Beruflich Dokumente

Kultur Dokumente

TC Kta-50

Hochgeladen von

jengandxbOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TC Kta-50

Hochgeladen von

jengandxbCopyright:

Verfügbare Formate

12/6/2016

Turbocharger

010033Turbocharger

GeneralInformation

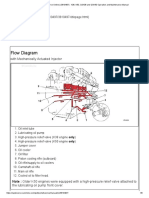

withMechanicallyActuatedInjector

AllK38andK50enginesareturbocharged.AllturbochargersonK38andK50enginesareoil

cooledandlubricated.Theenginecanhavetwoorfourturbochargers.

Iftheenginehasfourturbochargers,thetwothataremountedontheexhaustmanifoldarethe

highpressureturbochargers,andthetwothataremountedonthesupportbracketsarethe

lowpressureturbochargers.

Thecorrectturbochargerassemblymustbeinstalled.Manyturbochargersappearthesame

physically,butcontaindifferentinternalparts.Ifthewrongturbochargerassemblyisinstalled,

theperformanceoftheenginewillbelessthanspecification,ortheenginewillbedamageddue

toexcessivepressureandtemperatureinthecylinders.

K38andK50enginescancontainturbochargersthataremanufacturedbyHolset,Brown

Boveri,orAiResearch.Insomecasesturbochargersfromtwodifferentvendorsareonthe

sameengine.Oneofthedataplatesthatisattachedtotheturbochargeridentifiesthevendor,

theturbochargermodel,andtheCumminspartnumber.CumminsInc.identifiesthe

turbochargerbythepartnumber,notthemodelnomenclature.

Thismanualdoesnotcontaininformationtorebuildtheturbocharger.Seethefollowing

turbochargerrebuildmanuals:

Manufacturer

Bulletin

ModelNumberandDescription

Holset

3810243

HC5ATurbochargerShopManual

Holset

3810386

HT100SeriesTurbochargerShopManual

BrownBoveri

3810235

BrownBoveriTurbochargerManual

AiResearch

3379091

T18A,TurbochargerRebuildManual

TwooilsupplyhosesareinstalledonK38andK50engines.ThelengthofthehoseforKT38,

KTA38,andKTA50enginesis1295mm[51in].ThelengthofthehoseforKTTA38andKTTA5O

enginesis1092mm[43in].

TheturbochargeroildrainassemblyfortheK38isshorteronengineswithdrytypeexhaust

manifoldsthanonengineswithwettypeexhaustmanifolds.Theturbochargeroildrain

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

1/69

12/6/2016

Turbocharger

assemblyfortheK50isthesameasthatinstalledontheK38withawettypeexhaustmanifold.

Themethodforconnectingtheturbochargeroildraintothecylinderblockwaschanged.

Engineswithanengineserialnumber(ESN)of33106693andgreaterhaveaflangeandano

ringsealtypeconnectionthatissecuredwithacapscrew.EngineswithanESNof33106692

andlowerhavea90degreefittingwithpipethreads.

ArevisedturbochargercompressorwheelwasreleasedforKTA50GenginesinSeptember,

1985,ESNFirst33110070.

Turbochargerswithahosenippleonthecompressordischargeandahosetypeaircrossover

werereleasedforuseinproductionontheKTA38enginesinSeptember1986,ESNFirst

33111500.

AchamferwasaddedtothediffuserplateonHC5Aturbochargerstoallowoildrainbacktothe

sumpinFebruary,1987,ESNFirst33111870.

Arevisedprofile,turbochargermountinggasketwasreleasedinAugust,1987,ESNFirst

33112713.

Aturbochargeroildrainhosethatismanufacturedofflexiblehoseisavailableforenginesbuilt

previouslywithaoneortwopiecesteeltubefortheoildrainhose.Thetwopiecesteeltubethat

isconnectedbyahumphoseisavailableforserviceonenginesthathaveAiResearch

turbochargersonly.

TheKTTA50lowpressureturbochargeroildrainhoseanddrainlocationwaschangedin1988,

toprovideabetterdownhillreturntothecylinderblock.Therevisedoildrainhoseroutingalso

requiresarevisedturbochargersupport,whichismodifiedtoprovideclearanceforthenewoil

drainhoseandadifferentclamptoretaintheoildrainhose.

Therevisedhosedrainstheoiltodrillingsonthetopdeckatthefrontoftherightbankandthe

leftoftherearbankofthecylinderblock.Theholesusedarepartiallycoveredbythe

turbochargersupport.Thissupportrequiresmodificationorreplacement.

Themountingcapscrewfortheflangeandoringsealtypeturbochargerdrainhoseconnection

waschangedfrom0.250inch20UNCto0.375inch16UNC.Thecylinderblockwiththe

smallerholesrequiresaspacer,PartNumber3177195,betweentheconnectionflangeandthe

cylinderblockattheleftbankrearlocation.Ifthespacerisnotinstalled,anoilleakwillresult

becausetheoringsealwillnotbeintheborecorrectly.

Theflangeontheturbochargeroildrainhosethatfitstotheturbochargerisdifferentfor

HolsetandAiResearchturbochargers.TheoildrainhoseflangeisdifferentfortheBrown

Boveritypeturbocharger.Ifthemodelofturbochargerischanged,theoildrainhosemust

bechanged.

AK50turbinehousingwithathickenedflangebetweenthecapscrewholestoreduceflange

distortionwasreleasedinFebruary1988,ESNFirst33114833.ThisisfortheK50pulse

exhaustmanifoldsonly.

Longerstuds,nuts,andspacerswerereleasedfortheK50pulseexhaustmanifoldinMay,

1989,ESNFirst33115948.

TheK50turbochargermountingflangewascompletelythickenedtoimprovegasketreliability.

ThespacerisnolongerrequiredforK50pulseexhaustmanifoldenginesproducedinFebruary,

1990,ESNFirst33117281.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

2/69

12/6/2016

Turbocharger

TheK50pulseexhaustmanifoldreceivedabosstoallowuseofcapscrewsinplaceofstudson

enginesproducedfromFebruary,1990,ESNFirst33117392.

Asteeloilsupplyfittingreplacedthebrassfittingtopreventtorqueloss/looseningonengines

producedfromFebruary,1990,ESNFirst33117392.

Asteeloilsupplyfittingreplacedthebrassfittingtopreventtorqueloss/looseningonengines

producedfromSeptember1990,ESNFirst33118322.

TheHolsetHT100lowpressureturbochargerreplacedtheBrownBoveriRR151

turbochargerforC1800BandK2000enginesinJanuary1991,ESNFirst33119163.

NOTE:TheHT100turbochargercannotbeusedtoreplacetheBrownBoveriModel

RR153thatisusedontheKTTA50C1800Aengines.

TheHolsetHX80watercooledturbochargerdesignwasrevisedin1997,toallowfortheuse

ofGASfittingsonallcoolantpassageopeningsinthecasting.Oringsealfittingsarelessprone

toleakage,andareeasiertoremoveandinstall.Thediffuserplatewasalsochangedtoasunk

wheeldesign.

PreparatorySteps

withMechanicallyActuatedInjector

WARNING

Batteriescanemitexplosivegases.Toreduce

thepossibilityofpersonalinjury,always

ventilatethecompartmentbeforeservicingthe

batteries.Toreducethepossibilityofarcing,

removethenegative()batterycablefirstand

attachthenegative()batterycablelast.

WARNING

Donotremovethepressurecapfromahot

engine.Waituntilthecoolanttemperatureis

below50C[120F]beforeremovingthe

pressurecap.Heatedcoolantsprayorsteam

cancausepersonalinjury.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

3/69

12/6/2016

Turbocharger

WARNING

Coolantistoxic.Keepawayfromchildrenand

pets.Ifnotreused,disposeofinaccordance

withlocalenvironmentalregulations.

WARNING

Toreducethepossibilityofpersonalinjury,

avoiddirectcontactofhotoilwithyourskin.

Disconnectthebatteries.RefertotheOEM

servicemanual.

TurntheairOFFtotheairstarter,if

equipped,andtagthevalveclosed.Referto

Procedure012022inSection12.

Drainthecoolingsystemtoapointbelow

theturbochargers.RefertoProcedure008

018inSection8.

Removethecoolantsupplyandreturnlines.

RefertoProcedure010041inSection10.

withElectronicallyActuatedInjector

WARNING

Batteriescanemitexplosivegases.Toreduce

thepossibilityofpersonalinjury,always

ventilatethecompartmentbeforeservicingthe

batteries.Toreducethepossibilityofarcing,

removethenegative()batterycablefirstand

attachthenegative()batterycablelast.

WARNING

Donotremovethepressurecapfromahot

engine.Waituntilthecoolanttemperatureis

below50C[120F]beforeremovingthe

pressurecap.Heatedcoolantsprayorsteam

cancausepersonalinjury.

WARNING

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

4/69

12/6/2016

Turbocharger

Coolantistoxic.Keepawayfromchildrenand

pets.Ifnotreused,disposeofinaccordance

withlocalenvironmentalregulations.

WARNING

Toreducethepossibilityofpersonalinjury,

avoiddirectcontactofhotoilwithyourskin.

Disconnectthebatteries.RefertotheOEM

servicemanual.

TurntheairOFFtotheairstarter,if

equipped,andtagthevalveclosed.Referto

Procedure012022inSection12.

