Beruflich Dokumente

Kultur Dokumente

Head Loss Estimation For Water Jets From Flip Buckets

Hochgeladen von

theijesOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Head Loss Estimation For Water Jets From Flip Buckets

Hochgeladen von

theijesCopyright:

Verfügbare Formate

The International Journal Of Engineering And Science (IJES)

|| Volume || 5 || Issue || 11 || Pages || PP 48-57 || 2016 ||

ISSN (e): 2319 1813 ISSN (p): 2319 1805

Head Loss Estimation for Water Jets from Flip Buckets

Cuneyt Yavuz1, Ali E. Dincer2, Ismail Aydin3

1,2

Ph.D. Candidate, Water Resources Lab., Dept. of Civil Engineering, Middle East Technical University,

06800, ankaya/Ankara, Turkey.

3

Professor, Hydromechanics Lab., Dept. of Civil Engineering, Middle East Technical University, 06800,

ankaya/Ankara, Turkey.

------------------------------------------------------- -ABSTRACT------------------------------------------------------------Water jet issued from flip bucket at the end of the spillway of a dam can be a threat for the stability and safety of

the dam body due to subsequent scour at the impingement point. However, a strong jet from the flip bucket

interacts with the surrounding air and develops into an aerated turbulent jet while the jet impact and scouring

effect is reduced significantly. Aeration of the jet, at the same time, cause head losses along the trajectory. An

experimental study is conducted to measure the trajectory lengths and investigate the effect of water depth in the

river on the dynamic pressures acted on the river bed. The trajectory lengths with and without air entrainment

are calculated using empirical equations and compared with the measurements. Head losses due to air

entrainment are determined using the difference of the trajectory lengths with and without aeration, based on

the projectile motion theory. Numerical simulation of the flow over the spillway, along the flip bucket and the jet

trajectory is made and the results are compared with the experimental data. It is observed that trajectory

lengths obtained from experiments, numerical simulation and empirical formulas are comparable with

negligible differences. This allows us to combine alternate approaches to determine the trajectory lengths with

and without air entrainment and estimate the head losses accordingly.

Keywords: Water Jet, Flip Bucket, Impact Assessment, Trajectory Length, Jet Dispersion, Numerical Method

--------------------------------------------------------------------------------------------------------------------------------------Date of Submission: 10 November 2016

Date of Accepted: 18 November 2016

----------------------------------------------------------------------------------------------------------------------------- --------I.INTRODUCTION

Reports of investigations of jets issued from a flip bucket can be found in French literature between

1930s and 1950s [1], [2], [3], [4]. These studies were conducted on prototype dams as reported in the

observations of Maitre and Obolensky [5]. Flip buckets are used to dissipate energy of water coming from the

spillway especially for high flow velocities. Flip buckets can be designed in various shapes and scales

according to the geological and economic circumstances affecting the relative curvature, deflection angles,

take-off angles and other components that are in operation. There are only a few guidelines available to

standardize the design of flip buckets [6]. Heller et al. [7] considered the 2-D ski jump and they worked on the

scale effects of the water jets and found that aerated water jets coming from the spillway required the approach

flow depth of at least 40 mm. They have examined the pressure distribution on the ski jumps for different take off angles. It was shown that the lower and upper jet trajectories have a different take-off angle from the

bucket angle with parabolic jet trajectory depending on the Froude number and the approach flow depth.

Mason [8] developed several empirical formulas to predict the scour depth and found that scour might be

affected by the percentage of air entrainment present in the free jet. A new empirical equation to calculate the

scour depth of aerated jets was also proposed based on experiments. It was found that the scour profiles caused

by aerated jets are flatter than those caused by non-aerated jets.

In the present study, a hydraulic model [9] in the Hydromechanics laboratory of Middle East Technical

University (METU) is used as the test basin (Fig. 1).

www.theijes.com

The IJES

Page 48

Head Loss Estimation for Water Jets from Flip Buckets

Fig. 1 Hydraulic Model

The physical model was constructed using Froude Similarity with a length scale of 1:25. Geometric elements

of the spillway are shown in Fig. 2.

Lt

Fig. 2 Geometric elements of the Spillway and Flip Bucket

In order to assess the impact at the impingement area of the jet, 10 pressure transducers are used to record

dynamic pressure distribution at the impact region (Fig. 3). Total pressures at the impingement area are

measured for different tail water depths at the downstream of the flip bucket.

zi

Lt

Transducers

Fig. 3 Transducer arrangement and measured parameters

Additionally, trajectory lengths and jet velocities on the flip bucket lip are measured for all test cases.

Trajectory lengths with and without air entrainment were also calculated using empirical formulas and

measured jet velocities. Experimental data is evaluated to predict the head losses due to air entrainment.

