Beruflich Dokumente

Kultur Dokumente

8801 Servohydraulic Fatigue Testing System: Up To 100 KN

Hochgeladen von

onnly1964Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

8801 Servohydraulic Fatigue Testing System: Up To 100 KN

Hochgeladen von

onnly1964Copyright:

Verfügbare Formate

8801 Servohydraulic Fatigue Testing System Up to 100 kN

The Instron 8801 is a compact servohydraulic fatigue testing system that meets the challenging demands of various static and

dynamic testing requirements. 8801 systems provide complete testing solutions to satisfy the needs of advanced materials and

component testing, and are ideally suited for fatigue testing and fracture mechanics. The compact design of the 8801 frame

makes it ideal for installation within any laboratory environment, generally without the need for strengthened floors or raised

ceiling heights.

Features

Double-acting servohydraulic

actuator with force capacity up

to 100 kN (22 kip)

High-stiffness,

precision-aligned load frame

with twin columns and

actuator in lower base

150 mm (6 in) of

usable stroke

Compact servohydraulic

fatigue test system frame

requires less than 0.5 m

(5.4 ft) of floor space

Optional hydrostatic bearing

actuators for higher side-load

resistance or material critical

applications, such as

low-cycle fatigue

Designed for both dynamic

and static testing on a variety

of materials and components

Choice of hydraulic

configuration and dynamic

performance to suit application

Extra-height frame option for

testing longer load strings

Adjustable upper crosshead

with hydraulic lifts and locks

fitted as standard for easy

adjustment of daylight

Patented1 Dynacell

advanced load cell technology

for faster testing and reduction

of inertial errors

Designed to be used with the

3520 Series of Hydraulic

Power Units

Compatible with a large range

of grips, fixtures, chambers,

video extensometers,

protective shields, and

other accessories

Controller and Software

The Instron 8801 is supplied with a digital 8800 controller that

provides full system control including features such as automatic loop

tuning, amplitude control, specimen protect, 19-bit resolution across

the full range of transducers, and adaptive control technology. It also

allows access to WaveMatrix Dynamic Testing Software, Bluehill

Software for static tests, and other application specific software, such

as the Low Cycle Fatigue or Fracture Mechanics suite.

www.instron.com

Typical Testing Applications

The Instron 8801 servohydraulic testing system is designed to give the maximum return on investment through improved

productivity in a value engineered package. A wide range of system options, grips, fixtures, and accessories allow the

8801 system to be customized for specific applications. Whether the test application demands low or high temperatures,

crack measurement, or complex specimen gripping geometry, Instron offers a complete tailored package.

Fracture Mechanics

The Instron 8801 system can be

configured with CT grips or flexure

fixtures and crack measurement

sensors for crack growth and

fracture toughness studies of

metallic materials.

High-Cycle Fatigue

Mechanical or hydraulic wedge-action or collet grips and dynamic

extensometers allow high-frequency fatigue testing of a variety of

specimens. Tests can be at ambient conditions or combined with

environmental accessories for testing at higher temperatures.

www.instron.com

High-Temperature Testing

Environmental Testing

Low-cycle fatigue (LCF) and other tests

can be carried out at very high

temperatures using furnace technologies

and specialized load strings.

Environmental chambers provide

the capability to study mechanical

properties of materials and

components at high or

low temperatures.

Composite Testing

Fatigue testing is critical for

understanding the long-term

cyclic properties of composite

materials - especially for mission

critical applications such as

aerospace, wind turbine, and

automotive applications.

