Beruflich Dokumente

Kultur Dokumente

Siemens S7 PI Communication

Hochgeladen von

Brahimi MohamedCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Siemens S7 PI Communication

Hochgeladen von

Brahimi MohamedCopyright:

Verfügbare Formate

optris PI160, PI200, PI400, PI450

Simatic S7 communication

Manual

____________________________________________________________________________________________________________

Table of contents

Table of contents ................................................................................................................................................................ 1

1.

2.

3.

4.

Hardware specification ............................................................................................................................................. 2

Create a new project ................................................................................................................................................. 6

Hardware Settings..................................................................................................................................................... 8

Software programming ........................................................................................................................................... 12

____________________________________________________________________________________________________________

1. Hardware specification

Regarding long distances (up to 3 km) between the infrared camera Optris PI and a SPS master system

there is now an easy solution available.

With the Optris RS485 Kit (product code: ACCTRS485USBK) you can connect the USB port of your PC with

a RS485 module of a SPS master system

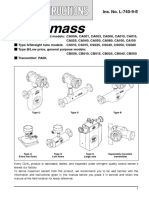

Picture: Optris PI infrared camera connection to a SPS master system (SIEMENS S7)

2

____________________________________________________________________________________________________________

With the software CD which is included at the RS485 kit you have the possibility to create a virtual COM port

at your PC.

To connect the software PI Connect with the RS485 kit is very easy.

Activate in the software PI Connect at the menu TOOLS CONFIGURATION - EXTERNAL

COMMUNICATION the mode Comport and select the COM port regarding your RS485 connection.

On the other site of the RS485 kit you have an A and B cable connected to the RS485 module of the

SIEMENS S7 SPS.

____________________________________________________________________________________________________________

Example of the hardware configuration which shows you a RS485 connection

between the optris PI camera to the SIEMENS S7 SPS which includes a PROFIBUS module and a RS485

module:

-

optris PI 160 / optris PI200 / optris PI400 / optris PI450

RS485 kit (ACCTRS485USBK)

SIMATIC S7-300, CPU 313C-2 DP

(processor with a PROFIBUS module)

SIMATIC S7-300, front module with digital and analog outputs

(switch actors, for example signal lights)

SIMATIC S7-300, CP 340

(communication processor with RS422/485 interface)

Software STEP 7

(to configure the SPS regarding the RS485 and the PROFIBUS module)

With the optris PROFIBUS kit you will get a GSD file to install each CT / CTlaser sensors at the SPS.

____________________________________________________________________________________________________________

Picture: Optris PI infrared camera connection to a SPS master system (SIEMENS S7)

included a PROFIBUS network with slave devices

____________________________________________________________________________________

All implemented commands for the Optris PI are described in the

Serial Communication Description.doc which is included on the PI Connect Software.

____________________________________________________________________________________

5

____________________________________________________________________________________________________________

2. Create a new project

The best way to implement a new project in STEP 7

is to use the internal wizard. Step 1 of the wizard program

only describe the functionality of the program. Next

creates the project step by step. To create a project

according to the preview it is necessary to activate

Finish.

In Step 2 the user can choose the right CPU

corresponding to his project. All other hardware

settings are automatically set, based on this CPU.

If there are more than one CPU in one project the name

of this specific CPU can be set.

The Multi Point Interface (MPI) address set the

communication address between the CPU and the

STEP 7 software computer.

____________________________________________________________________________________________________________

The communication between the PI and the Siemens S7

system is a cycle execution process. To add this

communication process the OB1 for Cycle Execution

should be selected.

The language options for the selected blocks are

LAD: Ladder Logic

FBD: Function Block diagram

STL: Statement List

The following project is explained with LAD language.

The last picture of the wizard program shows the existing

projects and permits to enter the new project name.

____________________________________________________________________________________________________________

3. Hardware Settings

The process tree of this new Point to Point program

includes the SIMATIC Station, the CPU and the S7

program.

CPU

The Hardware configurations of the system and the selected

CPU are part of the SIMATIC 300 Station. In the Hardware

configuration menu the user has the possibility to add

a Point to Point module manually.

