Beruflich Dokumente

Kultur Dokumente

7 2th Semester Pump-Operator Cum Mechanic

Hochgeladen von

Yuvaraj ChinthOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

7 2th Semester Pump-Operator Cum Mechanic

Hochgeladen von

Yuvaraj ChinthCopyright:

Verfügbare Formate

Draft Syllabus

On

(2nd semester)

Pump Operator cum Mechanic

(Automobile Trade)

Under Craftsmen Training Scheme (CTS)

Revised in

2011

By

Government of India

Ministry of Labour & Employment (DGE&T)

Advanced Training Institute

CTI Campus, Guindy, Chennai 600 032

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

1

2

3

Name of the Trade

N.C.O. Code No.

Entry Qualification

4

5

Unit size

Duration of

Craftsmen Training

6

7

Space requirement

Power requirement

Page 2 of 13

Pump Operator cum Mechanic

Essential : Passed 10th class examination under

10+2 system of education or its equivalent.

16 trainees

6 month 2nd semester ( 1 year Duration)

6 (Sq. Mtrs / Trainee)

8 kw

General Information

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

Page 3 of 13

List of members attended the Trade Committee Meeting for revision of syllabus for

Automobile Trade under Craftsmen Training Scheme (CTS)

Sl.

No.

Name & Designation

Representing Organisation

Remarks

Shri R. Senthil Kumar, Director

ATI, Chennai

Chairman

Shri S.Harinath Babu, Joint Director of Training

ATI, Chennai

Member

Shri E.Balakrishna, Ex_ Joint Director of Training

NIMI, Chennai

Member

Shri A.Suganthan, Assistant Training Officer

Govt, ITI, Arakkonam

Member

Shri N. Ramesh Kumar, Training Officer

CTI, Chennai

Member

Shri T Nandagopal,

Anna University, Chennai

Member

Shri K. Thaniyarasau, Assistant Training Officer

Govt . ITI, Trichy

Member

Shri P.K. Ramakrishnan Nair

Ram international Industrial

Academy (p) Ltd, Chennai

Member

Shri S.Arul Selvan, Assistant professor

Dept Auto Engg, M.I.T, Anna

University, Chennai.

Member

10

Shri R. Lakshmanan

Bosch Ltd, Bangalore

Member

11

Shri S. Jayaraj, Associate Professor

Dept Auto Engg, M.I.T, Anna

University, Chennai.

Member

12

Shri V.ChandraMohan

NATRIP, Global Automotive

Research centre, Chennai

Member

13

Shri V.Vadivelan

NATRIP, Global Automotive

Research centre, Chennai

Member

14

Shri A.D.Shewale Training Officer

CTI, chennai

Member

15

Shri B. Gridharan

Visa Diesel Service, Chennai

Member

16

Shri K.k.Valasarajan , Vice president

Two Wheeler workshop owners

Association, Chennai

Member

17

Shri Jayapal,

Two Wheeler workshop owners

Association, Chennai

Member

18

Shri V. Vadivelan

Two Wheeler workshop owners

Association, Chennai

Member

19

Shri Syedshwath

Two Wheeler workshop owners

Association, Chennai

Member

20

P. Marveldass, Assistant Director of Training

(Electronics)

ATI, Chennai

Member

21

K. ArulSelvi, Training Officer (Electronics)

ATI, Chennai

Member

22

Shri Gurcharan Singh, Assistant Director of Training

ATI, Ludhiana

Member

23

Shri O.R. Arjun Mohan, Assistant Executive Engineer

Agricultural Engg Dept,Chennai

Member

24

Shri R.Murugesan, Assistant Executive Engineer

Agricultural Engg Dept,Chennai

Member

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

Page 4 of 13

25

Shri Ramakrishne Gowda, Assistant Director of Training

FTI, Bangalore

Member

26

C.Yuvaraj, Assistant Director of Training

ATI, Chennai

Member

2nd semester

Pump Operator Cum Mechanic

On completion of this module, the trainee should be able to:

Know the different type of keyways, preparing keys to fit into keyways.

Identifying, selecting, use of different types of ropes.

Use of different types lifting tackles both mechanical and hydraulic.

Removal of bearings from s h a f t s & housing by using pullers.

Dismantling and assembling of reciprocating pumps, rotary pumps, centrifugal pumps,

Identifying and rectifying defects of pump sets.

Practice on preventive & scheduled maintenance of pump sets.

Building up of electrical series, parallel and combination of series & parallel circuits.

Identifying of A.C motors, their testing.

Trouble shooting for diesel engines & its component and their repairing

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

Duration

6 Month

Week

Trade Theory

NO.

1

Types of key and key ways, their uses

and applications. Preparation of keys,

allowable tolerance, clearances. Key

fitting procedure-methods. Procedure

for removing keys. Types & uses of

key pullers.

Practical

Identifying, selecting, use

of different types of ropes

such as hemp, manila,

nylon, wire etc.

Practicing different types

of

knots

and

its

applications. Method of

joining two ropes,

Together for extension.

Detection

of

unsafe/defective

conditions of ropes and

knots.

Use of different types

lifting tackles both

mechanical and hydraulic

such as

Screw jacks, chain pulley

block, crabs and winches,

rollers and bars, levers,

lashing and packing. Use

of inclined plane,

hydraulic trolleys etc.

Care and maintenance of

lifting equipment and

safety to be observed by

handling the equipment.

