Beruflich Dokumente

Kultur Dokumente

Effect of Raw Meal Fineness On Quality of Clinker

Hochgeladen von

Prasann R NamannavarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Effect of Raw Meal Fineness On Quality of Clinker

Hochgeladen von

Prasann R NamannavarCopyright:

Verfügbare Formate

Journal of Multidisciplinary Engineering Science and Technology (JMEST)

ISSN: 3159-0040

Vol. 2 Issue 11, November - 2015

The Effect Of Raw Materials Fineness And

Lime Saturation Factor On Clinkers Grindability

And Energy Effeciency In The Gabes Cement

Industry

Soumaya Ibrahimi, Environment Catalyses and

Analyzes of Processes Unit Research (ECAP),

National School of Engineering of Gabes, Tunisia,

Ibrahimi.soumaya@gmail.com

Njib Ben Jamaa, College of Engineering of Arar

Northern Border University P.O. Box 1321, Arar

91431, Kingdom of Saudi Arabia.

Mohamed Bagan, Applied Thermodynamics

Unit Research, National School of Engineering of

Gabes, Tunisia.

AbstractThe aim of the present research is to

improve the manufacturing conditions of cement

and therefore its quality. For this purpose, various

reference samples of clinker were produced in the

normal manufactures conditions considered by

the Company of Cement of Gabes, then compared

to other samples which are variable in the Lime

Saturation Factor and the raw materials fineness.

All the samples are analyzed by X-Ray

Fluorescence, X-ray diffraction and optical

microscopy including a study of measurement of

clinkers crystal sizes. Besides, tests of

compressive strength were made after 2, 7 and 28

days. Finally, a study of clinkers grindability

enabled us to evaluate the probability of grinding

of these samples. In all cases, the best clinker is

the one that has a vintages fineness close to 1315% for the refusal of 100 m. This latter gives a

well-formed clinker nodules, well homogenized

phases and indicating cements good quality. This

clinker presents also the best grindability.

Keywords Cement; clinker; LSF; raw

fineness; compressive strength; grindability

I.

materials

INTRODUCTION

Portland cement is a highly sought material. It is a

fine powder produced by grinding Portland cement

clinker (more than 90%), a limited amount of calcium

sulfate (which controls the set time) and up to 5%

minor constituents allowed by various standards.

Portland cement clinker is typically composed of 42.975.4% alite (C3S), 0.1-27.6% belite (C2S), 0.4-10.9%

aluminate (C3A), and 0.6-14.4% ferrite(C4AF)(1). The

world production of cement was about 2.55 billion tons

in 2006 (2), it increased to 3.2 billion tons in 2011 (3).

The global market economy has always forced

industrials to be more competitive in monitoring their

Mekki Ben Ammar, Cement Society of Gabes,

Tunisia, mbenammar@scg.com.tn.

Andr Lecomte, Jean Lamour Institute CP2S

Department, 207 Materials for Civil Engineering, IUT

Nancy-Brabois Le Montet, F-54601 Villers-ls-Nancy

Cedex

Ccile Diliberto, Jean Lamour Institute CP2S

Department, 207 Materials for Civil Engineering, IUT

Nancy-Brabois Le Montet, F-54601 Villers-ls-Nancy

Cedex

activities. This involves developing more efficient and

economically viable means of production. The

production of cement involves several steps which are

particularly electrical energy consuming: raw materials

grinding and heating and clinkers grinding.

The total electrical energy consumed by the cement

manufacturing process is approximately 110 kWh/t.

About 40% of this energy is consumed in grinding

clinker (4). Therefore, the objective of cement

producers is to make this phase of production more

economical and this is the major goal of the present

work. Several investigations studied the subject of

clinker grinding. They were primarily articulated around

the effects of the chemical (5, 6), structural (7) and

morphological (8, 9) characteristics of the clinker.

However, there are few studies which treat the effect

of the vintages chemistry on the grindability of clinker

and the quality of cement.

The objectives of the present study were to

determine the effects of the fineness and the lime

saturation factor (LSF) of the raw materials on the

cements quality (chemical composition, fineness,

resistance) and the clinkers characteristics and to

study the influence of these two factors on the clinkers

grindability.

II. EXPERIMENTAL

PROCEDURE

MATERIALS

AND

Typical Portland cement raw mix and plant clinkers

were obtained from the cement plant of Gabes (South

of Tunisia).

A.

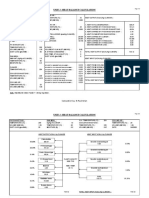

X- Ray Fluorescence analysis

The

chemical

and

potential

compound

compositions of the clinkers used in this study are

listed in table I.

www.jmest.org

JMESTN42351178

3149

Journal of Multidisciplinary Engineering Science and Technology (JMEST)

ISSN: 3159-0040

Vol. 2 Issue 11, November - 2015

CHEMICAL AND MINERALOGICAL COMPOSITIONS OF THE CLINKERS (%).

