Inspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CDokument1 SeiteInspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CYash SharmaNoch keine Bewertungen

- 09 - Method Statement For Paint WorkDokument6 Seiten09 - Method Statement For Paint WorkAnsar WarraichNoch keine Bewertungen

- Project Inspection Test Plan Steel StructureDokument47 SeitenProject Inspection Test Plan Steel StructureMohammed Ady Ganjar100% (4)

- Mobilization Checklist 1Dokument3 SeitenMobilization Checklist 1MuslimkarimjeeNoch keine Bewertungen

- Inspection Test Plan: When Required Depth Is Achieved When Bearing Layer Is IdentifiedDokument16 SeitenInspection Test Plan: When Required Depth Is Achieved When Bearing Layer Is IdentifiedAziz Fathiry RahmanNoch keine Bewertungen

- Itp For Site Preparation & Earth WorksDokument17 SeitenItp For Site Preparation & Earth WorksDaniel Martinez100% (1)

- Method Statement of Foundation Concrete CoatingDokument17 SeitenMethod Statement of Foundation Concrete CoatingGerry Dwi PutraNoch keine Bewertungen

- 027-ITP For Pre - Cast Concrete PDFDokument11 Seiten027-ITP For Pre - Cast Concrete PDFKöksal Patan75% (4)

- Installation Method StatementDokument6 SeitenInstallation Method StatementgururajNoch keine Bewertungen

- Steel Structure Erection ProcedureDokument15 SeitenSteel Structure Erection ProcedureElias EliasNoch keine Bewertungen

- Storm Drain Flushing Method StatementDokument12 SeitenStorm Drain Flushing Method Statementarshad iqbalNoch keine Bewertungen

- Method Statement For Stone WorksDokument10 SeitenMethod Statement For Stone WorksvisanuNoch keine Bewertungen

- 03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFDokument5 Seiten03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFYati R. TankNoch keine Bewertungen

- 4 Construction Method Site PreparationDokument7 Seiten4 Construction Method Site Preparationmiradhilaa05100% (1)

- Concrete Foundation Handover FormDokument5 SeitenConcrete Foundation Handover Formrobby a. malikNoch keine Bewertungen

- Method of Statement For HDPE Pipe InstallationDokument2 SeitenMethod of Statement For HDPE Pipe InstallationYe Yint100% (2)

- Install Insulated CladdingDokument16 SeitenInstall Insulated CladdingfabinNoch keine Bewertungen

- MS of Instrumentation Installation & MonitoringDokument32 SeitenMS of Instrumentation Installation & Monitoringmbp planning100% (1)

- ITP C 005 (Structural Concrete)Dokument4 SeitenITP C 005 (Structural Concrete)segun ajibolaNoch keine Bewertungen

- Method Statement Survey.Dokument3 SeitenMethod Statement Survey.Manas Kumar Samal100% (7)

- Site Setup and Safety ProceduresDokument92 SeitenSite Setup and Safety ProceduresMarko AnticNoch keine Bewertungen

- Method Statement Steel Structure 1 4 Meg PDFDokument26 SeitenMethod Statement Steel Structure 1 4 Meg PDFemeka2012Noch keine Bewertungen

- ITP For CW and ACW Piping WorkDokument8 SeitenITP For CW and ACW Piping WorkPhong DoNoch keine Bewertungen

- DSC QC Daily ReportDokument2 SeitenDSC QC Daily Reportanon_688841981Noch keine Bewertungen

- ITP-FW For Civil & Building WorksDokument17 SeitenITP-FW For Civil & Building WorksRajnath Rajbhar Pancham86% (7)

- ITP FW For Civil Building WorksDokument17 SeitenITP FW For Civil Building WorksAjit Singh RathoreNoch keine Bewertungen

- Counterproductive (Safety and Security) StrategiesDokument24 SeitenCounterproductive (Safety and Security) StrategiesRizki KresnaNoch keine Bewertungen

- Qualityassuranceppt 160905042719Dokument41 SeitenQualityassuranceppt 160905042719Rizki KresnaNoch keine Bewertungen

- Challenging and Enforcing SafetyDokument17 SeitenChallenging and Enforcing SafetyRizki KresnaNoch keine Bewertungen