Drainthecoolingsystemtoapointbelow

theturbochargers.RefertoProcedure008

018inSection8.

Removethecoolantsupplyandreturnlines.

RefertoProcedure010041inSection10.

Removetheoilsupplylines.Referto

Procedure010046inSection10.

Removetheoildrainlines.Referto

Procedure010045inSection10.

Remove

withMechanicallyActuatedInjector

NOTE:Theturbochargers,mounting

hardware,andconnectionsarenotthesame

forallmodelsofK38andK50engines.

Becausethepartsaredifferent,procedures

aregivenforremovalofthefollowing

turbochargers.

KT38,KTA38,andKTA50withCenter

MountAftercooler

KTTA38LowPressure

KTTA50LowPressure

K2000ELowPressure

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

5/69

12/6/2016

Turbocharger

KTTA38,KTTA50,K1500E,K1800Eand

K2000EHighPressure,andKT38,KTA38,

andKTA50withOutboardAftercoolers

NOTE:Theoilinletanddrainhoseroutingand

clampscanbedifferentthanshown,

dependingontheageoftheengine.

KT38,KTA38,andKTA50withCenterMount

Aftercooler

NOTE:TheillustrationsshowaKTA38.The

KTA50hasalongerconnectionbetweenthe

turbochargerandtheaftercooler.

Olderenginescanhaveaspacerforthe

capscrew(23).Keepthespacerforfuture

assembly.

Detachtheoildrainhosefromthecylinderblock.

Removetheoringseal(21).

Discardtheseal.

Detachtheoildrainhosefromtheturbocharger.

Removethegasket(17).

Discardthegasket.

Checkthehose(18)fordamage.Discardthepart

ifitisdamaged.

Detachtheoilinlethose(16).Removalofthe

fitting(15)andtheoringseal(14)isnotrequired

unlesstheyaredamaged.

Removeanysupportclampsfromthehose.

Removethehose.Checkthehosefordamage.

Discardthepartifitisdamaged.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

6/69

12/6/2016

Turbocharger

Newerengineshaveahoseandclampsbetween

theturbochargersandairtransferhousings.

Theclampsarespecialhighstrengthparts.

Loosenthehoseclamps(2).

Olderengineshaveretainingstraps.

Removethecapscrewsandtheretainingstraps

(10).

Checkthestrapsfordamage.Discardthepartifit

isdamaged.

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Removethefourcapscrews(8)andnuts(9).

Removetheturbochargerandgasket.

Discardthegasket.

Onnewerengines,removetheclampsandthe

hose.

Discardthehose.

Checktheclampsfordamage.Discardthepartif

itisdamaged.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

7/69

12/6/2016

Turbocharger

Onolderengines,removethetube(5).Remove

theoringseals(4).

Discardtheseals.

Removethedustseal(3).

Ifthedustsealishardorsoakedwithoil,discard

thepart.

KTTA38LowPressure:

Removetheoildrainhose(30).Removethe

gasket(29)andtheoringseal(33).

Discardthegasketandseal.

Checkthehosefordamage.Discardthepartifit

isdamaged.

Detachtheoilinlethose(16).Theremovalofthe

fitting(15)andtheoringseal(14)isnotrequired

unlessdamaged.

Removeanysupportclampsfromthehose.

Removethehose.

Checkthehosefordamage.Discardthepartifit

isdamaged.

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

8/69

12/6/2016

Turbocharger

Removethefourcapscrews(27)andthenuts

(28).

Removetheturbochargerandthegasket.

Discardthegasket.

Loosenthehoseclamps(24).Removethe

clampsandthehose(23)fromthehighpressure

turbochargerairconnection.

Removetheairconnection(21)fromthehigh

pressureturbocharger.Removetheoringseals

(19).

Discardtheseals.

Removethedustseal(22).Ifthedustsealishard

orsoakedinoil,discardthepart.

Removethefourcapscrews(12)andnuts(18).

Theheavywashers(13)andcapscrewsare

specialheatresistantparts.

Removetheexhaustconnection(11)andthe

exhaustoutletpipe(10).

Removethevbandclamp(8)andtheexhaust

outletconnection(9).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

9/69

12/6/2016

Turbocharger

Removethesixcapscrews(7).Theheavyflat

washers(5)arespecial.Removethesupport

plate(4).

Removethesocketheadcapscrew(3).Remove

theturbochargersupportlegs(1).

KTTA50LowPressure

TheBrownBoveri,ModelRR151,

turbochargerscontainmetricfastenersfortheoil

connectionplates.

Removetheoildrainhose(48).

Removethegasket(47)andoringseal(51).

Discardthegasketandseal.

Checkthehosefordamage.Discardthepartifit

isdamaged.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

10/69

12/6/2016

Turbocharger

SomeBrownBoveriturbochargersdonot

containtheadapterplatesfortheoilinlet.

Detachtheoilinlethose.Theadapterplates(44)

andfittingsdonotrequireremoval.

Removeanysupportclamps.Removethehose.

Checkthehosefordamage.Discardthepartifit

isdamaged.

Removethefourcapscrews(40)andnuts(42).

Removethegasket.

Discardthegasket.

Removethetwocapscrews(35)thatholdthe

exhaustsideoftheturbochargertothesupport

bracket.

Removethetwocapscrews(31)andnuts(34)

thatholdtheintakesupportbrackettothe

turbochargersupportbracket.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

11/69

12/6/2016

Turbocharger

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Removethelowpressureturbocharger(16).

Loosenthehoseclamps(12).Pulltheintake

connectionpipe(15)fromthehighpressure

turbocharger.Removeanddiscardtheoring

seals(13)andthehose(11).Removethedust

seal.

Ifthedustsealishardorsoakedwithoil,discard

thepart.

Removetheexhaustconnection(11)andoutlet

pipe(10).

Removethevbandclamp(8)andtheexhaust

outletconnection(9).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

12/69

12/6/2016

Turbocharger

Removethesixcapscrews(7).Removethe

turbochargersupportbracket(4).

Removethesocketheadcapscrews(3).Remove

theturbochargerbracketsupportlegs(1).

K2000ELowPressure:

Removetheoildrainhose(60).Removethe

gasket(59)andoringseal(63).

Discardthegasketandseal.

Checkthehosefordamage.Discardthepartifit

isdamaged.

Detachtheoilinlethose.Removalofthefitting,

plate,(56)andgasket(55)isnotrequired.

Removeanysupportclampsfromthehose.

Removethehose.

Checkthehosefordamage.Discardthepartifit

isdamaged.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

13/69

12/6/2016

Turbocharger

Removetheheatshield(blanket)fromthe

interstageairhose.

LoosenthetwoTboltclamps(45)ontheair

intakepipe(47)andthecompressorinlet.

Removethefourcapscrews(49)andnuts(52)

thatholdtheairintakepipe(47)tothe

turbochargercompressoroutlet.

Removetheairintakepipe(47).

Checkthepipefordamage.Discardthepartifitis

damaged.

Loosenthevbandclamp(8).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

14/69

12/6/2016

Turbocharger

Removethefourcapscrews(12)andnuts(14)

thatholdthetwoexhaustconnections(9and11).

Removethefourcapscrews(40)andnuts(42)

thatholdtheexhaustconnectiontotheturbine

housing.

Removetheexhaustconnection.

Removethetwocapscrews(31)andnuts(25)

thatholdthebracket(32)totheconnection(26).

Removethetwocapscrews(43)andthenuts(34)

thatholdthebracket(32)tothesupportbracket

(4).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

15/69

12/6/2016

Turbocharger

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Removethetwocapscrews(35)andnuts(38)

thatholdtheturbochargerexhaustoutlet

connectiontothebracket.

Removetheturbocharger.

KTTA38,KTTA50,K1500E,K1800EandK2000E

HighPressure,andKT38,KTA38,andKTA50

withOutboardAftercoolers

IftheenginebeingservicedisaKT38,KTA38,or

KTA50,recordthedirectionoftheturbocharger

exhaustoutletandmarktheexhaustmanifoldsfor

location.Thiswillaidtheassemblyprocessasthe

exhaustcanbeeitherfrontoutorrearout.

Detachtheoildrainhosefromthecylinderblock.

Removetheoringseal(9).

Discardtheoringseal.

Checkthehosefordamage.Discardthepartifit

isdamaged.

Detachtheoildrainhosefromtheturbocharger.

Removeanysupportclampsandthehose.

Removethegasket(5).

Discardthegasket.

Checkthehosefordamage.Discardthepartifit

isdamaged.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

16/69

12/6/2016

Turbocharger

Removalofthefitting(15)andtheoring(14)is

notrequired.

Detachtheoilinlethose.Removeanysupport

clamps.Removethehose.

Checkthehosefordamage.Discardthepartifit

isdamaged.

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Removethefourcapscrews(3)andthenuts(4).

Removetheturbochargerandgasket.

Discardthegasket.

withElectronicallyActuatedInjector

Removethelowpressureturbochargerairintake

andbracket.

Removethelowpressureturbochargerexhaust

adapterandbracket.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

17/69

12/6/2016

Turbocharger

Removetheeightnuts,plainwashers,nuts,

capscrewsandpclipsfromtheairtransfer

connections.

Removetheairtransferconnectionsanddiscard

thegaskets.