TABLE I.

Clinker samples

F

CaO

SiO2

Al2O3

Fe2O3

SO3

K2O

F1

F2

66.34

65.78

21.65

21.75

4.91

5.03

3.12

3.24

1.31

1.29

0.60

0.59

N1L1

N2L1

N3L1

N4L1

N1L2

N2L2

N3L2

N4L2

66.46

66.05

65.78

65.49

66.41

66.61

66.56

66.5

22.37

21.47

22.2

22.05

22.21

22.05

22.16

22.2

4.97

4.99

5.17

5.27

4.93

4.88

4.9

4.99

3.29

3.45

3.51

3.48

3.24

3.21

3.29

3.33

0.52

0.67

1.04

1.22

0.51

0.41

0.3

0.22

G1

G2

G3

G4

G5

G6

G7

G8

65.97

65.43

66.1

66.52

65.85

65.39

65.07

65.17

21.66

20.6

21.18

21.37

21.82

21.65

21.42

21.54

4.97

5.26

4.88

4.93

5.14

5.17

5.06

5.01

2.79

3.07

2.91

3.02

3

2.88

2.88

2.89

1.42

2.64

1.16

0.41

1.03

1.04

1.77

1.45

The cement clinker produced under the normal

conditions of manufacturing considered by the

cements company is designed clinker G. It is

considered as the reference cement clinker. Clinker F

is the cement clinker which is made by changing the

raw mix fineness (8.5 14.93 % for the refusal of 100

m (R100)). The product made by changing the Lime

Saturation Factor (LSF) (94.9% - 98.7 %) is designed

as clinker L. The global characteristics of the raw

materials are shown in table II.

TABLE I.

CHARACTERISTICS

COLLECTIONS USED IN THIS STUDY.

OF

THE

RAW

Raw

materials

F1

F2

L1

L2

LSF (%)

98.6

98.

97.5

94.

98.7

R100 (%)

19.7

3

8.5

5

14.9

13.

9

15.1

5

B.

MATERIALS

Optical microscopy analyses

Microscopy gives visual form to the data from other

methods of analysis. The microscopic observation of

cement clinker is done in reflected light [9]. So we

need the preparation of polished sections. At first, four

to five nodules of clinker were selected and placed in a

cylindrical mould made of polyethylene, 40 mm in

diameter and 30 mm in height. Theses clinkers were

completely immersed in a cold mounting resin. After 20

minutes of impregnation, we obtain a pellet clinker.

The sample is cut with a saw to bring up the nodules

and get a flat section of clinker.

Free

lime

0.84

C3S

C2S

1.06

60.93

56.07

16.13

20.08

0.29

0.66

0.52

0.57

0.58

0.58

0.52

0.37

1.05

2.45

0.94

1.01

2.9

2.86

2.59

0.86

56.70

55.38

52.53

51.06

56.70

55.38

52.53

51.06

21.39

19.8

24.04

24.72

25.56

22.95

23.17

18.72

0.59

0.62

0.48

0.42

0.46

0.6

0.75

0.63

1.52

1.36

1.3

0.89

1.06

0.95

1.27

1.19

57

58.4

63.4

67.1

57.2

57.4

55.5

56.2

19.2

15.1

12.8

10.8

19.5

18.9

19.6

19.5

This section was ready for polishing on disc by

using abrasive paper with adhesive reverse of number

320, 400, 600, 800, 1000 and 1200 m respectively

until obtaining an increasingly polished section. The

final phase of polishing is done on cloth by using an

alumina suspension, diluted with alcohol and acting as

a lubricant. Then the section is washed with alcohol in

an ultrasonic cleaner (10).

By taking account of the resemblance of the

various phases of the clinker, a surface chemical

attack must be made on all samples in order to make

the various phases of the clinker apparent. The

crystals of alite (C3S) are prismatic, those of belite

(C2S) are rounded and the interstitial mass (C3A +

C4AF) is clear (11). The samples used in this study

were etched with hydrofluoric acid vapor or a solution

of nitric acid HNO3 with 0.25 % in alcohol.

C.

Grinding tests

Grinding tests were carried out using a standard

laboratory apparatus consisting in a cylindrical ball mill

uncoated type TTS50. The dimensions of the mill are

typically 400 mm in length and 400mm in diameter. Its

weight, including steel balls, is 380 kg. The feed

charge was held constant at 1460g of clinker

combined with 40g of fluogypsum, and then rotated for

10 minutes of grinding and 3 minutes of discharge.

