Beruflich Dokumente

Kultur Dokumente

Cabletrays Institute Technical Bulletin5

Hochgeladen von

ahmodah0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

9 Ansichten2 Seitenbvn

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenbvn

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

9 Ansichten2 SeitenCabletrays Institute Technical Bulletin5

Hochgeladen von

ahmodahbvn

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Cabletrays Institute Technical Bulletin

1 of 2

Tie Down Practices for Multiconductor Cables in Cable Trays

(note single conductor practices are to covered in a new bulletin)

Revised 6/10/06

There are three items which require decisions concerning the tying down of multiconductor cables in cable

tray wiring systems. Item #1 is to define under what conditions the multiconductor cables in cable trays are

to be tied down. Item #2 is to define the frequency at which the multiconductor cables are to be tied down.

Item #3 is to select the ties that have the proper characteristics for the specific installations. In the following

material, where the word cable is used it means multiconductor cable.

Item #1- Conditions Requiring Cable Tie Down:

The reasons for tying down cables are to keep them in the cable trays, to maintain the proper spacing

between cables, or to confine the cables to specific locations in the cable trays. National Electrical Code

Section392.8(B) states that in other than horizontal cable tray runs, the cables shall be fastened securely to

transverse members of the cable trays. In horizontal cable tray runs, cables are not required to be tied

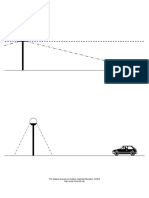

down. The cable's weight will keep them in the cable trays. In non-horizontal cable tray runs, the cables

must be tied down. For a vertical cable tray installation, the cables may hang away from the cable tray if

they are not tied down. The more flexible small diameter cables will hang further away from the cable trays

than the large diameter cables if they are not tied down. The smaller diameter cables will need to be tied to

the cable tray more frequently than the stiff large diameter cables.

Cable installations as per the 2005 NEC ,sections 392.11(A) (3) and 392.13(A)

392.13(A) permit higher ampacities, even the free air rating of the cable, where cables are installed in a

single layer ,in uncovered trays ,with a maintained spacing not less than one cable diameter between

cables. Cable ties maintain this spacing and thereby permit hicher ampacities

.

.

There are installations where the owner may want the cables tied down to guarantee the separation of low

energy signal cables and power cables. This condition may also be obtained by installing a permanent

barrier in the cable tray.

For installations where a single large cable or several cables are installed in ventilated channel cable trays,

it is at times desirable to tie the cables to the horizontal as well as to the non-horizontal ventilated channel

cable trays. Then if an abnormal condition occurs, the cables would not be knocked out of the ventilated

channel cable trays which are only 1 1/2 inches high.

Where Type MI cables are installed that are to have two hour fire resistant ratings, the MI cables must be

securely supported every three feet. A desirable installation would be to install the MI cable in steel cable

trays and to use stainless steel ties to secure the MI cable to the cable tray every three feet.

Where cables drop from the cable trays to equipment enclosures, it may be desirable to anchor the cables

to the last one, two or three rungs before the drop depending on the size of the cables. This easily provides

distributed secured support for the cables when the length of cable between the cable tray and the

Cabletrays Institute Technical Bulletin

2 of 2

equipment enclosure is six feet or longer.

Item #2 - Comments on Cable Tie Down Frequencies:

The NEC doesn't specify any distances between ties for cables in cable tray wiring systems. This is a

decision that must be made by those designing and installing the cable tray wiring systems. It is desirable

to develop some standards for this activity.

A conservative recommendation for non-horizontal cable trays is that the small diameter cables (diameters

less than 1 inch) be tied down at approximately 3 foot intervals and that cables 1 inch and larger be tied

down at approximately 6 foot intervals.

The vertical cable wiring system installations that contain horizontal bends require the cables to be tied

down at every or every other rung in the bend and to the first rung before entering the bend and the first

rung after exiting the bend.

In horizontal cable trays where cable spacing is to be maintained, the cables should be tied down at

approximately 10 foot intervals. For horizontal ventilated channel cable trays, there are installations

containing a single large cable or several cables where it is desirable to tie down the cables at

approximately 10 foot intervals.

Item #3 - Comments on the Types of Cable Ties:

Designers should select cable ties that have the proper characteristics for the specific installations. The

initial installation of the wrong cable ties may require maintenance expenditures to replace the cable ties.