II.EXPERIMENTAL SETUP

Experiments are performed for 6 different discharges [10]. Dynamic pressures at the impingement area

are measured for 6 different tail water depths for all discharges. Thus, a total of 36 different pressure

measurements are recorded. Jet velocity (Vj) and the water depth (y0) at the flip bucket lip and trajectory length

(L1) data measured from the test facility are given in Table 1.

Table 1 Data describing the test cases

Q (m3/s)

0.07

0.10

0.13

0.16

0.19

0.22

y0 (m)

0.035

0.031

0.027

0.023

0.019

0.015

Vj (m/s)

7.86

7.66

7.41

7.07

6.58

5.83

(L1)m (m)

5.49

5.10

5.04

4.67

4.07

3.55

Before starting the measurements, the discharge and tail water level are fixed for all test cases. Then,

velocity of the jet, the flow depth and the horizontal throw distance to the point of impingement are measured.

Velocity at the lip of the flip bucket is measured using a pitot tube. These measurements are repeated for each

test case given in Table 1. Dynamic pressures are recorded by electronic transducers arranged along the impact

region from the beginning to the end of the jet impingement line. Electronic signals from the pressure

www.theijes.com

The IJES

Page 49

Head Loss Estimation for Water Jets from Flip Buckets

transducers are digitized by Data Acquisition system (DAQ) [11]. Dynamic pressures are recorded for a period

of 180 seconds and digitized at 40 Hz frequency for every test case.

III.JET TRAJECTORIES

To predict non-aerated trajectory lengths the projectile motion theory is used. In this theory, the water jet is

considered to be frictionless. The equation for the horizontal travel distance of the projectile motion is expressed

as [12]

[1]

where Lt is the trajectory length for non-aerated jet, zi is the vertical drop from lip to tail-water level, Hj is the

velocity head of the jet at the bucket lip (Vj2/2g), j is the bucket lip angle (in degrees). The velocity head Hj at

the bucket lip can be calculated by accounting the head losses from reservoir up to the bucket lip. In this study,

this is done by using the measured jet velocity at the lip of the bucket. Concerning the trajectory lengths with air

entrainment, Kawakami [13] presented results of some field research on trajectories that are affected by the air

resistance and defined a coefficient, k for the following equations

[2]

where

[3]

andL1 is the trajectory length considering air resistance, k is the aeration constant, V j is the velocity at the bucket

lip.

z

t

L1

Lt

0.03

0.02

0.01

0

10

20

30

Vj (m/s)

40

20

30

Vj (m/s)

40

1.00

0.75

0.50

0.25

0

10

Fig. 4 Effect of air resistance on jet trajectory. [13]

Fig. 4 shows the experimental relationship between Vj and k and also L1/Lt values for variable Vj,

given by Kawakami [13], where Lt is the throw distance without considering the air resistance, t represents the

trajectory angle at the impingement point. It is observed that the effect of air resistance is small when V j is less

than about 20 m/s but, it reduces the throw distance by about 30% when the velocity is about 40 m/s.

Since the velocities measured in the present hydraulic model are small to use the graphs prepared by Kawakami,

prototype velocities are calculated by using the Froude similarity law and appropriate comparisons are made.

IV.NUMERICAL MODEL

Numerical investigations can also be used to determine the characteristics of the flow in addition to

experimental and empirical studies. Computational fluid dynamics (CFD) tools are used to solve the problem

numerically. The commercial CFD code Flow 3D is used in the numerical study [14]. The Reynolds-Averaged

Navier-Stokes (RANS) equations for an incompressible, Newtonian fluid are used in the numerical model. The

k- model of turbulence [15] is used in the computation of Reynolds stresses.

www.theijes.com

The IJES

Page 50

Head Loss Estimation for Water Jets from Flip Buckets

The CFD code uses fractional area volume obstacle representation (FAVOR), improved volume of

fluid technique (VOF) and multi-block meshing to increase accuracy of the solution. In order to discretize the

flow domain, structured grids are used by free gridding method. In this way, the time required for the grid

generation and computation decreases considerably.

The spillway used for the experiments was constructed by using AutoCAD, commercially available

CAD software [16]. Then the constructed model was imported to Flow-3D. Mesh sizes were taken as 5 cm in z

direction and 10 cm in x direction in order to determine the wall shear stresses and slip effects between the

boundary and the water correctly. For 3 m upstream of the spillway, reservoir levels were fixed for each case.

Boundary conditions were defined as specified pressure with a constant water height at the flow inlet, symmetry

at the top of the spillway and outflow at the downstream of the spillway. Time intervals were determined by

considering the CourantFriedrichsLewy (CFL) condition. For modeling turbulence k- model was used and

turbulent mixing length was dynamically computed. In order to save computational time, the computational

model is assumed as 2-dimensional and the calculations were done in a 2D vertical plane.

