Beruflich Dokumente

Kultur Dokumente

Effect of Overageing Conditions On Microstructure and Mechanical Properties in Al-Si-Mg Alloy

Hochgeladen von

AJER JOURNALOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Effect of Overageing Conditions On Microstructure and Mechanical Properties in Al-Si-Mg Alloy

Hochgeladen von

AJER JOURNALCopyright:

Verfügbare Formate

American Journal of Engineering Research (AJER)

2016

American Journal of Engineering Research (AJER)

e-ISSN: 2320-0847 p-ISSN : 2320-0936

Volume-5, Issue-11, pp-321-325

www.ajer.org

Research Paper

Open Access

Effect of Overageing Conditions on Microstructure and

Mechanical Properties in AlSiMg Alloy

a

Sujoy Saha, aMd. Sarower Hossain Tareq, aRoisul Hasan Galib,

a

Dr. Bazlur Rashid

Department of Materials and Metallurgical Engineering, Bangladesh University of Engineering & Technology,

Dhaka 1000

ABSTRACT: Al-Si alloys have occupied significant position in the field of automobile applications. They are

mainly used in engine parts where the alloys have to withstand high temperature for considerable length of time

i.e ageing effect. This research work has been carried out to investigate the overageing effect on a series of heat

treateble Al-Si-Mg alloy (A355 alloy). The alloys were heat treated at 175C for different length of time and

microstructure and mechanical properties were studied. Considerable changes in miocrostructure were

observed by SEM. Microstructure of moderately aged (1, 2 & 5 hours) alloys showd small precipitated

particles, where overaged (1000, 10000 & 100000 hours) alloys showed coarse precipitated particles in grain

boundary. Composition of the matrix and precipitated phase were ensured by EDS. These changes in

microstructure signeficantly changed mechanical properties of the alloys over different ageing time. Initially the

yield strength and hardness of the alloys increased up to a certain length of heat treatment and then it started to

decrease with increasing heating time. Total elongation before fracture reduced initially and then increased

with increasing heating time. Initially the dispersed second phase particles increased the mechanical strength.

But eventually these properties decreased due to the coarsening of the particles. The study leads to the

conclusion that the optimum aged was achieved between 3 to 5 hours of ageing time.

Keywords: Ageing effect, precipitated phase, coarsening of the particles, Al alloys, tensile properties,

precipitation hardening.

I.

INTRODUCTION

Precipitation-hardenable Al alloys have the potential for being used in the manufacture of several parts

and components in the automotive and aerospace industries, including strategic power train components [1-5],

mostly due to their inherent lightness and good weight-to-strength ratio [6]. Among them, Al-Si alloys have

shown excellent formability and corrosion resistance in practical application [7].

However, effectiveness of

these applications requires development in high operating temperature and internal pressure for a remarkable

length of time. The Al-Si alloys have limited thermal stability and lose their strength above approximately

150C [8-10]. Thus, search for new Al-Si based grades with sufficient thermal stability at continuously

increasing temperatures are going on [10-13]. According to recent findings, alloying elements, such as Cu, Zn,

Mg and transitional metals are being used in the base Al-Si chemistry to modify mechanical properties and

corrosion resistance at elevated temperature [10, 12, 14-19]. As documented in the literature, the effects of Mg

content on the mechanical properties and quality index of AlSi casting alloys were examined in a number of

studies. Drouzy et al. [20] reported that increasing the Mg content from 0.25 to 0.44 % in a sand cast AlSiMg

alloy results in increasing the strength of the alloy without any appreciable change being observed in its quality

index. A further study [21, 22] investigated the influence of Mg content on the tensile properties and quality

index of AlSiMg casting alloys containing Mg in the range of 0.060.44 %. It was observed that increasing

