Beruflich Dokumente

Kultur Dokumente

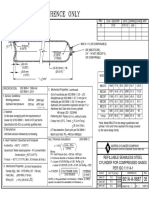

Cylinder Valve Catalog

Hochgeladen von

bkprodhCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cylinder Valve Catalog

Hochgeladen von

bkprodhCopyright:

Verfügbare Formate

CYLINDER VALVES

Cramer Decker Industries

has been a leader in gas

containment and delivery

technologies for over thirty

years. Our uniquely diversified operations deliver

gas management solutions

to five distinct markets

with twelve proprietary

brands and more than

eleven thousand products.

Cramer Decker operations

serve more than twenty-five

thousand customers in all

fifty states and more than

one-hundred countries and

territories around the world.

With three distribution

centers located in California

and Maryland, Cramer

Decker maintains the

largest inventory of compressed gas equipment

and related products in

the United States. And,

as the largest supplier of

Sherwood, Harrison,

Ceodeux and Cavagna

cylinder valves in the nation,

were able to pass our

significant buying and pricing

advantage on to you.

We hope youll explore our

extensive Cylinder Valve

and Accessories catalog,

review our expansive

product offering and

discover our unique

selection of brands. We

invite you to give us a

call at 800-752-4579

or visit us online at

www.cramerdecker.com.

Our knowledgeable staff

of industry experts is ready

to assist you 12 hours each

business day, from 5:00

a.m. PST to 8:00 p.m. EST.

714.566.3850

Fax 714.566.3869

www.cramerdecker.com

ALL-IN-ONE VALVE

AND REGULATORS

GO TO PAGES 4-5

The preferred choice in hospital

applications are the all-in-one

portable oxygen systems with the

convenience of a cylinder, valve

and regulator. These systems

reduce multiple components

into one unique package ending

confusion with hospital staff.

MEDICAL VALVES

GO TO PAGES 6-10

BRASS VALVES FOR STEEL

AND ALUMINUM CYLINDERS

GO TO PAGES 11-15

Medical valves are available in

three major brands, in all

configurations including standard

wrench operated, toggle and the

popular Z valve hand knob. CDI

is ready to handle any volume

order immediately.

Variety of brand selection is

the key to uninterrupted

supply. CDI stocks three major

manufacturers brass valves

offering the best design solution

at the most competitive prices.

RESIDUAL PRESSURE VALVES

GO TO PAGES 16-19

Increase profits and reduce

labor utilizing RPV valves. Ask

a CDI representative to show

you how it works.

SPECIALTY GAS VALVES

GO TO PAGES 20-26

Specialty gas is becoming ever

so popular with equipment

available for all companies to

participate. CDI stocks a wide

selection of diaphragm valves

for all highly technical gases.

LECTURE BOTTLE VALVES

GO TO PAGES 27-28

Are you mixing Specialty Gas

already? Package the gas in a

small cylinder with CDIs lecture

bottle valves and ship it across

the country.

CHLORINE VALVES

GO TO PAGES 29-30

The new Chlorine Institute

alternative approved designs

save major labor costs by

reducing the necessity to rebuild

valves on every turn around.

This saves major time and parts

expenditure.

ACETYLENE VALVES

GO TO PAGES 31-36

PROPANE AND FUEL

GAS VALVES

GO TO PAGES 37-42

CYLINDER VALVE ACCESSORIES

AND TOOLS

GO TO PAGES 43-47

Basic wrench operated B & MCs

to the ever so popular new hand

knob valves make CDI the number

one supplier for Acetylene valves

in America.

Take advantage of CDIs diverse

product line. CDI stocks valves for

industrial fuel gas applications,

commercial fork lift trucks and

simple BBQ valves.

CDI is a total resource for repair

parts, safeties, tools and

accessories. Take a look at our

comprehensive repair section.

ALL-IN-ONE VALVES AND REGULATORS

Integrated Medical Valve & Regulator

Sherwood

VRA Series

NGT Tapered Thread Inlets for Steel Cylinders

Parallel Threads for Aluminum Cylinders

KEY FEATURES

Compact

35% lower profile than comparable models provides

more efficient racking and storage capabilities.

15% 25% lighter weight than comparable models combined

with ergonomically designed shroud with integral carrying handle

improves mobility and reduces fatigue.

Shroud circumference is sized to fit within the footprint diameter

of standard medical E cylinders.

Reliable

Flow rate accuracy within + or - 10%.

Regulator adjustment knob with positive flow detents guards

against inadvertent flow setting changes.

Windows incorporated in the shroud permit convenient

leak inspection.

All units are 100% helium leak tested.

Each Oxy-Gen1 unit is assigned a unique serial number for

positive identification.

Convenient

Pressure gauge located at the top of the unit is protected by the

shroud-handle and provides good visibility through a full range of

cylinder pressures.

Capable

Protective shroud does not require removal during the

filling process.

Fill and evacuation rates are equivalent to standard medical post

valves and deliver substantial time and money savings on the fill line.

Durable

Shroud material is a high performance nylon ABS polymer blend

and exhibits excellent toughness and chemical / UV resistance.

DESIGN SPECIFICATIONS

Working Pressure (MAWP)

Weight

Body

Tested Operating Temp.

Seal Integrity

Tested Storage Temp.

Fill Port

Outlet Connection

Safety

Conforms to CGA V-9

Conforms to EN 738-3

3,000 PSIG

2.1lbs

Brass, Chrome plated

0 - 120F

1 x 10-3

-40 - 120F

CGA540

Medical hose barb

CG-4, 165 Fuse metal

Cramer Decker Industries

Shut off valve operates fill port like standard cylinder valve. Customer

controls on/off and flow with the regulator flow control dial only. No special

fill tools required. Plant can fill with standard CGA540 fill connection.

Part Number

Fill Port Cylinder Connection Flow Settings

VRAM5TV-32-75-15

VRAM5TV-32-75-25

VRAM4TV-32-15

VRAM4TV-32-25

CGA540

CGA540

CGA540

CGA540

3/4-16UNF-2A

3/4-16UNF2A

1/2 NGT

1/2 NGT

0-15LPM

0-25LPM

0-15LPM

0-25LPM

STANDARD SHUT OFF VALVE SERIES - Brass valves

Part Number

Fill Port Cylinder Connection Flow Settings

VRM5V-32-75-15

VRM5V-32-75-25

CGA540

CGA540

.750-16UNF2A

.750-16UNF2A

0-15LPM

0-25LPM

MASTER SHUT OFF VALVE SERIES

Shut off valve operates fill port and the flow selector. User must open valve

before allowing gas to flow through the flow selector dial. Regulator is only

under pressure when the valve is in open position.

Part Number

Fill Port Cylinder Connection Flow Settings

VRAM5TVC-32-75-15

CGA540

3/4-16UNF-2A

0-15LPM

Add a D to end of the part number for Oxygen I units with DISS constant flow connection.

Pressure Relief Devices for VRA Series

FLOW OPTIONS

0-15LPM (Hospital & Pediatric) ( 0, 1/4, 1/2, 1, 2, 3, 4, 6, 8, 10, 15)

0-25LPM (EMS) (0, 1/4, 1/2 1, 2, 3, 4, 6, 8, 10, 15, 25)

INLET OPTIONS

3/4-16UNF2A O-ring seal (Aluminum Cylinders)

1/2-14NGT (Steel Cylinders)

5/8-18UNF2A (Composite Cylinders)

OTHER OPTIONS

DISS Outlet (Provides 50PSI on demand) Add D to part number

STANDARD SHUT OFF VALVE SERIES

800.752.4579

DISC RUPTURE RANGE

PSIG @ 160F

PRESSURE

RELIEF DEVICE

-XX CYLINDER SERVICE PRESSURE

MIN

MAX

CG-4

165F FUSE

METAL

-32

2015 PSIG

3025

3360

6513MFB-32

-48

3000 PSIG

4500

5000

6513MFB-48

714.566.3850

Fax 714.566.3869

www.cramerdecker.com

ALL-IN-ONE VALVES AND REGULATORS

O2GO Series Harrison

NGT Tapered Thread Inlets for Steel Cylinders

Parallel Threads for Aluminum Cylinders

KEY FEATURES

Unique, lightest weight design offers the most compact and economical

valve/regulator combination.

Integrated regulator with a built-in fill valve using a standard CGA540 connection.

Fill port cap and chain supplied standard with all units shipped.

Fill valve is a check valve inlet eliminating the necessity for a manual on/off valve.

Oxygen is dispensed with regulator flow selector. One single operation releases the

flow of gas.

LPM flow and cylinder contents gauge are easy to read.

Available in 15, 25 and pediatric flow settings.

Supplied with a high flow DISS outlet for 50PSI equipment applications.

All brass internal construction designed to perform in optimum in an oxygen

environment safely.

Design passes the ASTM G175 ignition sensitivity testing for oxygen regulators.

Built in safety device protects the cylinder to DOT specifications.

Unique regulator/valve guard protects the complete system, yet allows user to

easily perform FDA required leak detection after the filling process is complete.

Customizing available including color anodizing and laser etching.

