Beruflich Dokumente

Kultur Dokumente

Firestopping Mechanical and Electrical

Hochgeladen von

jack.simpson.changOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Firestopping Mechanical and Electrical

Hochgeladen von

jack.simpson.changCopyright:

Verfügbare Formate

D&C FS:dja

MECHANICAL & ELECTRICAL

SECTION 078400

FIRESTOPPING

PART 1 GENERAL

1.01

1.02

REFERENCES

A.

UL 1479 Fire Tests of Through-Penetration Firestops.

B.

ASTM E 814 Method of Fire Tests of Through-Penetration Fire Stops.

DEFINITIONS

A.

UL Fire Resistance Directory: Product directory published yearly, with

supplements, by Underwriters Laboratories Inc., containing listings and

classifications in effect as of the published date for product categories covered by

UL.

B.

Inchcape Directory of Listed Products: Product directory published

yearly by Inchcape Testing Services containing listings which reflect certifications

granted for materials, products, systems and equipment which have been tested by

Inchcape Testing Services to recognized governing standards.

C.

Omega Point Laboratories Listings Directory: Product Directory

published yearly by Omega Point Laboratories, Inc. containing listed building

products, materials, and assemblies which have been tested by Omega Point

Laboratories to recognized governing standards.

D.

Factory Mutual Approval Guide: Product directory published yearly, with

supplements, by Factory Mutual Research Corp., containing listed building

products, materials, and assemblies which have been tested by Factory Mutual

Research Corp., to recognized governing standards.

E.

F Rating: Prohibits flame passage through the system and requires

acceptable hose stream test performance.

F.

T Rating: Prohibits flame passage through the system and requires the

maximum temperature rise on the unexposed surface of the wall or floor assembly,

on the penetrating item and on the fill material not to exceed 325 degrees F above

ambient, and requires acceptable hose stream test performance.

G.

Company Field Advisor: An employee of the Company which lists and

markets the primary components of the system under their name who is certified in

writing by the Company to be technically qualified in design, installation, and

servicing of the required products or an employee of an organization certified by

the foregoing Company to be technically qualified in design, installation and

servicing of the required products. Personnel involved solely in sales do not

qualify.

1.03

DESIGN REQUIREMENTS

Updated 04/09/2008

Printed 12/10/2016

078400 - 1

Project No.

D&C FS:dja

MECHANICAL & ELECTRICAL

A.

Devices and materials shall meet the hourly fire resistance ratings required

by the Project as determined by UL 1479, or ASTM E 814 and be listed and

detailed in the UL Fire Resistance Directory, Inchcape Directory of Listed

Products, Factory Mutual Approval Guide, or the Omega Point Laboratories

Listings Directory.

1.

Exception: Where no listed designs exist that meet the

requirements of a specific project condition, submit details and

manufacturers written recommendations for a design meeting the

requirements. Include evidence of engineering judgement and

extrapolation from listed designs.

1.04

SUBMITTALS

A.

Submittals Package: Submit the following items specified below the same

time as a package:

1.

Product Data.

2.

Samples.

3.

Quality Control Submittals.

4.

Firestop Schedule.

B.

Product Data: Catalog sheets, specifications and installation instructions

for each firestop device and material.

1.

Indicate design number for each firestop proposed to be

used which is detailed in the UL Fire Resistance Directory, Inchcape

Directory of Listed Products, Factory Mutual Approval Guide, or the

Omega Point Laboratories Listings Directory.

2.

State the specific locations where each firestop system is

proposed to be installed.

Updated 04/09/2008

Printed 12/10/2016

C.

Samples: One of each product if requested.

D.

Quality Control Submittals:

1.

Design Data: Show details and include engineering

information and manufacturers written recommendations required under

Design Requirements Article for each proposed firestop if other than a

design detailed in the UL Fire Resistance Directory, Inchcape Directory of

Listed Products, Factory Mutual Approval Guide, or the Omega Point

Laboratories Listings Directory.

a.

State the specific locations where each

firestop is proposed to be installed.

2.

Installers Qualifications Data:

a.

Name of each person who will be

performing the Work and their employers name, business address

and telephone number.

b.

Names and addresses of 3 similar

projects that each person has worked on during the past 5 years.