Mg levels in this range resulted in increasing the strength and raising the quality index of the alloys. The

improved quality of the casting, in this case, is related to the fact that the amount by which alloy ductility is

decreased as a result of adding Mg is less than the amount by which the strength is increased; thus, the overall

effect of increasing Mg from 0.06 to 0.44 % is an increase in the quality index. [23]. Caceres and Barresi [24]

studied the influence of Mg content (0.3, 0.5, and 0.7 %) on the quality index of AlSiMg casting alloys

investigated under conditions of various iron levels, solidification rates, and heat treatments. It was concluded

that the quality index value of 355 alloys may be optimized if the Mg content does not exceed 0.5 % in order to

avoid the precipitation of the p-Al8Mg3FeSi6 phase. The general precipitation sequence of AlMgSi alloys is

as follows. Super-saturated solid solution (SSSS) clusters/GP zones [2528].

www.ajer.org

Page 321

American Journal of Engineering Research (AJER)

2016

The needle-like monoclinic phase is considered to be the most effective strengthening precipitate

among all types of precipitates in AlMgSi alloys. Its composition is normally accepted as Mg5Si6 [25, 29].

Natural aging (NA) can significantly depress the hardening kinetics and the maximum strength obtained in

subsequent artificial aging of AlMgSi alloys. This phenomenon, also well-known as negative NA effect,

has attracted a lot of interest because of its link with practical industrial process [3034]. However, overageing

has adverse effect on this alloy [23]. So, it is very beneficial to have clear concept regarding the actual state of

mechanical properties at that severe ageing condition. In this research work change of microstructure and

mechanical properties with different ageing time have been investigated.

Thus this project has a potential of

determining the actual state of strength and hardness when any Al-Si alloy parts experience any elevated

temperature for any length of time.

II.

EXPERIMENTAL

a) Preparation of master alloy

Two distinct alloys have been taken to make the Al-Si master alloy of composition around 4-7% Si and 0.30.6% Mg. The nominal composition selected for this experiment are shown in Table-01.

Table-01: Nominal composition of modified alloys and master alloy

Alloy

Alloy 1

Alloy 2

Master Alloy

Si (%)

3.60

6.33

4.50

Mg (%)

0.04

1.07

0.40

Taken amount

65 %

35 %

100 %

Selected alloys were melted in pit furnace at temperature 750C and permanent metal mold was used to

prepare master alloy. The composition of the alloys obtained from OES analysis showen in Table-02 resembles

with desired composition.

Table-02: Average composition from OES analysis of master alloy.

Constituent

wt (%)

Al

91.15

Si

4.59

Mg

0.45

Cu

1.64

Fe

0.85

Zn

0.26

Ti

0.15

Cr

0.22

b) Preparation of Test samples

Master alloy was melted in pit furnace at 750C and rectangular test bar were prepared from sand

mold. Sand mold were preheated for half an hour to resist thermal shock and also to remove moister conten.

Total 45 rectangular samples were used to study nine different conditions of alloys.

From rectangular plate,

cubic shaped samples were sectioned for SEM analysis. The alloys were fine polished on a polishing wheel

using -alumina particles powder as polishing medium. Non-ferrous metallographic fine polishing standard

technique was carried out with 0.5m -alumina particles in order to obtain the microstructure. Kellers reagent

was used as etching reagent. The ingots were mechanically machined into tensile specimens with a gauge length

of 25.0 mm for each sample as per sub-standard size of the ASTM E8/E8M-11 and the width and thickness of

the samples were 6.00 mm and 5.00 mm respectively. For hardness test cubic shaped samples were prepared.

c)

Solution treatment

The samples were packed together with steel wire and placed in automatic digital induction furnace.

Temperature was raised to 540 C at the rate of 4 C per minute to avoid cracking and distortion. The samples

were kept at 540C for 10 hours. After that, they were brought out of the furnace and quickly quenched in water.

Next they were refrigerated at 15C for 24 hours.

d) Ageing treatment

After solution treatment and ageing delay the test samples were divided into 8 groups. Seven ageing

periods (1, 2, 5, 100, 1000, 10000, 100000 hours) were aged at 175C. After ageing, the samples were cooled in

air. Overall heat treatment cycle is shown in Fig-1. The modified ageing temperature and ageing time are shown

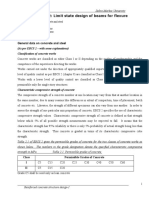

in Table-03.

www.ajer.org

Page 322

American Journal of Engineering Research (AJER)

2016

Fig-1: Heat Treatment cycle.