Part Number

Description

O2GO-3-4-15

O2GO-3-4-25

O2GO-3-4-15

O2GO-3-4-25

O2GO-4-4-15

O2GO-4-4-25

O2GO valve/regulator

O2GO valve/regulator

O2GO valve/regulator

O2GO valve/regulator

O2GO valve/regulator

O2GO valve/regulator

Cramer Decker Industries

Inlet

DISS

.750-16UNF2A

.750-16UNF2A

.750-16UNF2A

.750-16UNF2A

1/2 NGT

1/2 NGT

800.752.4579

FLOW

Yes

15LPM

Yes

25LPM

Yes 15LPM w/ Pediatric

Yes 25LPM w/ Pediatric

Yes

15LPM

Yes

25LPM

714.566.3850

Fax 714.566.3869

www.cramerdecker.com

MEDICAL VALVES

KVAB Series Sherwood

KEY FEATURES

Nominal stroke is 1.5 turns. Full flow at 1/3 turn.

Strong, durable body is made from extruded brass rod

and coated with a protective chrome finish.

Exceptional machining finishes for low torque sealing

and long packing life.

Chamber design protects threads and stem from damage.

Durable lower plug is made of tough naval brass and coated

with Teflon for lubricity.

Pressure relief device is a single unit to ensure proper assembly

and to resist tampering.

Inert Teflon packing provides leak-free stem seal, long cycle life

and resistance to corrosion.

Secondary O-ring helps to provide a secure seal under vacuum

purging and low pressure operation.

Copper sealing gasket provides permanent, leak resistant

bonnet seal.

All parts cleaned and oil free.

Designed for use with all yokes made to CGA 860

drawing specifications.

Available in wrench, toggle, or handwheel type.

STANDARDS OF CONFORMANCE

CGA V-9

CGA S1.1

CGA V-1

Standard for Compressed Gas Cylinder Valves

Standard for Pressure Relief Devices

Compressed Gas Cylinder Valve Outlet and Inlet Specifications

DESIGN SPECIFICATIONS

Maximum Working Pressure

Burst Pressure

Operating Temperature

Storage Temperature

Leak Rate Internal/External

Minimum Cycle Life

Cv Flow Factor

3,000 PSIG

12,000 PSIG

Min: -50F -45C Max: 120F 55C

Min: -65F -54C Max: 155F 68C

1 x 10-5 cc/sec

5,000 Cycles

Standard: .102

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

MEDICAL VALVES

Gas Service

CGA Outlet

Pin Indexing Hole Numbers

Inlet Thread Size

Sherwood Part Number

Air

950

Pins #1 and #5

- 14 NGT

.750 - 16 UNF-2A

KVAB95044-XX

KVAB95054-XX

Carbon Dioxide

940

Pins #1 and #6

- 14 NGT

.750 - 16 UNF-2A

KVAB94041-XX

KVAB94051-XX

Helium

930

Pins #4 and #6

- 14 NGT

.750 - 16 UNF-2A

KVAB93044-XX

KVAB93504-XX

Medical Gas Mixtures

973

Pins #11 and #24

- 14 NGT

.750 - 16 UNF-2A

KVAB97344-XX

KVAB97354-XX

Nitrogen

960

Pins #1 and #4

- 14 NGT

.750 - 16 UNF-2A

KVAB96044-XX

KVAB96054-XX

Nitrous Oxide

910

Pins #3 and #5

- 14 NGT

.750 - 16 UNF-2A

KVAB91041-XX

KVAB91051-XX

Nitrous Oxide and

Oxygen Mixtures

965

Pin #7

- 14 NGT

.750 - 16 UNF-2A

KVAB96544-XX

KVAB96554-XX

Oxygen

870

Pins #2 and #5

- 14 NGT

.750 - 16 UNF-2A

KVAB87044-XX

KVAB87054-XX

Oxygen and Carbon

Dioxide Mixtures

880

Pins #2 and #6

- 14 NGT

.750 - 16 UNF-2A

KVAB88044-XX

KVAB88054-XX

Oxygen and Helium

Mixtures

890

Pins #2 and #4

- 14 NGT

.750 - 16 UNF-2A

KVAB89044-XX

KVAB89054-XX

OPTIONS

1/8-27 NPT gauge port: To order, add G to end of part number. e.g. KVAB87054-32G

Diecast aluminum toggle lever: To order, add TG to end of part number. e.g. KVAB87054-32

becomes KVAB87054-32TG

Lexan polycarbonate, wing style handwheel: To order, add H to end of part number.

e.g. KVAB87054-32 becomesKVAB87054-32H

ONLY AVAILABLE ON .750-16 UNF -2A INLET VALVES.

Teflon inlet o-ring. To order, add R to end of part number.

e.g. KVAB87054-32 becomes KVAB87054-32R

ONLY AVAILABLE ON .750-16 UNF -2A INLET VALVES.

NOTES

All valves are supplied with 165F fusible metal backed, flush style pressure relief devices and copper alloy rupture

discs EXCEPT Carbon Dioxide and Nitrous Oxide and which are supplied with un-backed hex-style pressure relief

devices and nickel 201 rupture discs.

All valves are supplied with rupture discs rated for 2015 psig service pressure cylinders. Rupture discs rated for other

service pressures available on request.

PRESSURE RELIEF DEVICES FOR KVAB SERIES MEDICAL VALVES

DISC RUPTURE RANGE

PSIG @ 160F

PRESSURE RELIEF DEVICE

-XX CYLINDER SERVICE PRESSURE

MIN

MAX

CG-1*

NO FUSE METAL

CG-4**

165F FUSE

METAL

-28

1800 PSIG

2700

3000

9-4000-60-28

6513MFB-28

-32

2015 PSIG

3025

3360

9-4000-60-32

6513MFB-32

-48

3000 PSIG

4500

5000

9-4000-60-48

6513MFB-48

NOTES

* CG-1 safeties are commonly used for CGA910 and 940 valve outlet connections.

** CG-4 safeties are commonly used for CGA870, 880, 890, 930 and 950 valve outlet connections.

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

MEDICAL VALVES

YVBA Series Sherwood

Vertical Outlet Medical

Oxygen Valves

KEY FEATURES

Compact design for use on small medical aluminum and composite oxygen

cylinders (home health care applications).

Chamber designed for easy operation.

Stainless steel stem design for dependable service and long life.

Durable lower plug made of tough naval brass resists wear.

Lower plug is Teflon-coated to add lubricity, which minimizes seizing and

galling especially under high pressure operation.

Internal bonnet gasket seal resists damage to chamber sealing area.

Compact molded Lexan polycarbonate handwheel is easy to operate.

Single unit, compact pressure relief device incorporates 165 F fusible metal

backing to resist premature rupture and provide maximum cylinder protection.

Chrome plated for corrosion resistance and cosmetic appeal.

Oxygen cleaned with aqueous detergent.

Part Number

CGA Outlet Outlet Thread Size

YVBA5454-XX-62

YVBA5454-XX-62MSS

YVBA5454-XX-75

YVBA5454-XX-75GH

540

540

540

540

Inlet Thread Size

.903-14 NGO RH Ext.

.625-18 UNF2A

.903-14 NGO RH Ext. .625-18 UNF2A (MS Thread

.903-14 NGO RH Ext.

.750-16 UNF2A

.903-14 NGO RH Ext.

.750-16 UNF2A

Gauge Port

None

18 NPT

None

18 NPT

All valves supplied with 165 F fusible metal backed, flush style, pressure relief devices and copper alloy rupture discs.

XX denotes Pressure Relief Device burst disc rupture pressure. See page xix for part number suffix.

All valves are supplied with rupture discs rated for 2015 psig service pressure cylinders.

Rupture discs rated for other service pressures available on request.

PRESSURE RELIEF DEVICES FOR KVAB SERIES MEDICAL VALVES

DISC RUPTURE RANGE

PSIG @ 160F

PRESSURE RELIEF DEVICE

-XX CYLINDER SERVICE PRESSURE

MIN

MAX

CG-1

NO FUSE METAL

CG-4

165F FUSE

METAL

-28

1800 PSIG

2700

3000

9-4000-60-28

6513MFB-28

-32

2015 PSIG

3025

3360

9-4000-60-32

6513MFB-32

-48

3000 PSIG

4500

5000

9-4000-60-48

6513MFB-48

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

MEDICAL VALVES

EV Series Vertical Outlet Oxygen Valves Harrison

Medical Homecare, Hospital and

Emergency Applications

CGA540 Outlet, Chrome Plated for Durability

All Harrison valves are produced to meet or exceed the highest US

and international standards. Harrison Valves are rigorously tested

through a robust quality assurance system, and Harrison Valve

maintains carefully monitored manufacturing processes to ensure

that all Harrison valves meet or exceed design and performance

specifications.

KEY FEATURES

Compact design for use in aluminum medical and

composite oxygen cylinders for homecare, hospital and

emergency oxygen applications.

Easy to read markings with Open/Close on durable easy

to grip handwheel.

Durable chrome plated brass body resists corrosion.

Compact design especially suited for use with compact

oxygen systems.

Durable lower plug with Teflon coating for easy operation.

Easy operation under all pressures.

100% leak testing on entire production.

All valves bagged for cleanliness.

Common design internal parts and handwheels

readily available.

Single unit, compact pressure relief device with 165F

fusible metal safety for maximum cylinder protection.

Oxygen cleaned to CGA G4.1 specification.