NOTE:Notetheorientationofthecapscrews

andnutsinthetransfertubepriortoremoval.

Thecapscrewsmustbeinstalledinthesame

orientationduringinstallation.

Removetheeightnuts,plainwashers,and

capscrews,andremovetheairtransferpiping.

Discardthegaskets.

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Removethelowpressureturbochargers.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

18/69

12/6/2016

Turbocharger

Loosenandremovetheclampsandhoses

connectingtheturbochargerstotheintake

manifold.

Removetheclampsfromthehighpressure

turbochargerandairtransferconnection.

Removetheairtransferfromthehighpressure

turbocharger.

Removethefourcapscrews,nuts,andwashers

andremovetheexhaustoutletconnectionfrom

thehighpressureturbocharger.

Removetheexhaustoutletclampandoutlet

connectionfromtheturbocharger.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

19/69

12/6/2016

Turbocharger

Removethefourmountingcapscrews,nutsand

washersfromeachhighpressureturbocharger.

GasCompression

WARNING

Thiscomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Removethemountingcapscrewsandlock

washers.

Removetheturbochargerandgasket.

Discardthegasket.

Clean

CAUTION

Tapeorplugallopeningstopreventsolventor

steamfromenteringtheoilcavitiesinthe

turbocharger.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

20/69

12/6/2016

Turbocharger

Thisprocedureappliestoallmodelsof

turbochargeronK38andK50engines.See

GeneralInformationatthebeginningofthis

section.

WARNING

Whenusingsolvents,acids,oralkaline

materialsforcleaning,followthe

manufacturer'srecommendationsforuse.

Weargogglesandprotectiveclothingtoreduce

thepossibilityofpersonalinjury.

WARNING

Whenusingasteamcleaner,wearsafety

glassesorafaceshield,aswellasprotective

clothing.Hotsteamcancauseserious

personalinjury.

Usesolventorsteam.Cleantheexteriorofthe

turbocharger.

InspectforReuse

Inspecttheturbineandcompressorwheelsfor

frettingandbrokenvanes.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

21/69

12/6/2016

Turbocharger

Useadialdepthgauge,PartNumberST537,or

adialindicatortomeasuretheaxialmotion(end

toend).

CompressorImpellerAxialEndClearance

HolsetHC5,HC5A,(127

mmwheel)

HolsetHC5,HC5A,(130

mmwheel)

HolsetHX80/HX85

HolsetHT100

mm

in

0.025 MIN 0.001

0.152 MAX 0.006

0.025 MIN 0.001

0.152 MAX 0.006

0.025 MIN 0.001

0.152 MAX 0.006

0.050 MIN 0.002

0.152 MAX 0.006

MakesurethemovementiswithintheMIN/MAX

TotalIndicatorReadings(TIR)valuesshown

above.

NOTE:Iftheendclearanceexceedsthe

specifications,theturbochargermustbe

replacedorrebuilt.ContactaCummins

AuthorizedRepairLocation.Referencethe

HC5ATurbochargerShopManual,Bulletin

3810243,ortheHT100SeriesTurbocharger

ShopManual,Bulletin3810386,forrebuild

instructions.

Measuretheradialclearance(sidetoside)atthe

compressornose,usingadialgauge.

CompressorImpellerRadialClearance

mm

in

HolsetHC5,HC5A,(127 0.228 MIN 0.009

mmwheel)

0.686 MAX 0.027

HolsetHC5,HC5A,(130 0.228 MIN 0.009

mmwheel)

0.762 MAX 0.03

HolsetHX80/HX85

0.254 MIN 0.01

0.787 MAX 0.031

HolsetHT100

0.254 MIN 0.01

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

22/69

12/6/2016

Turbocharger

0.813 MAX 0.032

MakesurethemovementiswithintheMIN/MAX

TIRvaluesshownabove.

NOTE:Iftheclearanceexceedsthe

specifications,theturbochargermustbe

replacedorrebuilt.ContactaCummins

AuthorizedRepairLocation.SeeHC5A

TurboShopManual,Bulletin3810243,or

HT100SeriesTurbochargerShopManual,

Bulletin3810386,forrebuildinstructions.

NOTE:Checkthemodelofturbocharger

installedontheengine,thisisfor:

BrownBoveri,ModelRR153andRR151.

Tomeasureaxialclearance,usePartNumberST

537,DialDepthGauge,oradialindicator.

Measuretheaxialmotion.

BBC(RR151)and(RR153)EndClearance

mm

0.09

0.13

in

0.004

0.005

MIN

MAX

Iftheendclearanceexceedsthespecifications,

theturbochargermustbereplacedorrebuilt.

Usethefollowingmanualforrebuildinstructions.

ReferencetheBrownBoveriTurbocharger

Manual,Bulletin3810235.

NOTE:Thecompressorandturbinecasings

donotrequireremovaltomeasuretheradial

clearance.Thepartsshownareremovedfor

clarity.

Useafeelergaugetomeasuretheradial

clearance.

BBC(RR151)and(RR153)BearingRadial

Clearance

mm

RR153

0.55

in

MAX

0.021

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

23/69

12/6/2016

Turbocharger

RR151

0.75

MAX

0.030

Iftheradialclearanceexceedsthespecification,

thepartmustbereplacedorrebuilt.Usethe

followingmanualforrebuildinstructions.

ReferencetheBrownBoveriTurbocharger

Manual,Bulletin3810235.

NOTE:Checkthemodelofturbocharger

installedontheengine,thisisfor:

AiResearch,ModelT18A.

Useadialindicatortomeasuretheend

clearance.

AiResearchT18AEndClearance

mm

0.10

0.23

MIN

MAX

in

0.004

0.009

Iftheendclearanceexceedsthespecifications,

theturbochargermustbereplacedorrebuilt.

Usethefollowingmanualforinformation

concerningrebuildinstructions.Referencethe

TurbochargerComponentShopManual,Bulletin

3379091.

AiResearchMethodOne:

Checktheradialclearanceofboththe

compressorimpellerandturbinewheel.

Useyourhandtopushthecompressorimpelleror

turbinewheeltowardthehousing.

Useafeelergaugethatisnotmorethan13mm

[0.5in]wide.Measuretheclearancebetweenthe

impellerandthehousingattheminimum

clearancepoint.

AiResearchT18AImpellerandTurbineWheel

RadialClearance

mm

0.08

0.18

MIN

MAX

in

0.003

0.007

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

24/69

12/6/2016

Turbocharger

Iftheclearanceexceedsthespecifications,the

turbochargermustbereplacedorrebuilt.Use

thefollowingmanualforinformationconcerning

rebuildinstructions.ReferencetheTurbocharger

ComponentShopManual,Bulletin3379091.

AiResearchMethodTwo:

Tomeasurethedirectbearingradialclearanceon

theT18A,placeadialindicatorthroughtheoil

drainholeasillustrated.Besuretheindicator

touchesthehighestpartoftheshaft.

Movetheturbineandcompressorwheelsbyhand

totheupperandlowerlimits.

AiResearchT18ABearingRadialClearance

mm

0.20

0.46

MIN

MAX

in

0.008

0.018

Iftheclearanceexceedsthespecifications,the

turbochargermustbereplacedorrebuilt.Use

thefollowingmanualforinformationconcerning

rebuildinstructions.ReferencetheTurbocharger

ComponentShopManual,Bulletin3379091.

Allmodels:

Aftertheturbochargerhasbeenchecked:

Lubricatethebearingswithengineoil

throughtheoilinletfitting

Coverallopeningstoprevententryofdirt

untilinstalledontheengine.

NOTE:Checkthemodeloftheturbocharger

installedontheengine.Thisisfor:

Honeywell,allmodels.

Specificationsforcheckingradialandaxial

clearancearenotavailable.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

25/69

12/6/2016

Turbocharger

Inspectforsignsofcontactbetweenthe

turbochargervanesandhousing.

Checkthebearingsystemforwear:

Holdbothendsoftheturbochargershaft

androtatetheshaftwhileapplyingpressure

downonthecompressorsideanduponthe

turbineside.Itshouldrotatefreelyandthere

shouldbenocontactbetweenthe

compressorwheelandthecompressor

housing,ortheturbinewheelandthe

turbinehousing.

Replacetheturbochargerifanymalfunctionsare

identified.

Disassemble

Removetheoringanddiscard.

Ifthecompressorcoverhasaninletbaffleitcan

beremovedwithaflattipscrewdriver.Prythe

retainingringupandremovetheretainingring.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

26/69

12/6/2016

Turbocharger

CAUTION

Usecautioninhandlingtheturbineblades.The

turbinebladescanbeeasilydamagedwhen

theturbinehousingisremoved.

Removetheturbinehousingbybendingthelock

platetabsawayfromthecapscrewheads.

Removethecapscrews.

Makesuretheturbinewheelrotatesfreelyinside

theturbinehousing.Tapontheturbinehousing

withamallettoseparatetheturbinehousingfrom

thebearinghousing.

Removetheoilsupplyfittingsandthecoolant

linesfromthecenterhousingassembly.

Discardtheorings.

CleanandInspectforReuse

WARNING

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

27/69

12/6/2016

Turbocharger

Somesolventsareflammableandtoxic.Read

themanufacturer'sinstructionsbeforeusing.