____________________________________________________________________________________________________________

The Hardware configuration window shows the reserved

slots for the CPU (Profibus DP, Digital Input / Digital Output

DI16/DO16 and Counter).

The green slots indicate the open positions for extra

Modules like Point to Point communication.

The CP340 module has three different types of

communication protocols (RS232, 20mA TTY, RS 422/485).

For a communication with the PI via USB-RS485 converter

(ACCTRS485USBK) the CP340 RS422/485 module must be

dragged and released on a free slot.

A double click on the reserved CP340 slot leads to

configuration menu of the CP340 module.

____________________________________________________________________________________________________________

The Input and the Output Addresses of the CP340

specify the internal address range of the communication

data.

The optrisPI communication operates with an ASCII protocol

structure.

The settings for the CP340 protocol structure can be set

inside the Parameter menu.

A double click on the Protocol envelope guides to the

protocol settings.

For a correct communication with the PI it is necessary to

set the baudrate to 9600bps, 8 Data Bits, 1 Stop Bits and

Parity None.

10

____________________________________________________________________________________________________________

The Operation Mode defines the Full Duplex (Four Wire) or

the Half Duplex (Two Wire) mode.

The communication with the optrisPI via ACCTRS485USBK

works in a Half Duplex (RS485) mode.

The implemented communication process needs a clock

memory bit to start every sending cycle.

In the factory default settings of the Siemens S7 300 is this

option deactivated.

Clock Memory Bit

Mx.7 Mx.6 Mx.5 Mx.4 Mx.3 Mx.2 Mx.1 Mx.0

Frequency in Hz

0,5

0,625

1,25

2,5

10

Periodic time in

seconds

1,6

0,8

0,5

0,4

0,2

0,1

11

____________________________________________________________________________________________________________

4. Software programming

At the beginning of the programming process it is necessary

to enter two different blocks into the system.

The Function Block (FC10) allows the creating of function

schematic block diagrams.

Inside the Data Block (DB10) it is possible to generate all

data structures which are needed for the Send, Receive

and Post Processing processes.

The best way for the beginning is to use the FDB

(Function Block diagram) program language.

For the Send Data process via the CP340 module, special

Function Blocks (FB) are included inside the Siemens S7

Software.

REQ:

R:

LADDR:

DB_NO:

DBB_NO:

LEN:

DONE:

ERROR:

STATUS:

12

Initiates request

Aborts request

The basic address of the CP340

Data block number

Data byte number

Data Length

Request completed without errors

Request completed with errors

Error specification

____________________________________________________________________________________________________________

Each of this FBs for the data communication needs an

Instance Data Block to save the internal settings.

This Instance Data Blocks are integrated in the system like

normal Data Blocks.

The only setting which must be changed is from Shared

DB to Instance DB.

The FB3 (Send Data to CP340) from the FC10 Block is

automatically set inside the properties.

All other setting can be let like shown in the picture.

With the Clock Byte M0.4 the frequency of the initiates

request is 1,25Hz.

The Input Address and the Data Block Number are the

same we entered in the previous settings.

The first byte of the Data String should be the byte 0.

The length of the Data String corresponding to the

specific PI Command.

To read the temperature of a measurement area with

Index x is the command ?T(x).

Any command must end with CR/LF (0x0D, 0x0A).

The DONE, ERROR and STATUS values are assign

to the M1.2, M1.3 and MW10 parameters.

13

____________________________________________________________________________________________________________

The next step is to enter the PI Command inside the

DB10.

For a better survey it is helpful to use a single Byte structure

instead of an ARRAY or STRING structure.

BYTE NUMBER

CHARACTER

LF

CR

3F

54

28

00

29

0A

0D

ASCII HEX

The initial value describes the start value if the system is set

from STOP to RUN mode.

After the three blocks (FC10, DB1 and DB10) for the Send

Data process are inserted in the system, every SIMATIC

System needs a special block for the Receive Data

process.

The first steps to implement this process are the same like

for the Send Data process.

