Beruflich Dokumente

Kultur Dokumente

Moment Curvature Analysis of Concrete Beam

Hochgeladen von

Rishabh LalaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Moment Curvature Analysis of Concrete Beam

Hochgeladen von

Rishabh LalaCopyright:

Verfügbare Formate

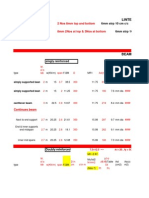

Homework #7

Due Date 10/07/2016

Rishabh Lala

M-Phi Singly Reinforced Rectangular Concrete Section

Given: Signly Reinforced Rectangular Concrete Section

Task I

Section Geometry and Reinforced Concrete Properties:

Section Height

h := 34in

Section Width

b := 18in

Depth of centroid of reinforcement or Effective Depth

d := 31in

Measured Cylinder Compressive Strength

fcc := 5800psi

Yield Strength of Steel

fy := 67ksi

2

As := 6As9 = 6 in

Area of Steel in the section

cu := 0.0038

Limiting concrete compressive strain

Ec := 57000

o :=

1.8 fcc

Ec

(fcc psi) = 4.341 10 ksi

= 2.405 10

-3

CES: 6706: Advanced Reinforced Concrete

Modulus of Elasticity

Concrete Strain Associated with Peak Stress

1/34

Homework #7

Due Date 10/07/2016

c

fc( c) := fcc 2

o

c

-

o

Rishabh Lala

Hognested Stress Function

if c o

0 if c > cu

(

(

)

)

c - o

fcc 1 - 0.15

cu - o

otherwise

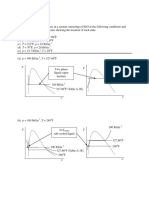

Stress Strain Model

3

Stress (ksi)

610

( )

fc c

Stress Block of Hognested Model

410

psi

210

0

-3

2 10

-3

410

( c)

in/in

Youngs modulus of Mild Steel

Es := 29000ksi

fcr := 7.5 fcc psi

fcr = 571.183 psi

( )

( Es s)

fs s :=

fy

if s <

Es

fy

fy if s

Es

80

60

( ) 40

fs s

ksi

20

0

0.01

0.02

0.03

0.04

CES: 6706: Advanced Reinforced Concrete

2/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

Solution

To Find: Key Points on Moment Curvature Diagram

1. Determine the curvature before cracking. This can be done using the modulus of elasticity and tensile strength of

concrete, using Igross (i.e. ignoring steel) for calculating section modulus.

Sg :=

b h

Section Modulus

6

Cracking Moment

M cr := fcr Sg

cr :=

ccr :=

fcr

Extreme tension fiber strain at cracking

Ec

h

Neutral Axis

gross :=

cr

Curvature

ccr

-6 1

gross = 7.74 10

M cr = 165.072 kip ft

in

CES: 6706: Advanced Reinforced Concrete

3/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

2. Determinination of moment and curvature immediately after cracking. The moment remains the same. The

curvature, however goes from that associated with gross section to cracked section.

cmax := 0.00017844

Maximum strain. Adjusting this member until output

moment is equal to the cracking moment

y

C cc ( c , cmax) := fc cmax dy b

c

d - c

T( c , cmax) := As fs cmax

Tension Force in Reinforcement as a function of maximum

Strain and depth of neutral Axis

y

f

y dy

c

cmax

yc c , cmax :=

Location of Centroid of compressive stress block

y

f

dy

c

cmax

Zero c , cmax := C cc c , cmax - T c , cmax

c := root Zero c , cmax , c , 0.001 h , h

Sum of resultant forces should be equal to zero

Root function to determine the depth of neutral axis based

on shaded (assumed) strain

c = 9.418 in

C cc c , cmax = 71.149 kip

Checking of Equilibruim. OK

)(

T c , cmax = 71.149 kip

)) = 165.07 kip ft

T c , cmax d - c + yc c , cmax

M cr = 165.072 kip ft

CES: 6706: Advanced Reinforced Concrete

Cracking Moment = Output Moment

4/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

Plotting Information

stressplot y , c , cmax :=

fc cmax

y + c - h

if y h - c

yplot := 0 ,

h

100

.. h

0 otherwise

fcstresslimit := 7000

fs cmax

fcstrainlimit := 0.008

d - c

Stress in Concrete after Cracking

= 11.858 ksi

Stress v/s Strain

80

30

60

Stress

Section Height (in)

Concrete Stress Block After Cracking

20

40

20

10

0.02

0

0

2 10

4 10

0.04

0.06

0.08

Strain

610

Concrete Stress (psi)

cr :=

CES: 6706: Advanced Reinforced Concrete

cmax

c

= 1.895 10

-5 1

in

5/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

3) Moment Curvature for Yield Strain:

Maximum strain. Adjust this value till steel strain is

exactly equal to yield.

cmax := 0.001095

c := root Zero c , cmax , c , 0.001 h , h = 9.969 in

C cc c , cmax = 401.948 kip

T c , cmax = 401.948 kip

)(

)) = 922.081 kip ft

M y := T c , cmax d - c + yc c , cmax

Using root function to determine depth of neutral axis

based on the assumed maximum strain (shaded in gray

above).