Thermomechanical

Fatigue (TMF)

Using specialist heating technologies, TMF

systems simulate the combined effects of

mechanical fatigue with the thermal cycling,

normally experienced by gas turbines and

similar equipment during operation.

www.instron.com

8801 Servohydraulic Fatigue Testing System | Up to 100 kN

Specifications

Extra

Height Frame

mm

1025

1405

in

40.4

100

22

150

5.9

Twin-Column High-Stiffness Load Frame

with Actuator in Lower Table

Lifts and Locks

Hydraulically-Powered Lifts and Locks

Load Cell

Load Weighing Accuracy

Hydraulic Pressure Supply

(Required)

bar

psi

Electrical Supply

Operating Environment

Frame Stiffness

Frame Weight

C

kN/mm

kg

lb

Patented1 Dynacell Fatigue-Rated

Load Cell Mounted to Upper Crosshead

with Capacity to Suit Actuator

0.5% of Indicated Load or 0.005%

of Load Cell Capacity (1-100%),

Whichever is Greater

207

3000

Single-Phase Mains 90-132 or

180-264 VAC 45/65 Hz

Power Consumption: 800 VA max

+10 to +38C (+50 to +100F) with

10 to 90% Humidity Non-Condensing

390

600

1322

M30 2 Right Hand Central Thread

Actuator

M30 2 Right Hand Central Thread

Table and Crosshead

4 M10 Holes on a 280 mm 90 mm for

Accessory Mounting

278

Mechanical Interfaces

Load Cell

546

Accessories

Catalog Number

2743-401

2743-402

8000-090

2750-119

2501-132

2810-181

2810-184

2840-118

70

562

STD: 975

EXT: 950

Configuration

STD: 300 MIN / 1100 MAX

EXT: 680 MIN / 1480 MAX

97

55.3

50

11

63

MIN

mm

in

(Total)

100

22

STD: 610 MIN / 1260 MAX

EXT: 990 MIN / 1640 MAX

Actuator Stroke

50

11

STD: 85

EXT: 60

Dynamic Load Capacity

kN

Kip

STD: 1773 MIN / 2423 MAX

EXT: 2128 MIN / 2778 MAX

Daylight Opening

(Maximum Between Load Cell and

Actuator at Mid-stroke)

Standard

Height Frame

100 kN Fatigued-Rated Hydraulic Wedge Grips

100 kN Fatigued-Rated Hydraulic Wedge Grips

M30 Attachment Kit

Fracture Mechanics Grips for 25 mm Wide

Compact Tension Specimen

Adapters Kit for 2750-119 Clevis Grips

100 kN Fatigue-Rated 3-Point Bend Fixture

4-Point Conversion Kit for 2810-181

50 mm (2 in) Diameter Compression Platens

920

Instron 8801 Dimensions (All Dimensions are in mm)

1) US Patent Number 6508132

www.instron.com

European Headquarters

Coronation Road, High Wycombe, Bucks HP12 3SY, UK

Tel: +44 1494 464646

Instron Industrial Products

900 Liberty Street, Grove City, PA 16127, USA

Tel: +1 724 458 9610

97

Worldwide Headquarters

825 University Ave, Norwood, MA 02062-2643, USA

Tel: +1 800 564 8378 or +1 781 575 5000

562

70

/ 1100 MAX

/ 1480 MAX

N / 1260 MAX

/ 1640 MAX

Instron is a registered trademark of Illinois Tool Works Inc. (ITW). Other names, logos, icons and marks identifying Instron products and services referenced herein are trademarks of ITW and may not be used without the

prior written permission of ITW. Other product and company names listed are trademarks or trade names of their respective companies. Copyright 2012 Illinois Tool Works Inc. All rights reserved. All of the specifications

shown in this document are subject to change without notice.

WB1103C

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- 12 Structural Integrity Management - Ersdal - PtilDokument10 Seiten12 Structural Integrity Management - Ersdal - PtilEyoma EtimNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Structural Integrity ManagementDokument12 SeitenStructural Integrity Managementonnly1964Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Structural Integrity ManagementDokument22 SeitenStructural Integrity Managementonnly1964100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- TS Coating Characterization SiegmannDokument22 SeitenTS Coating Characterization Siegmannonnly1964Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Structural Integrity ManagementDokument12 SeitenStructural Integrity Managementonnly1964Noch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Structural Integrity Management: Ageing Structures Workshop April 8thDokument10 SeitenStructural Integrity Management: Ageing Structures Workshop April 8thonnly1964Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Structural Integrity ManagementDokument12 SeitenStructural Integrity Managementonnly1964Noch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Specimen Grips and Test Tools PDFDokument20 SeitenSpecimen Grips and Test Tools PDFAhmed MagdyNoch keine Bewertungen