Making different types of

keys for fitting pulleys,

Assembling and

dismantling of bushes,

bearings and couplings

maintaining safety.

Specification and use of different types

of ropes such as hemp, manila, nylon,

wire etc. Practicing different types of

knots and its applications.

Method of joining two ropes together

for extension. Detection of

unsafe/defective conditions of ropes

and knots. Specification and correct

use of slings. Safety to be observed in

use of ropes and slings.

Description, operation, purpose,

application, care and use of Different

types of lifting tackles for components

of pump set.

Precaution to be observed while using

lifting tackles.

Types of pulleys solid, split, V

groove, step, cone, taper, guided and

jockey or rider pulleys, their functions

and uses. Procedure to assemble and

dismantle pulleys and impellers from

shafts following safety precautions

Types of belt drives, velocity ratio of

belt drive. Horse Power transmitted by

belt. Ratio & driving tension in a belt.

Parallel & cross belt drive, open

& cross belt drive, angular belt drive.

Methods of fixing

and uses. Description, types and

Page 5 of 13

Exercise on making out

key as per shaft, hub,

keyways, preparing keys

to fit into keyways.

Familiarization

with

plain/journal

bearings,

anti-friction

bearings

used

on

machine

assembly.

Workshop calculation

and science

Trigonometric system

of measurement of

angle, trigonometric

ration, relation and

formulae. Calculation

on height and

distance calculation

of lapses.

Friction, co-efficient

of friction, angle of

friction, laws of

friction-definition,

explanation &

application

Engineering Dra

Levers, screws jack,

wheel and axle

definition, application

and related shop

problems

Views of simple

hollow and solid

bodies with

dimensions. Use

different types o

lines and symbo

drawings.

Use of drawing

instruments, T-s

and drawing boa

Use of different

of scales in inch

and millimeters

Lettering numbe

alphabet

Explanation of s

Orthographic

projection-lst an

Free hand sketch

of screw jack

Gravity,

acceleration due

to gravity, weight,

centre of gravitydefinition,

explanation

examples and

calculation.

Torque - definition example torque

wrenches application

- problems involving

torque values.

Explanation of s

orthographic

projection 3rd an

Simple isometri

drawings, isome

views of simple

objects, such as

square, rectangle

cubes, rectangul

blocks etc.

Free hand sketch

assembly of pull

Free hand sketch

of bearing with

dimensions from

sample

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

application of bushes, bearing and

couplings. Procedure to fit bushes,

bearings and coupling safely.

Specification

&

selection

for

appropriate

use.

Use

of

manufacturers catalogues.

Mounting of bearing on shafts

and in housing with proper

fit & axis alignment.

Use of proper tools.

Removal of bearings

from s h a f t s & housing

by using pullers.

Cleaning up & removing

old metal form bearing

and replacing with new

metal. Checking of shafts

for alignment with dial

indicator.

Identification of different

pumps, its components,

prime movers. Practice on

operational safety.

Pumps-its importance for agricultural

& industrial applications.

Classification of pumps, its prime

movers, parts and operation safety.

Classification of reciprocating pump,

construction and operation.

Installation technique of reciprocating

pump. Tools and equipment required

& procedure.

Dismantling of

reciprocating pumpsvalves, pistons, cranks,

seals etc. for inspection,

repair & replacement.

Cleaning of parts &

assembling. Installing of

reciprocating pumps.

Classification of rotary pumpsConstruction and operation- repairing

procedure. Brief description of turbine

& stage pumps, positive displacements

and their advantages. Meaning of

priming and its effect. Installation

techniques of rotary pump-procedure,

tools and equipments required

Different types of valves-their

description, advantages & use. Special

pumps & glands used for corrosive

fluids. Different gasket cement used to

prevent leakage and advantages of

each over the other. Principle of direct

reading pressure and temperature

Dismantling of rotary

pumps- impeller, shaft,

bearing etc, for inspection,

Repair & replacement.

Cleaning of parts and

assembling. Checking for

alignment, clearance, etc.,

Priming technique and its

application. Installing,

operating & testing of

rotary pumps.

Servicing of pumps and

valves of general purpose

and of corrosive fluids.

Selection of gasket, packing

& gland materials, marking

& cutting off gasket as per

shape & profile. Using

Page 6 of 13

Newtons law of

motion definition

explanation and

related shop problem.

Free hand sketch

of plain and elev

of simple object

hexagonal bar, s

bar, circular bar,

tapered bar, holl

bar etc.

Liquids

properties, units

of measurement

and related

friction.

Measuring of

suction head &

delivery head and

effects of

atmospheric

pressure on them.

Related shop

problem.

Calculation on

repairing and

installation of

rotary pumps.

Free hand sketch

of reciprocating

component.

Pressure measuring

instruments- Brief

description and

method to read. Flow

measuring

instruments- brief

description and

Drawing section

views of geomet

solids hollows w

dimensions.

Free hand sketch

of rotary pump

component

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

measuring instruments. Method to

read and application of pressure and

temperature measuring instruments.

gasket cement to stop

leakage & for fixing

10

Various seals- their use and places of

application with advantages.

Lubrication-types of lubricant use &

methods of lubrication.

11

Various tools and accessories used in

pipe fitting with their details. Use of

protecting caps on threads. Pipe fitting

technique. Procedure to fit flanges &

for leak testing

12

Method of install, align and testing of

pumps for their serviceability. Concept

of lightening torque for different sizes

of bolts.