Table-03: Modification of ageing time and temperature.

Group

1

2

3

4

5

6

7

Ageing time at 175C

(hour)

1

2

5

100

1000

10000

100000

Modified

Ageing

temperature(C)

225

255

285

315

Modified ageing time

(hour)

3.125

3.90

4.88

6.10

e)

Mechanical tests

Tensile and hardness tests were performed with the samples obtained from different heat treatment.

Tensile tests were carried out with a universal testing machine (Instron-3369 Universal Testing Machine) at a

strain rate of 3.00 mm/min at 25C to obtain data on the stressstrain curves containing information of

elongation at fracture and UTS. Hardness tests were performed in Brinell Hardness Testing Machine. 250 kg

load was applied for 10 seconds on the samples to create indentation. The size of the indenter was determined

by measuring two diagonals of the round indenter using a portable microscope. The average of the two

diagonals is used in the following formula to calculate the Brinell hardness.

Brinell hardness number =

Where L = Test load in kg, D = Diameter of the ball in mm and d = Diameter of impression in mm.

f)

Microstructure observation

After heat treatment of as-cast samples, SEM analysis was performed to observe the microstructure

containing precipitated particles of different shapes. EDS analysis was also performed to be confirmed about the

composition of precipitated particles and matrix phase.

III.

RESULTS AND DISCUSSION

a) Microstructural Change

As-cast Al alloy contains proeutectic Al solution, eutectic mixture of Al and Si, Al oxide due to

oxidation at higher temperature and precipitataed particles. As the alloy is solution treated, almost all particles

get dissolved in the Al matrix. High temperature during solution treatment increased the solubility and lead to

quiet uniform microstructure as revealed by FESEM image (Fig-2,a).

Fig-2: FESEM images of (a) as cast, (b) as treated, (c) aged for 5 hours,

(d) over-aged for 100000 hours. All 300X magnification

www.ajer.org

Page 323

American Journal of Engineering Research (AJER)

2016

When the alloy was quenced in water, the solubility decreased, but Si and Mg particles d

id not get

sufficient time to be precipitated. Therefore, the structure became supersaturated solid solution.

At ageing

operation, with increasing time the supersaturated particles get enough time to precipitate. Thus the amount of

precipitaion gradually increased with increasing precipitation time. FESEM image (Fig 2,c) aged for 5 hours

shows medium sized particles precipitated in Al matrix. Finally excess ageing time facilitates the precipitated

particles to grow and becom e coarse r. This phenomenon is recognized as overageing.

Coarse precipitated

particles due to overageing for 10000 hour are seen Fig-2, d.

The EDS analysis of four different conditions are shown in Fig 3. EDS shows the chemical composition of

precipitated (Fig-3, left) and matrix phase (Fig-3, right). Precipitated phase is Si rich, where Al enrichment of

matrix phase also ensured by EDS.

b) Ageing effect on mechanical properties

To observe ageing effect on mechanical properties tensile and hardness test has been performed.

Obtained results of all tests in different conditions are given below in tabular form:

Table-4: Effect of ageing time on Mechanical properties (Tensile and hardness test result).

From above table it is seen that Yield strength for as cast alloy is lower than solution treated alloy.

Then it increased with the ageing time and reached maximum 105.75MPa for ageing at 5 hours. Then, gradually

decreased to 80.10MPa for ageing at 100000 hours. Initially, with increasing yield strength total percentage of

elongation decreased significantly and then as yield strength started to decreased total percentage elongation

increased with increasing ageing time. These changing trends of yield strength (Fig-4, a) and total percentage of

elongation (Fig. 4, b) with ageing time have been shown graphically in Fig-4. Brinnel hardness of the alloy also

gradually increased until ageing for 5 hours and then decreased gradually with increasing ageing time.