V.HEAD LOSS ESTIMATION

The main aim of the water jet diverted into the air by a flip bucket is to reduce the energy of the high

speed water coming from the spillway by creating jet dispersion. Dispersed jet entrains large amount of air and

this reduces the jet velocity as a result of significant head losses. Head loss due to the air entrainment can be

calculated from the difference between the trajectory lengths with and without air entrainment. The measured

length in the hydraulic model is affected by the head losses due to air entrainment while the calculated length

obtained from the projectile theory has no head loss effect since air entrainment is not accounted for. Energy for

the two cases can be related as

[4]

where

Hj (=Vj2/2g) is the jet head obtained from the jet velocity, V j1 is measured at the bucket lip, Hj2 (=Vj22/2g) is the

hypothetical jet head obtained from projectile theory using the measured trajectory length which is affected from

head losses. Vj2 is obtained from Eq. [1] by inserting the measured trajectory length, L 1 in place of Lt in the

equation. Then, the head loss due to air entrainment, h L is obtained from Eq. [4]. Various parameters related to

projectile motion of the jet are defined in Fig. 5.

Real Jet

Hypothetical

(frictionless) Jet

zi

L1

Lt

Fig. 5 Throw distance of jet

VI.DYNAMIC PRESSURE CALCULATIONS

Pressures recorded from electronic transducers represent the total pressure, P T, composed of mean and

fluctuating components. The mean pressure, P H, in this case is the hydrostatic component independent of time,

and Pd is the fluctuating component due to large scale turbulence. Subtracting the hydrostatic pressure head from

recorded total pressure head, the dynamic pressure head is obtained from Eq. [5].

[5]

Dynamic pressure variations at the bed for variable water cushion depths and different discharges obtained from

the experiments are shown in Fig. 6.

www.theijes.com

The IJES

Page 51

Head Loss Estimation for Water Jets from Flip Buckets

Fig. 6 Dynamic pressure variations due to different water depths for various discharges

If the measured pressure data in Fig. 6 is inspected, it can be seen that increasing the tail water depth in

the plunging area reduces the dynamic pressure for a constant discharge up to 0.13 m 3/s. However, dynamic

pressures suddenly increase for discharges lower than 0.13 m3/s. The enhancement of dynamic pressure at low

discharges has two reasons: the increased trajectory angle ( t) at the impingement point and insufficient aeration

of the water jet. Experimental data revealed that aeration of the jet is more effective in reducing the dynamic

pressures on the river bed rather than increasing the tail-water depth.

VII.ANALYSIS OF RELATIONSHIP BETWEEN EXPERIMENTAL, CALCULATED AND

SIMULATED DATA

a. Comparison of the Measured, Calculated and Simulated Trajectory Lengths

Flip bucket lip angle and the jet velocity on the bucket lip together define the profile of the trajectory.

Depending on the projectile motion theory, the water jet motion occurs in a frictionless domain. Therefore,

velocity does not change throughout the trajectory of the jet. If a measured trajectory length is compared to the

one obtained by assuming that the motion occurs in the frictionless medium, the velocity required to traverse

www.theijes.com

The IJES

Page 52

Head Loss Estimation for Water Jets from Flip Buckets

this length can be calculated. Since the environment is frictionless, the bucket lip velocity does not change until

the impingement point. Difference between the velocities obtained from the measured and calculated

(frictionless) lengths gives the head loss due to air entrainment.

Initially, the jet trajectory can be calculated on the basis of projectile theory from Eq. [1] and the

trajectory length with air entrainment should be calculated from Eq. [2]. In order to utilize Fig. 4 to define the

air resistance/air entrainment constant given by Kawakami, prototype velocities are required. In addition to this

calculation, simulations of trajectory lengths by using Flow-3D software are performed for the comparison of

the measured and calculated trajectory lengths for the same conditions. Results of the measured trajectory

lengths from the experiments, calculated trajectory lengths from projectile theory and Kawakamis equation and

numerical results are given in Table 2.