WARNING

Whenusingsolvents,acids,oralkaline

materialsforcleaning,followthe

manufacturer'srecommendationsforuse.

Weargogglesandprotectiveclothingtoreduce

thepossibilityofpersonalinjury.

Cleanthecompressorcoverandturbinehousing

inpartscleanertoloosendeposits.

WARNING

Wearappropriateeyeandfaceprotection

whenusingcompressedair.Flyingdebrisand

dirtcancausepersonalinjury.

Drythecompressorhousingwithcompressedair.

Useasoftbristlebrushtoremoveheavyscale

deposits.

Washanddrythepartsafterbrushing.

CAUTION

Donotusecompressedairtodryorspinthe

turbinewheelasthiscancausedamagetothe

turbochargerbearingsystem.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

28/69

12/6/2016

Turbocharger

Ifchemicalandbrushcleaningisnoteffective,

beadblastwithplasticabrasivemedia,Part

Number3822735,orequivalent.

Washanddrypartsafterbeadblasting.

Thecenterhousingrotatingassemblycanbe

cleanedwithelectricalcontactcleaner,Part

Number3824510,orequivalent.

Donotspraycontactcleanerintotheoiland

coolantports.

Inspectthecompressorcoverforcracks,dents,

andotherdamage.

Inspecttheinsideofthecompressorcoverfor

signsofscoringordamagefromthecompressor

wheel.Replacethecompressorcover,if

damaged.

Inspecttheturbinehousingforcracksand

damage.Crackslargerthan10mm[0.39in]can

causeanexhaustleak.Replacetheturbine

housingifdamageisfound.

Followthecriteriashownintheillustration.

Minorcracksintheturbinehousinginternalwall,

whereexhaustgasflowenterstheturbinewheel,

isanacceptablecondition.Theturbinehousing

canbereused.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

29/69

12/6/2016

Turbocharger

Inspecttheturbinehousingforsignsofcontact

withtheturbinewheel.Damagedturbinehousings

mustbereplaced.

Inspectthecenterhousingrotatingassemblyfor

anysignsofcracks,damagedthreads,orother

damage.

Rotatetheturbinewheelbyhandtomakesureit

spinsfreely.

Replacethecenterhousingrotatingassemblyifit

isdamagedordoesnotspinfreely.

Inspectthecompressorwheelfordamage,

broken,orbentblades.

Donotattempttorepairorstraightentheblades.

Instead,replacethecenterhousingrotating

assembly.

Inspecttheturbinewheelfordamaged,broken,or

bentblades.

Donotattempttorepairorstraightentheblades.

Instead,replacethecenterhousingrotating

assembly.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

30/69

12/6/2016

Turbocharger

Measure

Useadialdepthgauge,PartNumberST537,or

adialindicatortomeasuretheaxialmotion(end

toend).

CompressorImpellerAxialEndClearance

mm

in

HolsetHC5,HC5A,(127 0.025 MIN 0.001

mmwheel)

0.152 MAX 0.006

HolsetHC5,HC5A,(130 0.025 MIN 0.001

mmwheel)

0.152 MAX 0.006

HolsetHX80/HX85

0.025 MIN 0.001

0.152 MAX 0.006

HolsetHT100

0.050 MIN 0.002

0.152 MAX 0.006

MakesurethemovementiswithintheMIN/MAX

TIRvaluesshownabove.

Replacethecenterhousingrotatingassemblyif

theaxialclearanceisnotwithinspecifications.

Measuretheradialclearance(sidetoside)atthe

compressornose,usingadialgauge.

CompressorImpellerRadialClearance

mm

in

HolsetHC5,HC5A,(127 0.228 MIN 0.009

mmwheel)

0.686 MAX 0.027

HolsetHC5,HC5A,(130 0.228 MIN 0.009

mmwheel)

0.762 MAX 0.03

HolsetHX80/HX85

0.254 MIN 0.01

0.787 MAX 0.031

HolsetHT100

0.254 MIN 0.01

0.813 MAX 0.032

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

31/69

12/6/2016

Turbocharger

MakesurethemovementiswithintheMIN/MAX

TIRvaluesshownabove.

Replacethecenterhousingrotatingassemblyif

theradialclearanceisnotwithinspecifications.

Assemble

CAUTION

Usecautionwhenhandlingtheturbineblades.

Theturbinebladescanbeeasilydamaged

wheninstallingintheturbinehousing.

Assemblethecenterhousingrotatingassembly

ontotheturbinehousing.

Lubricatethethreadsofthenewcapscrewswith

antiseizecompound,PartNumber3824732,or

equivalent.

Installthecapscrews,withnewlockplates,tothe

turbochargerturbinehousing.

TorqueValue:20.3n.m[180inlb]

Useahammerandpunchtofoldthelockingplate

ontotheflatofthecapscrew,toprevent

loosening.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

32/69

12/6/2016

Turbocharger

Assembletheinletbaffleintothecompressor

coverandsecurewitharetainingring.Holdone

endoftheretainingringinthegroove.Pressthe

remainderoftheretainingringintoposition.Usea

flattipscrewdrivertomakesuretheretainingring

iscorrectlyseatedinthecompressorcover

groove.

NOTE:TheHX83Turbochargerusesa

titaniumcompressorwheel.Theedgeofthe

wheelisverysharp.Handlethecompressor

wheelwithcare.

Assemblethecompressorhousingneworingon

theturbocharger.

CAUTION

Donotdamagethecompressorwheelblades

duringassembly.

Assemblethevbandclampandcompressor

coverontotheturbocharger.

Placethevbandclampinposition.

Tightenthevbandclamp.

TorqueValue:12n.m[106inlb]

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

33/69

12/6/2016

Turbocharger

Makesurethecompressorwheelandturbine

wheelrotatefreely.

Install

withMechanicallyActuatedInjector

CAUTION

Checktobesurethecorrectturbocharger

assemblyisinstalled.Theturbocharger

assemblynumberisonthedataplatethatis

mountedontheturbocharger.Comparethe

assemblynumberwiththenumberinthe

ControlPartsList(CPL)Manualwiththe

correspondingCPLfortheenginebeing

serviced.Manyturbochargersappearthe

samephysically,butcontaindifferentparts.If

thewrongturbochargerassemblyisinstalled,

theperformanceoftheenginewillbelessthan

specification,ordamagecanresulttothe

engineduetoexcessivecylinderpressureand

temperature.

Theturbochargers,mountinghardware,and

connectionsaredifferentforvariousmodelsof

K38andK50engines.Becauseofthedifferent

parts,installationproceduresaregivenfor:

KT38,KTA38,andKTA50Turbochargers

withCenterMountAftercooler

KTTA38andKTTA50HighPressure,and

KT38,KTA38,andKTA50Turbochargers

withOutboardAftercoolers

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

34/69

12/6/2016

Turbocharger

KTTA38LowPressureTurbochargers

KTTA50LowPressureTurbochargers

K2000E,K1800EandK1500EHigh

PressureTurbochargers

K2000ELowPressureTurbochargers

Duringturbochargerinstallation,itisoften

necessarytoadjusttheangleofthebearing

housingoildrainandtheangleofthecompressor

housingoutlet.Instructionsfortheseadjustments

aredescribedfollowingtheprocedureforthe

KTTA50LowPressureTurbocharger.

Oilinletanddrainhoseroutingandclampscanbe

differentthanshownbecauseoftheageofthe

engine.Besuretheoilhoseshavethecorrect

clampsinstalledtopreventdamagefromvibration

orheatfromanotherpart.

KT38,KTA38,andKTA50Turbochargerswith

CenterMountAftercooler

NOTE:TheillustrationsshowaKTA38.The

KTA50hasalongerconnectionbetweenthe

aftercoolerhousingandtheturbocharger.

Theprocedureisthesameforthesemodels.

Newerengineshaveahoseandclampsto

connecttheturbochargertotheaftercooler

connection.Olderengineshaveatubewithadust

sealandtwooringsealstoconnectthe

turbochargertotheaftercoolerconnection.

Theclampsarespecialtoallowahighertorque.

StandardTbolttypeclampscanloosenandallow

anairleak.

NewerEngines:

Installthehose(1)andclamps(2)onthe

aftercoolerconnection.Donottightentheclamps.

SomeofthenewerK50engineshaveahoseand

heavydutyclampsinstalledoverthetubeando

ringasshowninthenextpicture.

OlderEngines:

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

35/69

12/6/2016

Turbocharger

Installthedustseal(3)andoringseals(4)onthe

tube(5).

Usevegetableoil.Lubricatetheoringseals.

Installthetubeintheboreoftheaftercooler

housing.Pushthetubeintotheboreuntilit

touchesthestepinthebore.

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Installthegasket(6)ontheexhaustmanifold.The

gasketmustbeinstalledsothattheraisedbead

onthegasketistowardtheturbocharger.

Installtheturbocharger(7).Pushthe

compressorhousingintothehoseoronthehose.

Thecapscrews(8)withnuts(9)aremanufactured

fromheatresistantmaterial.Ifheatresistant

capscrewsarenotinstalled,thepartswillfail,

causinganexhaustleak.

Applyanantiseizecompoundonthethreadsof

thecapscrew.

Installthefourcapscrews(8)withthenuts(9).

TorqueValue:

Capscrews40n.m[30ftlb]

Someofthecompressorhousingisnotshown

removedforclarity.