3.

Company Field Advisor Data:

a.

Name, business address and telephone

number of Company Field Advisor secured for the required

services.

078400 - 2

Project No.

D&C FS:dja

MECHANICAL & ELECTRICAL

b.

Certified statement from the Company

listing the qualifications of the Company Field Advisor, and

listing of services and each product specifically listed for this

Project for which Company Field Advisor is given authorization

by the Company to render advice.

E.

Firestop Schedule: Submit schedule itemizing the following:

1.

Manufacturers product reference numbers and/or

drawing numbers.

2.

UL, Inchcape Testing Services, Factory Mutual Research

Corp., or Omega Point Lab design number.

3.

Location of firestop material.

4.

Penetrating Item Description/Limits: Material, size,

insulated or uninsulated, and combustibility.

5.

Maximum allowable annular space or maximum size

opening.

6.

Wall type construction.

7.

Floor type construction.

8.

Hourly Fire resistance rating of wall or floor.

9.

F rating.

10.

T rating, if available.

NOTE: Firestop Schedule is for information only, and will not be acted on for approval.

Refer to Sample Firestop Schedule bound in Appendix.

1.05

QUALITY ASSURANCE

A.

Installer Qualifications: The persons installing the firestopping and their

supervisor shall be personally experienced in firestop work and shall have been

regularly employed by a company installing firestopping for a minimum of 3

years.

B.

Pre-Installation Conference: Before the firestop work is scheduled to

commence, a conference will be called by the Directors Representative at the Site

for the purpose of reviewing the Contract Documents and discussing requirements

for the Work. The conference shall be attended by related trade Contractors (if

any), their qualified firestopping installers, and associated firestopping

manufacturers Company Field Advisors.

C.

Container/Package Labels: Include manufacturers name and identifying

product number, date of manufacturer, lot number, shelf life (if applicable),

qualified testing and inspecting agency classification marking, curing time, and

mixing instructions for multi-component materials.

D.

Company Field Advisor: Secure the services of a Company Field Advisor

for the following:

1.

Render advice regarding suitability of firestopping

materials and methods.

2.

Assist in completing firestop schedule.

3.

Attend pre-installation conference.

Updated 04/09/2008

Printed 12/10/2016

078400 - 3

Project No.

D&C FS:dja

MECHANICAL & ELECTRICAL

E.

Field-Constructed Sample Installations: Prior to installing firestopping,

erect sample installations for each type through-penetration firestop system

indicated in the Firestop Schedule to verify selections made and to establish

standard of quality and performance by which the firestopping work will be

judged.

1.

Build sample installations to comply with the following

requirements, using materials indicated for final installations.

a.

Locate sample installations on site at

locations where directed.

b.

Obtain Directors Representatives

acceptance of sample installations before start of firestopping

installation.

c.

Retain and maintain sample installations

during construction in an undisturbed condition.

d.

Accepted sample installations in an

undisturbed condition at time of substantial completion of Project

may become part of completed firestopping work.

1.06

DELIVERY, STORAGE, AND HANDLING

A.

Deliver firestopping materials to the Site in original, new unopened

containers or packages bearing manufacturers printed labels.

B.

Store and handle firestopping materials to prevent deterioration or damage

due to moisture, temperature changes, contaminants, etc.

1.07

PROJECT CONDITIONS

A.

1.08

Environmental Requirements:

1.

Temperature: Do not install firestopping materials when

ambient or substrate temperatures are outside limits permitted by

manufacturer of firestopping materials.

2.

Humidity and Moisture: Do not install the Work of this

Section under conditions that are detrimental to the application, curing,

and performance of the materials.

3.

Ventilation: Provide sufficient ventilation wherever

firestopping materials are installed in enclosed spaces. Follow

manufacturers recommendations.

SEQUENCING AND SCHEDULING

A.

Leave exposed those firestopping installations that are to be concealed

behind other construction until the Directors Representative has examined each

installation.

PART 2 PRODUCTS

2.01

FIRESTOPPING-GENERAL

A.

Through-Penetration Firestop Devices, Forming Materials, And Fill, Void

or Cavity Materials: As listed in the UL Fire Resistance Directory, Inchcape

Updated 04/09/2008

Printed 12/10/2016

078400 - 4

Project No.