During experiments, the mill was rotated at 50 rpm. In

order to compare the grindability of the three types

of clinker described in Table 2, four samples of each

collection are grinded for 13 minutes then two samples

of them are grinded for 8 and after 18 minutes. The

quality of cement is measured by the surface area or

the Blaine index. This index is determined by the

Blaine air permeability test. All stages of grinding are

determining for the production of 3500 cm2/g Blaine

surface area (12). This surface area of the cement

www.jmest.org

JMESTN42351178

3150

Journal of Multidisciplinary Engineering Science and Technology (JMEST)

ISSN: 3159-0040

Vol. 2 Issue 11, November - 2015

powder depends on size distribution of cement

particles; smaller particles have larger surface area.

The breakage process is characterized by a selection

function that represents the fractional rate of breakage

of particles in each size class and so the probability of

breakage. To obtain the specific selection function and

the Blaine specific surface of this material, each

sample was individually ground in dry conditions at

different times of grinding, using a constant ball

diameter (32 mm). The other operating conditions

were also kept constant as those mentioned above. To

compare the energies of grinding, we used the law

developed by Bond (13).

III. RESULTS AND DISCUSSION

The fundamental use of the microscope in Portland

cement clinker analysis is to bring to the observer a

visual appreciation of phase identities, sizes,

conditions, and mutual relationships. If we compare

the micrographs of the reference collection G (Fig.1)

with the other collections which are represented in

Fig.2 and Fig.3, we can note that the distribution of

phases becomes more heterogeneous. This can

indicate unstable conditions of manufactures,

heterogeneous raw materials, insufficient smoothness

and short burning time. Whereas, for the clinker

collections F and L, we notice an improvement in

global crystals characteristics such as the sizes of

belite clusters which become smaller and the

distribution of the phases appears generally less

heterogeneous and sometimes very homogeneous. So

the conditions of manufacturing become more stable

and acceptable.

(a) 100x

(a) 400x

(b) 400x

Fig. 3. Micrography of the clinker L attacked by the vaporized

hydrofluoric acid (40%).The crystals of belite are rounded and blue.

The crystals of alite are prismatic and brown. The interstitial mass is

well crystallized and white. Homogeneous distribution of the

phases.

To confirm these qualitative interpretations, we

made a quantification of the clinkers phases by

measuring the sizes of alite and belite crystals.

Fig.4 shows the relationship between the length of

alite, the diameter of belite and the raw materials

fineness. On one hand, the crystal size of alite

becomes smaller by decreasing the raw materials

fineness. Thus, it seems clear that the raw

smoothness has a great role on the phase of

clinkerization. On the other hand, the crystal size of

belite becomes larger by decreasing the fineness of

the raw. These results are in good correlation with

Onos method (9).

(b) 200x

Fig. 1. Micrography of the clinker G attacked by the vaporized

hydrofluoric acid (40%): Heterogeneous distribution of the phases

and Clusters of belite are so frequent.

Fig. 4. Variation of crystals sizes with the raw material fineness.

The effect of the raw mix fineness on the

compressive strength is appreciated in Fig.5. This

diagram shows that the influence of the fineness is

better sensed for early-age resistances (2 and 7 days).

This result illustrates also that the fineness develop the

alites phase which is responsible of the 2 and 7 days

resistances.

(a) 200x

(b) 400x

Fig. 2. Micrography of the clinker F attacked with a nitric acid

solution in alcohol. The prismatic alite is light blue, the round belite

is brown and the interstitial mass is white. Homogeneous

distribution of the phases.

www.jmest.org

JMESTN42351178

3151

Journal of Multidisciplinary Engineering Science and Technology (JMEST)

ISSN: 3159-0040

Vol. 2 Issue 11, November - 2015

TABLE III.

SIZE AND SURFACE OF CLUSTERS.

Raw materials

Size of belite cluster(m)

-2

Area of cluster (10 mm )

Fig. 5. Variation of compressive strength with the raw material

fineness.

We can note that the crystal size of alite was

controlled by two factors: (a) heating rate above

1000C and, (b) the sizes of the raw meal

components, mainly that of quartz which largely

determines the size of the belite from which most of

the alite is derived. So it is important to have a rapid

heating rate and a finely ground raw meal. Belite size

also can partially relate to the number of belite nests

with large tightly packed crystals in the clinker, these

crystals can be quite large and are usually determined

by the number of large quartz grains in the raw meal.

These grains are difficult to disaggregate during

burning, thus the belite continues to grow. Belite

crystals, in general, grow at high temperature and also

during cooling; consequently, the cooling rate must be

rapid.

The relationship between the clinker crystals size

and the hydraulic activity of cement was shown in table

III.

TABLE II.

