Beruflich Dokumente

Kultur Dokumente

39

Hochgeladen von

tierradiegoyahooesCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

39

Hochgeladen von

tierradiegoyahooesCopyright:

Verfügbare Formate

CHAPTER 5

Moment Connections

Moment connections transfer the moment carried by the

flanges of the supported beam to the supporting member.

Moment connections (or continuous or rigid-frame connections) are assumed to have little or no relative rotation

between the supporting member and the supported members. A Fully Restrained (FR) connection assumes the

measured angles between intersecting members are maintained (i.e. no relative rotation) and there is full transfer of

the moments. Partially Restrained (PR) connections assume

that there will be some relative rotational movement that

occurs between intersecting members, though there will still

be transfer of the moments.

Infinite rigidity can never be realistically attained; therefore, even fully restrained moment connections do possess

some minimal amount of rotational flexibility, which is usually neglected. FR connections are idealized as having full

fixity between members.

To transfer the tension and compression forces carried by

the flanges, continuity between the supported beam flanges

and the supporting member must be realized. Hence, the

flanges of the supported member are attached to either a

connection element or directly to the supporting member.

Most moment connections are made from the supported

beam to either the flange or the web of column members

(called beam-to-column connections). Beam splices to

transfer moments are also common. Moment connections

also normally include a simple shear connection at the web

of the supported member to carry the shear component of

the beam reaction. Any load eccentricity considerations in

the shear connection as part of a moment connection may be

ignored as it is carried by the moment connection. If a

moment connection is made to the web of a column, the

connection elements may be extended so that field welds

and/or bolts can be located outside of the column flanges for

easier erectability.

Columns in beam-to-column connections are subjected to

concentrated forces from the flanges of the supported member. In some instances the column section may have insufficient local strength at the location of these concentrated

forces. In such circumstances, a heavier column section or

a higher strength column may be substituted, or transverse

column stiffeners and/or web doubler plates may be

installed.

Transverse stiffeners are plates fabricated to fit between

the flanges of the column at the point(s) of concentrated

loading (tension or compression). Web doubler plates are

steel plates that are fabricated to increase the overall thickness of the web of a section. Both types of components

(transverse stiffeners and web doubler plates) are welded to

the section to enhance the stiffness. The use of these components will increase fabrication costs, so it may be more

economical to select a heavier column section or one with

higher yield strength.

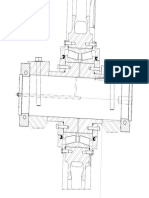

FLANGE-PLATED CONNECTIONS

(BEAM-TO-COLUMN)

Flange-plated connections are made with top and bottom

flange-plates that connect the flanges of the supported beam

to the supporting column. There are several types of flangeplated connections. The flange-plates are fillet or groove

welded to the supports. The flanges of the supported member may be either bolted or welded to the plates. Flangeplates are usually shop attached to the column and field

attached to the flanges of the supported member.

Flange-plates are usually positioned slightly wider apart

than the depth of the supporting member if they are to be

bolted to the flanges of the supported member. This arrangement makes it easier to erect, providing adequate clearance.

Shims are provided to fill any of the resulting gaps. If the

flange-plates are welded to the flanges of the supporting

member, then the plates are designed and detailed such that

flange plate welding can be performed in the flat position.

This can be accomplished by using a flange-plate that is

slightly narrower than the beam flange on top and a flangeplate that is slightly wider than the beam flange on the bottom. This arrangement permits flat-position (down-hand)

welding.

If the beam frames into the web of a column, the plates

should be sized wide enough to fill the space within the column flanges, but narrowing outside the column to allow

downhand welding. In this case the top plate will likely be

wider than the top flange of the supported beam. Thus, to

accommodate the flat welding position of flange plates

attached to column webs, the top flange plate should be

blocked to make an easier joint for welding to the supported

member. Regardless of the bolting or welding arrangements, if the connection is made to the web of a column, the

supported side attachment should provide enough space to

accommodate bolting or welding access (i.e. extending

plates past the column flanges). See the AISC Manual for

discussion of corner clips and plate configurations when

attaching to column webs.