D&C FS:dja

MECHANICAL & ELECTRICAL

Directory of Listed Products, Factory Mutual Approval Guide, or the Omega

Point Laboratories Listings Directory.

1.

For firestopping exposed to moisture, furnish products

that do not deteriorate when exposed to this condition.

2.

For firestopping systems exposed to view, furnish

products with flame-spread values of less than 25 and smoke developed

values less than 50, as determined per ASTM E 84.

3.

For penetrations for piping services below ambient

temperature, furnish moisture-resistant through-penetration firestop

systems.

4.

For penetrations involving insulated piping, furnish

through-penetration firestop systems not requiring removal of insulation.

B.

Accessories: Components required to install fill materials as

recommended by the firestopping manufacturer for particular approved fire rated

system.

C.

Identification Labels:

1.

Furnished by fire stopping manufacturer of suitable

material for permanent field identification of through-penetration

firestops.

2.

Identify the following:

a.

WARNING - FIRESTOP

MATERIAL.

b.

Company Name.

c.

Product Catalog number.

d.

F rating.

e.

T rating, if available.

3.

Field fabricated labels are not acceptable.

PART 3 EXECUTION

3.01

EXAMINATION

A.

Examine existing through-penetrations of floors, walls, partitions, ceilings

and roofs in the Work areas.

B.

Where firestopping is missing or not intact, submit a written report to the

Directors Representative describing the existing conditions.

3.02

PREPARATION

A.

Clean out openings immediately before installation of through-penetration

firestopping. Comply with recommendations of firestopping manufacturer and the

following requirements:

1.

Remove foreign materials from surfaces of openings, and

from penetrating items that could interfere with adhesion of firestopping.

2.

Clean opening and penetrating items to produce clean,

sound surfaces capable of developing optimum bond with firestopping.

Remove loose particles remaining from cleaning operation.

3.

Remove laitance and form release agents from concrete.

Updated 04/09/2008

Printed 12/10/2016

078400 - 5

Project No.

D&C FS:dja

3.03

MECHANICAL & ELECTRICAL

B.

Protection:

1.

Protect surfaces adjacent to through-penetration firestops

with non-staining removable masking tape or other suitable covering to

prevent firestopping from contacting adjoining surfaces that will remain

exposed upon completion of Work and that would otherwise be

permanently stained or damaged by such contact or that would be caused

by cleaning methods used to remove smears from firestopping materials.

C.

Substrate Priming:

1.

Prime substrates in accordance with the firestopping

manufacturers printed installation instructions using recommended

products and methods.

2.

Do not allow primer to spill or migrate onto adjoining

exposed surfaces.

INSTALLATION OF THROUGH PENETRATION FIRESTOPS

A.

Use through-penetration firestop devices, forming materials, and fill, void

or cavity materials to form through-penetration firestops to prevent the passage of

flame, and limit temperature rise of the unexposed surface as detailed in the UL

Fire Resistance Directory, Inchcape Directory of Listed Products, Factory Mutual

Approval Guide, or the Omega Point Laboratories Listings Directory.

1.

Where applicable design is not detailed in the Directories,

use forming materials and fill, void or cavity material to form throughpenetration firestop in accordance with approved printed details and

installation instructions from the company producing the forming

materials and fill, void or cavity material.

2.

If the construction type(s) of the building cannot be

determined, provide firestopping with fire resistance ratings as specified in

the Building Code of New York State, Tables 720.1(1), 720.1(2),

720.1(3), and 302.3.2.

B.

Provide through-penetration firestop systems with F ratings which shall

equal or exceed the fire resistance rating of the penetrated building construction.

C.

Provide through-penetration firestop systems with T ratings, in addition to

F ratings, at floors where the following conditions exist:

1.

Where firestop systems protect penetrations located

outside the wall cavities.

2.

Where firestop systems protect penetrations located

outside fire resistive shaft enclosures.

3.

Through-penetration firestop systems protecting floor

penetrations require a T-rating of at least 1 hour, but not less than the

required floor fire-resistance rating.

D.

Firestop through-penetrations of floors, walls, partitions, ceilings, and

roofs.

E.