Plastic ties that are not ultraviolet resistant will fail in one to two years if they are installed where they are

exposed to the rays of the sun. Where both indoor and outdoor cables are to be tied down on the same

project, it is best to have only ultraviolet resistant ties on the project and use them on both the indoor and

the outdoor cables. This way it will not be possible to have the incorrect type of ties for the outdoor cables.

When selecting cable ties the following must be considered: moisture resistance, ultraviolet resistance,

extremely high ambient temperatures, extremely low ambient temperatures, chemical resistance,

flammability (UL 94 V-O flammability rating), low smoke characteristics, tensile strength, appropriate

lengths (the surplus lengths of the cable ties are cut off so it is possible to use one tie length as standard

where many different lengths are required). There are quality plastic ties available that if properly applied

have a life span of up to 20 years. There are non-magnetic stainless steel ties as well as the plastic ties.

The stainless steel ties are capable of satisfactorily satisfying a wide range of requirements.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Chapter 5 Contents: 5 - Electrical Design 5 - 3 - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . .Dokument2 SeitenChapter 5 Contents: 5 - Electrical Design 5 - 3 - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . .ahmodahNoch keine Bewertungen

- Cabletrays Institute Technical Bulletin9Dokument4 SeitenCabletrays Institute Technical Bulletin9ahmodahNoch keine Bewertungen

- Cabletrays Institute Technical Bulletin7Dokument1 SeiteCabletrays Institute Technical Bulletin7ahmodahNoch keine Bewertungen

- Hot-Dip Galvanized vs. Aluminum: Design and InstallationDokument2 SeitenHot-Dip Galvanized vs. Aluminum: Design and InstallationahmodahNoch keine Bewertungen

- Gland Chart For BS5308Dokument1 SeiteGland Chart For BS5308ahmodahNoch keine Bewertungen

- Prkglot Ped GraphicDokument1 SeitePrkglot Ped GraphicahmodahNoch keine Bewertungen

- Life Time - DR ShadyDokument1 SeiteLife Time - DR ShadyahmodahNoch keine Bewertungen

- Cramolin Urethane Red (Lacquer) : Technical Data SheetDokument2 SeitenCramolin Urethane Red (Lacquer) : Technical Data SheetahmodahNoch keine Bewertungen

- Cabletrays Institute Technical BulletinDokument3 SeitenCabletrays Institute Technical BulletinahmodahNoch keine Bewertungen

- Distrbtn GraphicDokument1 SeiteDistrbtn GraphicahmodahNoch keine Bewertungen

- Gland Chart For BS6724: Booklet CablesDokument1 SeiteGland Chart For BS6724: Booklet CablesahmodahNoch keine Bewertungen

- Cabletrays Institute Technical Bulletin3Dokument2 SeitenCabletrays Institute Technical Bulletin3ahmodahNoch keine Bewertungen

- Cabletrays Institute Technical Bulletin8Dokument2 SeitenCabletrays Institute Technical Bulletin8ahmodahNoch keine Bewertungen

- Cabletrays Institute Technical Bulletin2Dokument2 SeitenCabletrays Institute Technical Bulletin2ahmodahNoch keine Bewertungen

- Conductors: Bare Copper TapeDokument1 SeiteConductors: Bare Copper TapeahmodahNoch keine Bewertungen

- Cabletrays Institute Technical Bulletin10Dokument2 SeitenCabletrays Institute Technical Bulletin10ahmodahNoch keine Bewertungen

- Gland Chart For BS5467: Booklet CablesDokument1 SeiteGland Chart For BS5467: Booklet CablesahmodahNoch keine Bewertungen

- Earthing: Earth Rod To Cable ClampsDokument1 SeiteEarthing: Earth Rod To Cable ClampsahmodahNoch keine Bewertungen

- Lightning Protection: Tape ClipsDokument1 SeiteLightning Protection: Tape ClipsahmodahNoch keine Bewertungen

- Earthing: Coupling - For Threaded Copperbond Earth RodDokument1 SeiteEarthing: Coupling - For Threaded Copperbond Earth RodahmodahNoch keine Bewertungen

- Page 28Dokument1 SeitePage 28ahmodahNoch keine Bewertungen

- Earthing: Earth Rods - Copperbond ThreadedDokument1 SeiteEarthing: Earth Rods - Copperbond ThreadedahmodahNoch keine Bewertungen

- Lightning Protection: Flexible Braid BondDokument1 SeiteLightning Protection: Flexible Braid BondahmodahNoch keine Bewertungen

