Beruflich Dokumente

Kultur Dokumente

Us5417955 PDF

Hochgeladen von

kothandaramanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Us5417955 PDF

Hochgeladen von

kothandaramanCopyright:

Verfügbare Formate

.

USOO5417955A

Umted States Patent [19]

[11] Patent Number:

Connolly

[45]

[S4]

MANUFACTURE OF FERRIC SULFATE AND

5,194,241

HYDROCHLORIC ACID FROM FERROUS

5,266,297

CHLORIDE

Inventon

David W-c""l1,5338 Casa Royal

[21]

Appl_ No; 204,068

22

Fld:

[51]

Int. Cl.6 ........................ .. C01B 7/07; COlB 7/01;

May 23, 1995

3/1993 Derka ................................ .. 423/558

11/1993

Kodama . . . . . .

. . . .. 423/DIG. 1

46-63154 8/1976 Japan ................................. .. 423/558

St- Lows, MO 63129

1C

Date of Patent:

FOREIGN PATENT DOCUMENTS

[76]

[ 1

5,417,955

ar

251495 5/1926 United Kingdom

423/558

562596 7/1944 Umted Kmgdom .............. .. 423/558

Prima

.1 1994

'3

ExaminerGar

P. Straub

Attorney, Agent, or FirmPolster, Lieder, Woodruff &

Lucchesi

COlG 49/00

[52]

US. Cl. .................................. .. 423/488; 423/481;

[57]

ABSTRACT

423/558; 423/DIG. 1

A two step method of converting ferrous chloride from

[58] Field of Search ........ .. 423/481, 488, 558, DIG. 1

a pickling liquor to produce hydrochloric acid and

[56]

ferric sulfate is disclosed. The ferrous chloride is ?rst

References Clted

U-S- PATENT DOCUMENTS

mixed with sulfuric acid to produce ferrous sulfate and

HCl. The HCl is carried to an absorbtion tower where

1,430,551 10/1922 Herrly ............................... .. 423/558

most of the HCl is Collected and the reminder is re

3,542,503 11/1970 sercombe et a1

____ ,_ 4123/1316, 1

turned to the reactor. The ferrous sulfate is separated

. . . . . . . .. 423/481

from the sulfuric acid. The unreacted sulfuric acid is

3,635,664

1/1972

Morimoto . . . . . . .

4,102,784

7/1978

Schlauch . . . . .

. . . . . .. 210/47

4322997

9/ 1980

Beecher ~ - - - - -

~ - - ~ - - - -- 423/481

43251407 3/1981 Puumne

iigg

423/DIG' 1

32:22:;

'

sulfuric acid and air (02) to produce ferric sulfate. The

'' '' '"

4:707:349 11/1987 Hiersted

' '

5,154,769 10/1992 Kuske et a1

ferric sulfate is removed from the second reactor. Both

558

. 106/459

5,l8l,993

1/1993

5,194,240

3/1993 Derka ................................ .. 423/558

Furuya ..... ..

fl A

returned to the reactor and the ferrous sulfate is trans

ported to a second reactor where it is reacted with

reactions are carried out at relatively low temperatures

under atmOSPhenc Pressures

204/86

A In

23 Claims, 1 Drawing Sheet

26

\l

28

H 20 . HC 1

_@

1.6

H20

A 'J

> __J19 g0

,\ AIR

21.12 HCI)<I

H2O> 10 F

15

17: Fe+2.

HCl

H2D.HC1

1) -@

GENERATOR

22

Ft

1/

l8\

24

_/

____Q_

85 F

2Q

2: H121

FeC12SOLUTION

I H2504

l4

G

hi2

AIR To SCRUBBER

3s

A H2804. H2O

60

34

F9804. H2O. H2504.

AIR

F8804

358

SEPARATOR

32 J

40

FERRIC SULFATE

54

REACgDR

H2504

44

180 F

G56

MIXING JETS

H20

42

Fez-2t $0413

[I

\

_/51

45

STEAM

38 _/

57 J

52

gig-[ta

so

48

5,417,955

Another object is to provide such a process wherein

the risk of release of HCl to the atmosphere is substan

MANUFACTURE OF FERRIC SULFATE AND

HYDROCHLORIC ACID FROM FERROUS

CHLORIDE

tially reduced.