This moment is much larger than the cracking moment.

M cr = 165.072 kip ft

stressplot y , c , cmax :=

fc cmax

y + c - h

if y h - c

yplot := 0 ,

h

100

.. h

0 otherwise

fs cmax

d - c

cmax

( d - c)

c

= 66.991 ksi

= 0.0023100

CES: 6706: Advanced Reinforced Concrete

Adjust maximum strain until steel strain is equal to the

yield strain i.e. 0.00231 for GR67.

6/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

Concrete Stress Block at Yield

Steel Stress Strain Diagram

30

60

Stress

Section Height (in)

80

20

40

20

10

0

0.02

0.04

0.06

0.08

0

0

2 10

4 10

610

Strain

Concrete Stress (psi)

y :=

CES: 6706: Advanced Reinforced Concrete

cmax

c

= 1.098 10

-4 1

in

7/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

4 Select Arbitrary curvature to continue plot:

Maximum Concrete compressive Strain

cmax := 0.002

c := root Zero c , cmax , c , 0.001 h , h = 6.406 in

Use root function to determine depth of neutral axis based

on the assumed maximum strain

C cc c , cmax = 402 kip

)(

) ) = 960.107 kip ft

This moment is not much larger than the yield moment.

M 1 := T c , cmax d - c + yc c , cmax

Concrete Stress Block At 0.002

Steel Stress Strain Diagram

60

Stress

Section Height (in)

80

30

20

40

20

10

0

0.02

0.04

0.06

0.08

0

0

2 10

4 10

Strain

6 10

Concrete Stress (psi)

1 :=

CES: 6706: Advanced Reinforced Concrete

cmax

c

-4 1

= 3.122 10

in

8/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

5 Select arbitrary curvature to continue plot

cmax := 0.003

c := root Zero c , cmax , c , 0.001 h , h = 5.301 in

C cc c , cmax = 402 kip

)(

) ) = 968.61 kip ft

M 2 := T c , cmax d - c + yc c , cmax

Steel Stress Strain Diagram

80

30

60

Stress

Section Height

Stress Strain Diagram for 0.003

20

10

0

40

20

2000

4000

6000

0.02

0.06

0.08

Strain

Concrete Stress

2 :=

CES: 6706: Advanced Reinforced Concrete

0.04

cmax

c

-4 1

= 5.66 10

in

9/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

6) Select Arbitrary Curvature to Continue Plot:

cmax := 0.004

c := root Zero c , cmax , c , 0.001 h , h = 5.323 in

C cc c , cmax = 402 kip

)(

) ) = 958.615 kip ft

M 3 := T c , cmax d - c + yc c , cmax

Steel Stress Strain Diagram

80

30

60

Stress

Section Height

Stress Block for 0.004

20

10

0

40

20

2000

4000

6000

0.02

0.06

0.08

Strain

Stress

3 :=

CES: 6706: Advanced Reinforced Concrete

0.04

cmax

c

-4 1

= 7.515 10

in

10/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

7 Arbitrary curvature to continue moment curvature plot:

cmax := 0.005

c := root Zero c , cmax , c , 0.001 h , h = 6.653 in

C cc c , cmax = 402 kip

)(

) ) = 914.034 kip ft

M 4 := T c , cmax d - c + yc c , cmax

4 :=

cmax

c

-4 1

= 7.515 10

in

Steel Stress Strain Diagram

80

30

60

Stress

Section Height

Stress Block for 0.005

20

10

0

40

20

2000

4000

Stress

CES: 6706: Advanced Reinforced Concrete

6000

0.02

0.04

0.06

0.08

Strain

11/34

Homework #7

Due Date 10/07/2016

0

M

cr

Mcr

My

M h :=

M

1

M2

M3

M4

Rishabh Lala

gross

cr

y

h :=

1

2

Moment Curvature Graph: Hognested Stress - Strain Model

3

110

Curvature

800

Mh

kip ft

600

400

200

0

0

2 10

-4

-4

410

6 10

-4

-4

8 10

h in

Moment

CES: 6706: Advanced Reinforced Concrete

12/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

Todishini Model

Section Geometry and Reinforced Concrete Properties:

h := 34in

Section Height

b := 18in

Section Width

d := 31in

Depth of centroid of reinforcement or Effective Depth

fcc := 5800psi

Measured Cylinder Compressive Strength

Yield Strength of Steel

fy := 67ksi

2

As := 6As9 = 6 in

Area of Steel in the section

cu := 0.0038

Limiting concrete compressive strain

3

(fcc psi) = 4.341 10 ksi

Ec := 57000

o :=

1.71 fcc

Ec 0.9

Modulus of Elasticity

-3

Concrete Strain Associated with Peak Stress

= 2.539 10

c

2

cc

o if

fc( c) :=

c

cu

2

c

1+

0 otherwise

Todishini Stress Function

Stress Block for Todeschini Model

3

8 10

6 10

( )

fc c

Stress Block of Todishini Model

3

4 10

psi

3

2 10

0

0

-3

1 10

2 10

-3

-3

3 10

-3

4 10

( c)

CES: 6706: Advanced Reinforced Concrete

13/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

Youngs modulus of Mild Steel

Es := 29000ksi

fcr := 7.5 fcc psi

fcr = 571.183 psi

( )

fs s :=

( Es s)

fy

if s <

Es

fy

fy if s

Es

80

60

( ) 40

fs s

ksi

20

0

0.01

0.02

0.03

0.04

CES: 6706: Advanced Reinforced Concrete

14/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

Solution (Todishini)

To Find: Key Points on Moment Curvature Diagram

1. Determine the curvature before cracking. This can be done using the modulus of elasticity and tensile strength of

concrete, using Igross (i.e. ignoring steel) for calculating section modulus.

Sg :=

b h

Section Modulus

6

Cracking Moment

M cr_t := fcr Sg

cr_t :=

ccr :=

fcr

Extreme tension fiber strain- at cracking

Ec

Neutral Axis

gross_t :=

cr

Curvature

ccr

gross_t = 7.74 10

-6 1

M cr_t = 165.072 kip ft

in

CES: 6706: Advanced Reinforced Concrete

15/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

2. Determinination of moment and curvature immediately after cracking. The moment remains the same. The

curvature, however goes from that associated with gross section to cracked section.

cmax := 0.000181950

Maximum strain. Adjusting this member until output

moment is equal to the cracking moment

C cc ( c , cmax) :=

fc cmax dy b

c

d

c

T( c , cmax) := As fs cmax

Tension Force in Reinforcement as a function of maximum

Strain and depth of neutral Axis

y

f

y dy

c

cmax

yc c , cmax :=

Location of Centroid of compressive stress block

y

f

dy

c

cmax

Zero c , cmax := C cc c , cmax - T c , cmax

c := root Zero c , cmax , c , 0.001 h , h

Sum of resultant forces should be equal to zero

Root function to determine the depth of neutral axis based

on shaded (assumed) strain

c = 9.541 in

C cc c , cmax = 71.208 kip

Checking of Equilibruim. OK

)(

T c , cmax = 71.208 kip

)) = 165.064 kip ft

T c , cmax d - c + yc c , cmax

M cr_t = 165.072 kip ft

CES: 6706: Advanced Reinforced Concrete

Cracking Moment = Output Moment

16/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

Plotting Information

stressplot y , c , cmax :=

fc cmax

y + c - h

if y h - c

yplot := 0 ,

h

100

.. h

0 otherwise

fcstresslimit := 7000

fs cmax

fcstrainlimit := 0.008

d - c

Stress in Concrete after Cracking

= 11.868 ksi

Steel Stress Strain Diagram

80

30

60

Stress

Section Height (in)

Concrete Stress Block After Cracking

20

40

20

10

0

0

0

2 10

4 10

0.02

0.04

0.06

0.08

610

Strain

Concrete Stress (psi)

cr_t :=

CES: 6706: Advanced Reinforced Concrete

cmax

c

-5 1

= 1.907 10

in

17/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

3) Moment Curvature for Yield Strain:

Maximum strain. Adjust this value till steel strain is

exactly equal to yield.

cmax := 0.00107784

c := root Zero c , cmax , c , 0.001 h , h = 9.863 in

C cc c , cmax = 401.943 kip

T c , cmax = 401.943 kip

)(

)) = 924.559 kip ft

M y_t := T c , cmax d - c + yc c , cmax

Using root function to determine depth of neutral axis

based on the assumed maximum strain (shaded in gray

above).

This moment is much larger than the cracking moment.

M cr = 165.072 kip ft

stressplot y , c , cmax :=

fc cmax

y + c - h

if y h - c

yplot := 0 ,

h

100

.. h

0 otherwise

d - c

fs cmax

= 66.991 ksi

c

cmax

( d - c)

c

= 0.0023100

CES: 6706: Advanced Reinforced Concrete

Adjust maximum strain until steel strain is equal to the

yield strain i.e. 0.00231 for GR67.