Fig-4: Changes of (a) yield strength and (b) percentage of elongation with ageing time

www.ajer.org

Page 324

American Journal of Engineering Research (AJER)

2016

These phenomena of mechanical properties can be described by relating ageing effect on microstructure. After

solution treatment microstructure of the alloy became almost homogeneous without significant precipitated particle in grain

boundary. As the alloy was heated to observe ageing effect, intermetallic particles started to precipitate in grain boundary.

With the increasing ageing time, amount of precipitated particles increased gradually until ageing for 5 hours. These

precipitated particles hindered dislocation to move and consequently increased yield strength. Total elongation also reduced

due to pinning effect by precipitated particles. When the alloys were heated further more time, precipitated particles began to

become coarser. These coarse particles reduced effective pinning effect of particles allowing dislocations to move more

easily than before. As a result yield strength of the alloy gradually became lower and as dislocation could move easily total

percentage of elongation also increased gradually.

IV.

CONCLUSION

Effect of ageing time on microstructure and mechanical properties has been studied in the work. With

increasing ageing time amount of precipitated particles increased gradually. These precipitated particles in grain

boundary hindered the movement of dislocation. As a result yield strength of the alloy increased and total

percentage of elongation decreased gradually until a particular ageing time. With increasing ageing time

precipitated particles become coarser and reduced the pinning effect of the dislocation. Consequently yield

strength decreased and total percentage of elongation increased.

REFERENCE

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

[10].

[11].

[12].

[13].

[14].

[15].

[16].

[17].

[18].

[19].

[20].

[21].

[22].

[23].

[24].

[25].

[26].

[27].

[28].

[29].

[30].

[31].

Chaudhury S K and Apelian D, Effects of rapid heating on solutionizing characteristics of AlSi-Mg alloys using a fluidized bed,

Metallurgical and Materials Transactions A, vol. 37A, pp. 763-778, 2006.

Ran G, Zhou J E and Wang Q G, Precipitates and tensile fracture mechanism in a sand cast

A356 aluminum alloy, Journal of Materials Processing Technology, vol. 207, pp. 46-52, 2008.

R.C. Lemon, C.R. Howle, Premium strength aluminum casting alloys 354 and 359. AFS Trans. 70, 465470 (1963)

J.G. Kaufman, E.L. Rooy, Aluminum Alloy Castings: Properties, Processing, and Applications (ASM

International, Materials Park, OH, 2004)

ASM Handbook Vol. 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials.

ASM International, Materials Information Society,USA (1990)

Davis, J. R. (1993). Aluminum and aluminum alloys. J. R. Davis (Ed.). ASM international.T. Abid, A. Boubertakh, S. Hamamda, J.

Alloys Compd. 490 (2010) 166169

Ringer, S. P., & Hono, K. (2000). Microstructural evolution and age hardening in Al alloys: atom probe field-ion microscopy and

transmission electron microscopy studies. Materials characterization, 44(1), 101-131.Li, J. F., Peng, Z. W., Li, C. X., Jia, Z. Q.,

Chen, W. J., & Zheng, Z. Q. (2008).

Kasprzak W, Emadi D, Sahoo M and Aniolek M, Development of aluminium alloys for high temperature applications in diesel

engines, Materials Science Forum, Vols. 618-619, pp. 595- 600, 2009.Lee J A, Automotive Alloys 2003, in TMS, San Diego, 2003.

Kasprzak W, Deng Z, Powell J and Niewczas M, Aging characteristics, dimensional stability and assesment of high temperature

performance of cast Al-Si alloy for power train applications, 12th International Conference on Aluminum Alloys, Yokohama,

Japan, 2010.

Voorhees P W, Alloys: Scandium overtakes zirconium, Nature Materials, vol. 5, pp. 435-436, 2006.

Kim, Y. W. (1989). Intermetallic alloys based on gamma titanium aluminide. Jom, 41(7), 24-30.

Kulekci, M. K. (2008). Mg and its alloys applications in automotive industry. The International Journal of Advanced Manufacturing

Technology, 39(9-10), 851-865.