Updated 04/09/2008

Printed 12/10/2016

Firestop through-penetrations associated with the new Work.

078400 - 6

Project No.

D&C FS:dja

MECHANICAL & ELECTRICAL

F.

Firestop through-penetration of partitions identified on the Construction

Work Drawings as smoke partitions and fire rated assemblies.

G.

Firestop through-penetrations of floors, walls, partitions, ceilings, and

roofs in accordance with the fire resistance rating assigned to the walls, partitions,

floors, ceilings, and roofs on the Construction Work Drawings.

H.

In areas where through-penetration items have been installed before the

construction work, firestop the through-penetration items after the construction

work has been completed. Furnish drawings or written information to the

Construction Work Contractor covering the provisions to be made in the

construction work to enable firestopping of the through-penetration items.

I.

Permanently affix label at each firestop. Use adhesive compatible with

surface construction at firestop location.

3.04

CLEANING

A.

Clean off excess fill materials and sealants adjacent to penetrations by

methods and cleaning materials recommended by manufacturers of firestopping

products and of products in which penetrations occur.

B.

Remove masking tape as soon as practical so as not to disturb the

firestoppings bond with substrate.

C.

Protect firestopping during and after curing period from contact with

contaminating substances, or damage resulting from adjacent Work.

D.

Cut out and remove damaged or deteriorated firestopping immediately,

and install new materials as specified in firestop schedule.

END OF SECTION

Updated 04/09/2008

Printed 12/10/2016

078400 - 7

Project No.

Das könnte Ihnen auch gefallen

- Field Installation, Inspection & Test PlanDokument2 SeitenField Installation, Inspection & Test PlanSaiful Ahda100% (1)

- 2018 Chapter 3-1 2018 Introduction To Industrial Higiene & Occupational Health PDFDokument59 Seiten2018 Chapter 3-1 2018 Introduction To Industrial Higiene & Occupational Health PDFLove StrikeNoch keine Bewertungen

- Aspect Impact RegisterDokument17 SeitenAspect Impact RegisterVi KraNoch keine Bewertungen

- Aluminum WindowsDokument6 SeitenAluminum Windowsjack.simpson.changNoch keine Bewertungen

- Environmental Aspects & Impacts For PlantDokument5 SeitenEnvironmental Aspects & Impacts For PlantDarren TanNoch keine Bewertungen

- Precast Pre Stressed ConcreteDokument6 SeitenPrecast Pre Stressed Concretejack.simpson.changNoch keine Bewertungen

- Environmental Aspects and ObjectivesDokument4 SeitenEnvironmental Aspects and Objectivesum erNoch keine Bewertungen

- Synerquest Team of Experts 2013Dokument2 SeitenSynerquest Team of Experts 2013Robin RubinaNoch keine Bewertungen

- Air PollutionDokument39 SeitenAir PollutionWarisha RanaNoch keine Bewertungen

- Speaker:: S. Veerasingam Vice-President Malaysian Society For Occupational Safety and Health (Msosh)Dokument52 SeitenSpeaker:: S. Veerasingam Vice-President Malaysian Society For Occupational Safety and Health (Msosh)EdumineroNoch keine Bewertungen

- ILO - OSH-2001 - Guidelines On OS&H MGM SystemsDokument28 SeitenILO - OSH-2001 - Guidelines On OS&H MGM SystemsbarmaniNoch keine Bewertungen

- Bosh Module 8Dokument19 SeitenBosh Module 8Ging FreecsNoch keine Bewertungen

- COMPRESSION, REFRIGERATION CYCLE DocumentDokument26 SeitenCOMPRESSION, REFRIGERATION CYCLE DocumentMuhammad Irfan MalikNoch keine Bewertungen

- Notes On Sprockets and ChainsDokument6 SeitenNotes On Sprockets and Chainsjjoohhnn90Noch keine Bewertungen

- Energy Saving Opportunities in IndustriesDokument70 SeitenEnergy Saving Opportunities in IndustriesIrawan SutionoNoch keine Bewertungen

- House KeepingDokument14 SeitenHouse KeepingAcholonu Emeka JpNoch keine Bewertungen