- Human Factors Risk Assessment and ManagementDokument27 SeitenHuman Factors Risk Assessment and ManagementRizki KresnaNoch keine Bewertungen

- Assesment Workshop PJB PT Lycon Asia Mandiri: Operating Quality Testing and EquipmentDokument4 SeitenAssesment Workshop PJB PT Lycon Asia Mandiri: Operating Quality Testing and EquipmentRizki KresnaNoch keine Bewertungen

- Spectrometer SootblowerDokument1 SeiteSpectrometer SootblowerRizki KresnaNoch keine Bewertungen

- Development of A Functional Model Which IntegratesDokument32 SeitenDevelopment of A Functional Model Which IntegratesRizki KresnaNoch keine Bewertungen

- Improving human factors, incident reporting, and safety managementDokument5 SeitenImproving human factors, incident reporting, and safety managementRizki KresnaNoch keine Bewertungen

- Health and Safety Management in Ghanaian Construction SMEsDokument12 SeitenHealth and Safety Management in Ghanaian Construction SMEsRizki KresnaNoch keine Bewertungen

- Specimen Preparation and Testing Options For Metal SamplesDokument14 SeitenSpecimen Preparation and Testing Options For Metal SamplesRizki KresnaNoch keine Bewertungen

- Behavioural Safety and Accident PreventionDokument7 SeitenBehavioural Safety and Accident PreventionRizki KresnaNoch keine Bewertungen

- Under Keel Clearance Policy PaperDokument6 SeitenUnder Keel Clearance Policy PaperRizki KresnaNoch keine Bewertungen

- Specimen Preparation and Testing Options For Metal SamplesDokument14 SeitenSpecimen Preparation and Testing Options For Metal SamplesRizki KresnaNoch keine Bewertungen

- Qualityassuranceppt 160905042719Dokument41 SeitenQualityassuranceppt 160905042719Rizki KresnaNoch keine Bewertungen

- Stage-Gate Process For Life Sciences and Medical Innovation InvestmentDokument8 SeitenStage-Gate Process For Life Sciences and Medical Innovation InvestmentRizki KresnaNoch keine Bewertungen

- Assesment Workshop PJB PT Lycon Asia Mandiri: Operating Quality Testing and EquipmentDokument4 SeitenAssesment Workshop PJB PT Lycon Asia Mandiri: Operating Quality Testing and EquipmentRizki KresnaNoch keine Bewertungen

- Evaluasi Dokumen Aspek Teknis Pada Proses Pelelang PDFDokument8 SeitenEvaluasi Dokumen Aspek Teknis Pada Proses Pelelang PDFRizki KresnaNoch keine Bewertungen

- Game Theory As A Tool of Project ManagementDokument7 SeitenGame Theory As A Tool of Project ManagementRizki KresnaNoch keine Bewertungen

- Weekly Progress Report 34Dokument15 SeitenWeekly Progress Report 34Rizki KresnaNoch keine Bewertungen

- PT Lycon Asia Mandiri Purchasing Requisition Engineering UniformsDokument1 SeitePT Lycon Asia Mandiri Purchasing Requisition Engineering UniformsRizki KresnaNoch keine Bewertungen

- Company Profile 2014-Plus SipilDokument29 SeitenCompany Profile 2014-Plus SipilRizki KresnaNoch keine Bewertungen

- PLTM Tangka Schedule Rev.01Dokument1 SeitePLTM Tangka Schedule Rev.01Rizki KresnaNoch keine Bewertungen

- Perbandingan Grafik Spektrum Dengan Variasi GDokument23 SeitenPerbandingan Grafik Spektrum Dengan Variasi GRizki KresnaNoch keine Bewertungen

- Acne Treatment Strategies and TherapiesDokument32 SeitenAcne Treatment Strategies and TherapiesdokterasadNoch keine Bewertungen

- Inside Animator PDFDokument484 SeitenInside Animator PDFdonkey slapNoch keine Bewertungen

- Do You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Dokument1 SeiteDo You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Mary Rose BaluranNoch keine Bewertungen

- Casting Procedures and Defects GuideDokument91 SeitenCasting Procedures and Defects GuideJitender Reddy0% (1)