13

Principle of centrifugal pump.

Construction and operation of

centrifugal pump in series and parallel.

Finding out defects and method to

recondition centrifugal pump.

Installation of seals leather

polythene, asbestos, rope

rubber and mechanical

seals. Maintenance of

lubrication systems.

Fitting of flanges and

assembling of pipe work,

leak testing and

rectification. Use of tee,

elbow, bend, socket,

rectifiers and other pipe

fittings. Cutting threads

for pipes.

Installation of stationary &

coupled pumps, checking

and correcting of

alignment of pump with its

prime movers and its

serviceability test. Testing

of pumps for their delivery

flow & pressure.

Reconditioning of

centrifugal pumps.

14

Submersible pump- construction,

operation and selection of appropriate

type. Procedure to recondition, install

and test of submersible pumps. Causes

of failures and remedial measures.

15

&

16

Defects in pump sets- procedure for

detection of causes & rectification.

Purpose and procedure for balancing

of rotor. Procedure to be followed for

preventive & scheduled maintenance,

planning for spares and other stores.

17

Safety rules to be followed in

connection with electrical work. First

aid when affected by electrical shock.

Purpose, types, description and

method to use common electrical hand

tools.

Page 7 of 13

method to read, level

measuring

instruments- Brief

description and

method used to read,

related calculations.

-do-

Different type of

seal materials and

its application.

Calculation on the

cost of installation

and repairing of

stationary &

coupled pumps.

Free hand sketch

the precision

instruments rela

the trade.

Views of simple

and hollow bodi

by section plane

-do-

Calculation on the

cost of installation

and repairing of

centrifugal

pumps.

Free hand sketch

of centrifugal pu

component.

Dismantling identifying of

parts, finding out defects,

repairing, and replacement

of components, cleaning,

assembling, installing and

testing of submersible

pumps. Finding out &

rectifying faults developed

during operation.

Identifying and rectifying

defects of pump sets.

Practice on preventive &

scheduled maintenance of

pump sets.

Calculation on the

cost of installation

and repairing of

Submersible pump.

Free hand sketch

of Submersible p

component.

Concept of

condition

monitoring

system.

Prepare a schedu

maintenance cha

Familiarization with the

safety precautions to be

followed for electrical

work. Treatment for

electrical shock. Use of

hand tools connected with

electrical work and

maintenance of electrical

machines.

Definition and

explanation of

matter molecule,

atom, electron and

flow of electric

current,

conductors,

insulators and

semi conductors.

Views of simple

and hollow bodi

by section plane

Drawing of elec

symbol as per

IS:1248

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

18

19

20

21

Description and method to use current,

voltage and resistance measuring

instruments and precaution to be

taken. Insulation Tester- description,

method to use and precautions to be

taken. Alternating current- Definition

explanation and advantages over.

Direct current and vice-versa. Concept

and application of phase, star and delta

connection. Procedure to identify live,

neutral, single phase and 3-phase

power supply. Method to measure

power and energy consumed by

electrical appliances using wattmeter

and Energy meter.

AC Motors related terminology.

Purpose, type, construction, operation,

testing for correct functioning,

maintenance and industrial

applications. Trouble shooting &

protection of induction motor.

-Do-

Principle of Compression-ignition

engine, Spark Ignition Engine,

differentiate between 4-stroke and 2

stroke, C.I engine and S.I Engine, Otto

cycle and Diesel cycle.

Different type of starting and stopping

method of Diesel Engine.

Engine output; Power range

Verification of Ohms law.

Building up of electrical

series, parallel and

combination of series &

parallel circuits.

Measurement of current,

voltage resistance.

Exercise on fixing and

connecting switches

holders, fuses, plugs

sockets, Push buttons, etc.

Use of test lamp and neon

tester. Identification of

live, neutral and earthling

wires. Measurement of

electrical power and

energy consumed for a

definite period of time.

Identifying of A.C motors,

their testing, identifying

terminals, connecting

running & reversing.

Measuring speed of A.C

motor using tachometer

with stop watch.

Dismantling, assembling

of A.C motors &

identification of parts.

Starting a single phase A.C

motor with Direct on line

(D.O.L) starter. Starting a

3 phase motor with stardelta starter. Checking for

proper running of motor,

overheating etc.

maintenance of motors use

and connection of single

phase preventor trouble

shooting in circuit.

Familiarisation with diesel

engines, tools and

equipment required for

maintenance, engine parts

and their handling

technique. Starting and

stopping of engines.

Running of engines and

checking temperatures,

fuel oil pressure and

consumption on load and

engine speed.

Page 8 of 13

Definition,

application &

calculation on ohms

law, series, parallel

and combination

circuits.

Electrical- Serie

parallel and

combination circ

with BIS symbo

Definition and

explanation of work,

power, energy. Simple

calculation to

determine electrical

power of electrical

appliance and energy

consumed by an

electrical circuit for a

definite period of

time and different

loading.

Magnets Properties,

types, molecular

theory and method to

induce magnetic

properties.

Electromagnetic

induction and electro

magnet.

Electrical circ

diagram

connecting A

motors.

Calculation of Horse

Power IHP, FHP and

applied shop problem

Free hand sketch

of of 4 stroke cy

& 2 stroke cycle

engine

Electrical circui

connecting watt

& Energy meter

Reading of the c

diagram of elect

circuits.