Table 2 Comparison of the measured, calculated and simulated trajectory lengths

Vj (m/s)

7.86

7.66

7.41

7.07

6.58

5.83

(Vj)prototype (m/s)

39.29

38.31

37.04

35.33

32.89

29.17

k from Fig. 9

0.025

0.026

0.022

0.021

0.020

0.020

Ltc (m)

7.06

6.77

6.41

5.95

5.32

4.42

Lts (m)

6.95

6.70

6.15

5.90

5.30

4.20

(L1)m (m)

5.49

5.10

5.04

4.67

4.07

3.55

(L1)c (m)

5.34

5.10

4.78

4.36

3.79

2.98

(L1)s(m)

5.40

5.40

4.85

4.60

4.40

3.83

In Table 2, (Lt)c and (Lt)s is the calculated and simulated trajectory lengths without air entrainment and

(L1)m, (L1)c and (L1)s is the measured, calculated and simulated trajectory lengths with air entrainment

respectively. As can be seen from the Table, calculated trajectory lengths using projectile motion formula and

the simulated trajectory lengths using Flow-3D software without considering air entrainment are almost

matching up with each other. On the other hand, measured, calculated and simulated trajectory lengths

considering air entrainment show small variations in the range of experimental accuracy. Since both analytical

and numerical methods give similar results with the experimental measurements, head losses due to air

entrainment in water jets can be estimated using either analytical methods or numerical approaches as well. So,

numerical simulations are also performed for non-aerated medium. But, measured trajectory lengths and

calculated trajectories using Kawakamis formula are reduced by significant amount of air absorbed which

turned the water jet into air-water mixture. Aerated jet trajectories can be obtained by using CFD solution as

well. Since the aerated trajectory lengths can be measured only from the test facility, comparing these lengths

can be more appropriate to see the difference between the measured, calculated and simulated trajectories.

Comparison of the measured, calculated and simulated trajectory lengths with air entrainment are shown in Fig.

7.

6

(L1)s (m)

(L1)m (m)

4

3

4

3

2

1

0

3

(L1)c (m)

3

(L1)c (m)

Fig. 7 Comparison of the measured, calculated and simulated trajectory lengths with air entrainment

When the arbitrariness in measurement and the difference between the equations in calculating and simulating

the trajectory length for this study is considered, the agreement is assumed to be good.

b.

Calculation of Head Loss Due to Air Entrainment

Fig. 7 shows that the measured, calculated and simulated trajectory lengths are very close. In order not

to perform any experiment and refrain from the uncertainty of the empirical equations, calculation of head loss

due to air entrainment can be reasonable via calculating the velocity difference considering the trajectory lengths

by neglecting the air entrainment from numerical results. Head losses due to air entrainment can then be

calculated depending on the simulated trajectory lengths. Initially simulated trajectory lengths without air

entrainment are used to obtain required jet velocities using Eq. [1]. Same calculations are made on the simulated

www.theijes.com

The IJES

Page 53

Head Loss Estimation for Water Jets from Flip Buckets

lengths by including the air entrainment. Head loss value is calculated using the velocity head difference

between calculations from Eq. [4]. Head loss calculations are given in Table 3 for the test cases.

Table 3 Head loss due to air entrainment

Q (m3/s)

0.22

0.19

0.16

0.13

0.10

0.07

Vj (m/s)

7.79

7.62

7.22

7.03

6.57

5.64

Vj2 (m/s)

6.65

6.65

6.20

5.99

5.82

5.30

Hj (m)

3.09

2.96

2.65

2.52

2.20

1.62

Hj2 (m)

2.25

2.25

1.96

1.83

1.73

1.43

hL (m)

0.84

0.71

0.69

0.69

0.47

0.19

c.Evaluation of Measured Dynamic Pressure Data

The maximum measured dynamic pressure values are shown as function of discharge in Fig. 8. When

the measured maximum dynamic pressure values are inspected carefully, it is observed that dynamic pressure

decreases with decreasing discharge. However, below a critical value, there is a sharp increase in dynamic

pressure. This result is due to reduced rate of aeration with less air bubbles penetrating the water body at the

impingement area. The sudden change in air bubble formation may be due to scale effect in the laboratory where

the Reynolds and Weber numbers may be small for small discharges used in the experiments. In order to avoid

scale effect in aerated flow, the Reynolds number of the jet flow should be above 3x10 5 and Weber number of

the jet flow should be above 2x104 for similar studies [17]. The measured dynamic pressures for the first two

test cases (0.07 and 0.10 m3/s) are significantly larger indicating that aeration of the water cushion body was not

sufficient for those test cases. Reynolds and Weber number values of the test cases are shown in Fig. 9 and Fig.

10.

Fig. 8 Dynamic pressure variations with respect to water discharge

Fig. 9 Reynolds number as function of discharge

www.theijes.com

The IJES

Page 54

Head Loss Estimation for Water Jets from Flip Buckets

Fig. 10 Weber number as function of discharge

The measured and numerical dynamic pressure heads are normalized by the total head (P +) and drawn against

the dimensionless tail water depth, d+ normalized with the total head HT at the bucket lip. The comparisons of

the results are shown in Fig. 11.