Checktheangleoftheoildrainandthealignment

ofthecompressorhousingtotheaftercooler

connection.Iftheangleoralignmentisnotcorrect,

adjusttheturbochargeroildrainangle,oradjust

theturbochargercompressorhousingalignment,

describedlaterinthissection.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

36/69

12/6/2016

Turbocharger

NewerEngines:

Tightentheclamps(2).

TorqueValue:

K389n.m[80inlb]

TheK50requiresaspecialclamp.

TorqueValue:

K5015n.m[133inlb]

OlderEngines:

Installtheparts.

Retainingplates(10)

Flatwashers(11)

Lockwashers(12)

Capscrews(13).

TorqueValue:

Capscrews16n.m[142inlb]

NOTE:Holsetturbochargershaveafitting

thathasstraightthreadsandrequiresano

ringseal.AiResearchturbochargershavea

fittingwithpipethreads.Thetorquevalueis

thesameforbothtypesofthefittings.

Installtheoringseal(14)ontheoilinletfitting

(15).Installthefitting.

TorqueValue:

OilInletFitting35n.m[26ftlb]

Connecttheturbochargeroilinlethose(16)to

thefitting.

Installtheclampsfortheoilinlethose.

Theotherendoftheoilinlethosemustbe

connectedtoafittinginthecylinderblock.Refer

toProcedure001026inSection1.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

37/69

12/6/2016

Turbocharger

Installtheparts.

Gasket(17)

Hose(18)

Lockwashers(19)

Capscrews(20).

TorqueValue:

Capscrews40n.m[30ftlb]

Newerengineshaveaflangeandanoringseal

typeoildrainhoseasshown.Thenewerhose

connectstothecylinderblockwithacapscrew.

Olderengineshaveahosethathasatubingnut

andconnectstotheblockwithafittingthathas

pipethreads.

Ifaflangeandanoringtypeconnectionis

installedonanolderblock,aspacerisrequired

betweentheholeintheblockforthecapscrew

andtheflange.Ifthespacerisnotinstalled,anoil

leakwillresult.

Installtheoringseal(21)onthehoseflange.

Usevegetableoil.Lubricatetheseal.

Installtheflange,thelockwasher(22),andthe

capscrew(23).

TorqueValue:

FlangeCapscrews40n.m[30ftlb]

Repeatthisproceduretoinstalltheother

turbochargerandconnecttheoilhoses.

KTTA38andKTTA50HighPressure,andKT38,

KTA38,andKTA50Turbochargerswith

OutboardAftercoolers

Theturbochargersmustbemountedonthe

correctenginebank.

KTTA38andKTTA50HighPressure:

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

38/69

12/6/2016

Turbocharger

Theturbochargerontheleftbankmustbe

installedwiththecompressorhousingpointed

towardthefrontoftheengine.Theturbocharger

ontherightbankmustbeinstalledwiththe

turbinehousingpointedtowardthefrontofthe

engine.

KT38,KTA38,andKTA50withOutboard

Aftercoolers:

Theturbinehousingonbothturbochargersmust

pointthesamedirection,eithertowardthefrontof

theengineortowardtherearoftheenginesothat

theexhaustpipingwillfittheapplication.

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

NOTE:TheturbochargersfortheK50engine

withpulsetypeexhaustmanifoldsaretobe

mountedwithfourstudsandnuts,not

capscrewsandnuts.Thetorquevalueisthe

same.SomeK38enginesdonotrequirethe

nuts.

Thegasketmustbeinstalledsothattheraised

beadonthegasketistowardtheturbocharger.

Installthegasket(1)ontheexhaustmanifold.

Applyanantiseizecompoundonthethreadsof

thecapscrewsorstuds(3).

Installtheturbocharger(2),thecapscrewsor

studs(3),andthenuts(4),ifrequired.

TorqueValue:

TurbochargerCapscrews40n.m[30ftlb]

NOTE:Someofthecompressorhousingis

shownremovedforclarity.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

39/69

12/6/2016

Turbocharger

Checktheangleoftheoildrain.Thealignmentof

thecompressorhousingtotheaircrossoverscan

notbecheckeduntiltheaftercoolerassemblyis

installed.Iftheangleisnotcorrect,adjustthe

turbochargeroildrainangle,describedlaterinthis

section.

NOTE:Holsetturbochargershaveafitting

thathasstraightthreadsandrequiresano

ringseal.AiResearchturbochargershavea

fittingwithpipethreads.Thetorquevalueis

thesameforbothtypesoffittings.

Installtheoringseal(14)ontheoilinletfitting

(15).Installthefitting.

TorqueValue:

OilInletFitting35n.m[26ftlb]

Connecttheturbochargeroilinlethose(16)to

thefitting.

Installtheclampsfortheoilinlethose.

Theotherendoftheoilinlethosemustbe

connectedtoafittinginthecylinderblock.Refer

toProcedure001026inSection1.

Installtheparts.

Gasket(5)

Hose(6)

Lockwashers(7)

Capscrews(8).

TorqueValue:

Capscrews40n.m[30ftlb]

Installtheoringseal(9)onthehoseflange.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

40/69

12/6/2016

Turbocharger

Usevegetableoil.Lubricatetheseal.

Installtheflangeintheboreoftheblock.Install

thelockwasher(10)withthecapscrew(11).

TorqueValue:

FlangeCapscrews40n.m[30ftlb]

Repeatthisproceduretoinstalltheother

turbochargerandconnecttheoilhoses.

KTTA38LowPressureTurbochargers

NOTE:Theenginehastwolowpressure

turbochargers.Theillustrationsshowthe

installationofoneturbocharger.Itis

recommendedthatthetwolowpressure

turbochargersbeinstalledatthesametime.

Theenginehassixturbochargersupports.Two

aremountedonthefrontoftherightbankandtwo

ontherearoftheleftbank.Oneismountedon

thefrontoftheleftbankandoneontherearof

therightbank.

Installtheturbochargersupports(1)andthelock

washers(2),withthesocketheadcapscrews(3).

TorqueValue:

TurbochargerSupport

Capscrews270n.m[199ftlb]

Donottightentheclampsorfastenerstofinal

torqueuntilthetorquevalueisgiven.Tightenthe

partsenoughtoholdthemtogether,butloose

enoughtoallowthepartstobemovedfor

alignment.

Installtheparts.

Bracket(4)

Flatwashers,heavy(5)

Lockwashers(6)

Capscrews(7).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

41/69

12/6/2016

Turbocharger

Therearesixeachoftheflatwashers,lock

washers,andcapscrews.

Installthevbandclamp(8)andtheexhaustoutlet

connection(9).

Applyanantiseizecompoundtotheslipjointsof

theexhaustoutletconnection(9),exhaustoutlet

pipe(10),andtheturbochargerconnection(11).

Installthepipe(10)totheconnection(9).Install

theconnection(11)inthepipe(10).

Applyanantiseizecompoundonthethreadsof

thecapscrews(12).

Installthefourcapscrews(12)throughthe

connectionandbracket.

Installtheheavyflatwashers(13),thelock

washers(17),andthenuts(18).

Installthelargeoringseal(19)andthesmallo

ringseal(20)ontheairinletpipe(21).

Installthedustseal(22)ontheairinletpipe.

Usevegetableoil.Lubricatetheoringseals.

Installtheairinletpipeinthehighpressure

turbocharger.

Installthehose(23)andthetwoTboltclamps

(24)ontheairinletpipeandhighpressure

turbocharger.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

42/69

12/6/2016

Turbocharger

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Thegasketmustbeinstalledsothattheraised

beadonthegasketistowardtheturbocharger

Installthegasket(25).

Installthelowpressureturbocharger(26).Push

thecompressorhousingontheairinletpipe.

Applyanantiseizecompoundtothethreadsof

thecapscrews(27).

Installthefourcapscrews(27)andlocknuts(28).

NOTE:Someofthecompressorhousingis

shownremovedforclarity.

Checktheangleoftheoildrain.Checkthe

alignmentofthecompressorhousingtotheairinlet

pipe.Iftheangleoralignmentisnotcorrect,see

Turbocharger,OilDrainAngle,Adjust,or

Turbocharger,CompressorHousingAlignment,

Adjust,describedinthissection.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

43/69

12/6/2016

Turbocharger

Tightenthesixcapscrews(7)thatholdthe

brackettothesupports.

TorqueValue:

BrackettoSupports90n.m[66ftlb]

Tightenthefourcapscrews(12)andnuts(18)that

holdtheconnectiontothebracket.

TorqueValue:

ConnectiontoBracket90n.m[66ftlb]

Tightenthefourcapscrews(27)andnuts(28)that

holdtheturbochargertotheconnection.

TorqueValue:

TurbochargerConnection40n.m[30ftlb]

Tightenthevbandclamp(8).

TorqueValue:

VbandClamp7n.m[62inlb]

Useamallet.Taparoundtheclamptobesureitis

seated.

Torquetheclampnuttothesametorquevalue.

Continuetappingandtighteningtheclampuntil

thenutdoesnotturnatthespecifiedtorqueafter

tapping.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

44/69

12/6/2016

Turbocharger

TightenthetwoTboltclamps(24).