- Exit Routes, Emergency Action Plans, Fire Prevention Plans, and Fire ProtectionDokument54 SeitenExit Routes, Emergency Action Plans, Fire Prevention Plans, and Fire ProtectionPriyasha RayNoch keine Bewertungen

- ConstructionHazards PDFDokument47 SeitenConstructionHazards PDFDEVA PRIYA ANIL 1861724Noch keine Bewertungen

- Occupational Safety and Health (Osafe) : 2nd Sem. S.Y. 2008-2009 Prof. Ruby Pineda-Henson, Ph. DDokument68 SeitenOccupational Safety and Health (Osafe) : 2nd Sem. S.Y. 2008-2009 Prof. Ruby Pineda-Henson, Ph. DTimothy James M. MadridNoch keine Bewertungen

- ASPECT-IMPACT ANALYSIS Reference No. VE-EMS-01/VA/02: ISO 14001:2004 Done by - V.B.TodkarDokument4 SeitenASPECT-IMPACT ANALYSIS Reference No. VE-EMS-01/VA/02: ISO 14001:2004 Done by - V.B.TodkarBalachandar SathananthanNoch keine Bewertungen

- Construction Workers Training PDFDokument80 SeitenConstruction Workers Training PDFAngela Mae FranciscoNoch keine Bewertungen

- 1 - 6 Low Risk 8 - 12 Medium Risk 15 - 25 High Risk: Hazard Identification and Risk Assessment (Hira) WorksheetDokument10 Seiten1 - 6 Low Risk 8 - 12 Medium Risk 15 - 25 High Risk: Hazard Identification and Risk Assessment (Hira) WorksheetSBNoch keine Bewertungen

- Carte Automatic TransmissionsDokument20 SeitenCarte Automatic TransmissionsGigelNoch keine Bewertungen

- Es Module 3 PDFDokument184 SeitenEs Module 3 PDFPallavi GangadharanNoch keine Bewertungen

- Fire Protection Facilities FOR Petroleum Depots, Terminals, Pipeline Installations AND Lube Oil InstallationsDokument42 SeitenFire Protection Facilities FOR Petroleum Depots, Terminals, Pipeline Installations AND Lube Oil InstallationsSanjay PatelNoch keine Bewertungen

- Dstan 03-25Dokument26 SeitenDstan 03-25jmills7560Noch keine Bewertungen

- Presidential Decree No. 1151: Philippine Environmental PolicyDokument16 SeitenPresidential Decree No. 1151: Philippine Environmental Policycoffee addictNoch keine Bewertungen

- Basics of Automobiles: EmmisionDokument76 SeitenBasics of Automobiles: EmmisionRavindra Joshi100% (1)

- Document No PCPL-0532-4-407-04-06-1 Control & Relay Panel Data Sheet Section - 4 PAGE: 1 of 12Dokument12 SeitenDocument No PCPL-0532-4-407-04-06-1 Control & Relay Panel Data Sheet Section - 4 PAGE: 1 of 12tceterexNoch keine Bewertungen

- Mechanical Hazards and Machine SafeguardingDokument29 SeitenMechanical Hazards and Machine SafeguardingVam ArmodiaNoch keine Bewertungen

- EAC CodesDokument2 SeitenEAC CodesRupal Fadia100% (1)

- 4.1.crude Oil Tank Fire Caused by LightningDokument6 Seiten4.1.crude Oil Tank Fire Caused by LightningYonathan EvanNoch keine Bewertungen

- Sources of Supply Chain Disruptions, PDFDokument38 SeitenSources of Supply Chain Disruptions, PDFUmang SoniNoch keine Bewertungen

- Republic Act No 7920Dokument3 SeitenRepublic Act No 7920Ako Si Goldie100% (1)

- HSE Risk Assessment ScribdDokument12 SeitenHSE Risk Assessment Scribdraju_kolapuramNoch keine Bewertungen

- P. Kumar Mechanical EngineerDokument50 SeitenP. Kumar Mechanical EngineerPravin KumarNoch keine Bewertungen

- Calculation of Duct SizingDokument7 SeitenCalculation of Duct SizingPhyu Mar Thein KyawNoch keine Bewertungen

- Qms/Quality Manual: Student: José Raúl Martínez Lara Teacher: Ricardo Ramirez AguilarDokument6 SeitenQms/Quality Manual: Student: José Raúl Martínez Lara Teacher: Ricardo Ramirez AguilarJosé MartínezNoch keine Bewertungen