Another object is to provide such a process which

can be carried out at relatively low temperatures.

Another object is to provide such a process which is

economical to operate and less expensive than existing

BACKGROUND OF THE INVENTION

This invention relates to the production of ferric

sulfate, and in particular to the production of ferric

conversion plants to build.

These and other objects will become apparent to

those skilled in the art in light of the following disclo

sure and accompanying drawing.

sulfate and hydrochloric acid from ferrous chloride or

liquors containing ferrous chloride produced in the

production of steel or from other industries.

According the invention, generally stated, ferrous

In the processing of steel, steel is pickled with hydro

chloride is converted to ferric sulfate in a two step

chloric acid. The pickling of the steel produces a waste

process. Initially, ferrous chloride is reacted with sulfu

liquor containing FeClz and HCl. Often, the liquor is

discarded, adding to the already existing pollution prob

ric acid in an HCl generator to produce ferrous sulfate

and HCl. The ferrous sulfate is then reacted with sulfu

ric acid and air in a ferric sulfate reactor to produce

ferric sulfate. Both reactions are carried out at between

lems. Various methods have been introduced to treat

the pickling liquor. As described in US. Pat. Nos.

4,382,916 and 4,222,997, both to Beecher, the hydro

chloric acid has been recovered from pickle liquor. The

120 and 400 F. and preferably at about 180 F. The

reactions are carried out preferably at atmospheric pres

sures and without the use of catalysts, although cata

lysts can be used to enhance the reaction. The reactants

are brought to temperature by cycling the reactants

through heat exchangers or by enveloping the reactors

in steam jackets. Other methods to heat the reactants

can, of course, be used. The reactants in both reactors

are mixed, preferably with the use of air jets or agita

Beecher process produces ferrous sulfate as a bypro

duct. Beecher recovers the hydrochloric acid by con

densing pickling liquor to remove HCl and water from

the feed stream. He does this by boiling the feed stream.

The concentrated pickle liquor is then added to sulfuric

acid to produce ferrous sulfate. The HCl and water

vapors are recovered using extensive heat recovery

tors.

equipment.

In the first reaction, the HCl and ferrous sulfate are

removed from an HCl generator in separate product

lines. The HCl, which is in a vapor state, is passed

through an absorber. Most of the HCl is collected and

the remainder is recycled back to the HCl generator.

pressure to obtain a ?ne spray. This process converts

An air stream is cycled through the reactor and carries

the ferrous chloride to Fe2O3 and HCl. It uses a great

the HCl vapor to the absorber and back to the HCl

deal of energy and requires high maintenance costs. The

generator. Water may be introduced into the air stream

Fe2O3 produced is of poor quality and low value.

to control the HCl concentration. Preferably, the col

These products (ferric oxide, ferrous sulfate, and

lected HCl is about 21% HCl by weight. This is near its

HCl) are of relatively low value. The processes, which

azeotrope and reduces the amount of HCl which is

are expensive to setup and operate, therefore, can not be 40 recycled, and to ensure that most of the HCl is col

economically justified. However, the ferrous sulfate can

lected. The returning air, water, and uncollected HCl

be oxidized to produce ferric sulfate. Ferric sulfate has

are preferably cooled, preferably to about 110 F.

The ferrous sulfate product line also includes sulfuric

many uses and has a higher value. For example, its main

acid and water. The ferrous sulfate, which has been

use is as a ?occulent to remove particulate matter in

potable water plants. It is also used to remove phos 45 precipitated out, is separated from the sulfuric acid and

A roasting process, described in Barczak US. Pat.

No. 4,436,681 et al., recovers HCl from pickle liquor by

injecting the pickle liquor into a roasting chamber at

very high temperatures (l,600 F.) using a very high

water, which are returned to the HCl generator. The

phates and HZS from waste streams or as an animal food

ferrous sulfate is then transported to the ferric sulfate

additive. I presently know of no processes that propose

to use the ferrous chloride from the pickling liquor to

produce ferric sulfate. Such a process is of particular

value at this time because of the need to replace alum as

a ?occulent in the potable water industry. Alum is be

reactor.

The second reaction is maintained at the desired tem

perature by cycling the reactor contents through a heat

exchanger. The ferric sulfate solution product is

pumped from the reactor contents for collection. The

reactor contents are pumped through a heat exchanger

coming subject to more restrictive regulations because

of its potential dangers. Ferric sulfate is equal to or

better than alum as a ?occulent without the potential

dangers posed by the use of alum.