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

22

Procedure to clean fuel tank & check

leak in the fuel line. Lubrication

system types, description and

advantages of each over others. Filters

and oil coolers their description

functions and method to overhaul for

efficient functioning.

Cleaning of fuel tank,

checking leaks in the fuel

lines. Cutting, flaring of

tubes to make T & Elbow

fitting using unions.

Fitting of lubrication pump

oil filters, air filters,

checking and adjusting of

oil pressure. Preventive

maintenance & repairing.

2324

Common troubles in diesel engines

and their remedies. Method to be

followed to assure quality servicing.

Ecological consideration & pollution

control.

Trouble shooting for diesel

engines & its component

and their repairing

2526

Revision and test

Page 9 of 13

Heat and temperature

definitions,

difference effects of

heat, temperature

scales and related

calculations.

Transmission of HeatMethods & examples.

Co-efficient of linear

expansion of solids.

Definition &

calculation

Abscissa, ordinates,

graphs of straight line

related of two sets of

varying qualities.

Exercises on blu

print reading.

Reading, interpr

& practicing

engineering draw

for identification

surfaces & edge

finish tolerance

allowance, study

assembly drawin

pumps.

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

Page 10 of 13

Second semester

List of Tools and Equipments for the trade of

Pump Operator cum Mechanic

Sl.No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Name of the Tools & Equipment

Steel rule 15 cm inch and metric

Steel rule 30 cm inch and metric

Steel measuring tape 10 meter in a case

Try Square 10 cm Blade

Calipers outside 15 cm spring

Caliper inside 15 cm Spring

Dividers 15 cm Spring

Scriber 15 cm

Knife double Blade Electrician

Wire insulation Stripper for shinning conductors from 0.4mm to 4mm

Electrician testing Pencil (Line / Neon tester)

Electrician Screw Driver 250mm

Centre punch 10 cm.

Chisel cold flat 20 mm x 150 mm

Hammer ball peen 0.5 kg with handle

Screw driver 20cm.X 9mm. Blade

Screw driver 30 cm. X 9 mm. Blade

Spanner D.E. set of 12 pieces (6mm to 32mm)

Pliers combination 20 cm.

Pliers side cutting 15 cm

Pliers round nose 15 cm

Pliers flat nose 15 cm

Hands file 20 cm. Second cut flat

Hand file 20 cm. Second cut half-round

Hand file 20 cm. smooth triangular

Hand file 30 cm. bastard

Hand file 30 cm. round bastard

File card or cleaner

Wire cutter and stripper

Steel tool box with lock and key (folding type) 400x200x150 mm

Tools Instruments and General Shop outfits

Quantity

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

16+1

31

Adjustable micrometer sprit level to measure flatness, indication and

taper with prismatic measuring base

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

Vernier caliper A 200 with inside and depth measurement

Telescope gauge

Surface gauge with dial test indicator plunger type i.e. 0.01 mm

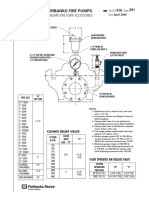

Vacuum gauge to read 0 to 760 mm of Hg.

Pressure gauge 0 -5 Kg/cm2

Flow meter 0-400 lt/min

Temperature Gauge 0-100 Deg C

Marking Material (Consumable)

Electric testing screw driver

Allen Key set of 12 pieces (2mm to 14mm)

Spanner, adjustable 15cm.

Spanners socket with speed handle, T-bar, ratchet and universal upto 32

mm set of 28 pieces with box

Adjustable spanner (pipe wrench 350 mm)

Spanner, ring set of 12 metric sizes 6 to 32 mm.

Spanner T. flocks for screwing up and up-screwing inaccessible

positions

Spanner Clyburn 15 cm

Magneto spanner set with 8 spanners

Spirit level 2V 250, 05 metre

Torque wrenches 5-35 Nm, 12-68 Nm & 50-225 Nm

Universal puller for removing pulleys, bearings

Radius Gauge, Metric

Voltmeter AC to 500 V

Ammeter AC 0 to 50 A

Wattmeter AC/DC, 0 to 10 Kw

Energy meter, AC, Single Phase, 5 Amps, 230 Volts

Megger 500 V

Digital Tonge Tester 0-20 A AC

Single Phase 220 V Capacitor type AC Meter squirrel gage Induction

motor

Three Phase 50 Hz, 5 HP AC squirrel gage induction motor with star

delta starter

DC Ohmmeter 0 to 300 Ohms, mid scales at 20 Ohms

Electric Soldering Iron 230 V 60 watts 230 V 25 watts

Copper bit soldering iron 0.25 Kg

Thimbles of different sizes

Wire Gauge (metric)

Hand operated crimping tool (i) for crimping up to 4mm and (ii) for

crimping up to 10mm

Hand rubber gloves tested for 5000 V

Holders, lamp teakwood boards, plug sockets, solders, flux wires and

cables batteries round consumable blocks and other consumables as

required

Multimeter digital

Scientific Calculator

Hydrometer

High rate discharge tester (cell tester)

Bradawl

Rawl plug tool & kit

Masonary bit (Assorted up to 12 mm)

Hand key way broacher

Page 11 of 13

2

1

2

1

2

2

2

As required

2

2

2

2

2

2

2

1

1 set

2

1 each

1

2

2

2

2

2

2

2

1

1

1

2 each

5

2

2

2

5 pair

As required

2

1

2

2

2

2set

2sets

1

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

Manila ropes 12, 20, 30 mm dia.