TorqueValue:

TboltClamps9n.m[80inlb]

NOTE:Holsetturbochargershaveafitting

thathasstraightthreadsandrequiresano

ringseal.AiResearchturbochargershavea

fittingwithpipethreads.Thetorquevalueis

thesameforbothtypesoffittings.

Installtheoringseal(14)ontheoilinletfitting

(15).Installthefitting.

TorqueValue:

OilInletFitting35n.m[26ftlb]

Theotherendoftheoilinlethosemustbe

connectedtoafittinginthecylinderblock.Refer

toProcedure001026inSection1.

Installthefollowingparts.

Gasket(29)

Hose(30)

Lockwashers(31)

Capscrews(32).

TorqueValue:

Capscrews40n.m[30ftlb]

NOTE:SomeolderKTTA38enginesequipped

withAiResearchlowpressure

turbochargershaveadrainhosethathastwo

piecesconnectedbyatemperatureresistant

humphose.

Installtheoringseal(33)onthehoseflange.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

45/69

12/6/2016

Turbocharger

Usevegetableoil.Lubricatetheseal.

Installtheflange,thelockwasher(34),andthe

capscrew(35).

TorqueValue:

FlangeCapscrews40n.m[30ftlb]

KTTA50LowPressureTurbochargers

NOTE:Theenginehastwolowpressure

turbochargers.Theillustrationsshowthe

installationofoneturbocharger.Itis

recommendedthatthetwolowpressure

turbochargersbeinstalledatthesametime.

Theenginehassixturbochargersupports.Two

aremountedonthefrontoftherightbank,and

twoareontherearoftheleftbank.Oneis

mountedonthefrontoftheleftbank,andoneon

therearoftherightbank.

Installtheturbochargersupports(1),thelock

washers(2),andthesocketheadcapscrews(3).

TorqueValue:

TurbochargerSupport

Capscrews270n.m[199ftlb]

Donottightentheclampsorfastenerstofinal

torqueuntilthetorquevalueisgiven.Tightenthe

partsenoughtoholdthemtogether,butloose

enoughtoallowthepartstobemovedfor

alignment.

Installthebracket(4),thesixlockwashers(6),

andthesixcapscrews(7).

Installthevbandclamp(8)andtheexhaustoutlet

connection(9).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

46/69

12/6/2016

Turbocharger

Applyanantiseizecompoundtotheslipjointsof

theexhaustoutletconnection(9),theexhaust

outletpipe(10),andtheturbochargerconnection

(11).

Installthepipe(10)ontheoutletconnection(9).

Installtheconnection(11)inthepipe(10).

Installthehose(11)andthetwoTboltclamps

(12)onthehighpressureturbocharger.

Installthetwooringseals(13)andthedustseal

(14)ontheairinletpipe(15).

Usevegetableoil.Lubricatetheoringseals.

Installtheairinletpipeinthehighpressure

turbocharger.

CAUTION

KTTA50enginesequippedwithLOGtype

exhaustmanifoldsmusthaveBrownBoveri

Corporation(BBC),ModelNumber153,

turbochargers.KTTA50engineswithPULSE

typeexhaustmanifoldsmusthaveBBC,

ModelNumberRR151,turbochargers.Be

surethecorrectturbochargersareinstalled,

ordamagetotheenginecanresult.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

47/69

12/6/2016

Turbocharger

CAUTION

NewerBBCRR153turbochargershave

fastenerthreadsthatareU.S.Customaryinch.

OlderBBCRR153turbochargershave

fastenerthreadsthataremetricmillimeter.The

fastenerthreadsinallBBCRR151are

metricmillimeter.Besurethecorrectfasteners

areinstalledorthepartscanbedamaged.

NOTE:Theexhaustandintakeadaptersfor

theBBCRR153andRR151appearthe

same,buthavedifferentdimensions.Besure

toinstallthecorrectpart.

Applyanantiseizecompoundtotheboreofthe

lowpressureturbocharger(16)fortheexhaust

outletconnection(17),andthethreadsofthe

capscrews(19)and(20).

Theconnectionmustbeinstalledasshownso

thattheflangewithtwoholesalignswiththe

bracket.

Thetwocapscrews(19)arelongerthanthesix

capscrews(20).

Installtheexhaustoutletconnection(17),thelock

washers(18),andthecapscrews(19)and(20).

TorqueValue:

ExhaustOutletConnection

Capscrews40n.m[30ftlb]

Installthepartsontheairintakeconnection(26).

Capscrews(21)

Bracket(22)

Flatwashers,heavy(23)

Lockwashers(24)

Nuts(25).

Installtheoringseal(27)inthegrooveonthe

connection(26).

Useengineoilorlubriplatetosecurethesealin

thegroove.

Installthepartsonthelowpressure

turbocharger.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

48/69

12/6/2016

Turbocharger

Connection(26)

Flatwashers(28)

Lockwashers(29)

Capscrews(30).

Tightenonlythecapscrews(30).

TorqueValue:

Capscrews25n.m[18ftlb]

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Useahoistandliftingstrap.Putthe

turbocharger(16)inpositionandpushthe

compressorhousingontheairpipe.

Installthecapscrews(31)throughtheheavyflat

washers(32),andthebrackets(22)and(4).

Installtheheavyflatwashers(32),lockwashers

(33),andthenuts(34).

Applyanantiseizecompoundtothethreadsof

thecapscrews(35).

Installthetwocapscrews(35)throughthe

exhaustoutletconnection(17)andthebracket

(4).

Installtheheavyflatwashers(36),thelock

washers(37),andthenuts(38).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

49/69

12/6/2016

Turbocharger

Thegasketmustbeinstalledsothattheraised

beadonthegasketistowardtheturbocharger.

Installthegasket(39)betweentheturbocharger

turbinehousingandtheexhaustconnection.

Applyanantiseizecompoundtothethreadsof

thecapscrews(40).

Installthefourcapscrews(40)throughtheholes

intheturbinehousing,thegasket,andthe

connection.

Installthelockwashers(41)andthenuts(42).

NOTE:Someofthecompressorhousingis

shownremovedforclarity.

Checktheangleoftheoildrain.Checkthe

alignmentofthecompressorhousingtotheairinlet

pipe.Iftheangleoralignmentisnotcorrect,see

Turbocharger,OilDrainAngle,Adjust,or

Turbocharger,CompressorHousingAlignment,

Adjust,describedinthissection.

Tightenthesixcapscrews(7)thatholdthe

brackettothesupports.

TorqueValue:

BrackettoSupports90n.m[66ftlb]

Tightenthetwocapscrews(35)andnuts(36)that

holdtheturbochargerexhaustoutletconnection

tothebracket.

TorqueValue:

ExhaustOutletConnectionto

Bracket90n.m[66ftlb]

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

50/69

12/6/2016

Turbocharger

NOTE:Besurethebracket(32)isflatagainst

theflangeontheairinletconnection.

Tightenthetwocapscrews(43)andthenuts(34)

thatholdtheairintakeconnection(32)tothe

bracket(4).

TorqueValue:

AirIntakeConnectiontoBracket40n.m[30ft

lb]

Tightenthetwocapscrews(31)andthenuts(25)

thatholdthebracket(32)totheconnection(26).

TorqueValue:

BracketCapscrews40n.m[30ftlb]

Tightenthefourcapscrews(40)andnuts(42)that

holdtheexhaustconnectiontotheturbine

housing.

TorqueValue:

ExhaustConnectionCapscrews90n.m[66ftlb]

Tightenthevbandclamp(8).

TorqueValue:

VbandClamp7n.m[62inlb]

Useamallet.Taparoundtheclamptobesureitis

seated.

Tightentheclampnuttothesametorquevalue.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

51/69

12/6/2016

Turbocharger

Continuetappingandtighteningtheclampuntil

thenutdoesnotturnatthespecifiedtorqueafter

tapping.

TightenthetwoTboltclamps(45)ontheairinlet

pipe.

TorqueValue:

TboltClamps7n.m[62inlb]

CAUTION

Besurethecorrectcapscrewsareinstalled.If

thewrongcapscrewsareinstalled,failureof

thepartcanresult.

NOTE:NewerBBCRR153turbochargers

haveafittingthatisthreadeddirectlyintothe

bearinghousing.OlderBBCRR153

turbochargersrequireanadapterplate,Part

Number3176567,andagasket,PartNumber

3176568,attachedtothebearinghousingwith

twocapscrews.

NOTE:AllBBCRR151turbochargershave

anadapterplateandgasket.Theadapterplate

andgasketaredifferentthanontheolder

BBCRR153turbochargers.

Installthepartsfortheturbochargeroilinlet.

Gasket(55)

Plate(56)

Lockwashers(57)

Capscrews(58).

TorqueValue:

OilInletCapscrew40n.m[30ftlb]

Ifthefittingisnotinstalledintheplate,installthe

oilinletfitting.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

52/69

12/6/2016

Turbocharger

TorqueValue:

FittingTorque35n.m[26ftlb]

Connecttheturbochargeroilinlethose.

Theotherendoftheoilinlethosemustbe

connectedtoafittinginthecylinderblock.Refer

toProcedure001026inSection1.

Installthepartsfortheturbochargeroildrain.

Gasket(47)

Hose(48)

Lockwashers(49)

Capscrews(50).

TorqueValue:

OilDrainCapscrews40n.m[30ftlb]

Installtheoringseal(51)onthehoseflange.