For a better overview it is good to create three blocks named

(FC20, DB2 and DB20).

14

____________________________________________________________________________________________________________

For the Receive Data process a special Function Blocks

(FB) are included again inside the Siemens S7 Software.

EN_R:

R:

LADDR:

DB_NO:

DBB_NO:

NDR:

ERROR:

LEN:

STATUS:

Enable data read

Aborts request

The basic address of the CP340

Data block number

Data byte number

Request completed without errors

Request completed with errors

Length of message received

Error specification

The Booleans for the enable data read and the abort request

should be set with marker bytes (M2.0, M2.1).

The basic address of the CP340 is the same like for the

sending process.

The data block number specifies the data block to save the

incoming data (DB20).

The Data byte number defines the byte position of the

incoming string which should be the first saved byte.

The byte 0 and 1 of the incoming string are uninteresting

(Byte 0 = maximal length, Byte 1 = real length of the string).

15

____________________________________________________________________________________________________________

The data block DB20 saves the incoming data. The S7

system needs the information how much space the internal

CPU should reserve for these data.

This information can be entered as a String value with a

maximum account of 14 Bytes in the Type column.

The 16 bytes as shown in the example are the result of the

14 bytes incoming data and the two information bytes for

every string (Byte 0 = maximal length, Byte 1 = real length of

the string).

This data string isnt only made up of the measured object

temperature. The following example shows that this string

only contains character bytes.

The optris Pi answers of the serial command ?T(x) with

!T(x)=27.7C.

To get the temperature value out of this string, a post

processing is required.

The solution of this problem is to delete the first 6 characters

(!T(x)=), the last two characters (C) and the dot (.) between

the values.

The result of this example process is only the 277 as three

character bytes.

A String to Integer data block allows to convert this 277 to

a normal integer value.

16

____________________________________________________________________________________________________________

To save the intermediate data it is helpful to enter a new

data block DB30 in the program.

The postprocessing string is to save the processed data.

The relation_data string is used to find the (C) character

bytes.

The AlarmPI REAL value defines the alarm threshold of the

PI temperature measurement.

The post processing will be implemented in a new function

block FC30.

The two entered data blocks DB20 and DB30 must be

initialized before the first usage.

The maximum length of the strings inside our data blocks is

14 bytes (DB20) and 18 bytes (DB30).

These both values should be loaded in the system and

transferred to the two first bytes of DB20 and DB30.

(Byte 0 = maximal length, Byte 1 = real length of the string)

17

____________________________________________________________________________________________________________

The second network of the FC30 includes a DELETE

function block FC4.

This block deletes the first 6 bytes of the incoming string and

saves the post processed string in a new string.

IN:

L:

P:

RET_VAL:

STRING variable to be deleted in

Number of characters to be deleted

Position of first character to be deleted

Result string

IN:

RET_VAL:

!T(x)=27.7C

27.7C

The next step is to find the position of the (C) character

bytes.

The function block FC11 is a FIND data block which can be

used to find specific data string inside a string.

IN1:

IN2:

RET_VAL:

STRING variable to be searched in

STRING variable to be found

Position of the string found

IN1:

IN2:

RET_VAL:

27.7C

C

5

18

____________________________________________________________________________________________________________

The next DELETE function block delete all character from

the position which was found of the FIND function block.

IN:

RET_VAL:

27.7C

27.7

A helpful information is, that the dot (.) character of every

incoming string is 2 bytes in front of the (C) character.

So the position of this character is two less than the position

which was found from the FIND function block.

The SUBTRACT function only subtract the position in

MW100 with 2 and save this value in a new MW101.

19

____________________________________________________________________________________________________________

The dot (.) character can be deleted because of this new

information about the dot (.) position saved in MW101.

IN:

RET_VAL:

27.7

277

The String to Integer function block allows a transformation

of a string into an integer value.

The only requirement is that the string is not equal to zero

and not greater than 6 character bytes.

The first character of this string can be a sign (+ or -) or a

number.