- FSRH Ukmec Summary September 2019Dokument11 SeitenFSRH Ukmec Summary September 2019Kiran JayaprakashNoch keine Bewertungen

- Describing-Jobs-British-English StudentDokument3 SeitenDescribing-Jobs-British-English Studentrenata pedroso100% (1)

- 3 - Performance Measurement of Mining Equipments by Utilizing OEEDokument8 Seiten3 - Performance Measurement of Mining Equipments by Utilizing OEEGonzalo GarciaNoch keine Bewertungen

- Coffee Table Book Design With Community ParticipationDokument12 SeitenCoffee Table Book Design With Community ParticipationAJHSSR JournalNoch keine Bewertungen

- Polyol polyether+NCO Isupur PDFDokument27 SeitenPolyol polyether+NCO Isupur PDFswapon kumar shillNoch keine Bewertungen

- Column Array Loudspeaker: Product HighlightsDokument2 SeitenColumn Array Loudspeaker: Product HighlightsTricolor GameplayNoch keine Bewertungen

- Good Ethics Is Good BusinessDokument9 SeitenGood Ethics Is Good BusinesssumeetpatnaikNoch keine Bewertungen

- ConductorsDokument4 SeitenConductorsJohn Carlo BautistaNoch keine Bewertungen

- 15142800Dokument16 Seiten15142800Sanjeev PradhanNoch keine Bewertungen

- Estimation of Working CapitalDokument12 SeitenEstimation of Working CapitalsnehalgaikwadNoch keine Bewertungen

- Cushman Wakefield - PDS India Capability Profile.Dokument37 SeitenCushman Wakefield - PDS India Capability Profile.nafis haiderNoch keine Bewertungen

- Sharp Ar5731 BrochureDokument4 SeitenSharp Ar5731 Brochureanakraja11Noch keine Bewertungen

- Exp 8 - GPG - D12B - 74 PDFDokument4 SeitenExp 8 - GPG - D12B - 74 PDFPRATIKSHA WADIBHASMENoch keine Bewertungen

- Pita Cyrel R. Activity 7Dokument5 SeitenPita Cyrel R. Activity 7Lucky Lynn AbreraNoch keine Bewertungen

- 2023-Physics-Informed Radial Basis Network (PIRBN) A LocalDokument41 Seiten2023-Physics-Informed Radial Basis Network (PIRBN) A LocalmaycvcNoch keine Bewertungen

- Lankeda 3d Printer Filament Catalogue 2019.02 WGDokument7 SeitenLankeda 3d Printer Filament Catalogue 2019.02 WGSamuelNoch keine Bewertungen

- Inventory Control Review of LiteratureDokument8 SeitenInventory Control Review of Literatureaehupavkg100% (1)

- Catalogoclevite PDFDokument6 SeitenCatalogoclevite PDFDomingo YañezNoch keine Bewertungen

- SQL Guide AdvancedDokument26 SeitenSQL Guide AdvancedRustik2020Noch keine Bewertungen

- LM1011 Global ReverseLogDokument4 SeitenLM1011 Global ReverseLogJustinus HerdianNoch keine Bewertungen

- Case Study Hotel The OrchidDokument5 SeitenCase Study Hotel The Orchidkkarankapoor100% (4)

- On The Behavior of Gravitational Force at Small ScalesDokument6 SeitenOn The Behavior of Gravitational Force at Small ScalesMassimiliano VellaNoch keine Bewertungen

- Towards A Human Resource Development Ontology Combining Competence Management and Technology-Enhanced Workplace LearningDokument21 SeitenTowards A Human Resource Development Ontology Combining Competence Management and Technology-Enhanced Workplace LearningTommy SiddiqNoch keine Bewertungen

- Maverick Brochure SMLDokument16 SeitenMaverick Brochure SMLmalaoui44Noch keine Bewertungen

- 8dd8 P2 Program Food MFG Final PublicDokument19 Seiten8dd8 P2 Program Food MFG Final PublicNemanja RadonjicNoch keine Bewertungen

- FX15Dokument32 SeitenFX15Jeferson MarceloNoch keine Bewertungen