Usevegetableoil.Lubricatetheseal.

Installtheflange,thelockwasher(52),andthe

capscrews(53)intheproperholesinthecylinder

block.

TorqueValue:

OilDrainFlangeCapscrews40n.m[30ftlb]

K2000EandK1800EHighPressure

Turbochargers

TheK2000EusesHolsetHC5AHighPressure

Turbochargers(2),theHT100LowPressure

Turbochargers(1)installationisdescribedlater

inthissection.

TheK1800Eengineissinglestageturbocharged

anddoesnotusetheturbochargerinterstage

connectionsorassemblyproceduresasdoesthe

K2000E.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

53/69

12/6/2016

Turbocharger

TheK1800EengineusesHolsetHX85

turbochargers(1).

NOTE:Thehighpressureturbochargers(2)

aremountedtotheexhaustmanifoldusing

fourcapscrews(3)andnuts(4).These

capscrewsandnutsaremanufacturedfrom

highstrengthstainlesssteelthathashigh

temperaturecapability.Donotsubstitutewith

lowerqualityparts.

Thegasketmustbeinstalledwiththeraisedbead

(2)towardtheturbocharger.

Installthegasket(1)ontheexhaustmanifold.

Coatthethreadsofthecapscrewswithantiseize

compound.

Installtheturbocharger(2),capscrews(3)and

nuts(4).

TorqueValue:

TurbochargerMounting

Capscrews40n.m[30ftlb]

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

54/69

12/6/2016

Turbocharger

NOTE:Someofthecompressorhousinghas

beenremovedforclarity.

Checktheangleoftheoildrainandthealignment

ofthecompressorhousingtotheaircrossovers

(thiscannotbecheckeduntiltheaftercooler

assembliesareinstalled).

Iftheangleisnotcorrect,thebearinghousing

mustberotatedinrelationtotheturbinehousing.

Adjusttheturbochargeroildrainangle.

Ifthealignmentiscorrectoraftertheadjustment,

lockthebearinghousingtotheturbinecasing

lockplatetabs.

Connecttheturbochargeroilinlethose(16)to

thefitting(15).

Installtheclampsfortheoilinlethose.

Theotherendoftheoilinlethosemustbe

connectedtoafittinginthecylinderblock.Refer

toProcedure001026inSection1.

Installthegasket(5),hose(6),lockwashers(7)

andtwocapscrews(8)totheturbochargeroil

drain.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

55/69

12/6/2016

Turbocharger

Installtheoringseal(9)onthehoseflange.Use

engineoiltolubricatetheseal.Installtheflangein

theboreoftheblock.Installthelockwasher(10)

andthecapscrew(11).

TorqueValue:

OilInletCapscrews40n.m[30ftlb]

Repeattheproceduretoinstalltheother

turbochargerandconnecttheoilsupplyandthe

drainhose.

K2000ELowPressureTurbochargers

TheK2000Eenginecontainstwolowpressure

turbochargers.Thisillustrationshowsthe

installationofonlyoneturbocharger.The

recommendationistoinstallbothlowpressure

turbochargersatthesametime.

TheK2000Eenginecontainssixturbocharger

supports.Twoofeachofthesupportsare

mountedonthefrontoftherightbankandrearof

theleftbank.Oneofeachofthesupportsis

mountedonthefrontoftheleftbankandrearof

therightbank.

Installtheturbochargersupports(1),andthe

lockwashers(2),andthesocketheadcapscrews

(3).

TorqueValue:

TurbochargerSupport

Capscrews270n.m[199ftlb]

NOTE:Fromthispointon,donottightenthe

clampsorfastenerstotheirfinaltorque

unlessthetorquevalueisgiven.Tightenonly

enoughtoallowthepartstomovefor

alignment.

Installthebracket(4),sixlockwashers(6),and

sixcapscrews(7).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

56/69

12/6/2016

Turbocharger

Installthevbandclamp(8)andexhaustoutlet

connection(9).

Applyantiseizecompoundtothethreadsofthe

capscrews(12).Installthegasket(10),capscrews

(12),lockwashers(13),andnuts(14).

Useantiseizecompoundtocoattheslipjointsof

theexhaustpipe(11)andtheturbocharger

connection(16).

Installtheturbochargerconnection(16)onthe

exhaustpipe(11).

Afterallinterstageconnectionsareinplace,there

mustbeaminimumof3.18mm[0.125inch]

expansionspacebetweenconnections(11and

16).

Thegapcanbeadjustedbymovingthelow

pressureturbochargerorlowpressure

turbochargermountingbracket.

Useantiseizecompoundtocoattheboreonthe

lowpressureturbocharger(22)fortheexhaust

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

57/69

12/6/2016

Turbocharger

outletconnection(17),andthethreadsofthe

capscrews(19and20).

Thebracket(21)mustbeorientedtoprovide

properturbochargeralignment.

NOTE:Thetwocapscrews(19)arelongerthan

thesixcapscrews(20).

Installtheexhaustoutletconnection(17),lock

washers(18),andcapscrews(19and20).

TorqueValue:

ExhaustOutletCapscrews40n.m[30ftlb]

Installthetwocapscrews(31),bracket(32),

heavyflatwasher(23),lockwashers(24),and

nuts(25)ontheairintakeconnection.

Installtheoringseal(27)inthegrooveonthe

connection(26).UseengineoilorLubriplateto

holdthesealinthegroove.

Installtheconnection(26),fourflatwashers(28),

lockwashers(29),andcapscrews(30),onthe

lowpressureturbocharger.Tightenonlythefour

capscrews(30).

TorqueValue:

AirIntakeConnectionCapscrews40n.m[30ft

lb]

Useahoistandliftingstraptopositionthe

turbochargerandtoalignthecapscrewholesin

thebrackets.

Installthecapscrews(43)throughtheheavyflat

washer(44)andbothbrackets(32and4).Install

theheavyflatwashers(44),lockwashers(33)

andthenuts(34).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

58/69

12/6/2016

Turbocharger

Useantiseizecompoundtocoatthethreadsof

thecapscrews(35).

Installthetwocapscrews(35)throughthe

exhaustoutletconnection(17)andthebracket

(4).Installtheheavyflatwashers(36),lock

washers(37),andnuts(38).

Theraisedbeadonthegasket(39)mustbe

towardtheturbocharger.

Installthegasket(39)betweentheturbocharger

turbinehousingandtheexhaustconnections(16).

Useantiseizecompoundtocoatthethreadsof

thecapscrews(40).

Installthefourcapscrews(40)throughtheholes

intheturbinehousing,gasket,andconnection.

Installthelockwashers(41)andnuts(42).

SlideoneTboltclamp(45)andhose(46)over

theendoftheintakepipe(47).Slidethehoseon

farenoughtoinstallthepipe.Installthesecond

clamp(45)overthecompressoroutlet.

Positiontheintakepipe(47)betweenthe

turbochargersandinsertthegasket(48).Secure

theflangeswithfourbolts(49),flatwashers(50),

lockwashers(51),andnuts(52).

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

59/69

12/6/2016

Turbocharger

NOTE:Someofthecompressorhousinghas

beenremovedforclarity.

Checktheangleoftheoildrain.Checkthe

alignmentofthecompressorhousingtotheair

inletpipe.

Iftheangleoralignmentisnotcorrect,the

bearinghousingmustberotatedinrelationtothe

turbinehousing.SeeTurbocharger,Compressor

HousingAlignment,AdjustandTurbocharger,Oil

DrainAngleAlignment,Adjust,describedinthis

section.

Priortoanyofthecapscrewsbeingtightened,

checktobesurethereisaminimumof3.18mm

[0.125in]expansionspaceattheslipjointson

bothexhaustinterstageconnections.

Tightenthesixcapscrews(7)thatholdthe

brackettothesupports.

TorqueValue:

SupportBracketCapscrews95n.m[70ftlb]

Tightenthetwocapscrews(35)andnuts(38)that

holdtheturbochargerexhaustoutletconnection

tothebracket.

TorqueValue:

BracketCapscrews95n.m[70ftlb]

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

60/69

12/6/2016

Turbocharger

Thebracket(32)mustbeflatagainsttheflange

ontheairinletconnection.

Tightenthetwocapscrews(43)andnuts(34)that

holdthebracket(32)tothesupportbracket(4).

TorqueValue:

AirInletConnectionCapscrews40n.m[30ftlb]

Tightenthetwocapscrews(31)andnuts(25)that

holdthebracket(32)totheconnection(26).

TorqueValue:

BracketConnectionCapscrews40n.m[30ftlb]

Tightenthefourcapscrews(40)andnuts(42)that

holdtheexhaustconnectiontotheturbine

housing.

TorqueValue:

ExhaustConnectionCapscrews95n.m[70ftlb]

Tightenthethreecapscrews(19)thatholdthe

bracket(21)totheexhaustoutletconnection(17).

TorqueValue:

ExhaustOutletConnection

Capscrews40n.m[30ftlb]

Tightenthefourcapscrews(12)andnuts(14)that

holdthetwoexhaustconnections(9and11).

TorqueValue:

ExhaustOutletConnections95n.m[70ftlb]

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

61/69

12/6/2016

Turbocharger

Tightenthevbandclamp.