- Structural Integrity ManagementDokument12 SeitenStructural Integrity Managementonnly1964Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

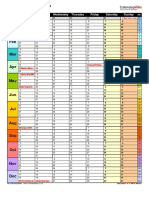

- Calendar 2017 Portrait RollingDokument1 SeiteCalendar 2017 Portrait Rollingonnly1964Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

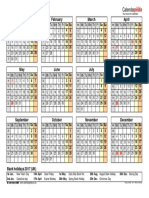

- Calendar 2017 Landscape Year at A GlanceDokument1 SeiteCalendar 2017 Landscape Year at A Glanceonnly1964Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Calendar 2017 LandscapeDokument1 SeiteCalendar 2017 Landscapeonnly1964Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Calendar 2017 Landscape Year at A GlanceDokument1 SeiteCalendar 2017 Landscape Year at A Glanceonnly1964Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Calendar 2017 Landscape PDFDokument1 SeiteCalendar 2017 Landscape PDFonnly1964Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Bulge/ FLC Tester Model 161: Testing Equipment For Quality ManagementDokument4 SeitenBulge/ FLC Tester Model 161: Testing Equipment For Quality Managementonnly1964Noch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Calendar 2017 Portrait RollingDokument1 SeiteCalendar 2017 Portrait Rollingonnly1964Noch keine Bewertungen

- NRES Report IllustrationDokument2 SeitenNRES Report Illustrationonnly1964Noch keine Bewertungen

- Calculation of The Crosshead Velocity Required To Achieve A Specified Stress Rate or An Estimated Strain RateDokument9 SeitenCalculation of The Crosshead Velocity Required To Achieve A Specified Stress Rate or An Estimated Strain Ratemp87_ing100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Universal Sheet Metal Testing Machine Model 146: Maximum Strain Deep Drawing Cup TestDokument4 SeitenUniversal Sheet Metal Testing Machine Model 146: Maximum Strain Deep Drawing Cup Testonnly1964Noch keine Bewertungen

- MagnetizingGuide PDFDokument50 SeitenMagnetizingGuide PDFonnly1964Noch keine Bewertungen

- Renewable Energy: Wenyi Liu, Baoping Tang, Yonghua JiangDokument5 SeitenRenewable Energy: Wenyi Liu, Baoping Tang, Yonghua Jiangonnly1964Noch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Distributed Intelligent Systems: Cursus Sem. TypeDokument2 SeitenDistributed Intelligent Systems: Cursus Sem. Typeonnly1964Noch keine Bewertungen

- IMoM 6BDokument42 SeitenIMoM 6BDaniel Laurence Salazar ItableNoch keine Bewertungen

- Composite Specimen Bearing Failure Reduction in Iosipescu Shear TestsDokument7 SeitenComposite Specimen Bearing Failure Reduction in Iosipescu Shear Testsonnly1964Noch keine Bewertungen

- Triaxial SampleDokument1 SeiteTriaxial Sampleonnly1964Noch keine Bewertungen

- Pressure VesselDokument32 SeitenPressure VesselYonjon SubhaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- SolidWorksToAbaqus AIDokument28 SeitenSolidWorksToAbaqus AIonnly1964Noch keine Bewertungen

- 3d Sample EightDokument1 Seite3d Sample Eightonnly1964Noch keine Bewertungen

- 3d SampleDokument1 Seite3d Sampleonnly1964Noch keine Bewertungen

- Python - PPT CieDokument18 SeitenPython - PPT CieSurisetty ManjuNoch keine Bewertungen

- Coolfreecv Resume en 03 NDokument1 SeiteCoolfreecv Resume en 03 NKenzi Sashi Kirono100% (1)

- 20480A ENU TrainerHandbookDokument627 Seiten20480A ENU TrainerHandbookMiticuta SurubNoch keine Bewertungen

- Heat Pump Standard EN 15316-4-2 - From Compliance To Real ConsumptionDokument5 SeitenHeat Pump Standard EN 15316-4-2 - From Compliance To Real ConsumptionMarcin BobińskiNoch keine Bewertungen