Pipe wrench 45 mm

Chain pipe wrench 65 m

Self alignment roller ball bearing

Vibrometer

Flow detector (magnetic crack detector)

Engg. Stethoscope

Pin spanner set

Bearing and gear tester

Pneumatic scraper with adjustable stroke

Hydraulic wheel and bearing puller

Master test bars (different size)

Level bottle (sprit) 150 ml.

Three cell torch

Bar type torque wrench

Cam lock type screw driver

Flaring tool

Tube expander up to 62 mm

Adjustable micrometer sprit level to measure flatness, indication and tape

with prismatic

measuring

Screw jacksbase

Hand operated chain pulley block

crab

Forks clips 02 tonnes (copa)

Forks clips 05 tonnes (copa)

Crow bar

Rollers (steel tubes) from 40 to 65 mm dia.

Block of timber (various sizes)

Portable jack

Carge winches 3, 5 tonnes

Wall hoists

Travelling and gantry cranes

Shear legs (tripod)

Mobile crank

Ratchet chain pulley

Foundation bolt

Plumb bob

Square box wrenches

Square T-wrenches

Engineers square 700 mm

Threaded fastener type B

Threaded fastener type C

Threaded fastener type F

SRDG ball bearing, DRDG ball bearing, self aligning ball bearing,

SRAC ball bearing,

needle bearing, single raw cylindrical roller bearing, tapered roller

bearing, plain bush bearing, thin walled bearing.

120 Universal puller for removing pulleys, bearings

121 Rotary pump working for dismantling and assembling

Page 12 of 13

1 each

2

2

2

2

1

2

2

2

2

2

1 set

1

1

1

1

1

1 set

1

1

1

1

1

1

2

5

5

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1 each

1

1

Automobile Trade_ Pump Operator cum Mechanic_2nd semester

122 Gasket material (consumable)

123 Gasket hollow punches 5, 6, 8, 10, 12, 19, 25 mm dia.

124 Various type of seal required for pump assembly (consumable)

General Machinery / Installation

125 Reciprocating Pump

127 Reciprocating Pump working for dismantling and assembling

128 Hydraulic Leak Testing equipment

129 Centrifugal pump coupled with mono block set

130 Back pull out type centrifugal pump

131 Horizontal split casing pump

132 Multi stage pump

133 Submersible pump set, eight stage upto 10 KW/ 15 HP

134 Overhead tank, pump, minimum 5000 litres with level indicators and

135 piping

Diesellayout

engine 2 stroke vertical (up to 10 KW/ ISHP)

136 Diesel Engine 4 stroke vertical (up to abouit 10 KW/ISHP)

137 Diesel Engine upto 3.5 KW /4.5 HP fitted with pump

138 Diesel Engine Driven portable pump set

139 Injector Testing set (Hand Tester)

140 Trolley type portable air compressor single cylinder with 45 liters

capacity Air

tank, along

withpurpose)

accessories

with working

pressure

141 Grinding

machine

(general

D.E.&pedestal

with 300

mm 6.5

dia

rough

and

smooth

142 wheels

Portable electric drill Machine

143 Spring tension tester

Sl.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10

11

12

13

14

15

Class Room/ Workshop Furniture

Suitable class room furniture

Suitable Work Tables with vices

Stools

Discussion Table

Tool Cabinet

Trainees locker

Fire Extinguishers, first- aid box

Book shelf (glass panel)

Storage Rack

Storage shelf

LCD projector

Multimedia CD for Automotive application

Desktop computer and related MS office software

Online UPS 2KVA

Laser printer

Page 13 of 13

As required

1 each

As required

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Quantity

As required

As required

As required

1 No.

2 Nos. to accommodate 20 lockers

2 Nos.

As required

1 No.

As required

As required.

1 no

As required

4 No

1 No

1 No

Das könnte Ihnen auch gefallen

- Types of FurnaceDokument73 SeitenTypes of FurnaceYuvaraj Chinth100% (1)

- OZ Racing Rims: Name Method Size Weight (LBS.) Weight (KGS.)Dokument4 SeitenOZ Racing Rims: Name Method Size Weight (LBS.) Weight (KGS.)ilpupNoch keine Bewertungen

- Machine Guarding PDFDokument133 SeitenMachine Guarding PDFbrsharmaNoch keine Bewertungen

- Six Sigma Green Belt Training Statistical Self Assessment ToolDokument5 SeitenSix Sigma Green Belt Training Statistical Self Assessment Toolashutoshsingh2302Noch keine Bewertungen

- Models, Databases, and Simulation Tools Needed For The Realization of Integrated Computational Materials Engineeriing 2011 ASM International PDFDokument205 SeitenModels, Databases, and Simulation Tools Needed For The Realization of Integrated Computational Materials Engineeriing 2011 ASM International PDFLuisGuzmanNoch keine Bewertungen

- DAF Superstructures BodyBuilders - GuideDokument34 SeitenDAF Superstructures BodyBuilders - GuideЮлия Дам100% (1)

- ASTM 6365 - 99 - Spark TestDokument4 SeitenASTM 6365 - 99 - Spark Testjudith_ayala_10Noch keine Bewertungen