- 273 Environmental Impact IevaluacionDokument95 Seiten273 Environmental Impact IevaluacionDiego SanchezNoch keine Bewertungen

- Penetration FirestoppingDokument8 SeitenPenetration FirestoppinginstrengNoch keine Bewertungen

- Module 3 Revision: Energy Audit AssignmentDokument22 SeitenModule 3 Revision: Energy Audit AssignmentSanchitNoch keine Bewertungen

- Environmental Law, Ethics and Social ResponsibilityDokument28 SeitenEnvironmental Law, Ethics and Social ResponsibilityaiynaNoch keine Bewertungen

- Flexpipe PDS FlexCord EnglishDokument2 SeitenFlexpipe PDS FlexCord EnglishpsycopaulNoch keine Bewertungen

- Historical Perspective of Six SigmaDokument15 SeitenHistorical Perspective of Six Sigmapadma_poornimaNoch keine Bewertungen

- InspectDokument6 SeitenInspectHaleemUrRashidBangash100% (1)

- Concrete ToppingDokument8 SeitenConcrete ToppingStraus WaseemNoch keine Bewertungen

- FSM 004 Internal Auditor For FamiQSDokument1 SeiteFSM 004 Internal Auditor For FamiQSSmdharwnNoch keine Bewertungen

- As 4696-2007 Hygienic Production and Transportation of Meat and Meat Products For Human ConsumptionDokument9 SeitenAs 4696-2007 Hygienic Production and Transportation of Meat and Meat Products For Human ConsumptionSAI Global - APACNoch keine Bewertungen

- BOSH, COSH and SPIES Invitation For April-May 2015Dokument6 SeitenBOSH, COSH and SPIES Invitation For April-May 2015robinrubinaNoch keine Bewertungen

- Synerquest 2013 Updated Profile Ver2Dokument10 SeitenSynerquest 2013 Updated Profile Ver2Robin RubinaNoch keine Bewertungen

- Earthquake Building Emergency AssessmentDokument10 SeitenEarthquake Building Emergency AssessmentCraig DaltonNoch keine Bewertungen

- SMR Sample RMMDokument9 SeitenSMR Sample RMMReymond IgayaNoch keine Bewertungen

- Brochure HIRACDokument2 SeitenBrochure HIRACaentiliNoch keine Bewertungen

- Marketing-Logistics VDokument14 SeitenMarketing-Logistics VABHISHEK100% (1)

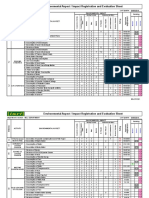

- Environmental Aspect / Impact Registration and Evaluation SheetDokument3 SeitenEnvironmental Aspect / Impact Registration and Evaluation SheetrewrtegamingNoch keine Bewertungen

- RESUME CV Tabeti Abdelkader English 2017Dokument11 SeitenRESUME CV Tabeti Abdelkader English 2017Habib TabetiNoch keine Bewertungen

- Pro-Forma Proponent Compliance Monitoring Report (CMR) : Semi-Annual Module 5 of SMRDokument4 SeitenPro-Forma Proponent Compliance Monitoring Report (CMR) : Semi-Annual Module 5 of SMRekweriNoch keine Bewertungen

- DocumentNew1 1Dokument22 SeitenDocumentNew1 1Rifath100% (1)

- Energy Forms Lesson 2Dokument45 SeitenEnergy Forms Lesson 2DomsNoch keine Bewertungen

- AO 2020-0031 Revised Rules and Guidelines For The Accreditation of LDWADokument38 SeitenAO 2020-0031 Revised Rules and Guidelines For The Accreditation of LDWAGluztavelle MercadoNoch keine Bewertungen

- 5S Principle of HousekeepingDokument20 Seiten5S Principle of HousekeepingAnonymous i3lI9MNoch keine Bewertungen

- OHSMS Manual v1.0Dokument9 SeitenOHSMS Manual v1.0Vignesh NayamozhiNoch keine Bewertungen

- AO1788-0108 Plant SafetyDokument2 SeitenAO1788-0108 Plant SafetycontrerasjhowayneNoch keine Bewertungen