18/34

Homework #7

Due Date 10/07/2016

Steel Stress Strain Diagram

Concrete Stress Block at Yield

80

30

60

Stress

Section Height (in)

Rishabh Lala

20

40

20

10

0

0.02

0

0

2 10

4 10

610

0.04

0.06

0.08

Strain

Concrete Stress (psi)

y_t :=

CES: 6706: Advanced Reinforced Concrete

cmax

c

-4 1

= 1.093 10

in

19/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

4 Select Arbitrary curvature to continue plot:

Maximum Concrete compressive Strain

cmax := 0.002

c := root Zero c , cmax , c , 0.001 h , h = 6.283 in

Use root function to determine depth of neutral axis based

on the assumed maximum strain

C cc c , cmax = 402 kip

)(

)) = 961.431 kip ft

M 1_t := T c , cmax d - c + yc c , cmax

This moment is not much larger than the yield moment.

Steel Stress Strain Diagram

80

30

60

20

Stress

Section Height (in)

Concrete Stress Block At 0.002

10

40

20

0

0

0

2 10

4 10

0.02

0.06

0.08

Strain

Concrete Stress (psi)

1_t :=

CES: 6706: Advanced Reinforced Concrete

0.04

6 10

cmax

c

-4 1

= 3.183 10

in

20/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

5 Select arbitrary curvature to continue plot

cmax := 0.003

c := root Zero c , cmax , c , 0.001 h , h = 5.206 in

C cc c , cmax = 402 kip

)(

)) = 969.876 kip ft

M 2_t := T c , cmax d - c + yc c , cmax

Steel Stress Strain Diagram

80

30

60

Stress

Section Height

Stress Block Diagram at 0.002

20

10

0

40

20

2000

4000

6000

0.02

0.06

0.08

Strain

Concrete Stress

2_t :=

CES: 6706: Advanced Reinforced Concrete

0.04

cmax

c

-4 1

= 5.762 10

in

21/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

6) Arbitrary curvature to continue moment curvature plot:

cmax := 0.004

c := root Zero c , cmax , c , 0.001 h , h = 5.16 in

C cc c , cmax = 402 kip

)(

)) = 961.753 kip ft

M 3_t := T c , cmax d - c + yc c , cmax

Steel Stress Strain Diagram

80

30

60

Stress

Section Height

Stress Model for 0.004

20

10

0

40

20

2000

4000

6000

0.02

0.06

0.08

Strain

Stress

3_t :=

CES: 6706: Advanced Reinforced Concrete

0.04

cmax

c

-4 1

= 7.752 10

in

22/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

7 Arbitrary curvature to continue moment curvature plot:

cmax := 0.005

c := root Zero c , cmax , c , 0.001 h , h = 6.45 in

C cc c , cmax = 402 kip

)(

)) = 918.538 kip ft

M 4_t := T c , cmax d - c + yc c , cmax

Steel Stress Strain Diagram

80

30

60

Stress

Section Height

Stress Diagram for 0.005

20

10

0

40

20

2000

4000

6000

0.02

0.06

0.08

Strain

Stress

4_t :=

CES: 6706: Advanced Reinforced Concrete

0.04

cmax

c

-4 1

= 7.752 10

in

23/34

Homework #7

Due Date 10/07/2016

0

M

cr_t

Mcr_t

My_t

M T :=

M

1_t

M2_t

M3_t

M

4_t

Rishabh Lala

gross_t

cr_t

y_t

T :=

1_t

2_t

3_t

4_t

Moment Curvature Graph: Hognested Stress - Strain Model

3

110

Curvature

800

MT

kip ft

600

400

200

0

0

2 10

-4

-4

410

6 10

-4

-4

8 10

T in

Moment

CES: 6706: Advanced Reinforced Concrete

24/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

Task II

ACI Moment Strength and Corresponding Curvature

f'c := fcc

a :=

As fy

0.85 f'c b

1 :=

0.85 if f'c < 4000psi

= 0.76

0.65 if f'c > 8000psi

f'c - 4000psi

0.85 - 0.05

otherwise

1000psi

y :=

fy

-3

y = 2.31 10

Es

cu := 0.003

c :=

a

1

c = 5.961 in

t :=

d-c

c

cu

t = 0.013

Tension := fy As

arm := d -

a

2

M n := Tension arm = 962.621 kip ft

is moment Reduction Factor

:=

return 0.9 if t > 0.005

return 0.65 if t y

(t - y) otherwise

return

0.65

+

0.25

(0.005 - y)

CES: 6706: Advanced Reinforced Concrete

25/34

Homework #7

Due Date 10/07/2016

Rishabh Lala

= 0.9

M n := M n

ACI :=

M n = 866.359 kip ft

cu

c

= 5.033 10

-4 1

in

Moment Curvature Graph: Hognested, Todeschini and ACI Model

110

800

Mh

Curvature

kip ft

600

MT

kip ft

Mn

400

kip ft

200

0

-4

2 10

4 10

-4

610

-4

-4

810

h in , T in , ACI in

Moment

Hognested Model

Todeschini Model

ACI Model

Discussion:

The key observations from the moment curvature of the three models are:

1. Moment-Curvature for both Hognested and Todeschini's models are almost the same.

2. The curvature seizes to increase after 0.004 strain is reached for both the models.

3. Before and after cracking, almost similar curvature change is observed.

4. Yield point given by both the models are almost the same with percentage change of 0.45 x 10-4%., and

Hognested's being on the higher side.