1

Numerical Data

P+=(Pd/)max/HT

0.8

Experimental Data

0.6

0.4

0.2

0

0.05

0.06

0.07

d+=d/HT

0.08

0.09

Fig. 11 Comparison of the measured and numerical maximum dynamic pressures to total head ratio as function

of tail water depth to total head ratio

It is obvious that the measured values of the first two test cases are considerably different than the other

four test cases with larger discharges. As discussed above, this is an indication of insufficient aeration in the

model. Therefore, they will not be considered as valid data to discuss the water cushion effect. The measured

dynamic pressure head data for discharges 0.13, 0.16, 0.19 and 0.22 m3/s collapses on to the same line for which

a functional representation can be given. The best fit line for the dimensionless dynamic pressure (P +) is written

in terms of dimensionless water depth (d+)

[6]

Equation [6] can be used to predict dynamic pressures from assumed tailwater depths.

VIII.CONCLUSIONS

In the present study impact of water jet from a flip bucket on the impingement point on the river bed has

been studied. Effects of aeration and water depth at the impingement point on the dynamic pressures were

investigated experimentally. Empirical equations were used to calculate the jet trajectory lengths with and

without air entrainment. The computed trajectory lengths were compared to measured ones for the six different

test discharges. From this experimental study, the following conclusions can be drawn:

1)Dynamic pressure is not directly proportional to the water discharge coming from the flip bucket. The

trajectory angle and the amount of air entrainment are important quantities for the impact assessment of the

jet at the downstream of the flip bucket.

2)Air entrainment affects the trajectory length and trajectory angle at the impingement point which is more

effective in energy dissipation than the tail water depth.

3)An expression (Eq.6) for predicting the dynamic pressures at the impingement point is developed as a function

of dimensionless tail water depth.

4)A significant increase in dynamic pressures were observed for jet discharges less than 0.130 m3/s for which

Weber number goes below 2x104 This behavior was partly attributed to less air bubble penetration into the

www.theijes.com

The IJES

Page 55

Head Loss Estimation for Water Jets from Flip Buckets

water cushion a result of scale effect specific to the present experimental set-up. This situation would not

occur in real structures since the Weber numbers are expected to be larger than the limiting value.

5)For decreasing discharges the trajectory angle at the impingement area increases which also increases the jet

impact and therefore dynamic pressures. The maximum discharge may not produce the maximum dynamic

pressures. Therefore, discharges smaller than the maximum should also be considered in the analysis and

design stages of the flip bucket type energy dissipaters.

6)Head loss due to air entrainment between the bucket lip and impingement point can be determined using both

analytical and numerical methods as demonstrated in this study.

7) Acknowledgement

8) The authors want to appreciate the cooperation and efforts of Prof. Dr. Mustafa M. Aral in completion of

this study.

Abbreviations

Q

: Water discharge (m3/s)

y0

: Water depth on the bucket lip (m)

Vj

: Velocity at the bucket lip (m/s)

(Vj)p

: Prototype velocity (m/s)

k

: Constant related to air resistance

g

: Gravitational acceleration (m2/s)

: Density

: Kinematic viscosity

: Dynamic viscosity

Pd/

: Dynamic pressure head (m)

Hj

: Jet head obtained from jet velocity (m)

Hj2

: Hypothetical jet head (m)

hL

: Head loss due to air entrainment (m)

(L1)m

: Measured trajectory length (m)

(Lt)c

: Calculated trajectory length without air entrainment (m)

(Lt)s

: Simulated trajectory length without air entrainment (m)

(L1)c

: Calculated trajectory length with air entrainment (m)

(L1)s

: Simulated trajectory length with air entrainment (m)

zi

: Vertical drop from lip to tail-water level (m)

: Trajectory length constant from Equation 2

j

: Flip bucket lip angle (degree)

: Specific weight of water (N/m3)

We

: Weber Number

Re

: Reynolds Number

Fr

: Froude Number

REFERENCES

[1].Godon, R. (1936). Le barrage et lusine hydro-electrique de Mare`ges, sur la Dordogne. Techniques des Travaux, 12, 101110 (in

French).

[2].Coyne, A. (1944). Prototypes modernes de barrages et dusines hydroelectriques. Travaux, 28, 2529 (in French).

[3].Coyne, A. (1951). Observations sur les deversoirs en saut de ski. Proc., 4th ICOLD Congr., Vol. Q12, R89, 737756 (in French).

[4].Auroy, F. (1951). Les evacuateurs de crues du barrage de Chastang. Proc., 4th ICOLD Congr., Vol. Q12, R82, 661-686 (in French).

[5].Maitre, R., and Obolensky, S. (1954). Etude de quelques caracteristiques de lecoulement dans la partie aval des evacuateurs de

surface. La Houille Blanche, Grenoble, France, 9(7), 481511 (in French).