TorqueValue:

VBand9n.m[80inlb]

Useamallet.Tapallaroundtheclamptomake

sureitisseated.

Tightentheclampnuttothesametorquevalue.

Continuetappingandtighteningtheclampuntil

thenutwillnotturnatthespecifiedtorqueafter

tapping.

Tightenthefourcapscrews(49)andnuts(52)that

holdtheairintakepipe(47)totheturbocharger

compressoroutlet.

TorqueValue:

IntakePipeCapscrews40n.m[30ftlb]

CAUTION

ThehosesandTboltclampsoftheairintake

systemareofheavydutydesigntowithstand

temperaturesandpressurestowhichtheyare

exposed.Onlyspecifiedpartsaretobeused.

Theclampscanberemovedandtightened

againamaximumofthreetimes.Thetorque

retentiononthenutwillbebeyondreuseafter

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

62/69

12/6/2016

Turbocharger

this.Atthistime,asecondnutMUSTbeadded

todoublelockthenutoranewclampMUST

beused.

Centerthehose(46)overthehighpressure

turbochargercompressorinletandthepipe(47).

SecurethetwoTboltclamps(45).

NOTE:Donotpositiontheclampsoverthe

hosebeads.Theclampsmustbepositioned

betweenthehosebeadsandtheendofthe

hose.Aportionofthehosemustextend

outsidetheclamp.

TightenthetwoTboltclamps(45)ontheair

intakepipe(47)andtheturbocharger

compressorinlet.

TorqueValue:

IntakePipeClamps8n.m[71inlb]

Theseclampsneedtobetightenedagainafter

theenginehasoperatedafewhours.

Wraptheinterstageairhosewithaheatshield

(blanket).Theblanketissecuredbyplacingthe

eyeletsthatarelocatedoneachendofthe

blanketoverthehoseclampTbolts.Useflat

washersandnutsontheTboltstoretaintheheat

shield.

Installthegasket(55),plate(56),lockwashers

(57),andcapscrews(58)forthelowpressure

turbochargeroilinlet.

TorqueValue:

LowPressureTurbochargerOil

Inlet25n.m[18ftlb]

Installtheoilinletfitting.

TorqueValue:

OilInletFitting35n.m[26ftlb]

Connecttheturbochargeroilinlethose.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

63/69

12/6/2016

Turbocharger

Theotherendoftheoilinlethosemustbe

connectedtoafittinginthecylinderblock.Refer

toProcedure001026inSection1.

Installthegasket(59),thehose(60),thelock

washers(61),andthecapscrews(62)forthelow

pressureturbochargeroildrain.

TorqueValue:

TurbochargerOilDrain25n.m[18ftlb]

Installtheseal(63)onthehoseflange.Use

engineoiltolubricatetheseal.Installtheflange,

lockwasher(64)andthecapscrews(65)inthe

properholesinthecylinderblock.

TorqueValue:

HoseFlange40n.m[30ftlb]

NOTE:Theturbochargeroildrainlinemust

rundownhillfromtheturbochargertothe

cylinderblock.

withElectronicallyActuatedInjector

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

NOTE:ThewordOUT,orraisedbeadonthe

gasketmustbepositionedtowardthe

turbocharger.

Liftthehighpressureturbochargers,using

approvedliftingstraps,andplacethemontothe

middlemountingpadswiththeairoutletsfacing

outboard.

Installthecapscrews,washers,andnuts,and

tighten.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

64/69

12/6/2016

Turbocharger

TorqueValue:

TurbochargerMountingCapscrewsand

Nuts45n.m[33ftlb]

Installtheexhaustoutletandclamp.

Applyantiseizecompound,PartNumber

3824397,orequivalenttobothendsofthe

exhaustinterstagepipingflanges.

Installbothhalvesoftheexhaustinterstageusing

newgaskets.

Applyantiseizecompound,PartNumber

3824397,orequivalenttothemounting

capscrews.

Tightentheexhaustoutletconnectionclamp.

TorqueValue:

HoseClamp8n.m[71inlb]

Installthecapscrews,washersandnutsfinger

tighttoallowforalignment.

Installthehoseandclamps(withtightening

screwsfacingdownward)totheinletsideofthe

turbocharger.

Tightenthehoseclampclosesttothe

turbochargerinlet.

TorqueValue:

HoseClamp8n.m[71inlb]

Installtheintakeairpipingintothehoseand

looselytightentheclamptoallowforalignment.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

65/69

12/6/2016

Turbocharger

WARNING

Thecomponentorassemblyweighsgreater

than23kg[50lb].Topreventseriouspersonal

injury,besuretohaveassistanceoruse

appropriateliftingequipmenttoliftthis

componentorassembly.

Liftthelowpressureturbochargers,using

approvedliftingstraps,ontothemountingpads

andalignthemwiththeinterstageairtransfer

connections.

Installnewsteelgasketsbetweentheouterlow

pressureturbochargerandtheouterlow

turbochargerexhaustconnection.Checkthatthe

raisedbeadsonthegasketsarefacingtheouter

turbocharger.

Installthecapscrews,washersandnutsinthe

sameorientationnotedpriortoremovalandhand

tighten.

Checkthealignmentandtightenthecapscrews.

TorqueValue:

ExhaustConnectionCapscrewsand

Nuts95n.m[70ftlb]

Installanewpapergasketbetweentheairintake

connectionandtheturbochargerandinstallthe

capscrews,washersandnuts.Handtightenonly

toallowforalignment.

Addthepcliptothetoprightcapscrew.Donot

tightenthisboltuntiltheoilsupplylineisinstalled.

Oncealignmentischecked,tightenthe

capscrews.

TorqueValue:

AirIntakeConnectionCapscrewsand

Nuts48n.m[35ftlb]

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

66/69

12/6/2016

Turbocharger

Checkthatallairtransferconnectionsarealigned

andtightentheinterstagehoseclamps.

TorqueValue:

InterstageHoseClamp8n.m[71inlb]

Installtheairintakeandbracketontothelow

pressureturbochargerandtrollyassembly.

Applyantiseizecompound,PartNumber

3824394,orequivalent,tothemounting

capscrewsandinstall.

Tightenallcapscrewswiththeexceptionofthe

twocapscrewsnotconnectedtothemounting

bracket.

TorqueValue:

AirIntakeCapscrews48n.m[35ftlb]

Applyantiseizecompound,PartNumber

3824394,orequivalent,totherearturbocharger

outletflangeandinstalltheexhaustadapterand

bracketontothelowpressureturbochargerand

trollyassembly.

Applyantiseizecompound,PartNumber

3824394,orequivalent,totheeightmounting

capscrewsandinstall.

TorqueValue:

ExhaustAdapterCapscrews48n.m[36ftlb]

FinishingSteps

withMechanicallyActuatedInjector

WARNING

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

67/69

12/6/2016

Turbocharger

Batteriescanemitexplosivegases.Toreduce

thepossibilityofpersonalinjury,always

ventilatethecompartmentbeforeservicingthe

batteries.Toreducethepossibilityofarcing,

removethenegative()batterycablefirstand

attachthenegative()batterycablelast.

WARNING

Somestateandfederalagencieshave

determinedthatusedengineoilcanbe

carcinogenicandcausereproductivetoxicity.

Avoidinhalationofvapors,ingestion,and

prolongedcontactwithusedengineoil.Ifnot

reused,disposeofinaccordancewithlocal

environmentalregulations.

WARNING

Coolantistoxic.Keepawayfromchildrenand

pets.Ifnotreused,disposeofinaccordance

withlocalenvironmentalregulations.

Fillthecoolingsystem.RefertoProcedure

008018inSection8.

TurntheairONtotheairstarter,if

equipped.RefertoProcedure012022in

Section12.

Connectthebatteries.RefertotheOEM

servicemanual.

withElectronicallyActuatedInjector

WARNING

Batteriescanemitexplosivegases.Toreduce

thepossibilityofpersonalinjury,always

ventilatethecompartmentbeforeservicingthe

batteries.Toreducethepossibilityofarcing,

removethenegative()batterycablefirstand

attachthenegative()batterycablelast.

Installtheoildrainlines.RefertoProcedure

010045inSection10.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

68/69

12/6/2016

Turbocharger

Installthecoolantsupplyandreturnlines.

RefertoProcedure010041inSection10.

Fillthecoolingsystem.RefertoProcedure

008018inSection8.

TurntheairONtotheairstarter,if

equipped.RefertoProcedure012022in

Section12.

Connectthebatteries.RefertotheOEM

servicemanual.

LastModified:03Nov2015

Copyright20002010CumminsInc.Allrightsreserved.

https://quickserve.cummins.com/qs3/pubsys2/xml/en/procedures/28/28010033tr.html?q=turbo%20repair

69/69

Das könnte Ihnen auch gefallen

- QuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualDokument2 SeitenQuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualjengandxbNoch keine Bewertungen

- QSK78 Owners Manual PDFDokument17 SeitenQSK78 Owners Manual PDFjengandxb100% (2)

- QuickServe Online - (5411406) Fluids For Cummins® Products Service ManualDokument7 SeitenQuickServe Online - (5411406) Fluids For Cummins® Products Service Manualjengandxb100% (1)

- QuickServe Online - (4021539) QST30 Service ManualDokument7 SeitenQuickServe Online - (4021539) QST30 Service Manualjengandxb33% (3)