Part Number EV540-3-4-3360G

shown with CGA540 outlet for

oxygen service, .750-16UNF2A inlet

for aluminum cylinders,

3360PSI safety for 2015PSI service

with a 1/8 FNPT gauge port.

OPTIONS AND SPECIFICATIONS

All valves are supplied with safety relief devices as

specified by the Compressed Gas Association Standard

S1.1. Safety relief devices are flush style CG-4 devices

backed by 165 F fuse metal. Rupture discs rated

for many cylinder service pressures are available

upon request.

Part Number

Description

EV540-2-4-xxxxG

EV540-3-4-xxxxG

Gas Service

Outlet Thread

Inlet

Oxygen

Oxygen

.625-18UNF2A

.750-16UNF2A

CGA540

CGA540

Vertical outlet oxygen valve

Vertical outlet oxygen valve

Safety

CG4, 165F

CG4 165F

PRESSURE RELIEF DEVICES FOR EV SERIES

DISC RUPTURE RANGE

PRESSURE RELIEF DEVICE

-XX CYLINDER SERVICE PRESSURE

MIN

MAX

CG-1

NO FUSE METAL

CG-4

165F FUSE

METAL

-28

1800 PSIG

2700

3000

HPM-CG1-3000 HPM-CG4-3000

-32

2015 PSIG

3025

3360

HPM-CG1-3360 HPM-CG4-3360

-48

3000 PSIG

4500

5000

HPM-CG4-5000

NA

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

MEDICAL VALVES

30

Medical Pin Index Valves Series Harrison

O-Ring Seal Technology for all Medical Gases

Yoke Outlet Pin Index System Connection Straight, Parallel

Threads for Aluminum Cylinders

NGT Tapered Threads for Steel Cylinders Straight, Parallel

Threads for Aluminum Cylinders

KEY FEATURES

O-ring seal technology provides superior leak integrity.

Easy operation under all pressures.

Protective and attractive chrome plated finish.

100% leak testing on entire production.

Meets and exceeds CGA V9 and ISO 10297.

Passed stringent adiabatic oxygen compression testing per ISO 10297.

All valves bagged and tagged for oxygen service per CGA G4.1.

All valves pre-drilled to accept aftermarket toggle device.

All straight thread inlet valves are supplied with cylinder sealing o-ring.

Part Number

Gas Service

P870-3-4-3360

P870-4-4-3360

P870-3-4-3360T

P870-4-4-3360T

P870-3-4-3360Z

P880-3-4-3360

P880-4-4-3360

P890-3-4-3360

P890-4-4-3360

P910-3-1-3360

P910-4-1-3360

P930-3-4-3360

P930-4-4-3360

P940-3-1-3360

P940-4-1-3360

P950-3-4-3360

P950-4-4-3360

P960-3-4-3360

P960-4-4-3360

P965-3-4-3360

P965-4-4-3360

P973-3-4-3360

P973-4-4-3360

Oxygen

Oxygen

Oxygen with toggle

Oxygen with toggle

Oxygen with Z valve hand knob

Oxygen-CO2 mixture

Oxygen-CO2 mixture

Oxygen-Helium mixture

Oxygen-Helium mixture

Nitrous Oxide

Nitrous Oxide

Helium

Helium

Carbon Dioxide

Carbon Dioxide

Medical Air

Medical Air

Nitrogen

Nitrogen

Nitrous Oxide - Oxygen mixture

Nitrous Oxide - Oxygen mixture

Medical Gas Mixtures

Medical Gas Mixtures

CGA

OPTIONS

Z Valve Handknob Example: P870-3-4-3360 changes to P870-4-3-3360Z

Chrome Plated Toggle Example: P870-3-4-3360 changes to P870-4-3-3360T

Gauge Port Example: P870-3-4-3360 changes to P870-4-3-3360G

10

Inlet

870

870

870

870

870

880

880

890

890

910

910

930

930

940

940

950

950

960

960

965

965

973

973

All valves are supplied with safety relief devices as specified by the

Compressed Gas Association Standard S1.1. Safety relief devices are flush

style CG-4 devices backed by 165 F fuse metal, except valves specified for

Carbon Dioxide (CGA 940) and Nitrous Oxide (CGA 940), where a CG-1 hex

style pressure relief device without fuse metal is required.

All valves are supplied with rupture discs rated for cylinders with a service

pressure of 2,015 psig. Rupture discs rated for other cylinder service pressures are available upon request.

.750-16UNF2A

1/2 NGT

.750-16UNF2A

1/2 NGT

.750-16UNF2A

.750-16UNF2A

1/2 NGT

.750-16UNF2A

1/2 NGT

.750-16UNF2A

1/2 NGT

.750-16UNF2A

1/2 NGT

.750-16UNF2A

1/2 NGT

.750-16UNF2A

1/2 NGT

.750-16UNF2A

1/2 NGT

.750-16INF2A

1/2 NGT

.750-16UNF2A

1/2 NGT

PRESSURE RELIEF DEVICES FOR EV SERIES

DISC RUPTURE RANGE

PRESSURE RELIEF DEVICE

CYLINDER

-XX SERVICE PRESSURE

MIN

MAX

CG-1

NO FUSE METAL

-28

1800 PSIG

2700

3000

HPM-CG1-3000 HPM-CG4-3000

-32

2015 PSIG

3025

3360

HPM-CG1-3360 HPM-CG4-3360

-48

3000 PSIG

4500

5000

HPM-CG4-5000

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

CG-4

165F FUSE

METAL

NA

www.cramerdecker.com

BRASS VALVES FOR STEEL AND ALUMINUM CYLINDERS

GV & GVA Series Sherwood

O-Ring Seal Design Brass and

Chrome Plated Cylinder Valves

NGT, Tapered Thread Inlets For Steel Cylinders

KEY FEATURES

Robust, durable forged brass body, precisely machined internal

components and design elements meet the most stringent international

valve performance standards.

Direct drive stem design with optimized single seal reduces friction

and operates at exceptionally low torque levels.

High durometer back-up ring prevents extrusion of o-ring with

proven success in extreme conditions.

Metal-to-Metal seal of bonnet below threads prevents pressure

from accumulating at top of valve body.

Unitized plug design of the pressure relief device (PRD) provides

excellent flow characteristics. Robust thread design and a unique

Sherwood exclusive webbed washer design to protect burst disc

during handling.

Optical character recognition technology utilized to verify

appropriate burst disc rating during automatic assembly.

Lower profile design, 1/4 lower than the previous TV Series design.

No flouropolymers, elimination of teflon packing.

Nickel Chrome Plating for durability. Also provides a protective coating

to help shield the valve from liquids and cleaning solutions containing

ammonia, chlorine and other chemicals harmful to copper alloys.

Meets or exceeds CGA, ISO 10297, EN 849, AS 2473.

ORDERING

When ordering, please specify:

Part Number.

Type of gas and CGA outlet.

Inlet connection.

Safety disc burst pressure options. Replace the XX with the suffix

for the burst pressure you require, (See catalog sheet on safety

device ordering information).

CHROME PLATING Replace GV with GVA for chrome

plated brass valves.

STANDARDS OF CONFORMANCE

CGA V-9

CGA S1.1

CGA V-1

10297

EN 849

AS2473

TPED

Standard for Gas Cylinder Valves

Standard for Pressure Relief Devices

Compressed Gas Cylinder Valve Outlet and Inlet Specifications ISO

International Standard for Cylinder Valves Design Specifications

International Standard for Cylinder Valves Design Specifications

Australian Standard for Compressed Gas Cylinder Valves

Transportable Pressure Equipment Directive Modules B & D

DESIGN SPECIFICATIONS

Maximum Working Pressure

Burst Pressure

Operating Temperature

Storage Temperature

Leak Rate Internal/External

Minimum Cycle Life

Cv Flow Factor

3000-6000 PSIG

413 BAR

15,000 PSIG

1,035 BAR

Min: -50F -45C Max: 130F 55C

Min: -65F -54C Max: 155F 68C

1 x 10-3 atm cc/s

2,000 Cycles

Standard:

.690

CO2/Manifold:

1.23

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

11

BRASS VALVES FOR STEEL AND ALUMINUM CYLINDERS

GV & GVA Series Sherwood

GV SERIES 0-RING DESIGN INDUSTRIAL VALVES

Gas Service @ 120F

Air

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

5,501 psi TO 7,500 psi

Argon

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

5,501 psi TO 7,500 psi

Carbon Dioxide

0 psi TO 3,000 psi

Carbon Monoxide

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

5,501 psi TO 7,500 psi

Helium

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

5,501 psi TO 7,500 psi

Hydrogen

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

5,501 psi TO 7,500 psi

Krypton

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

5,501 psi TO 7,500 psi

Neon

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

5,501 psi TO 7,500 psi

12

CGA Outlet

Outlet Thread Size

346

347

702

.825 14 NGO RH Ext.

.825 14 NGO RH Ext.

(long nipple)

1.125 14 NGO RH Int.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

580

680

677

.965 14 NGO RH Int.

1.045 14 NGO RH Int.

1.030 14 NGO LH Ext.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

- 14 NGT

GV58041-XX

GV58061-XX

GV58081-XX

GV58051-XX-75

GV58051-XX

GV68061-XX

GV67761-XX

320

.825 14 NGO RH Ext.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

GV32041-XX

GV32061-XX

GV32081-XX

GV32051-XX-75

GV32051-XX

350

695

703

.825 14 NGO LH Ext.