5. Comparitively, more ductility is observed in the moment curvature by Todesc hini's Model by 3.1 x 10-4% (comparing

0.004 curvature of both models).

6. ACI assumes conservative moment allowed for design as compared to aformentioned Moment Curvature Models.

CES: 6706: Advanced Reinforced Concrete

26/34

Das könnte Ihnen auch gefallen

- تصميم الكمرات بطريقة ultimate PDFDokument42 Seitenتصميم الكمرات بطريقة ultimate PDFqaisalkurdyNoch keine Bewertungen

- Am Exams Paper 2014Dokument12 SeitenAm Exams Paper 2014akanagesNoch keine Bewertungen

- Chapter 8 - Bending Members: A Beginner's Guide To The Steel Construction Manual, 14 EdDokument5 SeitenChapter 8 - Bending Members: A Beginner's Guide To The Steel Construction Manual, 14 Edv pavanNoch keine Bewertungen

- WIND02 v2-21: Detailed Wind Load Analysis Per ASCE 7-10Dokument3 SeitenWIND02 v2-21: Detailed Wind Load Analysis Per ASCE 7-10gmontesroy100% (1)

- AM Exam July 2016Dokument12 SeitenAM Exam July 2016Altin CeroNoch keine Bewertungen

- Rolled - MomentDokument5 SeitenRolled - MomentAdekimi EmmanuelNoch keine Bewertungen

- 05.06 Duct Supports DS-06 Base PlateDokument2 Seiten05.06 Duct Supports DS-06 Base Platehighway20049922Noch keine Bewertungen

- Chartered Membership Examination: Thursday, 5 July 2018Dokument18 SeitenChartered Membership Examination: Thursday, 5 July 2018Nitin shepurNoch keine Bewertungen

- CXXC XCFXCXCV DfethDokument16 SeitenCXXC XCFXCXCV Dfethprompt consortiumNoch keine Bewertungen

- Wood Shearwall & Connection: 'File:///var/www/apps/conversion/tmp/scratch - 7/347313706.xls'#$woodwallDokument3 SeitenWood Shearwall & Connection: 'File:///var/www/apps/conversion/tmp/scratch - 7/347313706.xls'#$woodwallChoky NguyenNoch keine Bewertungen

- RaftDokument48 SeitenRaftHariom KhungarNoch keine Bewertungen

- Earthquake Design of RectangularDokument6 SeitenEarthquake Design of RectangularFerry R. A. PratomoNoch keine Bewertungen

- Exam Preparation Associate Member Past Paper 20150710Dokument16 SeitenExam Preparation Associate Member Past Paper 20150710Sanjay ChowdhuryNoch keine Bewertungen

- UB UC Steel SectionsDokument10 SeitenUB UC Steel SectionsMuhammad HasanNoch keine Bewertungen

- Project: Steel Building Design Case Study Subject: Project Plan SHEET 1 of 131Dokument5 SeitenProject: Steel Building Design Case Study Subject: Project Plan SHEET 1 of 131clam2014Noch keine Bewertungen

- Shear Hinge For Coupling BeamDokument7 SeitenShear Hinge For Coupling BeamLavender HoneyNoch keine Bewertungen

- Bridge Design: Saif HaroonDokument30 SeitenBridge Design: Saif HaroonphiliSCDNoch keine Bewertungen

- Deck Girder - BracingDokument3 SeitenDeck Girder - BracingvibishnanNoch keine Bewertungen

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Dokument5 SeitenInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNoch keine Bewertungen

- Pinned Connection Precast ConcreteDokument3 SeitenPinned Connection Precast ConcreteFandy SipataNoch keine Bewertungen

- 03 Section 2 Example Bridge (E)Dokument11 Seiten03 Section 2 Example Bridge (E)Diego Benavides KNoch keine Bewertungen

- Design - Calculation - For - Bracing - Connection 1 PDFDokument10 SeitenDesign - Calculation - For - Bracing - Connection 1 PDFLian Jia JieNoch keine Bewertungen