RELATIONSHIP BETWEEN THE SIZE OF ALITE (L)

(D) CRYSTALS AND THE HYDRAULIC ACTIVITY (HA) OF

AND BELITE

CEMENT.

Samples

Size of crystals

Alite

F1

F2

L1

L2

106

144

126

12

4.2

6.8

.5

2.2

2

3.5

The aptitude of grinding the clinker depends on its

microstructural properties, like the crystals composition

and size. However, the clinkers microstructure is

influenced by the productions parameters especially

the raw materials smoothness and the homogeneity,

the burning time and the cooling rate. By knowing all

these relations it will be possible to predict the

grindability of the clinker and consequently its grinding

energy.

Grindability is a measure of how much energy is

required to change a particle from one size to another

(13). There are many methods for assessing and

studying grindability. At first we made a grading

analysis. This latter consists to separate and classify

the grains of the clinker according to their diameter

and using a series of sieve. The sieved grains can be

weighed to determine the proportion of each one in the

aggregate.

Fig.6 indicates the variation of the cumulative

percentage of passing with the opening sieve for the

collections F1, F2, L1 and G. The time of grinding was

constant and equal to 13 minutes.

The clusters present in clinker F1 are the smallest

in size and area. Moreover, the microscopic

observation shows that these clusters are dispersed.

The most remarkable difference between L1 and L2 is

the abundance of the clusters of belite in the latter.

Fundal (1980) shows that the large clusters of belite

associated with high contents of free lime are due to a

high lime saturation factor (14).This remark is well

applied to the example of clinker L2. It has the greatest

ratio of free lime (1.9%) and the highest lime saturation

factor (98.7%) which exceeds also the margin.

Belite

L (m)

HA

D (m)

HA

27.66

Excellent

27.51

Excellent

27.17

Excellent

27.35

Excellent

33.62

Good

20.67

Average

With reference to Onos method, the F and L

collections of clinkers have an excellent hydraulic

activity. However, this later varies between average

and good for the reference collection G. The clusters

size and surface are shown in Table IV.

Fig. 6. Grading curve of the passing. The collections used in this

part of study are F1, F2, L1 and G. We took 5 samples for each

collection, then we calculated their cumulative percentage of

passing and finally we made the average of these percentages.

www.jmest.org

JMESTN42351178

3152

Journal of Multidisciplinary Engineering Science and Technology (JMEST)

ISSN: 3159-0040

Vol. 2 Issue 11, November - 2015

Curve F1 shows the highest fractions of passing.

While, curve G indicates the lowest fractions of

passing. The margins of variation between the two

curves before and after grinding, for clinker G and

clinker F1, were shown in Fig.7.

Fig. 8. Specic selection functions versus particle size for the

collections F1, F2 and L1.

Fig. 7. Cumulative percentage of passing before and after

grinding.

Clinker F1 which have the best fineness of raw (8.5

% for the refusal of 100m) represents a margin of

variation considerably elevated. Whereas, the

reference clinker G which has the bad fineness of raw

shows the weakest margin of variation. This results

indicates that we produced further fine particles for

sample F1.

Clinker grinding process is often monitored and

controlled by measuring the product surface area

using a simple air-permeability procedure such as the

Blaine test and also measuring its energy of grinding

and index of breakage (15). Table V shows the values

of the index of breakage (I) of the collections used in

this work.

TABLE IV.

TABLE V. INDEX OF BREAKAGE.

Samples

F1

F2

L1

L2

SSB (cm2/g)

3718

4044

3953

3564

3087

0.91

0.99

0.97

0.87

0.76

The reference collection G had the lowest index of

breakage. It indicated also the highest value of the

grinding energy. It was estimated to 1.014 kWh/t for

clinker G. However it was valued to 0.814 kWh/t for

the collection F1. For better studying the probability of

breakage of each type of clinker, we calculated the

specific selection functions corresponding to the

fractions of sizes considered in this work.

Fig.8 and Fig.9 indicate the variation of the specific

selection functions for the collections F1, F2, L1 and

L2. The diameter of balls was considered constant in

this study.

Fig. 9. Specic selection functions versus particle size for the

collection L2.

Increasing trends for the collections F1, F2 and L1

were observed in figure 8. Contrary to the other

curves, L2 follows decreasing trends. This can be

explained by the fact that L2 was entered creased in

the mill. So a problem of adaptation of the size of

particles with the size of balls will be encountered.

Thus, the experimental results showed that the

grinding process is more efficient with a maximum

specific selection function. Therefore, F1 had a better

grinding probability while F2 and L1 had an acceptable

grindability.