SUMMARY OF THE INVENTION

to maintain the reactor contents at a desired tempera

55

ture (preferably about 180 F.) and then returned to the

ferric reactor. Preferably, a portion of the ferric prod

not is pumped out after the reactor contents are heated

and before the heated reactor contents are returned to

the reactor. The returning reactor contents are passed

One object of the present invention is to provide a

process to produce ferric sulfate from ferrous chloride. 60 through mixing jets to mix the contents. Air is injected

Another object is to provide such a process wherein

into the return line to aid in the mixing of the reactor

the HCl used to pickle steel and the HCl produced in

contents and to provide oxygen to oxidize the ferrous

the conversion process is recovered, and that which is

sulfate to ferric sulfate. The product line is about 50%

not recovered is recycled.

Fe3(SO4)3, by weight, and about 12% Fe+ + + by

Another object is to provide such a process in which 65 weight.

the HCl is recovered using an air sweep through an HCl

This process provides a more ef?cient manner of

generator and recovering the HCl in an absorbing

collecting the HCl since it is not dependent on condens

tower to which the air sweep is directed.

ing HCl/water vapors directly, as is Beecher. Further,

5,417,955

because the uncollected HCl is recycled, the risk of

of HCl (230 F.) or the boiling point of a water-HCl

pollution is reduced, thereby reducing the need for

binary system (227.4 F.). The HCl is cooled preferably

multiple absorbers. Only one absorber is needed in my

process, making the initial cost of a conversion plant,

to between 60 F. and 110 F. in the absorbtion system

to aid in collection of the HCl. The recycled air is re

heated preferably to about 180 F. as it passes through

the hot sulfuric acid in the HCl generator to pick up

additional HCl and water.

and operation of the conversion plant, less expensive.

BRIEF DESCRIPTION OF THE DRAWING

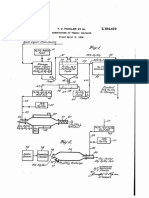

The Figure is a schematic representation of the pro

cess of the present invention.

DESCRIPTION OF THE PREFERRED

EMBODIMENT

My process manufactures Fe2(SO4)3 and HCl from an

FCC12 pickle liquor or any ferrous chloride solution or

crystal. The ferrous chloride solution is preferably a

pickling liquor produced from the pickling of steel

which contains H2O, HCl, and FeCl;. Often the pick

ling liquor is 38% FeClg and 2% HCl, by weight, the

remainder being water.

This ?rst step is unique in that the hydrochloric acid

and water vapors are swept out of the HCl generator by

an air purge and are recovered using an absorbing

tower 16. The air stream, with uncollected HCl, is recy

cled back through the HCl generator. Because the air

stream for the HCl reactor is maintained in a continuous

cycle, any HCl which is not collected is returned to the

HCl generator. Thus, no HCl is released to the atmo

sphere. My process thus substantially eliminates any air

pollution problems associated with HCl absorption.

Further, because the air stream is recycled, rather than

The process is essentially a two step process. In a ?rst 20 being released to the atmosphere, the HCl is also recy

cled. This allows for the use of a minimum number of

step, the ferrous chloride is mixed with hot sulfuric acid

absorbtion towers or columns. In fact, although more

to release the chloride from the ferrous chloride mole

absorbtion towers could be used, only one tower is

cule. The sulfuric acid, prior to mixing with the FeCl2 ,

needed and preferably only one tower is used. This

is preferably about 93% H2804 by weight and is prefer

reduces the equipment and operating costs of a conver

ably heated to between 100-200" F. The sulfuric acid in

sion plant.

the reactor may have a concentration of 10-98% by

weight, and preferably a concentration of about 60% by

weight. The sulfuric acid concentration in the generator

10 is in part dependant on the FeClg content of the

pickle liquor. The reaction is carried out in an HCl

generator 10 at a temperature of between 60 F.300

F ., preferably at about 180 F. The reactants preferably

have a residence time of about four hours in the reactor.