- Omnicell-HealthTrust Overview BrochureDokument8 SeitenOmnicell-HealthTrust Overview BrochuregurbaxeeshNoch keine Bewertungen

- Cimr-Vu2a0020faa SBDokument19 SeitenCimr-Vu2a0020faa SBعبد الكريم ملوحNoch keine Bewertungen

- Receptor TV Synaps - T20 T30 T50Dokument20 SeitenReceptor TV Synaps - T20 T30 T50nikushorNoch keine Bewertungen

- BDLO Labsii Fandii Daandii 224 Bara 2012Dokument10 SeitenBDLO Labsii Fandii Daandii 224 Bara 2012Freesun AbbasNoch keine Bewertungen

- 978 3 642 24106 2Dokument696 Seiten978 3 642 24106 2Purvi JainNoch keine Bewertungen

- CT S 941tx16u+Dokument453 SeitenCT S 941tx16u+Joel BorenNoch keine Bewertungen

- FS Input Sheet For L1 and Book and Bill ProjectsDokument4 SeitenFS Input Sheet For L1 and Book and Bill ProjectsShreeNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Whale Optimization AlgorithmDokument16 SeitenWhale Optimization Algorithmabc defNoch keine Bewertungen

- 6415 FundamentalsImprovements KZ-DC 20101025Dokument12 Seiten6415 FundamentalsImprovements KZ-DC 20101025rafeeque90Noch keine Bewertungen

- J Pole HandbookDokument10 SeitenJ Pole HandbookMR XNoch keine Bewertungen

- GX2 HSG PDFDokument2 SeitenGX2 HSG PDFMauro Barragan SanchezNoch keine Bewertungen

- Relational DB ChecklistDokument2 SeitenRelational DB ChecklistGabrielHolandiniNoch keine Bewertungen

- SPM Assignment 1Dokument5 SeitenSPM Assignment 1Mirza HammadNoch keine Bewertungen

- B.tech. III - Electrical Engg 2012-2013Dokument26 SeitenB.tech. III - Electrical Engg 2012-2013SaurabhNoch keine Bewertungen

- Quiz1 SolutionsDokument7 SeitenQuiz1 SolutionsPrasad BobbyNoch keine Bewertungen

- Wind Energy SyllabusDokument3 SeitenWind Energy SyllabusShivanand ArwatNoch keine Bewertungen

- Rdso Summer Training ProgramDokument4 SeitenRdso Summer Training ProgramvlucknowNoch keine Bewertungen

- 13 The AtlanteansAndTheMisuseOfEnergyDokument21 Seiten13 The AtlanteansAndTheMisuseOfEnergyCristiano SantiagoNoch keine Bewertungen

- Baron Massey: Problem Management Analyst at Hewlett Packard EnterpriseDokument4 SeitenBaron Massey: Problem Management Analyst at Hewlett Packard EnterpriseBaron MasseyNoch keine Bewertungen

- Case Study Analysis of Rubco Huat PVT LTDDokument16 SeitenCase Study Analysis of Rubco Huat PVT LTDUma MaheswariNoch keine Bewertungen

- Conduit Installation WMSDokument7 SeitenConduit Installation WMSmanohar GurramNoch keine Bewertungen

- GIS Siemens Catalogo 36kVDokument16 SeitenGIS Siemens Catalogo 36kVCristian Rene Orozco PerezNoch keine Bewertungen

- Chapter 2 - C Programming LanguageDokument26 SeitenChapter 2 - C Programming LanguageJobet Reyes PalomaNoch keine Bewertungen

- Single Phase Ac Synchronous MotorDokument160 SeitenSingle Phase Ac Synchronous MotordeepaNoch keine Bewertungen

- Chemical Industry Supply ChainDokument6 SeitenChemical Industry Supply ChainSummerieNoch keine Bewertungen

- SAIC-W-C014-Post Weld Visual Inspection - Offshore StructuresDokument4 SeitenSAIC-W-C014-Post Weld Visual Inspection - Offshore StructuresVinu MadhavanNoch keine Bewertungen