Girders B2 and B4 are bolted and welded flange plate

connections to the web of Column C1, respectively. The

flange-plates for Girder B2 are bolted to the top and bottom

flanges of the beam. As mentioned above, the flange-plates

Connections Teaching Toolkit 5-1

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Bme-302 SomDokument41 SeitenBme-302 SomProf. Anurag KumarNoch keine Bewertungen

- E1.0Dokument1 SeiteE1.0Muhammad AbuBakarNoch keine Bewertungen

- Proposed Double Storey Brick Veneer Dwelling: Sheet ListDokument17 SeitenProposed Double Storey Brick Veneer Dwelling: Sheet ListdeepqnshiNoch keine Bewertungen

- Piping LabellingDokument64 SeitenPiping Labellingstormer_bw7585Noch keine Bewertungen

- DIN 529 EN-1986 Masonry and Foundation BoltsDokument5 SeitenDIN 529 EN-1986 Masonry and Foundation BoltsthachpnNoch keine Bewertungen

- VentilationDokument4 SeitenVentilationKarthy Ganesan100% (1)

- Noble Series New!: Notch-FreeDokument1 SeiteNoble Series New!: Notch-FreecrlaurenceNoch keine Bewertungen

- Carbon FiberDokument30 SeitenCarbon FiberAarizMalik100% (1)

- Cembre KatalogueDokument160 SeitenCembre KatalogueAli Osman SarnıkNoch keine Bewertungen

- FXZ1 (FRT, ZH) : Halogen FreeDokument4 SeitenFXZ1 (FRT, ZH) : Halogen FreeMario LuvineriNoch keine Bewertungen

- CE 3132 Module 05 - Analysis of Statically Determinate Structures (Part 1)Dokument8 SeitenCE 3132 Module 05 - Analysis of Statically Determinate Structures (Part 1)FedieTabaquiraoNoch keine Bewertungen

- Catalina Punta Pluma 7495 HRDokument1 SeiteCatalina Punta Pluma 7495 HRmilenko CortesNoch keine Bewertungen

- Surespan Power Capability Rev 1nov13Dokument18 SeitenSurespan Power Capability Rev 1nov13Nathsgel GelitoNoch keine Bewertungen

- Reparación de Motor Volvo D12D: Inversión Segura A Un Menor CostoDokument2 SeitenReparación de Motor Volvo D12D: Inversión Segura A Un Menor CostoRoberto CornejoNoch keine Bewertungen

- Noise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverDokument20 SeitenNoise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverAvinash JagtapNoch keine Bewertungen

- Essay 07Dokument5 SeitenEssay 07Mohammed ZohebNoch keine Bewertungen

- SS Tech Guide - Hand Pump Equipped Boreholes PDFDokument79 SeitenSS Tech Guide - Hand Pump Equipped Boreholes PDFJustice Machiwana100% (1)

- PR-SG-103 108 Standard Details-PR-SG-105Dokument1 SeitePR-SG-103 108 Standard Details-PR-SG-105ahmad fauziNoch keine Bewertungen

- 2.2.3 - DQR - PST Capacity-Rev B1Dokument7 Seiten2.2.3 - DQR - PST Capacity-Rev B1Sudip ShresthaNoch keine Bewertungen

- Super Duplex Stainless Steel PipesDokument3 SeitenSuper Duplex Stainless Steel Pipeskumar sandeepNoch keine Bewertungen

- Buena Mano Q3-2013 Greater Metro Manila Area CatalogDokument48 SeitenBuena Mano Q3-2013 Greater Metro Manila Area CatalogJay CastilloNoch keine Bewertungen

- Ukai Hydro Powerplant: Department of Mechanical & Automobile EngineeringDokument3 SeitenUkai Hydro Powerplant: Department of Mechanical & Automobile EngineeringYash SharmaNoch keine Bewertungen

- RK Pivot Doors AlbumDokument43 SeitenRK Pivot Doors AlbumJafarNoch keine Bewertungen

- DBTBDokument262 SeitenDBTBDarwin CornejoNoch keine Bewertungen

- ETTV CalculationDokument8 SeitenETTV Calculationmeeng2014Noch keine Bewertungen

- Manual For The Design of Reinforced Concrete Building Structures To EC2Dokument15 SeitenManual For The Design of Reinforced Concrete Building Structures To EC2heinsteinzNoch keine Bewertungen

- SPE 134169 Designing and Testing Cement System For SAGD ApplicationDokument12 SeitenSPE 134169 Designing and Testing Cement System For SAGD Applicationadvantage025Noch keine Bewertungen

- Izon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)Dokument4 SeitenIzon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)AcingEdogawaNoch keine Bewertungen

- Cerj MS Id 555662Dokument9 SeitenCerj MS Id 555662احمد الدلالNoch keine Bewertungen