Beruflich Dokumente

Kultur Dokumente

Rotary Bored Piles: Technique Sheet

Hochgeladen von

ValentVeeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rotary Bored Piles: Technique Sheet

Hochgeladen von

ValentVeeCopyright:

Verfügbare Formate

TECHNIQUE SHEET

ROTARY BORED PILES

Rotary Bored Piles can be used to support any structure where the highest load carrying

capacity is required. Balfour Beatty Ground Engineering has developed specialist expertise

to deliver large, complex and technically challenging projects.

BASIC TECHNIQUE

Drilling tools, including augers and buckets, are

used to excavate the soils to form an open hole to

the required depth. Where unstable ground

conditions are present, commonly within made

ground and in granular layers, a steel casing is used

to provide temporary support. This casing is either

screwed in using the rig or vibrated into place.

A reinforcing cage is then installed into the open

bore and concrete is poured via a delivery tube or

tremmie pipe. If a steel casing was used it is later

withdrawn.

ROTARY BORED PILE CONSTRUCTION SEQUENCE

STRENGTHS

Minimal ground disturbance - with limited risk

of damage to adjacent structures

Suitable for all soil types

Simple and efficient installation process

Ability to drill through most obstructions and

socket into rock

Ideal for insitu cast retaining walls where high

levels of reinforcement and tight drilling

tolerances are needed

TECHNIQUE SHEET

CAD IMAGE OF ROTARY BORED PILING RIG

ARISINGS FROM ROTARY BORED PILING

TECHNIQUE ENHANCEMENTS

Use of Oscillator

Where minimum disturbance is critical (e.g. close

to an existing building or railway line), an oscillator

can be used to install the steel casing with great

precision.

Hollow Piles

BBGE have developed piles with a hollow core,

saving concrete and steel with no loss in

performance, in collaboration with City University.

Under-reams

In stable soils the base of the pile can be extended

up to a 6.3m diameter to form an inverted cone,

which delivers a very high load-bearing capacity.

This allows piles to be founded at a shallower

depth, potentially avoiding lower unstable soils.

Plunge Columns

Standard H section beams, as well as fabricated

steel box or H sections, can be plunged into the pile

following concrete placement. These columns are

commonly used for top-down construction, which

enables simultaneous superstructure construction

and basement excavation, or where temporary

propping or support is required to adjacent

structures. This technique can significantly reduce

the overall build cycle.

Drilling Fluids

Where unstable ground exists at depth, and it

becomes uneconomical or impractical to use

casing, a vinyl polymer - or bentonite drilling fluid

can be introduced to support the bore during

excavation. When the concrete is being tremmied

into the bore, the polymer or bentonite fluid is

displaced and pumped out before being cleaned

and recycled for use in the next pile.

TECHNICAL CAPABILITIES ROTARY BORED PILES

Specification

From

To

Practical Depth

N/A

70m

Diameter

0.45m

3.0m

Typical Load Capacity

1000kN

30,000kN

Rig Height

12.5m

28m

Rig Weight

37,000kg

140,000kg

Rig Length

7m

10m

Rid Width

3m

5m

Noise Profile at 10m

85db

90db

CONTACT US

Balfour Beatty Ground Engineering

Pavilion B, Ashwood Park, Ashwood Way, Basingstoke RG23 8BG

T: 01256 400400 | W: www.bbge.com | E: info@bbge.com

Das könnte Ihnen auch gefallen

- Soosan Hydraulic Breaker Part List PDFDokument44 SeitenSoosan Hydraulic Breaker Part List PDFValentVee89% (9)

- Metro Clark Waste ManagementDokument7 SeitenMetro Clark Waste ManagementEloiza Acosta GutierrezNoch keine Bewertungen

- Driven Cast in Situ PilesDokument17 SeitenDriven Cast in Situ PilesSonu KumawatNoch keine Bewertungen

- UnderpinningDokument11 SeitenUnderpinningAhmad Mustanir HadadakNoch keine Bewertungen

- Retaining Walls and Basement OnstructionDokument18 SeitenRetaining Walls and Basement Onstructionreemadepon0% (1)

- Types of FoundationDokument69 SeitenTypes of FoundationAsadullah Khan GhalibNoch keine Bewertungen

- How to Build a Global Model Earthship Operation II: Concrete WorkVon EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNoch keine Bewertungen

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringVon EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringBewertung: 4 von 5 Sternen4/5 (5)

- Su Series CatalogueDokument4 SeitenSu Series CatalogueValentVee0% (1)