The generator is purged with air as the reaction is car

ried out. Air is introduced into the reactor at a rate of

1600 CFM. This ?rst step produces ferrous sulfate and

hydrochloric acid according to the following equation:

The hydrochloric acid (HCl) vapor and water vapor

are carried off by the air stream to an absorption system

having an absorber 16 where HCl is recovered. Most of

the HCl 15 is removed from the air stream for collec

tion. Water may be introduced into the air stream to

absorber 16 or into the absorber itself to control the HCl

concentration. Preferably the HCl solution exiting the

absorber has a concentration of about 21%, by weight.

This concentration is close to the azeotrope of hydro

chlon'c acid, and is a common concentration used in the

pickling of steel. This HCl may be returned to the steel

plant for use in pickling more steel. Bringing the HCl to

its azeotrope also reduces the amount of I-ICl which is

recycled, and thus increases the amount of HCl which is

collected on the ?rst pass of the air sweep through the

The ferrous sulfate is removed from the generator in

a second product line which also contains sulfuric acid

and water. Although FeSO4 is very soluble in a hot

aqueous solution, its solubility decreases substantially in

the presence of increasing amounts of sulfuric acid. The

process takes advantage of this decreasing solubility in

order to recover the FeSO4 from the sulfuric acid and

water. By maintaining the concentration of sulfuric acid

in the HCl generator at about 60% by weight, the fer~

rous sulfate precipitates and can be separated from sul

fun'c acid in a separator. The second product line thus

contains a slurry. This slurry is delivered to a separator

34 where the ferrous sulfate is separated from the sulfu

ric acid and water. The separation may be carried out

using a centrifuge, ?lter, cyclone, settling tank, or any

other desired separating means. The sulfuric acid and

water are returned to the HCl generator to replenish the

sulfate used in the reaction. This recycling of the sulfu

ric acid increases the yield of the reaction (1) by increas

ing the number of sulfate molecules present and de

creases the amount of fresh sulfuric acid needed for the

reaction. In a batch operation the sulfuric acid to re

plenish the sulfate can be added at the start of the opera

tion or periodically during the reaction.

The ferrous sulfate is delivered to a second reactor, a

ferric sulfate reactor 38, where it is oxidized to ferric

sulfate in the presence of at least stoichiometric amounts

of sulfuric acid according to the reaction:

absorbtion system. Thus, most of the HCl generated by

the ?rst reaction is collected If the HCL were, for ex

(2) 4FeS0430 2112504 + 02 = 2Fe2(SO4)3 + 21120

ample, at 23%, the amount of HCl recycled would

triple.

When less than stoichiometric amounts of sulfuric

acid are used, the ferric sulfate forms a basic polymer.

turned to the generator. The amount of HCl carried off 60 Preferably the reactor is monitored to keep the sulfuric

acid at about stoichiometric amounts. Most preferably,

by the air stream is dependant on the air temperature.

Although the reactor temperature could be reduced if

the sulfuric acid is maintained just slightly below stoi

higher concentrations of sulfuric acid were used, a

chiometric amounts. When stoichiometric amounts of

higher temperature is preferred so that the air stream

sulfuric acid are present, the sulfuric acid will react with

will entrain a larger amount of HCl. The higher temper 65 the ferrous sulfate, reducing the sulfuric acid concentra

ature also allows for a reduction of the residence time of

tion in the reactor. This will help prevent the precipita

the reactants in the HCl generator. The air stream thus

tion of ferrous sulfate in the reactor. It further prevents

has a temperature which is lower than the boiling point

the ?nal product from having excess or free acidity and

The uncollected HCl, water vapor and air are re

5,417,955

thus reduces the amount of ferrous sulfate in the ?nal

product. The ratio of the sulfate ion to the iron ion is

thus monitored to provide for near complete oxidation

so that the solution will contain ferric sulfate with sub

stantially no excess or free sulfuric acid. Preferably, the

ratio of the sulfate ion to iron ion is between 1.6 and

1.45, and is preferably about 1.5.

The reactants (water, sulfuric acid, air (oxygen), and

ferrous sulfate) are thoroughly mixed in the ferric sul

fate reactor using mixing jets. Air is passed into the

reactor at a rate of 10-500 CFM using an aeration jet or

cled back into the absorber through line 24. A line 26

exits absorber 16 to carry HCl, water, and air back to

generator 10. The temperature in return line 26 is about

110 F. A blower 28 is placed in line 26 and increases

pressure in the line to 30" H2O. Upon entering the gen

erator 10, the air is reheated to entrain additional HCl

for collection.

