Beruflich Dokumente

Kultur Dokumente

RDF Process

Hochgeladen von

muhamad imaduddinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RDF Process

Hochgeladen von

muhamad imaduddinCopyright:

Verfügbare Formate

Processing of Refuse Derived Fuels (RDF-Plants)

From waste to valuable secondary products.

Turn-key solutions for processing RDF.

Processing plant for RDF.

MACHINES

PLANTS

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

Definition

Processing municipal, industrial and

bulky waste, construction refuse and

surplus production with high

high-calorific

calorific

value into homogenous RDF or

secondary fuels for cement kilns or

power stations

stations.

MACHINES

PLANTS

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

Input material

Plastic packaging

Paper industry rejects

g

plastics

p

High-caloric

Mixed waste from households, industry, construction business

Wood

Textiles

MACHINES

Plastics

PLANTS

PROCESS SOLUTIONS

Mixed waste

Bulky waste, mattresses

Processing of Refuse Derived Fuels (RDF-Plants)

MACHINES

PLANTS

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

Overband magnet, Drum screen and Wind shifter

Pre-shredding

Plant concept

Granulation Line

Fe-Fraction

NF-Metal

RDF

MACHINES

PLANTS

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

Pre-shredding

Pre-shredding with

UNI CUT AC AlphaCutter

UNI-CUT

To obtain homogeneous RDF with

high-calorific value, the input

material should be well-mixed

in your system.

Massive extraneous materials

have to be removed at first.

MACHINES

PLANTS

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

Overview

Overband magnet

magnet, Drum screen

screen, Wind shifter

shifter, Granulators

Granulators, FeFe , NF

NF-separation

separation

MACHINES

PLANTS

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

Separation step after Pre-shredding

Overband magnet

MACHINES

PLANTS

Drum screen

PROCESS SOLUTIONS

Fine screen

Processing of Refuse Derived Fuels (RDF-Plants)

Granulation Line (Granulator UNI-CUT UG)

Wind shifter

MACHINES

PLANTS

Granulators

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

Fe- and NF-separation

MACHINES

PLANTS

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

Output

NF-fraction, 10-30 mm

Heavy fraction after Wind shifter

RDF depending on screen

size 10-90 mm

MACHINES

PLANTS

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

Optional: Further Processing

MACHINES

PLANTS

PROCESS SOLUTIONS

High-calorific fraction:

Pellets or fluff

Processing of Refuse Derived Fuels (RDF-Plants)

Technical Information

Capacity:

15 - 50 tons / h Pre-Shredding

Space needed:

approx. 70 x 25 meters

Granulation: approx. 70 x 25 meters

Height approx. 10 meters

Electrical connection:

Pre-Shredding AC L 2200: approx. 340 kW

Granulation 2 x UG 1608: approx. 580 kW

Granulation 2 x UG 2008: approx. 710 kW

Effective Power consumption approx

approx. 70%

Personnel requirement / Shifts:

Pre-Shredding: approx. 2 Persons

Granulation: approx. 3 Persons

MACHINES

PLANTS

PROCESS SOLUTIONS

Processing of Refuse Derived Fuels (RDF-Plants)

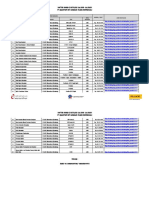

References

Albra Winschoten

Netherlands

Glitzner Entsorgung GmbH

Germany

Jakob Becker GmbH & Co. KG

Germany

R.A.B.E. Abfallaufbereitung GmbH

Germany

Shanks Group

Belgium; United Kingdom

Remondis

Erftstadt, Germany

BEGO

Germany

PEG

Germany

MACHINES

PLANTS

PROCESS SOLUTIONS

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cancer Management 7e (2003)Dokument992 SeitenCancer Management 7e (2003)ccvmdNoch keine Bewertungen

- T300 UKrev5Dokument2 SeitenT300 UKrev5Servicii Curatenie ChisinauNoch keine Bewertungen