- Chapter IDokument74 SeitenChapter Ihoney mae100% (1)

- Troubleshooting of Rotating EquipmentsDokument4 SeitenTroubleshooting of Rotating Equipmentss33d_2010Noch keine Bewertungen

- Multicrop Harvesting MachineDokument9 SeitenMulticrop Harvesting MachineIJRASETPublicationsNoch keine Bewertungen

- Aspen Plus Model For Moving Bed Coal GasifierDokument30 SeitenAspen Plus Model For Moving Bed Coal GasifierAzharuddin_kfupm100% (2)

- Productivity and Reliability-Based Maintenance Management, Second EditionVon EverandProductivity and Reliability-Based Maintenance Management, Second EditionNoch keine Bewertungen

- Shree Nidhi EngineersDokument4 SeitenShree Nidhi EngineersVenkteshwarlu KNoch keine Bewertungen

- RTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TDokument27 SeitenRTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TxaloliNoch keine Bewertungen

- Product Design Project Report On Device To Aid Outdoor CleaningDokument23 SeitenProduct Design Project Report On Device To Aid Outdoor CleaningNajiNoch keine Bewertungen

- Gujarat Technological University: W.E.F. AY 2018-19Dokument3 SeitenGujarat Technological University: W.E.F. AY 2018-19Bhavesh Patel100% (1)

- Fldbee 01Dokument12 SeitenFldbee 01Halim Bessouf100% (2)

- A ProjectDokument14 SeitenA Projectajay0% (1)

- Project Report On Front Axle Beam and Stub AxleDokument9 SeitenProject Report On Front Axle Beam and Stub AxleEIRI Board of Consultants and PublishersNoch keine Bewertungen

- Submitted By: An Internship Project ReportDokument94 SeitenSubmitted By: An Internship Project Reportaastik bhatnagarNoch keine Bewertungen

- B.tech. Syllabus AE With Short NotesDokument64 SeitenB.tech. Syllabus AE With Short NotesAryan KumarNoch keine Bewertungen

- Bottle Filling and Capping Using Geneva MechanismDokument5 SeitenBottle Filling and Capping Using Geneva Mechanismabubeker muhamedNoch keine Bewertungen

- Water For Production Regional Centre Eastern (Wfprc-E) Aodi Naboth Busitema University Faculty of Engineering Week 2Dokument7 SeitenWater For Production Regional Centre Eastern (Wfprc-E) Aodi Naboth Busitema University Faculty of Engineering Week 2Aodi NabothNoch keine Bewertungen

- Training Experience at GAILDokument2 SeitenTraining Experience at GAILShyamSundarNoch keine Bewertungen

- Vertical Axis Wind TurbineDokument18 SeitenVertical Axis Wind TurbineKiran SaipolaNoch keine Bewertungen

- Design and Analysis of Drum Brake: Dr. Kodathalapalli SudheerDokument15 SeitenDesign and Analysis of Drum Brake: Dr. Kodathalapalli SudheerThalari VijayarajNoch keine Bewertungen

- Moltres Ppt. For Esvc-2014Dokument16 SeitenMoltres Ppt. For Esvc-2014pankajNoch keine Bewertungen

- NPTEL - Electrical Engineering - Introduction To Hybrid and Electric VehiclesDokument1 SeiteNPTEL - Electrical Engineering - Introduction To Hybrid and Electric VehiclesAshutosh TrivediNoch keine Bewertungen

- AT6501 (R-13) Notes PDFDokument131 SeitenAT6501 (R-13) Notes PDFAashiq NawinNoch keine Bewertungen

- Testing of CultivatorDokument33 SeitenTesting of CultivatorEr. Narendra Kumar Yadav100% (1)

- Automated Punching MachineDokument8 SeitenAutomated Punching MachineMohamed IbrahemNoch keine Bewertungen

- Motorized Ramming MachineDokument53 SeitenMotorized Ramming Machineilayaraja6100% (1)

- Green Engine: Presented BY: Akshay Kumar 1203240019Dokument19 SeitenGreen Engine: Presented BY: Akshay Kumar 1203240019Mukhil RajasekaranNoch keine Bewertungen

- Runner Casted-Vs-Microguss Wangdi DDokument0 SeitenRunner Casted-Vs-Microguss Wangdi DsapkotamonishNoch keine Bewertungen

- Attendance NoticeDokument1 SeiteAttendance NoticePavan KhetrapalNoch keine Bewertungen

- Performance Evaluation of An Airfoil Fabricated Through Additive Manufacturing, Using Simulation and Experimental TechniquesDokument15 SeitenPerformance Evaluation of An Airfoil Fabricated Through Additive Manufacturing, Using Simulation and Experimental TechniquesIJRASETPublicationsNoch keine Bewertungen

- First Pages-1 Weeder Project-1Dokument9 SeitenFirst Pages-1 Weeder Project-1Praveen Raja100% (1)

- Consultant Profile - CNPKDokument2 SeitenConsultant Profile - CNPKV.Venkatasubramanian100% (1)

- Chain Drive PresentationDokument20 SeitenChain Drive PresentationRohan KhadeNoch keine Bewertungen

- EIM PPT 1Dokument17 SeitenEIM PPT 1rahul0% (1)

- MT Ii 2 Marks PDFDokument19 SeitenMT Ii 2 Marks PDFParamasivam Veerappan100% (1)