Davis, J. R. (Ed.). (1999). Corrosion of aluminum and aluminum alloys. Asm International.

Vargel, C. (2004). Corrosion of aluminium. Elsevier.

Kasprzak W, Chen D L and Shaha S K, Heat treatment development for a rapidly solidified heat resistant cast Al-Si alloy, Journal

of Materials Engineering and Performance, vol. 22, pp. 1838-1847, 2013.

Kasprzak W, Amirkhiz B S and Niewczas M, Structure and properties of cast Al-Si based alloy with Zr-V-Ti additions and its

evaluation of high temperature performance, Journal of Alloys and Compounds, vol. 595, pp. 67-79, 2014.

M. Drouzy, S. Jacob, M. Richard, Interpretation of tensile results by means of quality index and probable yield strength. AFS Int

Cast Metals J 5, 4350 (1980)

G.K. Sigworth, Controlling Tensile Strength in Aluminum Castings. Special Communication (2006)

G.K. Sigworth, Aluminum Casting Alloys. Special Communication (2008)

Ibrahim, Mohamed F., et al. "Effect of Aging Conditions on Precipitation Hardening in AlSiMg and AlSiCuMg

Alloys." International Journal of Metalcasting (2016): 1-13.12. C.H. Ca ceres, J. Barresi, Selection of temper and Mg content to

optimize the quality index of Al7SiMg casting alloys. Int. J. Cast Met. Res. 12, 377384 (2000)

J.H. Chen, E. Costan, M.A. van Huis, Q. Xu, H.W. Zandbergen, Science 312 (2006) 416419.

P.H. Ninive, A. Strandlie, S. Gulbrandsen-Dahl, W. Lefebvre, C.D. Marioara, S.J. Andersen, J. Friis, R. Holmestad, O.M. Lvvik,

Acta Mater. 69 (2014) 126134.

K. Matsuda, Y. Sakaguchi, Y. Miyata, Y. Uetani, T. Sato, A. Kamio, S. Ikeno, J. Mater. Sci. 35 (2000) 179189.

S. Andersen, H. Zandbergen, J. Jansen, C. Traeholt, U. Tundal, O. Reiso, Acta Mater. 46 (1998) 32833298.

H.W. Zandbergen, S.J. Andersen, J. Jansen, Science 277 (1997) 12211225

C.D. Marioara, S.J. Andersen, J. Jansen, H.W. Zandbergen, Acta Mater. 51 (2003) 789796.

S. Pogatscher, H. Antrekowitsch, H. Leitner, T. Ebner, P.J. Uggowitzer, Acta Mater. 59 (2011) 33523363.

F.A. Martinsen, F.J.H. Ehlers, M. Torster, R. Holmestad, Acta Mater. 60 (2012) 60916101.

G.H. Tao, C.H. Liu, J.H. Chen, Y.X. Lai, P.P. Ma, L.M. Liu, Mater. Sci. Eng. A 642 (2015) 241248.

S.

Pogatscher,

H.

Antrekowitsch,

H.

Leitner,

A.S.

Sologubenko,

P.J.

Uggowitzer,

Scripta Mater. 68 (2013) 158161.

Singh, S., & Goel, D. B. (1990). Influence of thermomechanical ageing on tensile properties of 2014 aluminium alloy. Journal of

Materials Science, 25(9), 3894-3900.

www.ajer.org

Page 325

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Switching of Security Lighting System Using Gsm.Dokument12 SeitenSwitching of Security Lighting System Using Gsm.AJER JOURNALNoch keine Bewertungen

- Performance Analysis of LTE in Rich Multipath Environments Considering The Combined Effect of Different Download Scheduling Schemes and Transmission ModesDokument6 SeitenPerformance Analysis of LTE in Rich Multipath Environments Considering The Combined Effect of Different Download Scheduling Schemes and Transmission ModesAJER JOURNALNoch keine Bewertungen

- The Differentiation Between The Turbulence and Two-Phase Models To Characterize A Diesel Spray at High Injection PressureDokument7 SeitenThe Differentiation Between The Turbulence and Two-Phase Models To Characterize A Diesel Spray at High Injection PressureAJER JOURNALNoch keine Bewertungen