1.045 14 NGO LH Int.

1.125 14 NGO LH Int.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

- 14 NGT

GV35045-XX

GV35065-XX

GV35085-XX

GV35055-XX-75

GV35055-XX

GV69565-XX

GV70365-XX

580

680

677

.965 14 NGO RH Int.

1.045 14 NGO RH Int.

1.030 14 NGO LH Ext.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

- 14 NGT

GV58041-XX

GV58061-XX

GV58081-XX

GV58051-XX-75

GV58051-XX

GV68061-XX

GV67761-XX

350

695

703

.825 14 NGO LH Ext.

1.045 14 NGO LH Ext.

1.125 14 NGO LH Int.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

- 14 NGT

GV35045-XX

GV35065-XX

GV35085-XX

GV35055-XX-75

GV35055-XX

GV69565-XX

GV70365-XX

580

680

677

.965 14 NGO RH Int.

1.045 14 NGO RH Int.

1.030 14 NGO LH Ext.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

- 14 NGT

GV58041-XX

GV58061-XX

GV58081-XX

GV58051-XX-75

GV58051-XX

GV68061-XX

GV67761-XX

580

680

677

.965 14 NGO RH Int.

1.045 14 NGO RH Int.

1.030 14 NGO LH Ext.

Inlet Thread Size

Sherwood Part Number

- 14 NGT

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

- 14 NGT

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

GV34641-XX

GV34661-XX

GV34681-XX

GV34651-XX-75

GV34651-XX

GV34761-XX

GV70261-XX

GV58041-XX

GV58061-XX

GV58081-XX

GV58051-XX-75

GV58051-XX

GV68061-XX

GV67761-XX

www.cramerdecker.com

BRASS VALVES FOR STEEL AND ALUMINUM CYLINDERS

GV & GVA Series Sherwood

GV SERIES 0-RING DESIGN INDUSTRIAL VALVES

Gas Service @ 120F

CGA Outlet

Outlet Thread Size

Inlet Thread Size

Sherwood Part Number

580

680

677

.965 14 NGO RH Int.

1.045 14 NGO RH Int.

1.030 14 NGO LH Ext.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

- 14 NGT

GV58041-XX

GV58061-XX

GV58081-XX

GV58051-XX-75

GV58051-XX

GV68061-XX

GV67761-XX

326

.825 14 NGO RH Ext.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

GV32641-XX

GV32661-XX

GV32681-XX

GV32651-XX-75

GV32651-XX

540

577

701

.903 14 NGO RH Ext.

.960 14 NGO RH Ext..

1.103 14 NGO RH Ext.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

- 14 NGT

GV54041-XX

GV54061-XX

GV54081-XX

GV54051-XX-75

GV54051-XX

GV57761-XX

GV70161-XX

590

.965 14 NGO LH Int.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

GV59041-XX

GV59061-XX

GV59081-XX

GV59051-XX-75

GV59051-XX

580

680

677

.965 14 NGO RH Int.

1.045 14 NGO RH Int.

1.030 14 NGO LH Ext.

- 14 NGT

- 14 NGT

1-11 NGT

.750 16 UNF

1.125 12 UNF

- 14 NGT

- 14 NGT

GV58041-XX

GV58061-XX

GV58081-XX

GV58051-XX-75

GV58051-XX

GV68061-XX

GV67761-XX

Nitrogen

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

5,501 psi TO 7,500 psi

Nitrous Oxide

0 psi TO 3,000 psi

Oxygen

0 psi TO 3,000 psi

3,001 psi TO 4,000 psi

4,001 psi TO 5,500 psi

Sulfur Hexafluoride

0 psi TO 3,000 psi

Xenon

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

5,501 psi TO 7,500 psi

OPTIONS

4 & 7 & 24 threads oversize inlets: To order, add -4 or -7 or -24 to the end of the part number. e.g. GV35061-XX becomes GV35061-XX-7

Chrome Plating: To order, add letter A after letters GV in the part number. e.g. GV34661-XX becomes GVA34661-XX

Lexan polycarbonate handwheels: To order, add suffix LX to the end of the part number. e.g. GV34661-XX becomes GV34661-XXLX

Fusible backed pressure relief devices in 165F or 212F nominal melting temperatures:

To order, change 1 in the part number to 4 (165F) or to 5 (212F). e.g. GV35061-XX becomes GV35064-XX for 165F, or GV35065-XX for 212F

COMMON PRESSURE RELIEF DEVICES

CYLINDER SERVICE PRESSURE

XX

-28

-32

-35

-38

-48

-55

-65

-95

Cylinders PSIG

1800

2015

2265

2400

3000

3500/3600

4500

6000

DISC RUPTURE RANGE

PSIG @ 160F

Min

2700

3025

3400

3600

4500

5250

6075

9000

Max

3000

3360

3775

4000

5000

5833

6750

10000

PRESSURE RELIEF DEVICE

CG-1

CG-4**

CG-5**

Frangible Disc Frangible Disc Frangible Disc

No Fuse Metal 165F Fuse Metal 212F Fuse Metal

P625-19N9-28

P625-19N9-32

P625-19N9-35

P625-19N9-38

P625-19N9-48

P625-19N9-55

P625-19N9-65

P625-19N9-95

P625-19X9-28M

P625-19X9-32M

P625-19X9-35M

P625-19X9-38M

P625-19X9-48M

P625-19X9-55M

P625-19X9-65M

P625-19X9-95M

P625-19X9-28W

P625-19X9-32W

P625-19X9-35W

P625-19X9-38W

P625-19X9-48W

P625-19X9-55W

P625-19X9-65W

P625-19X9-95W

**Copper Disc must be used for Hydrogen Service

X = N for Nickel Disc or C for Copper Disc

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

13

BRASS VALVES FOR STEEL AND ALUMINUM CYLINDERS

Brass and Chrome Plated

Cylinder Valve Series Harrison

O-ring Seal Technology for all

Industrial and Medical Gases

NGT Tapered Threads for Steel Cylinders

KEY FEATURES

O-ring seal technology provides superior leak integrity.

Lower plugs are designed specific for the gas service intended.

Easy operation under all pressures.

100% leak testing on entire production.

Meets and exceeds CGA V9 and ISO 10297.

Unitized plug with robust hex and threads insure

easy installation.

Most valves supplied with threaded inlet for siphon tubes.

Oxygen valves passed stringent adiabatic oxygen

compression testing per ISO 10297.

All valves are bagged and cleaned for oxygen service per CGA G4.1.

Common design safety and hand wheels readily available.

Part Number

Gas Service

V280-6-1-XXXX

Medical Breathing Mixtures

V296-6-1-XXXX

Industrial Oxygen Mixture

V320-4-1-XXXX

Carbon Dioxide

V320-6-1-XXXX

Carbon Dioxide

V320-6-1-XXXX-7

Carbon Dioxide

V320-8-1-XXXX

Carbon Dioxide

V326-6-1-XXXX

Nitrous Oxide

V326-6-1-XXXX-7

Nitrous Oxide

V346-6-1-XXXX

Breathing Air

V346-6-1-XXXX-7

Breathing Air

V347-6-1-XXXX

Breathing Air, 3001-5500PSI

V350-6-5-XXXX

Hydrogen

V350-6-5-XXXX

Hydrogen

V500-6-1-XXXX

Medical Gas Mixture

V540-4-1-XXXX

Oxygen

V540-6-1-XXXX

Oxygen

V540-6-1-XXXX-7

Oxygen

V540-8-1-XXXX

Oxygen

V555-6-1-XXXX

Liquid withdrawal of propane/butane

V577-6-1-XXXX

Oxygen 3001-4000PSI

V580-4-1-XXXX

Inert (Helium, Nitrogen, Argon)

V580-6-1-XXXX

Inert (Helium, Nitrogen, Argon)

V580-6-1-XXXX-7

Inert (Helium, Nitrogen, Argon)

V580-8-1-XXXX

Inert (Helium, Nitrogen, Argon)

V590-6-1-XXXX

Inert (Helium, Nitrogen, Argon)

V590-6-1-XXXX-7

Inert (Helium, Nitrogen, Argon)