In the presence of sulfuric acid and the absence of

chlorides in the HCl generator 10, the ferrous sulfate

precipitates out. A second product line 32 carries the

ferrous sulfate product, sulfuric acid, and water from

generator 10 to a separator 34. Separator 34 removes

about 17.44 lbs/min of ferrous sulfate from the water

any other device to effectively add air to the system at

atmospheric pressures. The air stream, in addition to

mixing or agitating the reactor contents, provides the

oxygen for the oxidation of the ferrous to ferric. The 15 and sulfuric acid. The water and sulfuric acid are re

reaction preferably is carried out at a temperature of

between 120 F. and 300 F., and preferably at about

180 F. The reactants preferably have a residence time

of 18 hours in the reactor.

With a feed of 44000 lbs/day of ferrous chloride 20

turned to generator 10 by a line 36.

The ferrous sulfate is introduced into a ferric sulfate

reactor 38 by a line 40. Water (about 20.2 lbs/min) and

sulfuric acid (4.9 lbs/min) are introduced into reactor 38

by feed lines 42 and 44, respectively. The ferrous sulfate

reacts with the sulfuric acid and oxygen to produce

ferric sulfate in accordance with reaction (2) set forth

above. The reaction is carried out at about 180 F.

ferric sulfate a day by sizing the equipment correctly.

under atmospheric pressures.

The iron in the ?nished product stream is about 12%

The ferric sulfate reactor contents are cycled through

ferric iron. The whole process should take about 18 25

solution containing 17% Fe+ + by weight, it is reason

able to expect a production rate of about 21 tons of

hours. The above reaction can be accomplished in a

batch or continuous reaction.

a heat exchanger 50. They are removed from the reac

by a feed line 12 at a rate of about 30.56 lbs/min on a

be used, as could a reactor having a steam jacket or the

use of live steam.

tor through a line 46 having a pump 48. Heat exchanger

50 heats the reactor contents, with steam, to about 180

EXAMPLE 1

F. Because the reactants are heated using exchanger 50,

With reference to the FIGURE, 44,000 lbs/day of 30 a separate heater is not needed for the reactor, however,

pickling liquor is introduced into an HCl generator 10

heat exchangers installed inside the reactor could also

continuous basis. Prior to starting the feed, the HCl

generator 10 is ?lled with sulfuric acid and H20 which

is heated to about 180 F. The sulfuric acid charge is

preferably about 60% H2804 by weight. The feed line

includes 38.6% FeClg (17% Fe++) and 2% HCl by

weight, the remainder being water. The pickling liquor

is initially ?ltered to remove any dirt and carbon pres

ent in the solution.

A line 51 from heat exchanger 50 carries the reactor

contents to a line 52 where 43.29 lbs/min of 43% ferric

sulfate are pumped to storage tanks. Not all the ferric

sulfate is removed to storage at this point. Some of the

product, along with the heated reactants, are directed

back to reactor 38 through two lines 54 and 56. A split

ter, for example, could be used to direct the flow of

A feed of 9.77 lbs/min of sulfuric acid is introduced

product between storage and the reactor. Lines 54 and

into the reactor through a line 14. The reactants are

56 pass the ferric sulfate through mixing jets 57 to en

heated, preferably to 180 F., and mixed using mixing

sure that the reactants in the reactor are well mixed. By

jets or an agitator. The ferrous chloride and sulfuric

returning the ferric sulfate to the reactor, the residence

acid react according the above equation (1) to produce 45 time of ferrous sulfate in the reactor is increased, in

HCl and ferrous sulfate. Air is cycled through the gen

creasing the conversion ratio of ferrous sulfate to ferric

erator 10 and carries off HCl and water vapor to an

sulfate. Thus, the ferric sulfate which is removed is very

absorber 16 through a line 18.

pure.