[6].Rajan, B. H., and Shivashankara Rao, K. N. (1980). Design of trajectory buckets. J. Irrig. Power India, 37(1), 6376, ISSN: 0974-4711

[7].Heller, V., Hager, W. H., and Minor, H.E. (2005). Ski jump hydraulics. J. Hydraul. Eng., 131(5), 347355, DOI: 10.1061/(ASCE)07339429(2005)131:5(347)

[8].Mason, P. J. (1989) Effect of air entrainment on plunge pool scour. ASCE Jrnl. of Hyd. Eng. 385-399. DOI: 10.1061/(ASCE)07339429(1989)115:3(385)

[9].Aydin, I., G, M., Altan-Sakarya A.B., Kken M. (2012). Laleli Dam and HEPP Spillway Hydraulic Model Studies.

Hydromechanics Laboratory, Civil Engineering Department, METU.

[10].Yavuz C. (2014). Impact Assessment of Water Jets from Flip Buckets, Ms. Thesis, METU, Available at:

http://etd.lib.metu.edu.tr/upload/12617698/index.pdf

[11].Data Acquisition (DAQ) Software retrieved from: http://turkey.ni.com/

[12].Khatsuria, R. M. (2005). Hydraulics of Spillways and Energy Dissipators, CRC Press, Taylor & Francis Group, NW, ISBN: 978-0-20399698-0

[13].Kawakami K. (1973). A Study of the Computation of Horizontal Distance of Jet Issued from Ski-Jump Spillway. Proc. of the JSCE,

Vol. 219, No. 11, 37-44, DOI: 10.2208/jscej1969.1973.219_37

[14].Flow 3D. (2012). v10.1 User Manuel, Available at:http://www.easysimulation.com/public/flow3dcast/documentation/FLOW3D_Cast_3.2_Manual.pdf

www.theijes.com

The IJES

Page 56

Head Loss Estimation for Water Jets from Flip Buckets

[15].Launder, B.E., Spalding, D.B. (1974). The numerical computation of turbulent ows. Computer Methods in Applied Mechanics and

Engng. 3(2), 269289, DOI: 10.1016/0045-7825(74)90029-2

[16].AutoCad Software Available at: http://www.autodesk.com/products/autocad-lt/overview

[17].Pfister M. And Chanson H. (2012) Discussion: Scale effects in physical hydraulic engineering models, Journal of Hydraulic Research,

50(2):244-246.DOI: 10.1080/00221686.2012.654671

www.theijes.com

The IJES

Page 57

Das könnte Ihnen auch gefallen

- Literacy Level in Andhra Pradesh and Telangana States - A Statistical StudyDokument8 SeitenLiteracy Level in Andhra Pradesh and Telangana States - A Statistical StudytheijesNoch keine Bewertungen

- Analytical Description of Dc Motor with Determination of Rotor Damping Constant (Β) Of 12v Dc MotorDokument6 SeitenAnalytical Description of Dc Motor with Determination of Rotor Damping Constant (Β) Of 12v Dc MotortheijesNoch keine Bewertungen

- The Effect of Firm Size and Diversification On Capital Structure and FirmValue (Study in Manufacturing Sector in Indonesia Stock Exchange)Dokument12 SeitenThe Effect of Firm Size and Diversification On Capital Structure and FirmValue (Study in Manufacturing Sector in Indonesia Stock Exchange)theijesNoch keine Bewertungen

- Defluoridation of Ground Water Using Corn Cobs PowderDokument4 SeitenDefluoridation of Ground Water Using Corn Cobs PowdertheijesNoch keine Bewertungen

- Means of Escape Assessment Procedure For Hospital's Building in Malaysia.Dokument5 SeitenMeans of Escape Assessment Procedure For Hospital's Building in Malaysia.theijesNoch keine Bewertungen

- Big Data Analytics in Higher Education: A ReviewDokument8 SeitenBig Data Analytics in Higher Education: A ReviewtheijesNoch keine Bewertungen

- A Statistical Study On Age Data in Census Andhra Pradesh and TelanganaDokument8 SeitenA Statistical Study On Age Data in Census Andhra Pradesh and TelanganatheijesNoch keine Bewertungen

- Gating and Residential Segregation. A Case of IndonesiaDokument7 SeitenGating and Residential Segregation. A Case of IndonesiatheijesNoch keine Bewertungen

- Multimedia Databases: Performance Measure Benchmarking Model (PMBM) FrameworkDokument10 SeitenMultimedia Databases: Performance Measure Benchmarking Model (PMBM) FrameworktheijesNoch keine Bewertungen

- Impact of Sewage Discharge On Coral ReefsDokument5 SeitenImpact of Sewage Discharge On Coral ReefstheijesNoch keine Bewertungen