- Pneumatically Actuating Rammer-1596 PDFDokument4 SeitenPneumatically Actuating Rammer-1596 PDFM L PrabhuNoch keine Bewertungen

- Adigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Dokument50 SeitenAdigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Melese HaileNoch keine Bewertungen

- Magneto Abrasive Flow MachiningDokument24 SeitenMagneto Abrasive Flow MachiningArjun M BetageriNoch keine Bewertungen

- Mahindra Gears Transmiision Training ReportDokument32 SeitenMahindra Gears Transmiision Training Reportbestmadeeasy50% (2)

- Flange Coupling Lab PDFDokument25 SeitenFlange Coupling Lab PDFAli Raza MalikNoch keine Bewertungen

- Weeder SynopsisDokument8 SeitenWeeder SynopsisParas ChauhanNoch keine Bewertungen

- A Design of 360 Degree Flexible Drilling MachineDokument26 SeitenA Design of 360 Degree Flexible Drilling MachineSai RamNoch keine Bewertungen

- Automatic Tyre Pressure Inflation SystemDokument35 SeitenAutomatic Tyre Pressure Inflation SystemmujeebNoch keine Bewertungen

- OAT751 Production of Automotive Components LTPC 3 0 0 3 ObjectivesDokument2 SeitenOAT751 Production of Automotive Components LTPC 3 0 0 3 ObjectivesMr.Babu T50% (2)

- ANITS PPT On GREEN ENGINEDokument13 SeitenANITS PPT On GREEN ENGINESampath KumarNoch keine Bewertungen

- Parabolic Solar CollectorDokument9 SeitenParabolic Solar CollectorWise manNoch keine Bewertungen

- Inplant Training ReportDokument56 SeitenInplant Training Reportsankey11286Noch keine Bewertungen

- Crompton Greaves IE2 Brochure 5Dokument28 SeitenCrompton Greaves IE2 Brochure 5vikas kansalNoch keine Bewertungen

- IIT Hyderabad Workshop ManualDokument37 SeitenIIT Hyderabad Workshop ManualMadhu PunjalaNoch keine Bewertungen

- Literature Review: Automatic Pneumatic Bumper and Braking SystemDokument10 SeitenLiterature Review: Automatic Pneumatic Bumper and Braking Systemkathir venkatachalamNoch keine Bewertungen

- Design Analysis and Fabrication of Manual Rice Transplanting Machine - J4rv4i1011Dokument5 SeitenDesign Analysis and Fabrication of Manual Rice Transplanting Machine - J4rv4i1011Journal 4 ResearchNoch keine Bewertungen

- Drilling Machine ProjectDokument18 SeitenDrilling Machine ProjectVikas SalveNoch keine Bewertungen

- Design Modification and Structural Analysis of Rotavator Blade by Using Hyperworks 12.0Dokument10 SeitenDesign Modification and Structural Analysis of Rotavator Blade by Using Hyperworks 12.0sapandeep singhNoch keine Bewertungen

- Designof Power Driven Dough Mixing MachineDokument5 SeitenDesignof Power Driven Dough Mixing MachineTewodros B.Noch keine Bewertungen

- Problems With Conventional NCDokument15 SeitenProblems With Conventional NCAbhinav Kumar MishraNoch keine Bewertungen

- Cost Report: Chassis & Body WorksDokument6 SeitenCost Report: Chassis & Body WorksJisselAroraNoch keine Bewertungen

- Fabrication of 360 Angular Drilling MachineDokument28 SeitenFabrication of 360 Angular Drilling MachineDinesh KumarNoch keine Bewertungen

- Kinetic Energy Recovery SystemDokument25 SeitenKinetic Energy Recovery SystemAmeen MNoch keine Bewertungen

- Hybrid Metal Additive ManufacturingDokument75 SeitenHybrid Metal Additive ManufacturingNursultan JyeniskhanNoch keine Bewertungen

- A Seminar Report OnDokument7 SeitenA Seminar Report OnSagar Pandit0% (1)

- A Review On Multi Spindle Drilling Speci PDFDokument3 SeitenA Review On Multi Spindle Drilling Speci PDFAdelina RomanNoch keine Bewertungen

- Final Cits TractorDokument22 SeitenFinal Cits Tractorparveenrathee123Noch keine Bewertungen

- DDO Merge 16.12.2019Dokument2 SeitenDDO Merge 16.12.2019Yuvaraj ChinthNoch keine Bewertungen

- 5 2nd Semester AutotronicsDokument15 Seiten5 2nd Semester AutotronicsYuvaraj ChinthNoch keine Bewertungen

- Adhoc BonusDokument4 SeitenAdhoc BonusSatyanarayan SwainNoch keine Bewertungen

- Cits Et Mmv&Mech DieselDokument7 SeitenCits Et Mmv&Mech DieselYuvaraj ChinthNoch keine Bewertungen

- 9 3th Semester MAM CompleteDokument13 Seiten9 3th Semester MAM CompleteYuvaraj ChinthNoch keine Bewertungen

- CITS Auto MMV TT1Dokument17 SeitenCITS Auto MMV TT1Yuvaraj ChinthNoch keine Bewertungen

- CITS Auto MMV TT2Dokument14 SeitenCITS Auto MMV TT2Yuvaraj ChinthNoch keine Bewertungen