- 0 - BASE SHEAR REDISTRIBUTION BETWEEN THE RC DUAL SYSTEM STRUCTURAL COMPONENTS - V.Sigmund Itd. - 2008 - 8158 PDFDokument8 Seiten0 - BASE SHEAR REDISTRIBUTION BETWEEN THE RC DUAL SYSTEM STRUCTURAL COMPONENTS - V.Sigmund Itd. - 2008 - 8158 PDFnebojsadj6411Noch keine Bewertungen

- Pages From Hilti BE 500Dokument1 SeitePages From Hilti BE 500Anonymous S7Cq7ZDgPNoch keine Bewertungen

- Development Length Calculation For 20Mm Dia Bar: B y C DC RDokument2 SeitenDevelopment Length Calculation For 20Mm Dia Bar: B y C DC RkarthiNoch keine Bewertungen

- Arch ActionDokument14 SeitenArch ActionvempadareddyNoch keine Bewertungen

- Design Calculation of Rss Building 3VIN 9 554 D1 S1 202 R0 Design of Foundations DataDokument56 SeitenDesign Calculation of Rss Building 3VIN 9 554 D1 S1 202 R0 Design of Foundations DataARUNKUMAR KNoch keine Bewertungen

- Hot Finished Square Hollow Sections in Accordance With EN 10210Dokument5 SeitenHot Finished Square Hollow Sections in Accordance With EN 10210bggariyoNoch keine Bewertungen

- Bearing Strength of Concrete Vu Area Required For Baseplate AreaDokument5 SeitenBearing Strength of Concrete Vu Area Required For Baseplate AreaSunidhi ItagiNoch keine Bewertungen

- Is 13920Dokument183 SeitenIs 13920p_ignatiusNoch keine Bewertungen

- Trial ExcelDokument15 SeitenTrial ExcelCyndrille John BragatNoch keine Bewertungen

- LiquidRet IndianDokument13 SeitenLiquidRet Indianchandra BandaraNoch keine Bewertungen

- Beams On Elastic FoundationDokument5 SeitenBeams On Elastic FoundationKazi Shahazada Shahanewaz HossainNoch keine Bewertungen

- XyzDokument64 SeitenXyzP S HARSHITANoch keine Bewertungen

- DE010 of-053123-1.0-P-Vulcraft Joist and Deck Plans - Datum ReviewedDokument9 SeitenDE010 of-053123-1.0-P-Vulcraft Joist and Deck Plans - Datum ReviewedAzeemuddin Gulam MohammedNoch keine Bewertungen

- Sesmic Load at Floor LevelDokument14 SeitenSesmic Load at Floor LevelJennifer PearsonNoch keine Bewertungen

- Given Data: Given Data:: Design of Raft Foundation Design of Raft FoundationDokument8 SeitenGiven Data: Given Data:: Design of Raft Foundation Design of Raft FoundationBikram BhusalNoch keine Bewertungen

- Bi Material BeamDokument22 SeitenBi Material BeamPraveen KumaarNoch keine Bewertungen

- Bearing Design Method BDokument3 SeitenBearing Design Method BDhurai KesavanNoch keine Bewertungen

- Stress Check For E.J PierDokument29 SeitenStress Check For E.J PierVasu Deva Rao ChilukuriNoch keine Bewertungen

- Welding Connection 2Dokument55 SeitenWelding Connection 2dinu69inNoch keine Bewertungen

- Basic Design Parameters:: Loads: 1Dokument5 SeitenBasic Design Parameters:: Loads: 1Timo SchenkoNoch keine Bewertungen

- Bridge Rating Flowchart SDDokument5 SeitenBridge Rating Flowchart SDSuvash DhakalNoch keine Bewertungen

- P-M Curve - 15-4-2015 - FinalDokument41 SeitenP-M Curve - 15-4-2015 - FinalVishal PatelNoch keine Bewertungen

- Design of ColumnDokument8 SeitenDesign of ColumnAfsar MansuriNoch keine Bewertungen

- Design of Rectangular Water TankDokument308 SeitenDesign of Rectangular Water Tankලහිරු විතානාච්චි100% (1)

- SBC of Soil at 2.5m DEPTH 25 T/M: (A) Check For One Way ShearDokument36 SeitenSBC of Soil at 2.5m DEPTH 25 T/M: (A) Check For One Way ShearAnonymous mcHqIfbnV1Noch keine Bewertungen

- RCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementDokument5 SeitenRCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementdsanandaNoch keine Bewertungen

- Racking Analysis of Underground Structures: Date: Note No. By: Sheet NoDokument4 SeitenRacking Analysis of Underground Structures: Date: Note No. By: Sheet NoStructural SpreadsheetsNoch keine Bewertungen

- Design of RCC Post-Tensioned Flat SlabsDokument6 SeitenDesign of RCC Post-Tensioned Flat SlabsjayadushNoch keine Bewertungen