- Ece Book PDFDokument66 SeitenEce Book PDFvijay cvijay50% (2)

- Bridge Construction: Dr. Ahmed Abdel-Atty Gab-AllahDokument32 SeitenBridge Construction: Dr. Ahmed Abdel-Atty Gab-Allahselva_651950Noch keine Bewertungen

- Ieee C 37.2Dokument16 SeitenIeee C 37.2fame920917100% (1)

- Process Piping DraftingDokument3 SeitenProcess Piping DraftingtsplinstNoch keine Bewertungen

- 2 Piping Catalogue 2017 2018Dokument414 Seiten2 Piping Catalogue 2017 2018Alejandro AlvarezNoch keine Bewertungen

- Content Area ResourcesDokument3 SeitenContent Area Resourcesapi-312565527Noch keine Bewertungen

- WMSU Annual Report 2010Dokument76 SeitenWMSU Annual Report 2010Western Mindanao State University100% (1)

- Punch and Die Cutting Clearance Calculation ProcedureDokument7 SeitenPunch and Die Cutting Clearance Calculation ProcedureVenkateswaran venkateswaranNoch keine Bewertungen

- Syllabus BS MS IS032IU Facility LayoutDokument5 SeitenSyllabus BS MS IS032IU Facility LayoutQuynh Chau TranNoch keine Bewertungen

- Heavy Plates CapabilitiesDokument26 SeitenHeavy Plates Capabilitieswindsurferke007Noch keine Bewertungen

- Blockchain in Banking: Minor Research Project OnDokument16 SeitenBlockchain in Banking: Minor Research Project OnJash garachNoch keine Bewertungen

- 5a Engine Ecu Pin OutDokument2 Seiten5a Engine Ecu Pin OutARTURO JESUS Kcomt33% (3)

- Chapter 14 Security Engineering 1Dokument48 SeitenChapter 14 Security Engineering 1Fattah MuhyiddeenNoch keine Bewertungen

- FTNON Product PortfolioDokument9 SeitenFTNON Product PortfolioJoe JavierNoch keine Bewertungen

- Use of Geosynthetics in WR ProjectsDokument3 SeitenUse of Geosynthetics in WR Projectsashwaniv_6Noch keine Bewertungen

- Software Testing Session 10 WIMSDokument30 SeitenSoftware Testing Session 10 WIMSkanthu1984Noch keine Bewertungen

- Recycled Concrete AggregateDokument28 SeitenRecycled Concrete AggregatePrashant pande100% (1)

- GesDokument8 SeitenGesAmey GudigarNoch keine Bewertungen

- Tank Settlement 규정Dokument2 SeitenTank Settlement 규정hiyeon100% (4)

- Differential Maintenance: Management GuideDokument12 SeitenDifferential Maintenance: Management GuideavinxhhbmbjNoch keine Bewertungen

- Asme Material Specs PDFDokument4 SeitenAsme Material Specs PDFJulio Cesar Morales CruzNoch keine Bewertungen

- Post Tensioning ManualDokument11 SeitenPost Tensioning Manualimzee25100% (7)

- Scalable Automation For Drug Delivery Devices: Phillips-MedisizeDokument5 SeitenScalable Automation For Drug Delivery Devices: Phillips-MedisizeQuality JiveNoch keine Bewertungen

- D3261 16Dokument8 SeitenD3261 16masoudNoch keine Bewertungen

- Introduction To MechatronicsDokument46 SeitenIntroduction To MechatronicsChristian Breth Burgos100% (2)

- National Diploma: Engineering: Mechatronics: Qualification Code: NDMR06 - NQF Level 6Dokument6 SeitenNational Diploma: Engineering: Mechatronics: Qualification Code: NDMR06 - NQF Level 6BennettNoch keine Bewertungen

- Napier NT1 BrochureDokument16 SeitenNapier NT1 Brochureairtupas100% (2)

- Advance Water Distrubution System Final1Dokument60 SeitenAdvance Water Distrubution System Final1Suraj RaghuwanshiNoch keine Bewertungen

- Hyper Compressor CatalougeDokument24 SeitenHyper Compressor Catalougetatarey79Noch keine Bewertungen

- Anna University Chennai:: Chennai - 600025. Office of The Controller of Examinations Rank List April / May 2022 ExaminationsDokument74 SeitenAnna University Chennai:: Chennai - 600025. Office of The Controller of Examinations Rank List April / May 2022 ExaminationsJoseph DurairajNoch keine Bewertungen