IV. 4. CONCLUSIONS

In this paper, we investigated the effects of the

variation of the fineness and the lime saturation factor

of the raw materials on the grindability of the clinker

and the quality of the cement. The results are

summarized as follows:

With comparison to the reference situation G,

the main structural modifications were: reduction of

the alite size and growth of the belite size. A

significant change in the distribution of phases was

also observed. So a phase of homogenization

www.jmest.org

JMESTN42351178

3153

Journal of Multidisciplinary Engineering Science and Technology (JMEST)

ISSN: 3159-0040

Vol. 2 Issue 11, November - 2015

appears when we improve the fineness of the raw

material. The belite clusters become smaller.

The lime saturation factor has a great role on

the compressive strength of the cement. If this

factor exceeds the margin (90-98%) we will have a

heterogeneous distribution and so large clusters

that adverse the grinding of the clinker.

Reduction of the clinkers energy consumption

with the improvement of the raw materials fineness.

So, we suggest having a raw materials fineness

of about 13 to 15 % of the refusal of 100 m because

this margin indicates a good optimum for both sizes of

alite and belite and also an energy improvement.

ACKNOWLEDGMENT

The work was supported financially by the Tunisian

Libyan Project on cement quality. The authors wish to

thank the Cement Company of Gabes for the material

support.

We would like to show also our appreciation to

Prof. Campbell D.H. for his kind advice and technical

discussion.

REFERENCES

[1] Taylor H F W(1997) Cement chemistry 2nd

edn. Thomas Telford, pp 28990.

[2] Hendrick G van Oss(January 2008) Cement,

Mineral Commodity Summaries, U.S Geological

Survey, pp 44-45.

[3] Hendrick G van Oss (January 2012) Cement,

Mineral Commodity Summaries, U.S Geological

Survey, pp 38-39.

[4] Romilliat E (2006) Etude des modes daction

dagents de mouture sur le broyage du clinker. Thse

de doctorat de lEcole Nationale Suprieure des

Mines SAINT-ETIENNE, France.

[5] Vldia Cristina G, Koppe J, Costa J, Vargas A

L M , Blando E and Hbler R (2008) The influence of

mineralogical, chemical and physical properties on

grindability of commercial clinkers with high MgO

level, Cement and Concrete Research, 38:1119-1125.

[6] Tokyay M (1999) Effect of chemical

composition of clinker on grinding energy requirement,

Cement and Concrete Research, 29, N4, pp 531-535.

[7] Hills Linda M (2007) Clinker Microstructure

and Grindability: Updated Literature Review, SN2967,

Portland Cement Association, Skokie, Illinois, USA.

[8] Burak, Kamile, Bulentet Akin A (2010) Effects

of porosity and related interstitial phase morphology

difference on the grindability of clinkers, Materials and

Structures, 43:179-193.

[9] Campbell D H (1999) Microscopical

examination and interpretation of Portland cement and

clinker, Portland Cement Association, Second Edition,

SP030, pp 30-128.

[10] Ben Jamaa N and Maki I (2006)

Characterization of Tunisian Portland cement clinkers

by optical microscopy, SEM and microprobe analysis,

Ann. Chim. Sci. Mat., Vol. 31, No. 4, pp 421-430.

[11] Ibrahimi S, Ben Jamaa N, Mliki K, and

Bagane M (2011). Comparative Study for Grinding of

Two Cement Clinkers, International Journal of

Concrete Structures and Materials, Vol.5, No.2, pp

113-117.

[12] Touil D, Belaadi S, Frances C (2008) The

specific selection function effect on clinker grinding

efficiency in a dry batch ball mill, International Journal

of Mineral Processing 87:141 145.

[13] Joel Simpson (Mai 2004) A Grindability Study

of Cement Clinker: Drop Weight Testing, The

University of Queensland, Australia.

[14] Rhodes M (1998) Introduction to Particles

Technology, John Wiley & Sons, Brisbane.

[15] M Katsioti, P E Tsakiridis, P Giannatos, Z

Tsibouki, J

Marinos (2009) Characterization of

various cement grinding aids and their impact on

grindability and cement performance, Construction

and Building Materials 23: 19541959.

www.jmest.org

JMESTN42351178

3154

Das könnte Ihnen auch gefallen

- Advances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UseVon EverandAdvances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UseBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Alite Modification by SO3 in Cement Clinker - An Industrial TrialDokument7 SeitenAlite Modification by SO3 in Cement Clinker - An Industrial TrialRaúl Marcelo Veloz100% (2)

- Chemical Technology Subject Code: CH2001Dokument13 SeitenChemical Technology Subject Code: CH2001U SANKAR TEJONoch keine Bewertungen

- Calculation of The Formation Process of Clinker inDokument7 SeitenCalculation of The Formation Process of Clinker inYounas BugtiNoch keine Bewertungen