- Aizawal-Tuipang (NH-54) - PKG 6: Design Notes-Retaining WallDokument114 SeitenAizawal-Tuipang (NH-54) - PKG 6: Design Notes-Retaining Wallnikhilnagpal2121994Noch keine Bewertungen

- Truss AnalysisDokument35 SeitenTruss AnalysisSandip BudhathokiNoch keine Bewertungen

- Pile Design SpreadsheetDokument180 SeitenPile Design SpreadsheetsubamanivelNoch keine Bewertungen

- v375 Ebook Ebook Download Reinforced Concrete Structures Analysis and Design by David FanellaDokument7 Seitenv375 Ebook Ebook Download Reinforced Concrete Structures Analysis and Design by David FanellaGandhi HammoudNoch keine Bewertungen

- Prepared by Date PRA 28-Jan-17 Checked by Revision Dr. Yeri R0 MegaDokument1 SeitePrepared by Date PRA 28-Jan-17 Checked by Revision Dr. Yeri R0 MegapravinNoch keine Bewertungen

- Appendix - Ii: Principles of Construction, Material and Design of Ferrocement TankDokument5 SeitenAppendix - Ii: Principles of Construction, Material and Design of Ferrocement TankbenzzenhdNoch keine Bewertungen

- R.C.C DesignDokument14 SeitenR.C.C DesignVinayan PuthukadNoch keine Bewertungen

- Cross Section Properties (All Dimensions Are in CMS)Dokument2 SeitenCross Section Properties (All Dimensions Are in CMS)Hanamantrao KhasnisNoch keine Bewertungen

- Torsion Tension and Column (11-16)Dokument33 SeitenTorsion Tension and Column (11-16)2011kumarNoch keine Bewertungen

- My UNIX CommandsDokument2 SeitenMy UNIX CommandsRishabh Lala100% (1)

- Python and PerlDokument21 SeitenPython and PerlRishabh LalaNoch keine Bewertungen

- Deflections Due To Loading As Per ACIDokument8 SeitenDeflections Due To Loading As Per ACIRishabh LalaNoch keine Bewertungen

- Ansys CommandsDokument1 SeiteAnsys CommandsRishabh Lala100% (1)

- Whats Research and How Do We Do ResearchDokument2 SeitenWhats Research and How Do We Do ResearchRishabh LalaNoch keine Bewertungen

- Lala 2 PDFDokument13 SeitenLala 2 PDFRishabh LalaNoch keine Bewertungen

- My UNIX CommandsDokument2 SeitenMy UNIX CommandsRishabh Lala100% (1)

- Resume Rishabh Lala PDFDokument1 SeiteResume Rishabh Lala PDFRishabh LalaNoch keine Bewertungen

- Matrix Structural AnalysisDokument2 SeitenMatrix Structural AnalysisRishabh LalaNoch keine Bewertungen

- McuserDokument253 SeitenMcuserIoan LeonteNoch keine Bewertungen

- Resume Rishabh LalaDokument1 SeiteResume Rishabh LalaRishabh LalaNoch keine Bewertungen

- Research, Building Codes, and Engineering PracticeDokument1 SeiteResearch, Building Codes, and Engineering PracticeRishabh LalaNoch keine Bewertungen

- One Who Tries Never FailsDokument1 SeiteOne Who Tries Never FailsRishabh LalaNoch keine Bewertungen

- State of Art PapersDokument1 SeiteState of Art PapersRishabh LalaNoch keine Bewertungen

- Major ProjectDokument59 SeitenMajor ProjectRishabh LalaNoch keine Bewertungen

- Assignment 1Dokument11 SeitenAssignment 1Rishabh LalaNoch keine Bewertungen

- ResearchDokument2 SeitenResearchRishabh LalaNoch keine Bewertungen

- Column ShorteningDokument10 SeitenColumn ShorteningRishabh LalaNoch keine Bewertungen

- Design Requirements RishabhDokument1 SeiteDesign Requirements RishabhRishabh LalaNoch keine Bewertungen

- Railway Engineering NotesDokument1 SeiteRailway Engineering NotesRishabh LalaNoch keine Bewertungen

- Software Analysis ConceptsDokument21 SeitenSoftware Analysis ConceptsRishabh LalaNoch keine Bewertungen

- Concentration Part IIIDokument2 SeitenConcentration Part IIIRishabh LalaNoch keine Bewertungen

- Report On Burj KhalifaDokument18 SeitenReport On Burj KhalifaRishabh Lala85% (13)

- Structural Engineering NotesDokument5 SeitenStructural Engineering NotesRishabh LalaNoch keine Bewertungen

- Handout Notes1Dokument6 SeitenHandout Notes1Rishabh LalaNoch keine Bewertungen

- Structural Engineering NotesDokument5 SeitenStructural Engineering NotesRishabh LalaNoch keine Bewertungen