- Gauche : Airconditioning ServicesDokument22 SeitenGauche : Airconditioning ServicesEvonne LeeNoch keine Bewertungen

- SOPI - Individual Membership FormDokument1 SeiteSOPI - Individual Membership FormJovn BorjaNoch keine Bewertungen

- Erp Ntu PDFDokument33 SeitenErp Ntu PDFEdmund YoongNoch keine Bewertungen

- Module 1-C Emergency PreparednessDokument9 SeitenModule 1-C Emergency PreparednessRobin RubinaNoch keine Bewertungen

- Brick MasonryDokument10 SeitenBrick Masonryjack.simpson.changNoch keine Bewertungen

- Special Masonry RestorationDokument4 SeitenSpecial Masonry Restorationjack.simpson.changNoch keine Bewertungen

- Protection Padding SystemDokument5 SeitenProtection Padding Systemjack.simpson.changNoch keine Bewertungen

- Sheet Metal RoofingDokument5 SeitenSheet Metal Roofingjack.simpson.changNoch keine Bewertungen

- Concrete RehabilitationDokument5 SeitenConcrete Rehabilitationjack.simpson.changNoch keine Bewertungen

- Cut StoneDokument7 SeitenCut Stonejack.simpson.changNoch keine Bewertungen

- Construction Manager Personnel Assignment Form: Agreed OnDokument1 SeiteConstruction Manager Personnel Assignment Form: Agreed Onjack.simpson.changNoch keine Bewertungen

- Electric Hand DryersDokument2 SeitenElectric Hand Dryersjack.simpson.changNoch keine Bewertungen

- Wall and Corner GuardsDokument2 SeitenWall and Corner Guardsjack.simpson.changNoch keine Bewertungen

- Neoprene Emulsion FlooringDokument7 SeitenNeoprene Emulsion Flooringjack.simpson.changNoch keine Bewertungen

- Metal Fabrications MechanicalDokument4 SeitenMetal Fabrications Mechanicaljack.simpson.changNoch keine Bewertungen

- Open Web Steel Joists KSeriesDokument5 SeitenOpen Web Steel Joists KSeriesjack.simpson.changNoch keine Bewertungen

- Crack Repairs by Epoxy InjectionDokument6 SeitenCrack Repairs by Epoxy Injectionjack.simpson.changNoch keine Bewertungen

- Tile Backer BoardDokument1 SeiteTile Backer Boardjack.simpson.changNoch keine Bewertungen

- Aluminum Combination Storm and Screen WindowsDokument4 SeitenAluminum Combination Storm and Screen Windowsjack.simpson.changNoch keine Bewertungen

- Security Roof ScuttleDokument4 SeitenSecurity Roof Scuttlejack.simpson.changNoch keine Bewertungen

- Composite Sectional Overhead DoorsDokument8 SeitenComposite Sectional Overhead Doorsjack.simpson.changNoch keine Bewertungen

- Folding DoorsDokument4 SeitenFolding Doorsjack.simpson.changNoch keine Bewertungen

- Opaque Exterior Wall ResurfacingDokument3 SeitenOpaque Exterior Wall Resurfacingjack.simpson.changNoch keine Bewertungen

- Building InsulationDokument6 SeitenBuilding Insulationjack.simpson.changNoch keine Bewertungen

- Fire Stopping Mechanical and ElectricalDokument7 SeitenFire Stopping Mechanical and Electricaljack.simpson.changNoch keine Bewertungen

- 2010 Code Compliance Review Checklist: OGS Project NoDokument8 Seiten2010 Code Compliance Review Checklist: OGS Project Nojack.simpson.changNoch keine Bewertungen

- 085663SteelDetentionWindows HotRolledFramingDokument11 Seiten085663SteelDetentionWindows HotRolledFramingjack.simpson.changNoch keine Bewertungen

- Plastic Simulated WoodDokument7 SeitenPlastic Simulated Woodjack.simpson.changNoch keine Bewertungen

- Long Span Steel Joints LHSeriesDokument6 SeitenLong Span Steel Joints LHSeriesjack.simpson.changNoch keine Bewertungen