- 7-Mineral Phases of Portland CementDokument28 Seiten7-Mineral Phases of Portland CementzamriseramikNoch keine Bewertungen

- Quailty Assurance of CementDokument30 SeitenQuailty Assurance of Cementabdullah100% (3)

- Raw Meal Grinding Aids: Improving BurnabilityDokument3 SeitenRaw Meal Grinding Aids: Improving BurnabilityfaheemqcNoch keine Bewertungen

- Chemical AnalysisDokument8 SeitenChemical Analysisصفاء رجبNoch keine Bewertungen

- Free LimeDokument10 SeitenFree LimeHazem DiabNoch keine Bewertungen

- Cement Technology Cement ChemistryDokument22 SeitenCement Technology Cement Chemistryshani5573Noch keine Bewertungen

- New Products - Wirsing 2015Dokument70 SeitenNew Products - Wirsing 2015Moud Sakly100% (1)

- Cement IndustryDokument27 SeitenCement IndustryAhmed Mahmoud100% (1)

- Short Note of Cement ChemistryDokument14 SeitenShort Note of Cement Chemistrynk_kanchkar80% (5)

- Physical Testing of Clinker & CementDokument61 SeitenPhysical Testing of Clinker & CementDineshNoch keine Bewertungen

- Cement Manufacturing ProcessDokument26 SeitenCement Manufacturing ProcessZubair KhanNoch keine Bewertungen

- Raw Meal & Clinker Quality ControlDokument139 SeitenRaw Meal & Clinker Quality ControlserkalemtayeNoch keine Bewertungen

- Calcination DegreeDokument1 SeiteCalcination DegreeHazem Diab100% (1)

- Circulation of Inorganic Elements in Combustion of Alternative Fuels in Cement PlantsDokument85 SeitenCirculation of Inorganic Elements in Combustion of Alternative Fuels in Cement PlantsBetonÇimento100% (3)

- Raw Meal To Clinker RatioDokument3 SeitenRaw Meal To Clinker RatiohamedNoch keine Bewertungen

- Transcript: Download Granulometry of ClinkerDokument4 SeitenTranscript: Download Granulometry of ClinkerfaheemqcNoch keine Bewertungen

- Cement Mill: History Materials Ground Temperature Control Ball MillsDokument5 SeitenCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiNoch keine Bewertungen

- Cement PDFDokument70 SeitenCement PDFhamza2k19Noch keine Bewertungen

- Cement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Dokument14 SeitenCement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Senthilkumar PragasamNoch keine Bewertungen

- Sampling & AnalysisDokument17 SeitenSampling & AnalysisNael100% (1)

- 6.1 Determination of Raw Mixture BurnabilityDokument2 Seiten6.1 Determination of Raw Mixture BurnabilityVipan Kumar DograNoch keine Bewertungen

- Quality & Composition of Cement Clinker - INFINITY FOR CEMENT EQUIPMENT PDFDokument74 SeitenQuality & Composition of Cement Clinker - INFINITY FOR CEMENT EQUIPMENT PDFSiddharth Singh100% (1)

- Cement Grinding OptimizationDokument9 SeitenCement Grinding OptimizationFran JimenezNoch keine Bewertungen

- Interpreting Cement Science Since 2005: Understanding Cement Book/ebookDokument14 SeitenInterpreting Cement Science Since 2005: Understanding Cement Book/ebookVirat ChintuNoch keine Bewertungen

- Blaine Apparatus ProcedureDokument7 SeitenBlaine Apparatus ProcedureVivek Pandey100% (3)

- Cement KilnDokument2 SeitenCement Kilnamir100% (2)

- The Role of Gypsum in CementDokument30 SeitenThe Role of Gypsum in Cementsafwat hassanNoch keine Bewertungen

- Slide 1 - 25.01.2007: HR Activities & Outlook 2007 - Sid TuliDokument33 SeitenSlide 1 - 25.01.2007: HR Activities & Outlook 2007 - Sid Tulishivam aggarwalNoch keine Bewertungen

- 3500TPD Cement Plant Heat BalanceDokument2 Seiten3500TPD Cement Plant Heat BalanceIrshad HussainNoch keine Bewertungen

- KILN Hot SpotDokument4 SeitenKILN Hot Spotabdulfetah100% (1)

- Grinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent GuillotDokument15 SeitenGrinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent Guillotnathaniel villanuevaNoch keine Bewertungen

- Burner Basic TheoryDokument10 SeitenBurner Basic Theoryehtisham zaibNoch keine Bewertungen

- The Effect of Coal Ash On Synthesis and Properties of C3SDokument6 SeitenThe Effect of Coal Ash On Synthesis and Properties of C3SNam HuynhNoch keine Bewertungen