V660-6-1-XXXX

Sulfur Dioxide

V677-6-1-XXXX

Inert 5501-7500PSI

V680-6-1-XXXX

Inert 3001-5500PSI

V695-6-1-XXXX

Hydrogen 3001-5500PSI

V701-6-1-XXXX

Oxygen, 5001-7500PSI

V702-6-1-XXXX

Air, 5501-7500PSI

V703-6-5-XXXX

Hydrogen, 5500-7500PSI

CGA

280

296

320

320

320

320

326

326

346

346

347

350

350

500

540

540

540

540

555

577

580

580

580

580

590

590

660

677

680

695

701

702

703

Outlet Thread

.745-14NGO RH EXT

.803-14UNS-2B RH INT

.725-14NGO RH EXT

.725-14NGO RH EXT

.725-14NGO RH EXT

.725-14NGO RH EXT

.825-14NGO RH EXT

.825-14NGO RH EXT

.825-14NGO RH EXT

.825-14NGO RH EXT

.825-14NGO RH EXT

.825-14NGO LH EXT

.825-14NGO LH EXT

.885-14NGO LH EXT

.903-14NGO RH EXT

.903-14NGO RH EXT

.903-14NGO RH EXT

.903-14NGO RH EXT

.903-14 NGO LH EXT

.903-14 NGO RH EXT

.965-14NGO RH INT

.965-14NGO RH INT

.965-14NGO RH INT

.965-14NGO RH INT

.965-14NGO LH INT

.965-14NGO LH INT

1.030-14NGO RH INT

1.030-14NGO LH EXT

1.045-14NGO RH INT

1.045-14NGO LH INT

1.103-14 NGO RH EXT

1.125-14NGO RH INT

1.125-14NGO LH INT

Inlet

Safety

3/4NGT

3/4NGT

1/2NGT

3/4NGT

3/4NGT 7O/S

1NGT

3/4NGT

3/4NGT 7O/S

3/4NGT

3/4NGT 7O/S

3/4NGT

3/4NGT

3/4NGT 7O/S

3/4NGT

1/2NGT

3/4NGT

3/4NGT 7O/S

1NGT

3/4NGT

3/4NGT

1/2NGT

3/4NGT

3/4NGT 7O/S

1NGT

3/4NGT

3/4NGT 7O/S

3/4NGT

3/4NGT

3/4NGT

3/4NGT

3/4NGT

3/4NGT

3/4NGT

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG5

CG5

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG1

CG5

CG1

CG1

CG5

The suffix xxxx denotes pressure relief device burst disc rupture pressure. Refer to the safety device ordering information chart for pressures available.

Chrome plating: To order, change the letter V in the part number to letter CV example: V540-6-1-xxxx becomes VC540-6-1-xxxx

Fusible backed pressure relief devices in 212F nominal melting temperatures are standard with CGA350, and CGA695 valves. Change the numeral in position 6 from a 1 to 5 for all valves other

than CGA350 and CGA695 requiring 212F fusible metal safeties. Fusible metal safeties at 165F are available special order.

NOTE:

Go to page 18 for replacement safety device ordering information.

14

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

BRASS VALVES FOR STEEL AND ALUMINUM CYLINDERS

Brass and Chrome Plated

Cylinder Valve Series Harrison

O-ring Seal Technology for all

Industrial and Medical Gases

Parallel / Straight Threads for

Aluminum Cylinders

KEY FEATURES

O-ring seal technology provides superior

leak integrity.

Lower plugs are designed specific for the

gas service intended.

Easy operation under all pressures.

100% leak testing on entire production.

Meets and exceeds CGA V9 and ISO 10297.

Unitized plug with robust hex and

threads insure easy installation.

Most valves supplied with

threaded inlet for siphon tubes.

Oxygen valves passed stringent adiabatic

oxygen compression testing per ISO 10297.

All valves are bagged and cleaned for

oxygen service per CGA G4.1.

Common design safety and hand wheels

readily available.

Part Number

Gas Service

CGA

Outlet Thread

Inlet

Safety

V320-3-1-XXXX

V320-5-1-XXXX

V326-5-1-XXXX

V346-5-1-XXXX

V350-5-5-XXXX

V500-5-1-XXXX

V540-3-1-XXXX

V540-5-1-XXXX

V580-3-1-XXXX

V580-5-1-XXXX

V590-5-1-XXXX

V660-5-1-XXXX

Carbon Dioxide

Carbon Dioxide

Nitrous Oxide

Breathing Air

Hydrogen

Medical Gas Mixture

Oxygen

Oxygen

Inert (Helium, Nitrogen, Argon)

Inert (Helium, Nitrogen, Argon)

Industrial Air, Sulphur Hexaflouride

Sulphur Dioxide

320

320

326

346

350

500

540

540

580

580

590

660

.725-14NGO RH EXT

.725-14NGO RH EXT

.825-14NGO RH EXT

.825-14NGO RH EXT

.825-14NGO LH EXT

.885-14NGO LH EXT

.903-14NGO RH EXT

.903-14NGO RH EXT

.965-14NGO RH INT

.965-14NGO RH INT

.965-14NGO LH INT

1.030-14NGO RH INT

.750-16UNF2A

1.125-12UNF2A

1.125-12UNF2A

1.125-12UNF2A

1.125-12UNF2A

1.125-12UNF2A

.750-16UNF2A

1.125-12UNF2A

.750-16UNF2A

1.125-12UNF2A

1.125-12UNF2A

1.125012UNF2A

CG1

CG1

CG1

CG1

CG5

CG1

CG1

CG1

CG1

CG1

CG1

CG1

The suffix xxxx denotes pressure relief device burst disc rupture pressure. Refer to the safety device ordering information chart for pressures available.

Chrome plating: To order, change the letter V in the part number to letter CV, example: V540-6-1-xxxx becomes VC540-6-1-xxxx

Fusible backed pressure relief devices in 212F nominal melting temperatures are standard with CGA350.

HARRISON VALVE REPLACEMENT SAFETY DEVICE ORDERING INFORMATION

Cylinder Service

Pressure in PSIG

1800

2015

2265

2400

3000

3500

4500

6000

Pressure Relief Disc Rupture Range 165F

Pressure Relief Device Replacement Number

Device Stamping

Minimum

Maximum

CG-1 Frangible Disc

3000

3360

3775

4000

5000

5833

6750

10000

2700

3025

3400

3600

4500

5250

6750

9000

3000

3360

3775

4000

5000

5833

6750

10000

HBV-CG1-3000

HBV-CG1-3360

HBV-CG1-3775

HBV-CG1-4000

HBV-CG1-5000

HBV-CG1-5835

HBV-CG1-6750

HBV-CG1-10000

CG-5 Frangible Disc/212 Fuse Metal

HBV-CG5-3000

HBV-CG5-3360

HBV-CG5-3775

HBV-CG5-4000

HBV-CG5-5000

HBV-CG5-5835

HBV-CG5-6750

HBV-CG5-10000

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

15

RESIDUAL PRESSURE VALVES

GRPV Series Sherwood

O-Ring Seal Design Brass and Chrome

Plated Residual Pressure Valves

NGT, Tapered Thread Inlets For Steel Cylinders

KEY FEATURES

Designed to shut off gas flow at 40-60PSIG. Elimination of cylinder

cleaning as contamination is kept out even if the valve is left open.

Special designed filling adaptor needed to fill the GRPV Series valves.

Robust, durable forged brass body, precisely machined internal

components and design elements meet the most stringent

international valve performance standards.

Direct drive stem design with optimized single seal reduces friction

and operates at exceptionally low torque levels.

High durometer back-up ring prevents extrusion of o-ring with

proven success in extreme conditions.

Metal-to-Metal seal of bonnet below threads prevents pressure from

accumulating at top of valve body.

Unitized plug design of the pressure relief device (PRD) provides

excellent flow characteristics. Robust thread design and a unique

Sherwood exclusive webbed washer design to protect burst disc

during handling.

Optical character recognition technology utilized to verify appropriate

burst disc rating during automatic assembly.

Lower profile design, 1/4 lower than the previous TV Series design.

No flouropolymers, elimination of teflon packing.

Nickel Chrome Plating for durability. Also provides a protective coating

to help shield the valve from liquids and cleaning solutions containing

ammonia, chlorine and other chemicals harmful to copper alloys.

ORDERING

When ordering, please specify:

Part Number.

Type of gas and CGA outlet.

Inlet connection.

Safety disc burst pressure options.

Replace the XXwith the suffix for the burst pressure you require.

CHROME PLATING Replace GRPV with GRPVA for chrome

plated brass valves.

DESIGN SPECIFICATIONS

Maximum Working Pressure

Burst Pressure

Leak Rate

Operating Torque

Operating Temperature

Flow Data, CV

Cycle Life

Shut Off Pressure

16

6,000 PSIG

15,000 PSIG

1 x 10-3 atm cc/s

10-20 IN LB

-50F to +130F

(.272 Thru Hole): .50

(.125 Thru Hole): .25

5,000 Minimum

40-60PSIG

STANDARDS OF CONFORMANCE

CGA V-9

CGA S1.1

CGA V-1

ISO 10297

EN 849

AS2473

TPED

Standard for Gas Cylinder Valves

Standard for Pressure Relief Devices

Compressed Gas Cylinder Valve

International Standard for Cylinder Valves Design Specifications

International Standard for Cylinder Valves Design Specifications

Australian Standard for Compressed Gas Cylinder Valves

Transportable Pressure Equipment Directive Modules B & D

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

RESIDUAL PRESSURE VALVES

GRPV Series Sherwood

Gas Service @120F

CGA Outlet

Air

0 psi TO 3,000 psi

Argon

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

Carbon Dioxide

0 psi TO 3,000 psi

Helium

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

Hydrogen

0 psi TO 3,000 psi

Nitrogen

0 psi TO 3,000 psi

3,001 psi TO 5,500 psi

Oxygen

0 psi TO 3,000 psi

Sulfur Hexafluoride

0 psi TO 3,000 psi

Outlet Thread Size

Inlet Thread Size

Sherwood Part Number

346

.825 14 NGO RH Ext.

- 14 NGT

- 14 NGT

GRPV34641-XX

GRPV34661-XX

580

680

.965 14 NGO RH Int.

1.045 14 NGO RH Int.