- Pixel Based Off-Line Signature Verification SystemDokument6 SeitenPixel Based Off-Line Signature Verification SystemAJER JOURNALNoch keine Bewertungen

- Experimental Investigation On The Effects of Digester Size On Biogas Production From Cow DungDokument6 SeitenExperimental Investigation On The Effects of Digester Size On Biogas Production From Cow DungAJER JOURNALNoch keine Bewertungen

- Recycling of Scrapped Mating Rings of Mechanical Face SealsDokument5 SeitenRecycling of Scrapped Mating Rings of Mechanical Face SealsAJER JOURNALNoch keine Bewertungen

- Structure and Surface Characterization of Nanostructured Tio2 Coatings Deposited Via HVOF Thermal Spray ProcessesDokument9 SeitenStructure and Surface Characterization of Nanostructured Tio2 Coatings Deposited Via HVOF Thermal Spray ProcessesAJER JOURNALNoch keine Bewertungen

- An Evaluation of Skilled Labour Shortage in Selected Construction Firms in Edo State, NigeriaDokument12 SeitenAn Evaluation of Skilled Labour Shortage in Selected Construction Firms in Edo State, NigeriaAJER JOURNALNoch keine Bewertungen

- Comparative Analysis of Cell Phone Sound Insulation and Its Effects On Ear SystemDokument6 SeitenComparative Analysis of Cell Phone Sound Insulation and Its Effects On Ear SystemAJER JOURNALNoch keine Bewertungen

- Unmanned Aerial Vehicle and Geospatial Technology Pushing The Limits of DevelopmentDokument6 SeitenUnmanned Aerial Vehicle and Geospatial Technology Pushing The Limits of DevelopmentAJER JOURNALNoch keine Bewertungen

- Improved RSA Cryptosystem Based On The Study of Number Theory and Public Key CryptosystemsDokument7 SeitenImproved RSA Cryptosystem Based On The Study of Number Theory and Public Key CryptosystemsAJER JOURNALNoch keine Bewertungen

- Production and Comparartive Study of Pellets From Maize Cobs and Groundnut Shell As Fuels For Domestic Use.Dokument6 SeitenProduction and Comparartive Study of Pellets From Maize Cobs and Groundnut Shell As Fuels For Domestic Use.AJER JOURNALNoch keine Bewertungen

- Experimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilDokument6 SeitenExperimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilAJER JOURNALNoch keine Bewertungen

- Minimizing Household Electricity Theft in Nigeria Using GSM Based Prepaid MeterDokument11 SeitenMinimizing Household Electricity Theft in Nigeria Using GSM Based Prepaid MeterAJER JOURNALNoch keine Bewertungen

- A Concept of Input-Output Oriented Super-Efficiency in Decision Making Units.Dokument6 SeitenA Concept of Input-Output Oriented Super-Efficiency in Decision Making Units.AJER JOURNALNoch keine Bewertungen

- Weighted Denoising With Multi-Spectral Decomposition For Image CompressionDokument13 SeitenWeighted Denoising With Multi-Spectral Decomposition For Image CompressionAJER JOURNALNoch keine Bewertungen

- The Role of Citizen Participant in Urban Management (Case Study: Aligudarz City)Dokument6 SeitenThe Role of Citizen Participant in Urban Management (Case Study: Aligudarz City)AJER JOURNALNoch keine Bewertungen

- An Exponent-Based Propagation Path Loss Model For Wireless System Networks at Vehicular SpeedDokument12 SeitenAn Exponent-Based Propagation Path Loss Model For Wireless System Networks at Vehicular SpeedAJER JOURNALNoch keine Bewertungen

- Statistical Method of Estimating Nigerian Hydrocarbon ReservesDokument10 SeitenStatistical Method of Estimating Nigerian Hydrocarbon ReservesAJER JOURNALNoch keine Bewertungen