- Steel Design NotesDokument3 SeitenSteel Design NotesRishabh LalaNoch keine Bewertungen

- Put Your Shoulders To WheelDokument1 SeitePut Your Shoulders To WheelRishabh LalaNoch keine Bewertungen

- Covers According To Exposure Class 4.1 (BS 8500-1:2006)Dokument3 SeitenCovers According To Exposure Class 4.1 (BS 8500-1:2006)Rishabh LalaNoch keine Bewertungen

- DPWH - Guard HouseDokument180 SeitenDPWH - Guard HouseErnest BelmesNoch keine Bewertungen

- Cantilever Calculation ToolDokument10 SeitenCantilever Calculation ToolEnoch Twumasi50% (2)

- GOST R 52029-2003 Water. Unit of HardnessDokument4 SeitenGOST R 52029-2003 Water. Unit of HardnessOMER EKERNoch keine Bewertungen

- Dream Residences - Water Supply & Fire Protection BOMDokument1 SeiteDream Residences - Water Supply & Fire Protection BOMPatrick LlenaresNoch keine Bewertungen

- Capital CostDokument2 SeitenCapital CostRajibDebNoch keine Bewertungen

- Construction Safety and Health Narrative MethodsDokument46 SeitenConstruction Safety and Health Narrative MethodsEldreen Ann Jebulan Vargas100% (1)

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDokument5 SeitenSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakinghafizNoch keine Bewertungen

- Seminar On Steam EngineDokument26 SeitenSeminar On Steam EngineEr Akhilesh Singh100% (1)

- Hd26000 Casing TongDokument121 SeitenHd26000 Casing TongTerry Smith100% (1)

- Lesson 6-GlassDokument32 SeitenLesson 6-Glasslewis imaNoch keine Bewertungen

- Chapter 11 CACCDHDokument60 SeitenChapter 11 CACCDHmeda012Noch keine Bewertungen

- Amercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsDokument4 SeitenAmercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsTony KhouryNoch keine Bewertungen

- Ieema Member's Directory Listing FormDokument12 SeitenIeema Member's Directory Listing Formsudhakarrrrrr0% (1)

- Superwool Plus BlanketDokument2 SeitenSuperwool Plus Blanketdnageshm4n244Noch keine Bewertungen

- ME 231 Montazami Whharris 9-10-18 SOLUTIONDokument4 SeitenME 231 Montazami Whharris 9-10-18 SOLUTIONEduardo Perez UriegasNoch keine Bewertungen

- Characteristics of NanomaterialsDokument9 SeitenCharacteristics of Nanomaterialssandhiya padmanabanNoch keine Bewertungen

- PowerTech 4.5L &6.8L Diesel Engines - Level 12 Electronic Fuel System-Stanadyne DE10 Pump-CTM331Dokument550 SeitenPowerTech 4.5L &6.8L Diesel Engines - Level 12 Electronic Fuel System-Stanadyne DE10 Pump-CTM331grand fir100% (39)

- Uses of The Elements and Compounds in Our Daily LifeDokument4 SeitenUses of The Elements and Compounds in Our Daily LifeTaibah Nurwahidah Mohamad89% (9)

- NCSE 2006 Integrated ScienceDokument19 SeitenNCSE 2006 Integrated ScienceChristian PatriceNoch keine Bewertungen

- EVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data SheetDokument3 SeitenEVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data Sheetsamira bashirvandNoch keine Bewertungen

- CatalogDokument482 SeitenCatalogAnonymous 6EW2MsFbkNoch keine Bewertungen

- MIL-F-5509D - Fittings, Flared Tube, Fluid ConnectionDokument18 SeitenMIL-F-5509D - Fittings, Flared Tube, Fluid ConnectionthomasNoch keine Bewertungen

- Commissioning ProceduresDokument152 SeitenCommissioning Proceduresmabrarahmed100% (1)

- Arch. DictionaryDokument68 SeitenArch. DictionaryVinay GuptaNoch keine Bewertungen

- 2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFDokument11 Seiten2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFMoataz Hesham SolimanNoch keine Bewertungen

- Visit ReportDokument13 SeitenVisit ReportAlankrutha DevuNoch keine Bewertungen

- Thin Cylinders: Presented By: Balvinder Budania Asstt - ProfDokument44 SeitenThin Cylinders: Presented By: Balvinder Budania Asstt - ProfBalvinderNoch keine Bewertungen

- 12d20105a Experimental Stress AnalysisDokument1 Seite12d20105a Experimental Stress AnalysissubbuNoch keine Bewertungen

- Ryobi ELS52G Manual 1 Log SplitterDokument14 SeitenRyobi ELS52G Manual 1 Log SplitterFrank MatzkaNoch keine Bewertungen