S:

RET_VAL:

20

Input string

Result

____________________________________________________________________________________________________________

The next networks convert this integer temperature value

into a real value.

The reason for these steps is a comparison between the

temperature value and an alarm value which was entered in

DB30.

IN:

OUT:

Value to be converted

Result

This calculated real value doesnt show the right

temperature at the moment.

The missing decimal place can be recovered with a division

of this integer value by 10.

IN:

RET_VAL:

21

277

27.7

____________________________________________________________________________________________________________

Network 11 shows a comparison between the saved

calculated real value of the temperature and the saved

AlarmPI value of DB30.

If the incoming temperature is higher than the entered

AlarmPI value, the analogue output A124.0 is switched on.

This output signal can control LEDs, motors or other

electronic devices to react of an incoming alarm.

22

____________________________________________________________________________________________________________

R (Send)

R (Receive)

EN_R (Receive)

M 1.1 = 1

M 2.1 = 0

M 2.0 = 1

R (Receive)

EN_R (Receive)

R (Send)

M 2.1 = 1

M 2.0 = 0

M 1.1 = 0

The intention is to get a cycle measurement of the object temperature. These two blocks (Send and

Receive) are normally used to send one command and receive one answer.

To achieve a cycle request for the temperature it is important to set and reset the marker bytes for the enable

and abort requests.

The diagram shows the set and reset processes which are needed to implement a cycle process between

the sending and receive data block.

23

____________________________________________________________________________________________________________

Network 1 - 3 should be

inserted in the FC10 data block

These setting processes can be included with Flip Flop data blocks of the Siemens Step 7 program.

Network 1 - 3 describe the functional configuration of the FC10 data block and the internal shifts of the

enable and abort requests.

24

____________________________________________________________________________________________________________

The cycle function block OB1 defines the process structure

of every single cycle.

The SEND (FC10), RECEIVE (FC20) and POST

PROCESSING (FC30) block should be integrated in this

block.

The integrated variable table (temperatures) can be used

to check the calculated temperature (MD105), to set a new

alarm value (DB30.DBD) or to change the number of the

measured area (DB10.DBB 3).

25

Das könnte Ihnen auch gefallen

- En Ac Cnc2018 N GRBL r2.x SchemaDokument1 SeiteEn Ac Cnc2018 N GRBL r2.x SchemaBrahimi MohamedNoch keine Bewertungen

- Structured Text For CitectDokument64 SeitenStructured Text For CitectMarcel kampNoch keine Bewertungen

- Sh080372ec PDFDokument40 SeitenSh080372ec PDFBrahimi MohamedNoch keine Bewertungen

- ZCM6044Dokument1 SeiteZCM6044Brahimi MohamedNoch keine Bewertungen

- ReadmeDokument1 SeiteReadmeBrahimi MohamedNoch keine Bewertungen

- SH 080367 EcDokument80 SeitenSH 080367 EcUnggas RimbaNoch keine Bewertungen

- WinCC Flexible SQL Datenbank enDokument30 SeitenWinCC Flexible SQL Datenbank engj42107Noch keine Bewertungen

- How Do You Simulate Communication Between Two CPU Modules - ID - 38726591 - Industry Support SiemensDokument3 SeitenHow Do You Simulate Communication Between Two CPU Modules - ID - 38726591 - Industry Support SiemensBrahimi MohamedNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cheatsheet For R ProgrammingDokument2 SeitenCheatsheet For R ProgrammingAbhi GuptaNoch keine Bewertungen

- Siprotec 7SJ61Dokument427 SeitenSiprotec 7SJ61alimaghamiNoch keine Bewertungen

- Sk015 - Jawapan Tutor EditDokument22 SeitenSk015 - Jawapan Tutor EditAriff IskandarNoch keine Bewertungen

- Sel351s Auto Transfer SchemeDokument110 SeitenSel351s Auto Transfer SchemeVICTOR JOSE VILORIANoch keine Bewertungen

- 07 Laboratory Exercise KIANMDokument4 Seiten07 Laboratory Exercise KIANMjohn Peter Besid100% (1)