- Data Clustering Using Autoregressive Integrated Moving Average (ARIMA) Model For Islamic Country Currency: An Econometrics Method For Islamic Financial EngineeringDokument10 SeitenData Clustering Using Autoregressive Integrated Moving Average (ARIMA) Model For Islamic Country Currency: An Econometrics Method For Islamic Financial EngineeringtheijesNoch keine Bewertungen

- Industrial Installation Skills Acquired and Job Performance of Graduates of Electrical Installation and Maintenance Works Trade of Technical Colleges in North Eastern NigeriaDokument8 SeitenIndustrial Installation Skills Acquired and Job Performance of Graduates of Electrical Installation and Maintenance Works Trade of Technical Colleges in North Eastern NigeriatheijesNoch keine Bewertungen

- Improving Material Removal Rate and Optimizing Variousmachining Parameters in EDMDokument5 SeitenImproving Material Removal Rate and Optimizing Variousmachining Parameters in EDMtheijesNoch keine Bewertungen

- Studio of District Upgrading Project in Amman - Jordan Case Study - East District WahdatDokument5 SeitenStudio of District Upgrading Project in Amman - Jordan Case Study - East District WahdattheijesNoch keine Bewertungen

- The Effect of Organizational Culture On Organizational Performance: Mediating Role of Knowledge Management and Strategic PlanningDokument8 SeitenThe Effect of Organizational Culture On Organizational Performance: Mediating Role of Knowledge Management and Strategic PlanningtheijesNoch keine Bewertungen

- Development of The Water Potential in River Estuary (Loloan) Based On Society For The Water Conservation in Saba Coastal Village, Gianyar RegencyDokument9 SeitenDevelopment of The Water Potential in River Estuary (Loloan) Based On Society For The Water Conservation in Saba Coastal Village, Gianyar RegencytheijesNoch keine Bewertungen

- Performance Evaluation of Calcined Termite Mound (CTM) Concrete With Sikament NN As Superplasticizer and Water Reducing AgentDokument9 SeitenPerformance Evaluation of Calcined Termite Mound (CTM) Concrete With Sikament NN As Superplasticizer and Water Reducing AgenttheijesNoch keine Bewertungen

- Experimental Study On Gypsum As Binding Material and Its PropertiesDokument15 SeitenExperimental Study On Gypsum As Binding Material and Its PropertiestheijesNoch keine Bewertungen

- A Study For Applications of Histogram in Image EnhancementDokument5 SeitenA Study For Applications of Histogram in Image EnhancementtheijesNoch keine Bewertungen

- A Lightweight Message Authentication Framework in The Intelligent Vehicles SystemDokument7 SeitenA Lightweight Message Authentication Framework in The Intelligent Vehicles SystemtheijesNoch keine Bewertungen

- Marginal Regression For A Bi-Variate Response With Diabetes Mellitus StudyDokument7 SeitenMarginal Regression For A Bi-Variate Response With Diabetes Mellitus StudytheijesNoch keine Bewertungen

- Short Review of The Unitary Quantum TheoryDokument31 SeitenShort Review of The Unitary Quantum TheorytheijesNoch keine Bewertungen

- Design and Simulation of A Compact All-Optical Differentiator Based On Silicon Microring ResonatorDokument5 SeitenDesign and Simulation of A Compact All-Optical Differentiator Based On Silicon Microring ResonatortheijesNoch keine Bewertungen

- The Effect of Varying Span On Design of Medium Span Reinforced Concrete T-Beam Bridge DeckDokument4 SeitenThe Effect of Varying Span On Design of Medium Span Reinforced Concrete T-Beam Bridge DecktheijesNoch keine Bewertungen

- Energy Conscious Design Elements in Office Buildings in HotDry Climatic Region of NigeriaDokument6 SeitenEnergy Conscious Design Elements in Office Buildings in HotDry Climatic Region of NigeriatheijesNoch keine Bewertungen

- Mixed Model Analysis For OverdispersionDokument9 SeitenMixed Model Analysis For OverdispersiontheijesNoch keine Bewertungen

- Fisher Theory and Stock Returns: An Empirical Investigation For Industry Stocks On Vietnamese Stock MarketDokument7 SeitenFisher Theory and Stock Returns: An Empirical Investigation For Industry Stocks On Vietnamese Stock MarkettheijesNoch keine Bewertungen

- Status of Phytoplankton Community of Kisumu Bay, Winam Gulf, Lake Victoria, KenyaDokument7 SeitenStatus of Phytoplankton Community of Kisumu Bay, Winam Gulf, Lake Victoria, KenyatheijesNoch keine Bewertungen

- Evaluation of Tax Inspection On Annual Information Income Taxes Corporation Taxpayer (Study at Tax Office Pratama Kendari)Dokument5 SeitenEvaluation of Tax Inspection On Annual Information Income Taxes Corporation Taxpayer (Study at Tax Office Pratama Kendari)theijesNoch keine Bewertungen