Preferably, the solution in product line 52 is about

In continuous operation, about 1600 CFM of recy

12%

F

e+ + +.

cled air will carry of 19.4.lbs/min of water vapor and 50

Air is also introduced into the reactor at a rate of

7.81 lbs/min of HCl to absorber 16. The temperature in

about 50-250 CFM to provide oxygen for the oxidation

line 18 is about 180 F., the temperature at which the

of ferrous to ferric. An air line 58 communicates with

reaction was carried out in HCl reactor 10. The HCl

return line 54. Line 54 has a mixing jet, as described

that is entrained in the air stream is about 28%29% by

above, and the air thus aids in mixing of the reactor

weight HCl. Water is therefore added to line 18 through

a line 19 to control the HCl concentration. Water can

contents. The air from reactor 38 is directed to a semb

alternatively be added to the absorbtion tower 16. The

ber through a line 60 prior to being released into the

atmosphere. No HCl enters the reactor 38. Thus, the

HCl concentration is controlled to be close to its azeo

scrubbed air can be released to the atmosphere without

water are introduced into the air line 18 to bring the 60 substantial risk of polluting the environment with HCl.

If a batch system is desired to convert the ferrous

HCl to this concentration. The water and HCl are cy

sulfate to ferric sulfate in reactor 38, 29,1198 lbs of

cled through a heat exchanger 20 to cool the water and

HCl to 110 F. Heat exchanger 20 is preferably a

water and 7,033.5 lbs sulfuric acid are initially fed into

1,750,000 BTU/hr exchanger which uses water as the

the reactor 38. After the reactor has been charged with

trope, about 21% HCl by weight. About 1.45 GPM of

cooling medium. About 35 lbs/min. of 21.1% HCl by 65 water and sulfuric acid, 25,111.41bs ferrous sulfate crys

weight are removed from the cooled stream through a

line 22 for collection. The uncollected HCl, which is

also at concentration of about 21.1% by Weight, is cy

tals for the HCl generator 10 are added to the reactor.

As in the continuous process, the reactants are heated to

180 F. with good agitation and oxidized with air.

5,417,955

4. The method of claim 3 wherein the reactants in said

HCl generator are heated to about 180 F.

5. The method of claim 2 wherein said HCl generator

Example 2

In this example, a pickling liquor containing 11.5%

Fe+ + and 3% HCl by weight is introduced into the

(a rate of approximately 45.8 lbs/min). The I-ICl reac

is maintained at atmospheric pressure.

6. The method of claim 2 including a step of continu

ously mixing said reactants in said HCl generator with

tor is fed with 40-80% H2804 which is heated to 120

F.-220 F. The sulfuric acid is introduced into the reac

an agitator.

7. The method of claim 1 wherein said step of collect

HCl reactor, after ?ltering, at a rate of 44000 lbs/ 16 hrs

tor at a rate of about 9.9 lbs/min. An air sweep of

ing said HCl includes passing said HCl vapor entrained

1500~3500 CFM air is cycled through the HCl genera 10 in said air sweep through an absorber and absorbing said

tor and absorber. Under these conditions, approxi

HCl vapor.

mately 17.7 lbs/min ferrous sulfate will be produced

8. The method of claim 7 including the step of con

which is then delivered to the ferric sulfate reactor. The

trolling the concentration of the HCl in the absorber by

HCl produced in the HCl generator is about 20% by

the step of adding water to one of said air sweep and

weight. Water therefor does not have to be added to the

said absorber.

air sweep line to dilute the HCl.

The feed of sulfuric acid is introduced into the ferric

9. The method of claim 8 wherein said step of con

trolling the concentration of said HCl includes main

taining said HCl concentration at about 21%.

sulfate reactor at a rate of about 4.95 lbs/min about

sixteen hours after the process has begun. At this same

10. The method of claim 1 wherein said second reac

time, ferric sulfate is drawn off the reactor at a rate of _

tion includes heating the reactants of said ferric sulfate

about 43.92 lbs/min and delivered to storage. This pro

cess will produce about 42,167 lbs of 43% ferric sulfate

reactor to between 120 F. and 300 F.

by weight daily.

reactor reactants are heated to about 180 F.

11. The method of claim 10 wherein said ferric sulfate

If a batch system is to be used, the ferric sulfate reac

12. The method of claim 10 wherein said heating step

includes heating the contents of said ferric sulfate reac

tor in a heat exchanger.

13. The method of claim 12 including introducing an

air stream into said ferric sulfate reactor, said air stream

tor is charged with 19,6955 lbs of water and 4,761 lbs of

sulfuric acid.