- Mil STD 1541aDokument42 SeitenMil STD 1541aramadhany_kizunaNoch keine Bewertungen

- Study On The Mechanism of Force Calculations in Flow Forming A ReviewDokument8 SeitenStudy On The Mechanism of Force Calculations in Flow Forming A ReviewIAEME PublicationNoch keine Bewertungen

- 3D NLS Grafiy EngDokument64 Seiten3D NLS Grafiy Engmedellincolombia100% (1)

- Projectile Motion: AP Physics CDokument26 SeitenProjectile Motion: AP Physics CCedric VargasNoch keine Bewertungen

- Slip FormationDokument28 SeitenSlip Formationpawan_aggarwal_22100% (2)

- Analysis of VOltage and Power Interactions in Multi-Infeed HVDC SystemsDokument9 SeitenAnalysis of VOltage and Power Interactions in Multi-Infeed HVDC SystemstinazdrilicNoch keine Bewertungen

- Budget Work Sample in Science 3Dokument5 SeitenBudget Work Sample in Science 3Nar ZieNoch keine Bewertungen

- EE276 Test 8Dokument3 SeitenEE276 Test 8fred francisNoch keine Bewertungen

- Flame TestDokument9 SeitenFlame TestChristopher YepmoNoch keine Bewertungen

- How To Be Happy, Dammit by Karen Salmansohn - ExcerptDokument22 SeitenHow To Be Happy, Dammit by Karen Salmansohn - ExcerptCrown Publishing Group33% (6)

- 1.constrution of Flying Quad Rotor With Video Surveillance SystemDokument45 Seiten1.constrution of Flying Quad Rotor With Video Surveillance SystemakhilNoch keine Bewertungen

- Wsf-M4d618-A 31au05Dokument4 SeitenWsf-M4d618-A 31au05Yan WendelNoch keine Bewertungen

- ORMOCERIDokument6 SeitenORMOCERIBogdanNoch keine Bewertungen

- Load and Stress Distribution in Screw Threads With Modified WashersDokument11 SeitenLoad and Stress Distribution in Screw Threads With Modified WashersminakirolosNoch keine Bewertungen

- Library CollectionDokument8 SeitenLibrary Collectionapi-282915005Noch keine Bewertungen

- Quantum Information and FoundationsDokument510 SeitenQuantum Information and FoundationsBrent AllieNoch keine Bewertungen

- PL Fluke Biomedical (Ekatalog Link) 2018 - 2020Dokument2 SeitenPL Fluke Biomedical (Ekatalog Link) 2018 - 2020lukas adi nugrohoNoch keine Bewertungen

- 342 B.sc.b.ed. Mdsu PDF 4yrDokument135 Seiten342 B.sc.b.ed. Mdsu PDF 4yrDINESH SALVINoch keine Bewertungen

- TDA7072 DatasheetDokument11 SeitenTDA7072 Datasheetsergio_741Noch keine Bewertungen

- Question PaperDokument1 SeiteQuestion PaperDeepak PradhanNoch keine Bewertungen

- Protection Relay - ANSI Standards - EEPDokument10 SeitenProtection Relay - ANSI Standards - EEPmuraliNoch keine Bewertungen

- Presentation For FPGA Image ProcessingDokument14 SeitenPresentation For FPGA Image ProcessingSaad KhalilNoch keine Bewertungen

- FS-l6S: Instruction ManualDokument25 SeitenFS-l6S: Instruction ManualFazrulNoch keine Bewertungen

- Fluid Report Exp 5Dokument9 SeitenFluid Report Exp 5Hon Siong LinNoch keine Bewertungen

- Euroclad Weathertightness RPTDokument15 SeitenEuroclad Weathertightness RPTy2kareinNoch keine Bewertungen

- Bmpa SouvenirDokument58 SeitenBmpa Souvenirthis_mail_for-forumNoch keine Bewertungen

- I.S.I. C.M.I EntranceDokument6 SeitenI.S.I. C.M.I Entrancegaurav kumarNoch keine Bewertungen