- 8 2 Semester Tractor Mechanic CompleteDokument15 Seiten8 2 Semester Tractor Mechanic CompleteYuvaraj ChinthNoch keine Bewertungen

- 2nd Semester Mech - DieselDokument7 Seiten2nd Semester Mech - DieselYuvaraj ChinthNoch keine Bewertungen

- 2nd Semester Mech - DieselDokument7 Seiten2nd Semester Mech - DieselYuvaraj ChinthNoch keine Bewertungen

- 3rd Semester R M HeavyDokument7 Seiten3rd Semester R M HeavyYuvaraj ChinthNoch keine Bewertungen

- HT M&e 270515Dokument6 SeitenHT M&e 270515Yuvaraj ChinthNoch keine Bewertungen

- Match 62Dokument1 SeiteMatch 62Yuvaraj ChinthNoch keine Bewertungen

- MathsDokument1 SeiteMathsYuvaraj ChinthNoch keine Bewertungen

- 01-Principles of HTDokument5 Seiten01-Principles of HTYuvaraj ChinthNoch keine Bewertungen

- Tailormade Course For Bhel - J&K Trainees (Tech)Dokument5 SeitenTailormade Course For Bhel - J&K Trainees (Tech)Yuvaraj ChinthNoch keine Bewertungen

- Heat Tratment MaintenanceDokument34 SeitenHeat Tratment MaintenanceYuvaraj ChinthNoch keine Bewertungen

- Furnaces and RefractoriesDokument54 SeitenFurnaces and RefractoriesYuvaraj ChinthNoch keine Bewertungen

- Heat Treatment - SafteyDokument4 SeitenHeat Treatment - SafteyYuvaraj ChinthNoch keine Bewertungen

- Hard NessDokument14 SeitenHard NessYuvaraj ChinthNoch keine Bewertungen

- Astentite GrainDokument10 SeitenAstentite GrainYuvaraj ChinthNoch keine Bewertungen

- The Discovery of Blood GroupsDokument6 SeitenThe Discovery of Blood GroupsYuvaraj ChinthNoch keine Bewertungen

- 6h WorksheetDokument5 Seiten6h WorksheetYuvaraj ChinthNoch keine Bewertungen

- Brazing Solutions For Car Body Production+ (EN)Dokument2 SeitenBrazing Solutions For Car Body Production+ (EN)komklaveNoch keine Bewertungen

- GemDokument23 SeitenGemMukesh KumarNoch keine Bewertungen

- Conceptual ModelingDokument24 SeitenConceptual ModelinggellymelyNoch keine Bewertungen

- Module 4-STS Espinas Bsat 1-1Dokument2 SeitenModule 4-STS Espinas Bsat 1-1Joseph Daniel EspinasNoch keine Bewertungen

- Related Learning Experience Journal: Lipa City, BatangasDokument7 SeitenRelated Learning Experience Journal: Lipa City, BatangasushenNoch keine Bewertungen

- MGT 162Dokument2 SeitenMGT 162Myra Choyy100% (1)

- Aksesoris PumpDokument10 SeitenAksesoris PumpDido AlexanNoch keine Bewertungen

- Tesco Shop On The GoDokument3 SeitenTesco Shop On The GoIkram KhokharNoch keine Bewertungen

- QAV - 1.1. Report (Sup1)Dokument2 SeitenQAV - 1.1. Report (Sup1)Rohit SoniNoch keine Bewertungen

- Appexchange Publishing GuideDokument29 SeitenAppexchange Publishing GuideHeatherNoch keine Bewertungen

- Fuzzy LogicDokument27 SeitenFuzzy LogicvibhutiNoch keine Bewertungen

- Thermal Plasma TechDokument4 SeitenThermal Plasma TechjohnribarNoch keine Bewertungen

- Job Miller AbstractDokument5 SeitenJob Miller AbstractTelika RamuNoch keine Bewertungen

- Fire Hydrant - WikipediaDokument9 SeitenFire Hydrant - WikipediaVaibhav SawantNoch keine Bewertungen

- sw8 chp06Dokument22 Seitensw8 chp06api-115560904Noch keine Bewertungen

- Trafo Manual ABBDokument104 SeitenTrafo Manual ABBMarcos SebastianNoch keine Bewertungen

- Ficha Tecnica Talesun 410WDokument2 SeitenFicha Tecnica Talesun 410WIes IngenieriaNoch keine Bewertungen

- Neon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationDokument24 SeitenNeon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationJimi CohenNoch keine Bewertungen

- DER11001 Reference DrawingsDokument2 SeitenDER11001 Reference DrawingsPrime Energy Warehouse-YemenNoch keine Bewertungen

- SJ 9 PDFDokument52 SeitenSJ 9 PDFNicolas X FloresNoch keine Bewertungen

- Hydraulic Eaton Vickers VQ Vane Pump: Intra-Vane Mechanism FeaturesDokument7 SeitenHydraulic Eaton Vickers VQ Vane Pump: Intra-Vane Mechanism FeaturesMiguel VlntìnNoch keine Bewertungen

- Helmholtz Resonator Effects On Engine Intake Air Mass Flow RateDokument9 SeitenHelmholtz Resonator Effects On Engine Intake Air Mass Flow Ratefzr67100% (1)

- An Overview of Transceiver SystemsDokument11 SeitenAn Overview of Transceiver SystemssurvivalofthepolyNoch keine Bewertungen