- 14 NGT

- 14 NGT

- 14 NGT

GRPV58041-XX

GRPV58061-XX

GRPV68061-XX

320

.825 14 NGO RH Ext.

- 14 NGT

- 14 NGT

GRPV32041-XX

GRPV32061-XX

580

680

.965 14 NGO RH Int.

1.045 14 NGO RH Int.

- 14 NGT

- 14 NGT

- 14 NGT

GRPV58041-XX

GRPV58061-XX

GRPV68061-XX

350

.825 14 NGO LH Ext.

- 14 NGT

- 14 NGT

GRPV35045-XX

GRPV35065-XX

580

680

.965 14 NGO RH Int.

1.045 14 NGO RH Int.

- 14 NGT

- 14 NGT

- 14 NGT

GRPV58041-XX

GRPV58061-XX

GRPV68061-XX

540

.903 14 NGO RH Ext.

- 14 NGT

- 14 NGT

GRPV54041-XX

GRPV54061-XX

590

.965 14 NGO LH Int.

- 14 NGT

- 14 NGT

GRPV59041-XX

GRPV59061-XX

OPTIONS

4 & 7 & 24 threads oversize inlets: To order, add -4 or -7 or -24 to the end of the part number. e.g. GRPV58061-XX becomes GRPV58061-XX-7

Chrome Plating: To order, add letter A after letters GV in the part number. e.g. GRPV58061-XX becomes GRPVA58061-XX

Fusible backed pressure relief devices in 165F or 212F nominal melting temperatures:

To order, change 1 in the part number to 4 (165F) or to 5 (212F). e.g. GRPV35061-XX becomes GRPV35064-XX for 165F, or GRPV35065-XX for 212F

SHERWOOD FILLING ADAPTORS ORDERING INFORMATION

Part #

Description

TL580B

TL580C

TLG320W

TLG346S

TLG350S

TLG540S

TL580D

TL590D

TLG680S

TLG580SLW

TLG590SLW

Locking Tool

Check Rod Tool

Fixed Pin CGA 320

Fixed Pin CGA 346

Fixed Pin CGA 350

Fixed Pin CGA 540

Fixed Pin CGA 580

Fixed Pin CGA 590

Fixed Pin CGA 680

Retractable Pin CGA 580

Retractable Pin CGA 590

COMMON PRESSURE RELIEF DEVICES

CYLINDER SERVICE

PRESSURE

XX

-28

-32

-35

-38

Cylinders PSIG

1800

2015

2265

2400

DISC RUPTURE RANGE

PSIG @ 160F

Min

2700

3025

3400

3600

Max

3000

3360

3775

4000

PRESSURE RELIEF DEVICE

CG-1

CG-4**

CG-5**

Frangible Disc Frangible Disc Frangible Disc

No Fuse Metal 165F Fuse Metal 212F Fuse Metal

P625-19N9-28

P625-19N9-32

P625-19N9-35

P625-19N9-38

P625-19X9-28M

P625-19X9-32M

P625-19X9-35M

P625-19X9-38M

P625-19X9-28W

P625-19X9-32W

P625-19X9-35W

P625-19X9-38W

**Copper Disc must be used for Hydrogen Service

X = N for Nickel Disc or C for Copper Disc

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

17

RESIDUAL PRESSURE VALVES

Brass Residual Pressure Valve Series Harrison

O-ring Seal Technology for all Industrial and Medical Gases

NGT Tapered Threads for Steel Cylinders

KEY FEATURES

VRP320

Harrison VRP Series valves retain 30-50PSI pressure

when valve is left open.

Harrison VRP Series valves eliminate the expense of time

consuming purge and clean cycles.

Positive 30-50PSI pressure maintains the integrity of the

cylinder contents against contaminants.

Universal adapters for Harrison VRP series valves accommodate

most major manufacturers residual pressure valves.

O-ring seal technology provides superior leak integrity.

Lower plugs are designed specific for the gas service intended.

Easy operation under all pressures.

100% leak testing on entire production.

Meets and exceeds CGA V9 and ISO 10297 and

ISO 15996 for residual pressure valves.

Unitized plug with robust hex and threads insure

easy installation.

Most valves supplied with threaded inlet for siphon tubes.

Oxygen valves passed stringent adiabatic oxygen compression

testing per ISO standards.

VRP346

DESIGN SPECIFICATIONS

Maximum Working Pressure

Burst Pressure

Operating Temperature

Storage Temperature

Minimum Cycle Life

3,000 PSIG

15,000 PSIG

Min: -50F

Max: 130F

Min: -65F

Max: 155F

5,000 Cycles

412 BAR

1,035 BAR

-45C

55C

-54C

68C

VRP350

HARRISON FILLING ADAPTORS ORDERING INFORMATION

Part #

Description

VRP540

AD-TOOL Locking Tool

AD320 Retractable Pin Nipple, CGA320

AD346 Retractable Pin Nipple, CGA346

AD350 Retractable Pin Nipple, CGA350

AD540 Retractable Pin Nipple, CGA540

AD580 Retractable Pin Nipple, CGA580

AD590 Retractable Pin Nipple, CGA590

All nipples are o-ring connection by 1/4M.NPT and can be

ordered as a wrenchtight or handtight connection.

Part Number

VRP320-6-1-XXXX

VRP346-6-1-XXXX

VRP350-6-5-XXXX

VRP540-6-1-XXXX

VRP580-6-1-XXXX

VRP590-6-1-XXXX

Gas Service

Carbon Dioxide

Breathing Air

Hydrogen

Oxygen

Inert (Helium, Nitrogen, Argon)

Air, Sulphur Hex.

CGA

320

346

350

540

580

590

Outlet Thread

.725-14NGO RH EXT

.825-14NGO RH EXT

.825-14NGO LH EXT

.903-14NGO RH EXT

.965-14NGO RH INT

.965-14NGORH INT

Inlet

3/4NGT

3/4NGT

3/4NGT

3/4NGT

3/4NGT

3/4NGT

Safety

CG1

CG1

CG5

CG1

CG1

CG1

VRP580

The suffix xxxx denotes pressure relief device burst disc rupture pressure. Refer to the safety device ordering information chart for pressures available.

Fusible backed pressure relief devices in 212F nominal melting temperatures are standard with CGA350. Change the numeral in position 6 from a 1 to

5 for all valves other than CGA350 requiring 212F fusible metal safeties.

Go to page 18 for Harrison safety device ordering information

18

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

VRP590

www.cramerdecker.com

RESIDUAL PRESSURE VALVES

BR Series Ceodeux

O-Ring Seal Design Brass Residual Pressure Valve

For Various Gases

NGT, Tapered Thread Inlets For Steel Cylinders

KEY FEATURES

Designed to shut off gas flow at 40-60PSIG. Elimination of cylinder

cleaning as contamination is kept out even if the valve is left open.

Special designed filling adaptor needed to fill the Ceodeux BR Series valves.

A new generation of high pressure brass cylinder valves with a unique

safety device.

Advanced O-Ring technology for absolute tightness under vacuum or

maximum operating pressure; lasts longer than traditional pressure

seal valves.

Each valve tested after assembly with severe Helium Leak Test rather than

the less stringent Water Test.

Lower plugs are designed specific for the gas service intended.

Special seat design to ensure smooth flow regulation and tightness even

with excessive torque.

Easy operation of valve under high pressure.

Unique safety device design minimizes incorrect installation and meets

CGA-S1.1 regulations.

Most valves supplied with thread for dip tube.

Special lower stem and seat design for oxygen service.

Designed to ensure a safe, long, trouble-free life under all service conditions.

Meets CGA standards.

ORDERING

When ordering, please specify:

Part Number.

Type of gas and CGA outlet.

Inlet connection.

Safety disc burst pressure options.

Replace the XX with the suffix for the burst pressure you require.

CHROME PLATING Replace BR with BRC for

chrome plated brass valves.

DESIGN SPECIFICATIONS

Maximum Working Pressure

Burst Pressure

Operating Torque

Operating Temperature

Flow Orifice

Cycle Life

Shut Off Pressure

Part Number

Gas Service

CGA Outlet

Outlet Thread Size

NGT Inlet

BR32061-XX

BR346061-XX

BR35065-XX

BR54061-XX

BR58061-XX

BR59061-XX

Carbon Dioxide

BreathingAir

Hydrogen

Oxygen

Inert Gases

Air, Sulphur Hex.

320

346

350

540

580

590

.825-14NGO RH EXT

.825-14NGO RH EXT

.825-14NGO LH EXT

.903-14NGO RH EXT

.965-14NGO RH INT

.965-14NGO RH INT

3/4

3/4

3/4

3/4

3/4

3/4

3,000 PSIG

1,2000 PSIG

10-20 IN LB

-40 F to +149 F

.158

5,000 Minimum

40-60 PSIG

Go to page 31 for

Ceodeux safety device

ordering information

Filling Adaptors Part Numbers, includes CGA Nut and Pin Nipple

Part Number

Description

039520095

039520096

039520097

039520098

039520099

039520100

CGA320 RPV212 Fill Adaptor, CGA320 Nut, Retractable Pin Nipple

CGA346 RPV212 Fill Adaptor, CGA346 Nut, Retractable Pin Nipple

CGA350 RPV212 Fill Adaptor, CGA350 Nut, Retractable Pin Nipple

CGA540 RPV212 Fill Adaptor, CGA540 Nut, Retractable Pin Nipple

CGA580 RPV212 Fill Adaptor, CGA580 Nut, Retractable Pin Nipple

CGA590 RPV212 Fill Adaptor, CGA590 Nut, Retractable Pin Nipple

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

19

SPECIALTY GAS VALVES

1214Y Series Sherwood

Aluminum Silicon Bronze Packed

Wrench Operated Valves for Specialty Gases

NGT Tapered Thread Inlets

KEY FEATURES

Aluminum Silicon Bronze (ASB) valve body offers proven resistance

against various corrosive gas applications.