- Mortar and Masonry GroutDokument3 SeitenMortar and Masonry Groutjack.simpson.changNoch keine Bewertungen

- Aluminum Combination Storm and Screen WindowsDokument4 SeitenAluminum Combination Storm and Screen Windowsjack.simpson.changNoch keine Bewertungen

- SECTION 083323 Rolling Doors Part 1 General 1.01 Related Work Specified ElsewhereDokument10 SeitenSECTION 083323 Rolling Doors Part 1 General 1.01 Related Work Specified Elsewherejack.simpson.changNoch keine Bewertungen

- Strength of Concrete Containing Basalt Fibre: Parvez Imraan Ansari, Rajiv ChandakDokument5 SeitenStrength of Concrete Containing Basalt Fibre: Parvez Imraan Ansari, Rajiv ChandakPathipati NarasimharaoNoch keine Bewertungen

- Innovations in Manufacturing of Flexible PackagingDokument8 SeitenInnovations in Manufacturing of Flexible PackagingMesbaul RatulNoch keine Bewertungen

- Manual Aire Acondicionado HaierDokument48 SeitenManual Aire Acondicionado Haierjguerrero.067100% (3)

- Hipon 20 DechloDokument3 SeitenHipon 20 DechloLopez GardoNoch keine Bewertungen

- Batchflux 5015 C: Electromagnetic Flowmeter For Volumetric Filling and BatchingDokument8 SeitenBatchflux 5015 C: Electromagnetic Flowmeter For Volumetric Filling and BatchingavikbhaiNoch keine Bewertungen

- RT 1 HowCastDokument5 SeitenRT 1 HowCastAboody WahdainNoch keine Bewertungen

- A-16-1-0028-K-050b - Chiller-House - Plan View - 20170303Dokument1 SeiteA-16-1-0028-K-050b - Chiller-House - Plan View - 20170303Danur RiswantoNoch keine Bewertungen

- Saw SoldaduraDokument17 SeitenSaw SoldaduraAnselmo C. RamirezNoch keine Bewertungen

- Product Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryDokument2 SeitenProduct Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryCristina CoceasuNoch keine Bewertungen

- History of The Development of Cement and Concrete (Non-HydraulicDokument2 SeitenHistory of The Development of Cement and Concrete (Non-HydraulicourebooksNoch keine Bewertungen

- Module SEPAM GeneralitiesDokument34 SeitenModule SEPAM Generalitiesmagrinraphael100% (1)

- DES-WA50 Manual V04VNAI0531Dokument24 SeitenDES-WA50 Manual V04VNAI0531Distrimar LimitadaNoch keine Bewertungen

- El FF TD 01Dokument2 SeitenEl FF TD 01Masood Alam FarooquiNoch keine Bewertungen

- Range of Flocculants and Caogulants For Water and Wastewater TreatmentDokument6 SeitenRange of Flocculants and Caogulants For Water and Wastewater Treatmentginga716Noch keine Bewertungen

- Monthly Test ScienceDokument4 SeitenMonthly Test ScienceDholly Dampil EspinosaNoch keine Bewertungen

- Solvay's Ammonia Distillation ProcessDokument18 SeitenSolvay's Ammonia Distillation ProcessWaleed KhanNoch keine Bewertungen

- 5PS 04 Parts ListDokument48 Seiten5PS 04 Parts Listkari6uskaliNoch keine Bewertungen

- Manesty DistillationDokument15 SeitenManesty DistillationGaurav Sharma0% (1)

- Temperature MeasurementDokument70 SeitenTemperature MeasurementMGHIRBI HAYKELNoch keine Bewertungen

- Hydro Test ProcedureDokument17 SeitenHydro Test Procedureyaser elgoharyNoch keine Bewertungen

- Forc106 - Module 8 NewDokument9 SeitenForc106 - Module 8 Newkimberlyn odoñoNoch keine Bewertungen

- Technical DocumentsDokument3 SeitenTechnical DocumentsRaluca MutuNoch keine Bewertungen

- Evaporation EvaporatorsDokument11 SeitenEvaporation EvaporatorsOhad CazesNoch keine Bewertungen

- Reverse Osmosis SystemsDokument1 SeiteReverse Osmosis SystemsNaresh KhubaniNoch keine Bewertungen