- The Management of Cyanide in Gold ExtractionDokument44 SeitenThe Management of Cyanide in Gold ExtractionYiannis BarasNoch keine Bewertungen

- Level 3 Food Safety and HygieneDokument85 SeitenLevel 3 Food Safety and HygieneNikade Confidence100% (2)

- Different Methods of Deep Foundation DesignDokument7 SeitenDifferent Methods of Deep Foundation DesignMuhammad ArhamNoch keine Bewertungen

- Deep Foundation PilingDokument3 SeitenDeep Foundation PilingVishnuPSNoch keine Bewertungen

- Deep Foundation: From Wikipedia, The Free EncyclopediaDokument9 SeitenDeep Foundation: From Wikipedia, The Free EncyclopediaAzhar HussinNoch keine Bewertungen

- Types of PilesDokument40 SeitenTypes of PilesMohamad HanifNoch keine Bewertungen

- Unique Solutions in Geotechnical WorksDokument72 SeitenUnique Solutions in Geotechnical WorksAlphaNoch keine Bewertungen

- 0 Pile FoundationDokument15 Seiten0 Pile FoundationGANGADHARAIAH SNNoch keine Bewertungen

- GuniteDokument46 SeitenGuniteprasad perkaNoch keine Bewertungen

- Building Construction 5 To 7Dokument30 SeitenBuilding Construction 5 To 7GeraldineNoch keine Bewertungen

- Pin Piles UnderpinningDokument13 SeitenPin Piles UnderpinningsenhuNoch keine Bewertungen

- 2008 FoundationsDokument62 Seiten2008 FoundationsMani Kandan ArunachalamNoch keine Bewertungen

- Piled Foundation ReportDokument7 SeitenPiled Foundation ReportDijo Mathews100% (1)

- Bearing Piles and GroupsDokument36 SeitenBearing Piles and Groupsjologscresencia100% (1)

- (FRANKI) Displacement PilesDokument18 Seiten(FRANKI) Displacement PilesHatta RizqNoch keine Bewertungen

- PilesDokument47 SeitenPilesnurulselangorNoch keine Bewertungen

- 2625 Deep Foundations For High Rise Buildings in Hong KongDokument11 Seiten2625 Deep Foundations For High Rise Buildings in Hong KongJulio MzpNoch keine Bewertungen

- Pile and Mat FoundationDokument9 SeitenPile and Mat FoundationMuhamad SafeenNoch keine Bewertungen

- 1.0 Piles: Piles Foundation Is Used WhenDokument11 Seiten1.0 Piles: Piles Foundation Is Used WhenMind RipNoch keine Bewertungen

- PilingDokument8 SeitenPilinghgor100% (1)

- BAUER Bored Cast-In-place Concrete PilesDokument12 SeitenBAUER Bored Cast-In-place Concrete Pilesjoaonunes.405443Noch keine Bewertungen

- TKBT Anchor EquipmentDokument32 SeitenTKBT Anchor EquipmentLuca Brandi100% (1)

- Pin Piles For Building FoundationsDokument15 SeitenPin Piles For Building FoundationsAntonio MorenoNoch keine Bewertungen

- Pile Foundation - Based On MaterialDokument36 SeitenPile Foundation - Based On MaterialAvani JNoch keine Bewertungen

- Deep FoundationDokument10 SeitenDeep Foundationvinod_commentNoch keine Bewertungen

- 0526 BT PccpilesDokument4 Seiten0526 BT Pccpilesrmorton03Noch keine Bewertungen

- Deep Basement ExcavationDokument4 SeitenDeep Basement Excavationmypenta2008Noch keine Bewertungen

- 1.pile Foundation: Q1. Write Down Functions and Classification of Pile FoundationDokument9 Seiten1.pile Foundation: Q1. Write Down Functions and Classification of Pile FoundationSuhail AhmedNoch keine Bewertungen

- Types of FoundationDokument77 SeitenTypes of FoundationThammu Tulasiram100% (1)

- Pile Foundation: For More Log On ToDokument35 SeitenPile Foundation: For More Log On ToBRAIN OF AN ARCHITECT100% (1)

- BACLIG, LORNA G. (BSCE 4-2) - CENGR 4220 Assignment No. 4Dokument14 SeitenBACLIG, LORNA G. (BSCE 4-2) - CENGR 4220 Assignment No. 4LORNA BACLIGNoch keine Bewertungen

- UNDERPINNING Text MaterialDokument14 SeitenUNDERPINNING Text MaterialYoga RajNoch keine Bewertungen