One piece monel stem provides positive shutoff in corrosive gas service

with exceptional durability.

Teflon packing promotes easy operation while providing a durable

leak-resistant stem seal.

Designed to ensure a safe, long, trouble-free life under all

service conditions.

Meets CGA standards.

OPTIONS

Optional tapped inlet threads for dip tube assembly.

Available with CGA connections and International connections.

Available with unitized pressure relief device having fuse

metal backing.

ORDERING

When ordering, please specify:

Part Number.

Type of gas and CGA outlet.

DESIGN SPECIFICATIONS

Maximum Service Pressure

Temperature Range

Leak Rate

Closing Torque

Cv

Burst Disc Material

Part Number

1214Y9-L

1214Y13-L

1214Y23-L

1214Y26

1214Y42

1214F6

1214Y20T

1214Y25

20

3,000 PSI

-50F to 120F

1 x 10-5 atm cc/sec

2,000 PSIG (138 bar): 15ft lbs

1.48

Platinum Clad Nickel

Features

Tapped, Cap & Chain

Cap & Chain

Tapped

Tapped

Tapped, Cap & Chain

CGA Outlet

Outlet Thread Size

Safety

Pressure

Inlet

330

330

330

330

330

660

660

660

.830-14NGO LH INT

.830-14NGO LH INT

.830-14NGO LH INT

.830-14NGO LH INT

.830-14NGO LH INT

1.030-14NGO RH EXT

1.030-14NGO RH EXT

1.030-14NGO RH EXT

CG-4

CG-2

CG-4

None

CG-4

None

CG-4

None

3000PSI

Fuse Plug

3360PSI

None

Fuse Plug

None

Fuse Plug

None

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

SPECIALITY GAS VALVES

5074 Series Sherwood

Brass Diaphragm Packless Valves for Specialty Gases

NGT, Tapered & Straight/Parallel Thread Inlets

KEY FEATURES

Forged brass construction.

Increased flow (CV) to aid in reducing vent and purge times.

Proven leak-tight diaphragm seal for all specialty gas applications.

Low operating torque design to ensure ease of operation.

Especially suitable in applications where purging of the cylinder under high vacuum is required.

Available with unitized pressure relief device having fuse metal backed or unbacked burst disc.

Pressure relief devices are in accordance with CGA S-1.1.

FDA recognized for service in medical applications.

Optional inlet threads for dip tube connection.

Available with standard CGA connections as well as International inlets and outlets.

Standardized anti-extrusion pin feature prevents seat extrusion and cold flow of the polymeric seat.

Available in multiple seat material configurations to accommodate all high purity gas applications.

DESIGN SPECIFICATIONS

Maximum Service Pressure

Temperature Range

Leak Rate

Closing Torque

Cv

3,000PSIG

-50F - 120F

1x10-7 atm cc/sec

50 in-lbs @ 2000PSI

.635

200 bar

-45C - 49C

1x10-7 barmL/sec

5.6N-m @ 138 Bar

.635

SPECIAL ORDER OPTIONS

Alternative seat disc materials: PCTFE,

PVDF, Vespel.

Safety disc materials: Nickel 200, Stainless

Steel, Platinum Clad Nickel.

CGA, DISS, BS341, DINN477, JIS Outlets

available.

Dip tube connection.

Aluminum handwheel available in red, blue,

chrome or rubber coated.

Flow restrictor tap.

Electropolishing of gas wetted areas.

Japanese inlet connections.

MP35N Diaphragms.

Part Number

5074T-320xx

5074-350xx

5074-540xx

5074-580xx

5074-590xx

5074-660xx

5074-350xx

5074-540xx

5074-580xx

5074-590xx

5074-660xx

5074X15-350xx

5074X15-540xx

5074X15-580xx

5074X15-590xx

5074X15-660xx

OPTIONS

When ordering, please specify:

Part Number.

Type of gas and CGA outlet.

Inlet connection.

Type of safety; CG-1, CG-4 or CG-5.

Safety disc burst pressure.

Gas Service

Carbon Dioxide

Flammable Gases

Oxygen

Inert Gases

Sulphur Hexafluoride

Oxidized,Toxic

Flammable Gases

Oxygen

Inert Gases

Sulphur Hexafluoride

Oxidized,Toxic

Flammable Gases

Oxygen

Inert Gases

Sulphur Hexafluoride

Oxidized,Toxic

CGA Outlet

Outlet Thread Size

320

350

540

580

590

660

350

540

580

590

660

350

540

580

590

660

.825-14NG0 RH EXT

.825-14NGO LH EXT

.965-14NGO RH EXT

.965-14NGO RH INT

.965-14NGO LH INT

1.030-14NGO RH INT

.825-14NGO LH EXT

.965-14NGO RH EXT

.965-14NGO RH INT

.965-14NGO LH INT

1.030-14NGO RH INT

.825-14NGO LH EXT

.965-14NGO RH EXT

.965-14NGO RH INT

.965-14NGO LH INT

1.030-14NGO RH INT

Inlet

Tapped, 3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

1.125-12 UNF2A

1.125-12 UNF2A

1.125-12 UNF2A

1.125-12UNF2A

1.125-12UNF2A

HOW TO ORDER 7 THREAD OVERSIZE VALVES

Oversize valves add -7 to the end of the part number

Ex. 5074-540A-7

(CGA 540 Outlet, 3/4-7 O/S Inlet)

COMMON PRESSURE RELIEF DEVICES

CYLINDER SERVICE

PRESSURE

Pressure Relief Device Table

XX

Service

Pressure

1800PSI

2015PSI

2265PSI

2400PSI

-28

-32

-35

-38

-48

-55

-65

-95

Burst

Pressure

3000PSI

3360PSI

3775PSI

4000PSI

CG-1

A

B

C

D

CG-4

AM

BM

CM

DM

CG-5

AW

BW

CW

DW

Cylinders PSIG

1800

2015

2265

2400

3000

3500/3600

4500

6000

DISC RUPTURE RANGE

PSIG @ 160F

Min

2700

3025

3400

3600

4500

5250

6075

9000

Max

3000

3360

3775

4000

5000

5833

6750

10000

PRESSURE RELIEF DEVICE

CG-1

CG-4**

CG-5**

Frangible Disc Frangible Disc Frangible Disc

No Fuse Metal 165F Fuse Metal 212F Fuse Metal

P625-19N9-28

P625-19N9-32

P625-19N9-35

P625-19N9-38

P625-19N9-48

P625-19N9-55

P625-19N9-65

P625-19N9-95

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

P625-19X9-28M

P625-19X9-32M

P625-19X9-35M

P625-19X9-38M

P625-19X9-48M

P625-19X9-55M

P625-19X9-65M

P625-19X9-95M

P625-19X9-28W

P625-19X9-32W

P625-19X9-35W

P625-19X9-38W

P625-19X9-48W

P625-19X9-55W

P625-19X9-65W

P625-19X9-95W

www.cramerdecker.com

21

SPECIALTY GAS VALVES

6074 & 6674 Series Sherwood

303 & 316 Stainless Steel High

Pressure Cylinder Valve, Diaphragm

Packless Valves for Specialty Gases

NGT, Tapered & Straight Thread Inlets

KEY FEATURES

Forged 303 & 316L stainless steel body to withstand severe conditions.

Proven leak-tight diaphragm seal for all specialty gas applications.

Low operating torque design to ensure ease of operation during filling and use.

Especially suitable in applications where purging of the cylinder under

high vacuum is required.

Available with unitized pressure relief device having fuse metal

backed or unbacked burst disc.

Pressure relief devices are in accordance with CGA S-1.1.

FDA recognized for service in medical applications.

Optional inlet threads for dip tube connection.

Available with standard CGA connections as well as International

inlets and outlets.

DESIGN SPECIFICATIONS

Maximum Service Pressure

Temperature Range

Leak Rate

Closing Torque

Cv

3,000PSIG

-50F - 120F

1x10-7 atm cc/sec

50 in-lbs @ 2000PSI

.635

SPECIAL ORDER OPTIONS

22

Alternative seat disc materials:

PCTFE, PVDF, Vespel.

Safety disc materials:

Nickel 200, Stainless Steel, Platinum Clad Nickel

CGA, DISS, BS341, DINN477,

JIS Outlets available.

Dip tube connection.

Aluminum handwheel available in red, blue,

chrome or rubber coated.

Flow restrictor tap.

Electropolishing of gas wetted areas.

Japanese inlet connections.

MP35N Diaphragms.