Various changes to the invention, within the scope of

the appended claims, may be apparent to those skilled in

the art. For example, the sulfuric acid that is returned to

the HCl generator could form part of the sulfuric acid

feed for the ferric sulfate reactor. In either case, the

sulfuric acid is recycled for further use. The tempera

ture and concentrations can be changed to change the

providing said oxygen for said reaction.

14. The method of claim 13 including a step of mixing

the reactants of said ferric sulfate reactor; said air being

introduced into a line which returns the reactants from

product recovery rate as needed (i.e. to increase or

the heat exchanger to the ferric sulfate reactor, said

mixing step including passing said air and reactants

decrease the reaction rate). The residence times in the

through mixing jets.

HCl generator and ferric sulfate reactor can be

15. The method of claim 1 wherein the amount of

sulfuric acid in said ferric sulfate reactor is about a

I claim:

stoichiometric amount.

1. A method for producing ferric sulfate from ferrous 40

16. The method of claim 15 wherein the amount of

changed. These examples are merely illustrative.

chloride comprising: reacting ferrous chloride with

sulfuric acid used in said ferric sulfate reactor is slightly

less than stoichiometric amounts.

sulfate and HCl;

17. The method of claim 15 wherein the ratio of sul

passing an air sweep through said HCl generator;

fate ions to iron ions is from about 1.6 to about 1.45.

entraining HCl vapor in said air sweep;

18. A method for producing ferric sulfate from fer

45

collecting said entrained HCl from said air sweep;

rous chloride comprising:

returning said air sweep and uncollected HCl to said

charging a reactor with said ferrous chloride and

HCl generator;

excess sulfuric acid, said sulfuric acid being

removing a product stream from said HCl generator

10%98% sulfuric acid by weight;

sulfuric acid in an HCl generator to produce ferrous

containing said ferrous sulfate and unreacted sulfu

ric acid:

reacting said ferrous chloride with said sulfuric acid

separating said ferrous sulfate from said unreacted

ture of between 60 F. and 300 F.;

passing an air sweep through said HCl generator;

entraining HCl in said air sweep;

collecting said entrained HCl from said air sweep;

controlling the concentration of said HCl such that

the concentration of HCl in said air sweep is at

to produce ferrous sulfate and HCl at a tempera

sulfuric acid;

adding sulfuric acid to the HCl generator to replenish

sulfuric acid consumed to make ferrous sulfate;

55

introducing said ferrous sulfate to a ferric sulfate

reactor;

reacting the ferrous sulfate with sulfuric acid and

oxygen in said ferric sulfate reactor to produce

ferric sulfate; and

collecting the ferric sulfate.

60

2. The method of claim 1 wherein said ferrous chlo

ride is added to said sulfuric acid, said method including

an initial step of charging said HCl generator with ex

cess sulfuric acid and heating said sulfuric acid to be 65

tween 60300 F.

3. The method of claim 2 wherein the reactants in said

HCl generator are heated to between 60 F. and 300 F.

about the azeotropic concentration of said HCl;

removing a product stream from said HCl generator

containing said ferrous sulfate and up-reacted sul

furic acid

separating said ferrous sulfate from said unreacted

sulfuric acid in said product stream;

reacting said ferrous sulfate with sulfuric acid and

oxygen at a temperature of between 120 F. and

300 F. to produce ferric sulfate; and

collecting said ferric sulfate, the concentration of the

ferric sulfate in said solution being about 43%.

5,417,955

10

21. The method of claim 17 wherein each reaction is

carried out at about 180 F.

22. The method of claim 21 wherein each said reac

tion is carried out at atmospheric pressures.

19. The method of claim 18 wherein said step of con

trolling said HCl concentration includes adding water

to said air sweep.

23. The method of claim 18 including a step of adding

sulfuric acid to the HCl generator to replenish sulfuric

20. The method of claim 19 including a step of return

acid consumed to make ferrous sulfate.

*

ing said air sweep and uncollected HCl to said reactor.