- Esa86882 UmDokument139 SeitenEsa86882 UmVishnuTej VinjamuriNoch keine Bewertungen

- Et200sp Im 155 6 PN Ba Manual en-US en-USDokument33 SeitenEt200sp Im 155 6 PN Ba Manual en-US en-USTomás GNoch keine Bewertungen

- Input DevicesDokument43 SeitenInput Devicessanjeewa UpulNoch keine Bewertungen

- Fatek PLC ControlerDokument12 SeitenFatek PLC ControlersdmitarNoch keine Bewertungen

- SMART PLC Catalogue PDFDokument36 SeitenSMART PLC Catalogue PDFsveatoslavNoch keine Bewertungen

- OS PURPOSE TITLEDokument10 SeitenOS PURPOSE TITLEBradley MuganyiNoch keine Bewertungen

- Input Output DevicesDokument16 SeitenInput Output DevicespetriNoch keine Bewertungen

- TrackballDokument3 SeitenTrackballselvakumar0275Noch keine Bewertungen

- 6th Java Sushil GoelDokument19 Seiten6th Java Sushil GoelAjNoch keine Bewertungen

- MPM4700液位变送器说明书 英文Dokument9 SeitenMPM4700液位变送器说明书 英文Samsudin AhmadNoch keine Bewertungen

- MAN PR5230 Inst en 949905052300-Rel3.50Dokument308 SeitenMAN PR5230 Inst en 949905052300-Rel3.50TatsuDONoch keine Bewertungen

- CS 251 Introduction To Computer Organization & Assembly LanguageDokument16 SeitenCS 251 Introduction To Computer Organization & Assembly LanguageidrissalmaNoch keine Bewertungen

- Datasheet hcf4094Dokument17 SeitenDatasheet hcf4094Diego Alejandro Gallardo IbarraNoch keine Bewertungen

- Technical Information Wirelesshart Fieldgate Swg70: Intelligent Wirelesshart Gateway With Ethernet and Rs-485 InterfaceDokument7 SeitenTechnical Information Wirelesshart Fieldgate Swg70: Intelligent Wirelesshart Gateway With Ethernet and Rs-485 InterfaceAndres HINoch keine Bewertungen

- DP Touchpad Alps 15015 DriversDokument107 SeitenDP Touchpad Alps 15015 DriversMohammed Tahver Farooqi QuadriNoch keine Bewertungen

- MVI69 AFC DatasheetDokument3 SeitenMVI69 AFC Datasheet김윤식Noch keine Bewertungen

- Instructions Alti Mass L 740 9 eDokument118 SeitenInstructions Alti Mass L 740 9 eitamarpereiraNoch keine Bewertungen

- Saco 16 D 3Dokument6 SeitenSaco 16 D 3PepeVichecheNoch keine Bewertungen

- Mitsubishi CNC Software Tools: Factory AutomationDokument7 SeitenMitsubishi CNC Software Tools: Factory AutomationVN MÁY TỰ ĐỘNGNoch keine Bewertungen

- Unit-1 MPMCDokument40 SeitenUnit-1 MPMCgunda manasaNoch keine Bewertungen

- Date Tehnice Control AccesDokument32 SeitenDate Tehnice Control AccesCornelCiorcanNoch keine Bewertungen

- Course Plan: Government of KarnatakaDokument8 SeitenCourse Plan: Government of KarnatakaRoshini Felix100% (1)

- Mpi Assignment Solution3Dokument25 SeitenMpi Assignment Solution3alkesh.engNoch keine Bewertungen

- AADvance, 1715, and HART ProtocolDokument4 SeitenAADvance, 1715, and HART ProtocolJuan Esteban Benjumea BenjumeaNoch keine Bewertungen

- DEGREE OF BACHELOR OF INFORMATION TECHNOLOGY (EXTERNAL) 1st Year Examination - Semester 2 Exam PaperDokument12 SeitenDEGREE OF BACHELOR OF INFORMATION TECHNOLOGY (EXTERNAL) 1st Year Examination - Semester 2 Exam Paperzanharjabir100% (1)