- Utilization of "Marble Slurry" in Cement Concrete Replacing Fine AgreegateDokument4 SeitenUtilization of "Marble Slurry" in Cement Concrete Replacing Fine AgreegateAJER JOURNALNoch keine Bewertungen

- Eye State Detection Using Image Processing TechniqueDokument6 SeitenEye State Detection Using Image Processing TechniqueAJER JOURNALNoch keine Bewertungen

- WHY JESUS CHRIST CAME INTO THE WORLD?... (A New Theory On "TIE MINISTRY")Dokument12 SeitenWHY JESUS CHRIST CAME INTO THE WORLD?... (A New Theory On "TIE MINISTRY")AJER JOURNALNoch keine Bewertungen

- DMP Packet Scheduling For Wireless Sensor NetworkDokument8 SeitenDMP Packet Scheduling For Wireless Sensor NetworkAJER JOURNALNoch keine Bewertungen

- Urbanization and The Risk of Flooding in The Congo Case of The City of BrazzavilleDokument6 SeitenUrbanization and The Risk of Flooding in The Congo Case of The City of BrazzavilleAJER JOURNALNoch keine Bewertungen

- Theoretical and Experimental Study of Cavitation Dispersing in "Liquid-Solid" System For Revelation of Optimum Influence ModesDokument10 SeitenTheoretical and Experimental Study of Cavitation Dispersing in "Liquid-Solid" System For Revelation of Optimum Influence ModesAJER JOURNALNoch keine Bewertungen

- The Design and Implementation of A Workshop Reservation SystemDokument7 SeitenThe Design and Implementation of A Workshop Reservation SystemAJER JOURNALNoch keine Bewertungen

- Distinct Revocable Data Hiding in Ciphered ImageDokument7 SeitenDistinct Revocable Data Hiding in Ciphered ImageAJER JOURNALNoch keine Bewertungen

- Frequency Selective Fading in Wireless Communication Using Genetic AlgorithmDokument6 SeitenFrequency Selective Fading in Wireless Communication Using Genetic AlgorithmAJER JOURNALNoch keine Bewertungen

- Risk Assessment and Risk MappingDokument7 SeitenRisk Assessment and Risk MappingAJER JOURNALNoch keine Bewertungen

- Head Determination and Pump Selection For A Water Treatment Plant in Villages Around Maiduguri, Borno State, NigeriaDokument5 SeitenHead Determination and Pump Selection For A Water Treatment Plant in Villages Around Maiduguri, Borno State, NigeriaAJER JOURNALNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Wave Optics and E.M Waves 3.0 With PracticeDokument92 SeitenWave Optics and E.M Waves 3.0 With PracticeAshutosh SinghNoch keine Bewertungen

- Prof. Dr.-Ing. Uwe Franzke ILK Dresden Cooling Loads - The New Standard VDI 2078Dokument25 SeitenProf. Dr.-Ing. Uwe Franzke ILK Dresden Cooling Loads - The New Standard VDI 2078Sashko GjorgievskiNoch keine Bewertungen

- Fluid Mechanics - BuoyancyDokument6 SeitenFluid Mechanics - BuoyancyAbduljalil AlabidiNoch keine Bewertungen

- Tugasan BDC4013 - Sem 2 0809Dokument4 SeitenTugasan BDC4013 - Sem 2 0809Shinee JayasilanNoch keine Bewertungen

- Durham E-Theses: Novel Block Co-Polymers As Potential Photonic MaterialsDokument118 SeitenDurham E-Theses: Novel Block Co-Polymers As Potential Photonic MaterialsWassini BensNoch keine Bewertungen

- Climate Change Test ReviewDokument1 SeiteClimate Change Test ReviewSabrina Lavega67% (3)

- Section 10.2: Theoretical Acid-Base Definitions: Chapter 10: Acids and BasesDokument2 SeitenSection 10.2: Theoretical Acid-Base Definitions: Chapter 10: Acids and BasesPavni ChandaniNoch keine Bewertungen

- Hygrophil HCDT: Product InformationDokument18 SeitenHygrophil HCDT: Product InformationDavidNoch keine Bewertungen