10

15

25

30

35

45

50

55

60

65

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Ferric Sulfate With SO2Dokument5 SeitenFerric Sulfate With SO2kothandaramanNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Frric SulphateDokument4 SeitenFrric SulphatekothandaramanNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Ferric Sulfate With SO2Dokument5 SeitenFerric Sulfate With SO2kothandaramanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Patent CA1257424A1 - Chemically Modified Lignite - Google PatentsDokument3 SeitenPatent CA1257424A1 - Chemically Modified Lignite - Google PatentskothandaramanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Bernette Ramirez Mariano Bernette Ramirez MarianoDokument1 SeiteBernette Ramirez Mariano Bernette Ramirez Marianomia palacioNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Business Plan On Plastic Recycling & ManufacturingDokument19 SeitenBusiness Plan On Plastic Recycling & ManufacturingSah Sanjiv KumarNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- UntitledDokument107 SeitenUntitledniko_seppanenNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Flextronics FINALDokument25 SeitenFlextronics FINALAnkit GauravNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Grasses Their Use in BuildingDokument8 SeitenGrasses Their Use in BuildingpitufitoNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- IEC Systems Manual - SCRDokument102 SeitenIEC Systems Manual - SCRgabriel100% (3)

- Mitsubishi Electric Industrial Robots: Communication Middleware (Melfarxm - Ocx) Instruction ManualDokument152 SeitenMitsubishi Electric Industrial Robots: Communication Middleware (Melfarxm - Ocx) Instruction ManualRafael GagoNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Data SheetDokument5 SeitenData Sheetsongtu2552Noch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Activity Sheets SMAW 7.23Dokument5 SeitenActivity Sheets SMAW 7.23Jerome Cailo DiazNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Technical Brochure Metal Ceilings V100-V200-en EUDokument12 SeitenTechnical Brochure Metal Ceilings V100-V200-en EUNicu PotîngNoch keine Bewertungen

- Didsn1811a (Skyair R-410a)Dokument12 SeitenDidsn1811a (Skyair R-410a)Ari SetyawanNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Odi2-065r16m18s02-Q DS 0-0-0Dokument3 SeitenOdi2-065r16m18s02-Q DS 0-0-0leolima trustitNoch keine Bewertungen

- Annex A - Technical SpecificationsDokument52 SeitenAnnex A - Technical SpecificationsNikko MontoyaNoch keine Bewertungen

- Mooring SystemsDokument6 SeitenMooring SystemsVinicius PessottiNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- 3 Esrtos IntroDokument8 Seiten3 Esrtos IntroVijayaraghavan VNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Final ProjectDokument4 SeitenFinal Projectsajad soleymanzadeNoch keine Bewertungen

- EBS Data MaskingDokument31 SeitenEBS Data MaskingNawab ShariefNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- SM 121 PDFDokument573 SeitenSM 121 PDFEnrique Arevalo LeyvaNoch keine Bewertungen

- Technical Information Sheet: General Information: ISO 12944 TI - G 9 / UsaDokument6 SeitenTechnical Information Sheet: General Information: ISO 12944 TI - G 9 / UsaBash MatNoch keine Bewertungen

- Physics 02-07 Centripetal Force and Banked CurvesDokument2 SeitenPhysics 02-07 Centripetal Force and Banked CurveslatteNoch keine Bewertungen

- Tem 3413354 0101Dokument67 SeitenTem 3413354 0101Kolawole KehindeNoch keine Bewertungen

- Cramkshaft Main Bearimg InstallDokument5 SeitenCramkshaft Main Bearimg InstallNimNoch keine Bewertungen

- Binsar Margiyanto: ND RDDokument2 SeitenBinsar Margiyanto: ND RDmoez ben youssefNoch keine Bewertungen

- Apollo Experience Report Electronic Systems Test Program Accomplishments and ResultsDokument70 SeitenApollo Experience Report Electronic Systems Test Program Accomplishments and ResultsBob AndrepontNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Chapter 14 - Storm and Sanitary Analysis PDFDokument41 SeitenChapter 14 - Storm and Sanitary Analysis PDFdobridorinNoch keine Bewertungen

- Dental CementDokument74 SeitenDental CementAisha samreenNoch keine Bewertungen

- 2032-10 - E Gazette SLDokument3 Seiten2032-10 - E Gazette SLhimaliNoch keine Bewertungen

- Types of Processors and RAM'sDokument26 SeitenTypes of Processors and RAM'sSneha NairNoch keine Bewertungen

- A Interview QuestionsDokument363 SeitenA Interview QuestionsJaishankar RenganathanNoch keine Bewertungen

- Designs of Canals and CM&CD WorksDokument61 SeitenDesigns of Canals and CM&CD WorksVenkataLakshmiKorrapatiNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)