- Integrated Approach To Wetland Protection: A Sure Means For Sustainable Water Supply To Local Communities of Nyando Basin, KenyaDokument6 SeitenIntegrated Approach To Wetland Protection: A Sure Means For Sustainable Water Supply To Local Communities of Nyando Basin, KenyatheijesNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cryptocurrency Research PDFDokument59 SeitenCryptocurrency Research PDFAnupriyaNoch keine Bewertungen

- Duties and Responsibilities - Filipino DepartmentDokument2 SeitenDuties and Responsibilities - Filipino DepartmentEder Aguirre Capangpangan100% (2)

- PUBLIC - Axie Origins Changelogs - Season 4Dokument2 SeitenPUBLIC - Axie Origins Changelogs - Season 4Alef CarlosNoch keine Bewertungen

- Ramo's TheoremDokument4 SeitenRamo's TheoremlucasNoch keine Bewertungen

- Comparison of Multi-Coil and Diaphragm Spring ClutchesDokument3 SeitenComparison of Multi-Coil and Diaphragm Spring Clutchesmasb_994077Noch keine Bewertungen

- Water Flow Meter TypesDokument2 SeitenWater Flow Meter TypesMohamad AsrulNoch keine Bewertungen

- Reflection - Reading and Writing 3Dokument3 SeitenReflection - Reading and Writing 3Quỳnh HồNoch keine Bewertungen

- STAB 2009 s03-p1Dokument16 SeitenSTAB 2009 s03-p1Petre TofanNoch keine Bewertungen

- 1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050Dokument2 Seiten1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050DennisSendoyaNoch keine Bewertungen

- Gender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected PlaysDokument6 SeitenGender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected Playsতন্ময়Noch keine Bewertungen

- LhiannanDokument6 SeitenLhiannanGreybornNoch keine Bewertungen

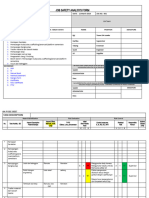

- JSA FormDokument4 SeitenJSA Formfinjho839Noch keine Bewertungen

- The Innovator - S SolutionDokument21 SeitenThe Innovator - S SolutionKeijjo Matti100% (1)

- Fabric DefectsDokument30 SeitenFabric Defectsaparna_ftNoch keine Bewertungen

- Trading Rules To Successful ProfitsDokument89 SeitenTrading Rules To Successful ProfitsOuattaraNoch keine Bewertungen

- Matrix CPP CombineDokument14 SeitenMatrix CPP CombineAbhinav PipalNoch keine Bewertungen

- Rfis On Formliners, Cover, and EmbedmentsDokument36 SeitenRfis On Formliners, Cover, and Embedmentsali tahaNoch keine Bewertungen

- 2015 Grade 4 English HL Test MemoDokument5 Seiten2015 Grade 4 English HL Test MemorosinaNoch keine Bewertungen

- D2E133AM4701 Operating Instruction UsDokument9 SeitenD2E133AM4701 Operating Instruction UsMohamed AlkharashyNoch keine Bewertungen

- Excel Lesson 5 QuizDokument5 SeitenExcel Lesson 5 Quizdeep72Noch keine Bewertungen

- Jurnal Direct and Indirect Pulp CappingDokument9 SeitenJurnal Direct and Indirect Pulp Cappingninis anisaNoch keine Bewertungen

- Matter Around Me: SC1 - Teaching Science in ElementaryDokument27 SeitenMatter Around Me: SC1 - Teaching Science in ElementaryYanna Marie Porlucas Macaraeg50% (2)

- Design and Analysis of DC-DC Boost Converter: September 2016Dokument5 SeitenDesign and Analysis of DC-DC Boost Converter: September 2016Anonymous Vfp0ztNoch keine Bewertungen

- MBA 2nd Sem SyllabusDokument6 SeitenMBA 2nd Sem SyllabusMohammad Ameen Ul HaqNoch keine Bewertungen

- Buku BaruDokument51 SeitenBuku BaruFirdaus HoNoch keine Bewertungen

- Cultural AnthropologyDokument12 SeitenCultural AnthropologyTRISH BOCANoch keine Bewertungen

- Appsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9Dokument12 SeitenAppsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9SURYA PRAKASHNoch keine Bewertungen

- A-Z Survival Items Post SHTFDokument28 SeitenA-Z Survival Items Post SHTFekott100% (1)

- Know Your TcsDokument8 SeitenKnow Your TcsRocky SinghNoch keine Bewertungen

- Paper:Introduction To Economics and Finance: Functions of Economic SystemDokument10 SeitenPaper:Introduction To Economics and Finance: Functions of Economic SystemQadirNoch keine Bewertungen