- MP ProblemsDokument2 SeitenMP Problemskartikesh prasadNoch keine Bewertungen

- Chapter 2: Limit State Design of Beams For Flexure: General Data On Concrete and SteelDokument27 SeitenChapter 2: Limit State Design of Beams For Flexure: General Data On Concrete and SteelAntenehNoch keine Bewertungen

- PROTECTIONS & Interlocks Diary 300MWDokument42 SeitenPROTECTIONS & Interlocks Diary 300MWkarthick.gNoch keine Bewertungen

- Fine Art Flowers PDFDokument23 SeitenFine Art Flowers PDFmrpiracyNoch keine Bewertungen

- Heat Shrinking AllDokument46 SeitenHeat Shrinking AllCaylie KirbyNoch keine Bewertungen

- A. Beccantini, A. Malczynski and E. Studer - Comparison of TNT-Equivalence Approach, TNO Multi-Energy Approach and A CFD Approach in Investigating Hemispheric Hydrogen-Air Vapor Cloud ExplosionsDokument18 SeitenA. Beccantini, A. Malczynski and E. Studer - Comparison of TNT-Equivalence Approach, TNO Multi-Energy Approach and A CFD Approach in Investigating Hemispheric Hydrogen-Air Vapor Cloud ExplosionsSodaMoussezNoch keine Bewertungen

- Earth Science: Journey ToDokument7 SeitenEarth Science: Journey ToAlyah Jannah HiñolaNoch keine Bewertungen

- OCE551-Air Pollution and Control EngineeringDokument14 SeitenOCE551-Air Pollution and Control EngineeringRanjith100% (1)

- Pump CavitationDokument5 SeitenPump Cavitationjrri16Noch keine Bewertungen

- AQA Physics Unit 6 Waves Student Progress SheetDokument7 SeitenAQA Physics Unit 6 Waves Student Progress SheetGabriel HoNoch keine Bewertungen

- Astm D3418 2012Dokument7 SeitenAstm D3418 2012Rodrigo TomazNoch keine Bewertungen

- Liquid Penetrant Examination Procedure For Asme CodeDokument15 SeitenLiquid Penetrant Examination Procedure For Asme Codeshabbir626Noch keine Bewertungen

- Optical Processes in SemiconductorsDokument6 SeitenOptical Processes in Semiconductorsvj.krlambaNoch keine Bewertungen

- Distinguishing Between Ionic and Covalent Compounds LabDokument3 SeitenDistinguishing Between Ionic and Covalent Compounds LabSamuelNoch keine Bewertungen

- Ce 6501 Sructural Analysis - I Question Bank - Kesavan Edition 2015Dokument24 SeitenCe 6501 Sructural Analysis - I Question Bank - Kesavan Edition 2015senthurrNoch keine Bewertungen

- Sol-Gel Synthesis of Zinc Oxide Nanoparticles Using Citrus Aurantifolia ExtractsDokument4 SeitenSol-Gel Synthesis of Zinc Oxide Nanoparticles Using Citrus Aurantifolia ExtractsAnonymous ix7WERGNoch keine Bewertungen

- Gamma RaysDokument34 SeitenGamma RaysuzmaNoch keine Bewertungen

- ANSI Z97.1 SummaryDokument4 SeitenANSI Z97.1 SummaryAli YalazNoch keine Bewertungen

- Beam Is Code Crackwidth ValidationDokument1 SeiteBeam Is Code Crackwidth ValidationNirbhayNoch keine Bewertungen

- BNT Quartet BrochureDokument2 SeitenBNT Quartet BrochureAnonymous 0oFWTQFNoch keine Bewertungen

- Lecture 7 Inclusions and Pinhole Formation in DIDokument33 SeitenLecture 7 Inclusions and Pinhole Formation in DILuis Arturo RamirezNoch keine Bewertungen

- 15NT101 Elements of Nanoscience and NanotechnologyDokument3 Seiten15NT101 Elements of Nanoscience and NanotechnologyAravind Chandar BNoch keine Bewertungen