- A To ZDokument126 SeitenA To ZMohamed Osama RagaaNoch keine Bewertungen

- Cement Testig NotesDokument28 SeitenCement Testig NotesSatish KumarNoch keine Bewertungen

- Sulphur, Spurrite, and Rings in Cement Kilns PDFDokument4 SeitenSulphur, Spurrite, and Rings in Cement Kilns PDFAnonymous NxpnI6jC100% (2)

- Cement AnalysisDokument51 SeitenCement AnalysisCHRISTOPHER NSENGIYUMVA100% (1)

- Heating Up ManualDokument9 SeitenHeating Up ManualharryNoch keine Bewertungen

- Measure Clinker Temperature at Cooler ExitDokument3 SeitenMeasure Clinker Temperature at Cooler ExitTamer FathyNoch keine Bewertungen

- Brown ClinkerDokument21 SeitenBrown ClinkerTamer Fathy0% (1)

- 4 Cement TechnologyDokument43 Seiten4 Cement TechnologySomu AdityaNoch keine Bewertungen

- Ash % Absorbed in ClinkerDokument1 SeiteAsh % Absorbed in ClinkerIrfan AhmedNoch keine Bewertungen

- Co2 Emission Per Ton ClinkerDokument5 SeitenCo2 Emission Per Ton ClinkerJunaid Mazhar50% (2)

- Cement Ball-Mill-Heat-BalanceDokument3 SeitenCement Ball-Mill-Heat-Balanceanurag soni100% (1)

- Production Process of CementDokument2 SeitenProduction Process of CementMarwaNoch keine Bewertungen

- The Role of Gypsum in CementDokument2 SeitenThe Role of Gypsum in Cementarylananyla100% (3)

- Raw MixDokument59 SeitenRaw MixYhaneNoch keine Bewertungen

- Influence of The Clinker SO3 On The Cement CharacteristicsDokument1 SeiteInfluence of The Clinker SO3 On The Cement Characteristicsroshan_geo078896Noch keine Bewertungen

- Cement Physical TestingDokument6 SeitenCement Physical TestingPradeep SinghNoch keine Bewertungen

- Technological Advancement in Cement Manufacturing Industry: System Length DiameterDokument16 SeitenTechnological Advancement in Cement Manufacturing Industry: System Length Diameterfaran100% (3)

- Alkali Sulfur RatioDokument2 SeitenAlkali Sulfur RatioGsm Subramanian100% (12)

- Cement PropertiesDokument4 SeitenCement PropertiesDebendra Dev KhanalNoch keine Bewertungen

- Conferences Effect of Grinding Aids On CementDokument16 SeitenConferences Effect of Grinding Aids On CementMarey MorsyNoch keine Bewertungen

- Cement Kiln Process Chemistry: Module 2. Cement Clinker Quality and CompositionDokument2 SeitenCement Kiln Process Chemistry: Module 2. Cement Clinker Quality and CompositionalbertbunguriNoch keine Bewertungen

- Pradeepkumar - Rawmix Characteristics FinalDokument96 SeitenPradeepkumar - Rawmix Characteristics FinalJackson VuNoch keine Bewertungen

- Jmestn42351178 PDFDokument6 SeitenJmestn42351178 PDFsattiricNoch keine Bewertungen

- 11-001 Gergess Author Proof CorrectedDokument18 Seiten11-001 Gergess Author Proof CorrectedJamil JmlNoch keine Bewertungen

- Student Advisory Form: Institute of Space TechnologyDokument6 SeitenStudent Advisory Form: Institute of Space Technologyjawad khalidNoch keine Bewertungen

- SPPU Report FormatDokument50 SeitenSPPU Report FormatAmit Devidas AherNoch keine Bewertungen

- HOUSEKEEPING - WEEK 1 UpdatedDokument5 SeitenHOUSEKEEPING - WEEK 1 UpdatedMaria Rizza IlaganNoch keine Bewertungen

- GLS Poland Z Tytuem Lidera Logistyki ENGDokument3 SeitenGLS Poland Z Tytuem Lidera Logistyki ENGFyikgfjijgNoch keine Bewertungen

- BAEnglish Language Linguistics PDFDokument93 SeitenBAEnglish Language Linguistics PDFAnonymous p5BEJzvqrkNoch keine Bewertungen

- LTE OFDMA SimulationDokument9 SeitenLTE OFDMA Simulationrajendra4343Noch keine Bewertungen