- UnderpinningDokument30 SeitenUnderpinningAimi Athirah ZahibNoch keine Bewertungen

- Pile Foundations Lecture Note 1 PDFDokument99 SeitenPile Foundations Lecture Note 1 PDFMalbattaNoch keine Bewertungen

- Pile Foundation ReportDokument11 SeitenPile Foundation ReportEduardo OrozNoch keine Bewertungen

- Soil NailingDokument6 SeitenSoil Nailingvinodreddy146Noch keine Bewertungen

- Types of FoundaitonsDokument75 SeitenTypes of FoundaitonsHina MalikNoch keine Bewertungen

- Plunge ColumnsDokument4 SeitenPlunge Columnschandar70Noch keine Bewertungen

- I. Deep Foundation: A. PileDokument7 SeitenI. Deep Foundation: A. PileNikol CapulongNoch keine Bewertungen

- Constech SelekDokument17 SeitenConstech Seleknur asyiqinNoch keine Bewertungen

- Under Reamed Pile-5108Dokument12 SeitenUnder Reamed Pile-5108anku510880% (5)

- Types of FootingDokument3 SeitenTypes of FootingRonald DolorNoch keine Bewertungen

- Portal FrameDokument46 SeitenPortal Frameakm100% (1)

- Pile Foundations Ii - CHP3-1Dokument37 SeitenPile Foundations Ii - CHP3-1Uveys kavakliNoch keine Bewertungen

- Precast ConcreteDokument69 SeitenPrecast Concretejaffna100% (2)

- Gabion Wall and Sheet PilesDokument18 SeitenGabion Wall and Sheet PilesVasanthapragash NadarajhaNoch keine Bewertungen

- Castinsituplace154 150108061806 Conversion Gate01Dokument6 SeitenCastinsituplace154 150108061806 Conversion Gate01Anjumara HaiderNoch keine Bewertungen

- Sheet PilingDokument24 SeitenSheet PilingniyatiNoch keine Bewertungen

- 10B UnderpinningDokument24 Seiten10B UnderpinningAlma AinaNoch keine Bewertungen

- Prestress ConcreteDokument135 SeitenPrestress ConcreteNishant AgrawalNoch keine Bewertungen

- JFE SheetPile CatalogDokument24 SeitenJFE SheetPile Cataloghutuguo100% (1)

- Turf Wall Architecture and Turf Furniture Assembly GuideVon EverandTurf Wall Architecture and Turf Furniture Assembly GuideNoch keine Bewertungen

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionVon EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNoch keine Bewertungen

- Log Cabins and Outbuildings: A Guide to Building Homes, Barns, Greenhouses, and MoreVon EverandLog Cabins and Outbuildings: A Guide to Building Homes, Barns, Greenhouses, and MoreBewertung: 5 von 5 Sternen5/5 (1)

- Fixed Invoice PDFDokument1 SeiteFixed Invoice PDFValentVeeNoch keine Bewertungen

- Water Tanker Truck 1Dokument1 SeiteWater Tanker Truck 1ValentVeeNoch keine Bewertungen

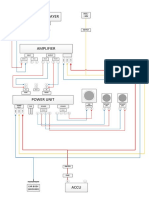

- Skema Audio CarDokument1 SeiteSkema Audio CarValentVeeNoch keine Bewertungen

- Fixed Invoice PDFDokument1 SeiteFixed Invoice PDFValentVeeNoch keine Bewertungen

- Denah KantinDokument1 SeiteDenah KantinValentVeeNoch keine Bewertungen

- H Series Service ManualDokument134 SeitenH Series Service ManualValentVeeNoch keine Bewertungen

- Airman Products: More Options, Better SolutionsDokument6 SeitenAirman Products: More Options, Better SolutionsValentVee100% (1)

- Brochure Tjs BBPP 2012Dokument8 SeitenBrochure Tjs BBPP 2012ValentVeeNoch keine Bewertungen

- Iota Engineering: Refer To Lumen Reference Chart For List of Compatible LampsDokument2 SeitenIota Engineering: Refer To Lumen Reference Chart For List of Compatible LampsValentVeeNoch keine Bewertungen

- Nippon Hycote 665Dokument3 SeitenNippon Hycote 665ValentVeeNoch keine Bewertungen

- Carmix 5.5 XLDokument1 SeiteCarmix 5.5 XLValentVeeNoch keine Bewertungen

- Flexible Solutions: Let Us Be Part of Your LifeDokument2 SeitenFlexible Solutions: Let Us Be Part of Your LifeValentVeeNoch keine Bewertungen