Part Number 303SS

Part Number 316SS

6074-xxx

6074-xxxSX

6074-xxxSXM

6074-xxxSXW

6074-xxxPXM

6074-xxxPXW

6074D-xxxSX

6074D-xxxSXM

6074D-xxxSXW

6074X15-xxxSX

6074X15-xxxSXM

6074X15-xxxSXW

6074X15-xxxPXM

6074X15-xxxPXW

6674-xxx

6674-xxxS

6674-xxxSM

6674-xxxSW

6674-xxxPM

6674-xxxPW

6674D-xxxS

6674D-xxxSM

6674D-xxxSW

6674-xxxS

6674-xxxSM

6674-xxxSW

6674-xxxPM

6674-xxxPW

200 bar

-45C - 49C

1x10-7 barmL/sec

5.6N-m @ 138 Bar

.635

ORDERING

When ordering, please specify:

Part Number.

Type of gas and CGA outlet.

Inlet connection.

Type of safety; CG-1, CG-4 or CG-5.

Safety disc burst pressure.

Inlet Size

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

1/2 NGT

1/2 NGT

1/2 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

3/4 NGT

Safety Device

No PRD

CG-1 Stainless Steel PRD

CG-4 Stainless Steel PRD

CG-5 Stainless Steel PRD

CG-4 Platinum PRD

CG-5 Platinum PRD

CG-1 Stainless Steel PRD

CG-4 Stainless Steel PRD

CG-5 Stainless Steel PRD

CG-1 Stainless Steel PRD

CG-4 Stainless Steel PRD

CG-5 Stainless Steel PRD

CG-4 Platinum PRD

CG-5 Platinum PRD

ORDERING INFORMATION

Replace the xxx with the appropriate CGA code for the gas

service you require.

Replace the X with the appropriate letter code for the safety

service pressure you require. See Chart.

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

SPECIALITY GAS VALVES

D300 Series Ceodeux

316L Stainless Steel & Brass High Pressure, High Flow

Cylinder Valves, Tied Diaphragm Seal Type for High

Purity/UHP Gases/Corrosive Gases

NGT Tapered & Straight/Parallel Thread Inlets

KEY FEATURES

Reduced dead spaces and gas wetted volumes allow easy purging process.

Freedom of internal threads and springs insures minimum particulate generation.

Very low internal volume with minimum dead spaces. This is particularly beneficial,

when using the valve for hygro-scopic, corrosive, phyophoric or high purity gases where

inert gas purging is necessary before opening or after closing the valve.

Freedom from seizure when used with corrosive gases. Gas does not come into contact

with the valve operating mechanism.

Positive and effective operation, valve lower spindle is mechanically linked to the

upper spindle and operating handle.

Backed up welded diaphragms provide a permanent and durable gas tight seal.

O-rings on gland and on spindle guarantee a secondary sealing.

Threaded vent hole.

Unique safety device design minimizes incorrect installation and meets CGA-S1.1 regulations.

Designed to ensure a safe, long, trouble-free life under all service conditions.

Meets CGA standards.

VALVE DESIGN OPTIONS

D300 Series

316L Stainless Steel Body Tied Diaphragm Valve

For Ultra High Purity Gases

D310 Series

Brass Body Tied Diaphragm Valve

For High Purity Gases

D335 Series

316L Stainless Steel Body Tied Diaphragm Valve

For Ultra High Purity Corrosive Gases

Ceodeux manufacturers a broad range

of cylinder valves for UHP, Corrosive and

Reactive gases for Specialty, Semi-Conductor & UHP industries. Call CDI today!

D336 Series

316L Stainless Steel Body Tied Diaphragm Valve

(all metal seal - No contamination)

For Ultra High Purity Reactive Gases

ORDERING INFORMATION

Example shown is a tied diaphragm valve, 316 AISI body, CGA660 outlet,1.125-12UNF2A Inlet, 212 F fuse metal safety, 3000PSI PRD.

D300

Valve Design Series

D300 Series

D310 Series

D335 Series

D336 Series

CGA/DISS Outlet Code*

320/716 - Carbon Dioxide

330/634 - Hydrogen Bromide

350/724 - Hydrogen

580/718 - Helium

590/716 - Sulphur Hexafluoride

660/728 - Nitric Oxide

*See CGA Manual for appropriate

CGA code for gas service you require.

660 5 5 - 28

Inlet Thread Size

6 - 3/4 NGT

5 - 1.125-12UNF2A

Safety Type

1 - CG-1, Unbacked

4 - CG-4, 165 F Fusible metal

5 - CG-5, 212 F Fusible metal

See page on safety device

ordering information for

correct suffix

Go to page 31 for Ceodeux safety device

ordering information

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

23

SPECIALTY GAS VALVES

D280 Series Ceodeux

316L Stainless Steel & Brass High Pressure,

Diaphragm Seal Type for Hydrocarbon Gases

NGT Tapered Thread Inlets

The D286 (Brass) and D287 (316L SS) Hydrocarbon valves have redefined the industry

standard. The uniquely designed valve is supplied with a CGA510 liquid withdrawal

outlet and 1/4 SAE flare pressurizing port gas extraction.

KEY FEATURES

High purity diaphragm seal design provides excellent leak tightness.

Brass and Stainless Steel construction materials are used to

provide various purity levels.

Separate liquid and vapor ports keep the safety in contact with

vapor phase at all times.

Low maintenance replaceable safety device permits easy repair

and variability of pressure application.

The liquid side is supplied with an adapter for easy attachment

of the dip tube.

Low operating torque under full pressure assures easy operation.

Integral forged pressure port reduces possible leak areas.

Designed to ensure a safe, long, trouble-free life under

all service conditions.

Meets CGA standards.

VALVE DESIGN OPTIONS

D286 Series

Brass Body, Diaphragm Valve

Part # D28600001001

Inlet: 3/4 NGT

Outlet: CGA510 x 1/4 SAE Flare

Safety: 375PSI

Part # D28600001003

Inlet: 3/4 NGT

Outlet: CGA510 x 1/4 SAE Flare

Safety: 450PSI

D287 Series

316L Stainless Steel Body, Diaphragm Valve

Part # D28700001001

Inlet: 3/4 NGT

Outlet: CGA510 x 1/4 SAE Flare

Safety: 375PSI

24

Part Number

Inlet

Outlet

Safety

Body

D28600001001

D28600001003

D28700001001

3/4 NGT

3/4 NGT

3/4 NGT

CGA510 x 1/4 SAE

CGA510 x 1/4 SAE

CGA510 x 1/4 SAE

375PSI

450PSI

375PSI

Brass

Brass

316L SS

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

SPECIALITY GAS VALVES

D303 & DS316 Series Ceodeux

Stainless Steel High Pressure Cylinder Valve,

Diaphragm Type Seal for Various High Purity

and Mild Corrosive Gases

NGT Tapered & Straight/Parallel Thread Inlets

KEY FEATURES

Valve available in 303SS or 316SS.

A new generation of high pressure stainless steel cylinder valves

with a unique safety device.

Soft seat sealing arrangement offers low operating torque.

Valve seat captured to avoid extrusion and blockage of valve.

High leak tightness integrity through diaphragm sealing.

Pressure relief devices are in accordance with CGA S-1.1.

Burst disc materials are nickel or AISI 316L.

Strict Helium leak testing on every valve seat, diaphragm seal and safety device.

SPECIAL ORDER OPTIONS

Alternative seat disc materials: Nylon, PVDF, Vespel.

Gas wetted components electro-chemically polished.

Clean room assembly.

UHP/ECD cleaning.

Dip tube connection.

ORDERING

When ordering, please specify:

Part Number.

Type of gas and CGA outlet.

Inlet connection.

Type of safety; CG-1, CG-4 or CG-5.

Safety disc burst pressure options.

Replace the XX with the suffix for the burst pressure you require.

(See catalog sheet on safety device ordering information)

ORDERING INFORMATION

(Example shown is a diaphragm valve, 316 AISI body, CGA660 outlet, 1.125-12UNF2A Inlet, 212 F fuse metal safety, 3000PSI PRD.)

DS316

Valve Body Material

CGA Outlet Code*

DS303 - AISI 303

DS316 - AISI 316

320 - Carbon Dioxide

330 - Non corrosive gases

350 - Flammable gases

580 - Inert gases

590 - Air

660 - Corrosive gases

660 5 5 - 28

Inlet Thread Size

6 - 3/4 NGT

5 - 1.125-12UNF2A

Safety Type

See page on safety device

ordering information for

correct suffix

1 - CG-1, Unbacked

4 - CG-4, 165 F Fusible metal

5 - CG-5, 212 F Fusible metal

CEODEUX PARTS PRESSURE RELIEF DEVICES

Style

2 Piece - Brass

2 Piece - Plated

Unitized Plug - Brass

Unitized Plug - Plated

Burst Disc

2

Rupture Disk Material

610

611

810

811

700

Nickel

316L Stainless Steel

3

Pressure Relief Device Type

N

S

Rupture Disk

165F + rupture disk

212F + rupture disk

CG-1

CG-4

CG-5

4

PRD Rated Burst Pressure

1

4

5

3000 PSI

3360 PSI

3775 PSI

4000 PSI

28

32

35

38

Example: 810N-32 is a unitized plug safety, nickel material, CG1 disc for 2015PSI service.

For more information, call Cramer Decker Industries at 800-752-4579 or 714-566-3850

www.cramerdecker.com

25

SPECIALTY GAS VALVES

DB & DC Series Ceodeux

Brass High Pressure Cylinder Valve,