- Chapter 6 QuizDokument8 SeitenChapter 6 QuizWael AyariNoch keine Bewertungen

- Ic NotesDokument67 SeitenIc NotesVijaya Kumar VadladiNoch keine Bewertungen

- SPHE8281DDokument35 SeitenSPHE8281Ddiego-tNoch keine Bewertungen

- FNDWRR PDFDokument5 SeitenFNDWRR PDFngole ngoleNoch keine Bewertungen

- Executive Leadership: Artificial Intelligence Primer For 2021Dokument10 SeitenExecutive Leadership: Artificial Intelligence Primer For 2021ranga.raman100% (1)

- Radical Pedagogies in Architectural Education - Architectural ReviewDokument11 SeitenRadical Pedagogies in Architectural Education - Architectural ReviewGabriella VillaçaNoch keine Bewertungen

- Eaton Industrial Special Process List (SPL)Dokument5 SeitenEaton Industrial Special Process List (SPL)amirkhakzad498Noch keine Bewertungen

- NF EN 10028-3-EnglishDokument17 SeitenNF EN 10028-3-Englishhakan gecerNoch keine Bewertungen

- Research ProposalDokument3 SeitenResearch Proposaljan ray aribuaboNoch keine Bewertungen

- A Study On Pushover Analysis Using Capacity Spectrum Method Based On Eurocode 8Dokument13 SeitenA Study On Pushover Analysis Using Capacity Spectrum Method Based On Eurocode 8ephNoch keine Bewertungen

- Rele A Gas BuchholtsDokument18 SeitenRele A Gas BuchholtsMarco GiraldoNoch keine Bewertungen

- Jurnal Internasional Pijat BayiDokument5 SeitenJurnal Internasional Pijat BayiAna SafitriNoch keine Bewertungen

- Standard Support: Figure 1: Pressing F1 Redirects User To A Bing SearchDokument4 SeitenStandard Support: Figure 1: Pressing F1 Redirects User To A Bing SearchDbluepengLumNoch keine Bewertungen

- Transient Thermal Analysis On Re-Entry Vehicle Nose Cone With Tps MaterialsDokument10 SeitenTransient Thermal Analysis On Re-Entry Vehicle Nose Cone With Tps Materialssiva shankarNoch keine Bewertungen

- Manual: InstructionDokument2 SeitenManual: InstructionBan ZanganaNoch keine Bewertungen

- Cryptography: Presented by Blances SanchezDokument91 SeitenCryptography: Presented by Blances SanchezLian PicartNoch keine Bewertungen

- Physiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsDokument12 SeitenPhysiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsRafida I CNoch keine Bewertungen

- Gep Primary Water Resource Aug12 NSWDokument50 SeitenGep Primary Water Resource Aug12 NSWNitin AroraNoch keine Bewertungen

- Effects of Reservoir Heterogeneity in Laminated ReservoirsDokument3 SeitenEffects of Reservoir Heterogeneity in Laminated ReservoirsErik Andres Garcia VillarroelNoch keine Bewertungen

- H-330 Field Installation Manual IndexDokument11 SeitenH-330 Field Installation Manual IndexRamon JimenezNoch keine Bewertungen

- Janice C. Vergel: ObjectiveDokument3 SeitenJanice C. Vergel: ObjectiveRency Reiz JhaniceNoch keine Bewertungen

- Basiccharge Ev Ftu Superfast Data Sheet 028413Dokument2 SeitenBasiccharge Ev Ftu Superfast Data Sheet 028413Cojoc Constantin-CosminNoch keine Bewertungen

- Karma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Dokument37 SeitenKarma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Lars JensenNoch keine Bewertungen

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionVon EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Laws of UX: Using Psychology to Design Better Products & ServicesVon EverandLaws of UX: Using Psychology to Design Better Products & ServicesBewertung: 5 von 5 Sternen5/5 (9)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CVon EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNoch keine Bewertungen

- Basic Digital Signal Processing: Butterworths Basic SeriesVon EverandBasic Digital Signal Processing: Butterworths Basic SeriesBewertung: 5 von 5 Sternen5/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionVon EverandThe Laws of Thermodynamics: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)Von EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Bewertung: 4 von 5 Sternen4/5 (12)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsVon EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNoch keine Bewertungen

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersVon EverandBulk Material Handling: Practical Guidance for Mechanical EngineersBewertung: 5 von 5 Sternen5/5 (1)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionVon EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNoch keine Bewertungen

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneVon EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsVon EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNoch keine Bewertungen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessVon EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNoch keine Bewertungen

- Safety Theory and Control Technology of High-Speed Train OperationVon EverandSafety Theory and Control Technology of High-Speed Train OperationBewertung: 5 von 5 Sternen5/5 (2)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionVon EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNoch keine Bewertungen

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseVon EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (51)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsVon EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNoch keine Bewertungen

- Mechanical Vibrations and Condition MonitoringVon EverandMechanical Vibrations and Condition MonitoringBewertung: 5 von 5 Sternen5/5 (1)