- RoundingDokument5 SeitenRoundingValentVeeNoch keine Bewertungen

- Maspion PVC Pipe and FittingDokument6 SeitenMaspion PVC Pipe and FittingValentVeeNoch keine Bewertungen

- 1-Introduction To Quality and Productivity (General) : Quality in Business, Engineering and Manufacturing Has ADokument10 Seiten1-Introduction To Quality and Productivity (General) : Quality in Business, Engineering and Manufacturing Has AAnupama SinghNoch keine Bewertungen

- AC SamsungDokument57 SeitenAC SamsungMihai MargineanuNoch keine Bewertungen

- Juan TambanDokument72 SeitenJuan TambanEmmanuel Rona100% (4)

- Answer Key Class 8thDokument3 SeitenAnswer Key Class 8thdeepti varshneyNoch keine Bewertungen

- Trends2 Ank Wbspa 16387Dokument12 SeitenTrends2 Ank Wbspa 16387Constantino CAAMAÑONoch keine Bewertungen

- Traffic Sor 19-5-14Dokument55 SeitenTraffic Sor 19-5-14Saurabh Pednekar100% (1)

- Code of Basic Requirements For Water Supply, Drainage and Sanitation (Fourth Revision)Dokument15 SeitenCode of Basic Requirements For Water Supply, Drainage and Sanitation (Fourth Revision)Kishore Ainavilli100% (1)

- Chapter 11 - ExcretionDokument46 SeitenChapter 11 - Excretionapi-372850875% (4)

- CE6605 Environmental Engineering IIDokument19 SeitenCE6605 Environmental Engineering IIunknown noNoch keine Bewertungen

- Muda, Mura, Muri in The Lean Lexicon ©Dokument3 SeitenMuda, Mura, Muri in The Lean Lexicon ©Michael ThompsonNoch keine Bewertungen

- Technology Developers v. CA RESOLUTIONDokument3 SeitenTechnology Developers v. CA RESOLUTIONStradivariumNoch keine Bewertungen

- CWTS 1 Module 4Dokument21 SeitenCWTS 1 Module 4Janna Marie GeronimoNoch keine Bewertungen

- Kip 700 Product Information GuideDokument24 SeitenKip 700 Product Information Guidechrisban35Noch keine Bewertungen

- EIA - Sumathi - Eng - Environmental Impect Analysis Steel Rolling MillDokument13 SeitenEIA - Sumathi - Eng - Environmental Impect Analysis Steel Rolling MillsarashviNoch keine Bewertungen

- Araling Panlipunan: Self-Learning ModuleDokument21 SeitenAraling Panlipunan: Self-Learning ModuleRoshelle Ann DulcaNoch keine Bewertungen

- Drawings - Baakline Stormwater ProjectDokument11 SeitenDrawings - Baakline Stormwater ProjectyaseenNoch keine Bewertungen

- Local and Worldwide Sustainable BenchmarksDokument13 SeitenLocal and Worldwide Sustainable Benchmarksmansi sharmaNoch keine Bewertungen

- 1 3 (Hyundai)Dokument12 Seiten1 3 (Hyundai)lastking_king17Noch keine Bewertungen

- Heat Exchanger Gaskets 1 PDFDokument2 SeitenHeat Exchanger Gaskets 1 PDFMuhammad Aftab AhmedNoch keine Bewertungen

- Republic of The Philippines Tanggapan NG Sangguniang Panlungsod City of NagaDokument5 SeitenRepublic of The Philippines Tanggapan NG Sangguniang Panlungsod City of NagaDhessa Mae MendiolaNoch keine Bewertungen

- Operating Manual Parts List: 1500VMC (FANUC 0iMD)Dokument261 SeitenOperating Manual Parts List: 1500VMC (FANUC 0iMD)apodsh100% (1)

- GPSNP Final Esmf 24 04 18Dokument135 SeitenGPSNP Final Esmf 24 04 18ANIKET BABUTANoch keine Bewertungen

- Turnaround Project Planning PrimerDokument6 SeitenTurnaround Project Planning PrimerSuresh Haldipur100% (1)

- Chemical and Environmental Mock TestDokument6 SeitenChemical and Environmental Mock TestRugi Vicente RubiNoch keine Bewertungen

- Sika Grout 212 215 212hp - MsdsDokument5 SeitenSika Grout 212 215 212hp - MsdsMohd MustafhaNoch keine Bewertungen

- Accomplishment in Waste SegregationDokument6 SeitenAccomplishment in Waste SegregationJaime Daileg100% (3)