Beruflich Dokumente

Kultur Dokumente

Project Piping Materials Specification

Hochgeladen von

alphahotelbravoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Project Piping Materials Specification

Hochgeladen von

alphahotelbravoCopyright:

Verfügbare Formate

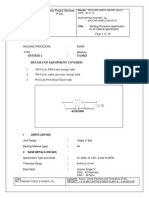

PROJECT PIPING MATERIALS SPECIFICATION

PIPING SPECIFICATION

CLASS 125 DUCTILE IRON CEMENT MORTAR LINED

UNDETERMINED CORR. ALLOW.

UNDERGROUND FIRE WATER SERVICE (NFPA-24) UL/FM

200 PSIG @ 33F (0.56C) to 100F (38C) (Note 1, 2)

Piping Specification No: 12LB-XFZ-SJ

Status of this

specification:

Clients Revised Spec

Clients Spec Rev. No.

Date:

BP Whiting Works, Fire Water Project, Whiting, Indiana

Jacobs Project Number: 58CV582T

J A C O B S

New

R E V I S I O N

R E C O R D

Revision No: A

Date: 09/25/07

Reviewed By:

O. B. Thomas

Prepared By:

Lucy Li

Checked By:

M. Zaidi

Project Approval:

Client Approval:

Coincident Pressure - Temperature Limits

Pressure psig (bar)

200 (51.0)

Temperature - F (C)

33 (0.56) to 100 (38)

COMPONENT &

DESCRIPTION

SIZE RANGE (NPS)

PIPE

4 - 12

Ductile Iron, centrifugally cast,

restrained push-on joint with

cement mortar lining

14 - 24

FITTINGS

4 - 24

RATING /

THICKNESS

Pressure Class

350 psi

Pressure Class

250 psi

Ductile Iron, restrained push-on

Pressure Rating

joint, fusion-bonded epoxy coated 350 psi

inside & outside. (Fittings will

include elbows, bends, tees,

reducers etc)

FLANGE ADAPTERS

4 - 24

Ductile Iron, FF flange one end x Class 125

plain end

Ductile Iron, FF flange one end x

push-on bell end

SLEEVES

4 - 24

Mechanical Joint Solid Sleeve

Ductile Iron, long pattern with

Ductile Iron Retainer Glands

GASKETS

4 - 24

Gasket with lubricant for push-on

restrained joints

1/8 thick NBR for flange joints

BOLTS

High strength low Alloy steel teehead bolts with nuts

BRANCH CONNECTIONS

Reducing fittings

COMPONENT

MATERIAL SPECIFICATION

SPECIFICATION (ASTM unless otherwise indicated)

Pipe: ANSI/AWWA C151/A21.51

UL/FM

Lining: ANSI/AWWA C104/A21.4

Pipe: ANSI/AWWA C151/A21.51

UL/FM

Lining: ANSI/AWWA C104/A21.4

SEE

NOTES

1, 2, 4, 5,

6

ANSI/AWWA C153/A21.53- UL/FM 1, 2,4, 5,

Fusion Bonded Epoxy Coating per 9

ANSI/AWWA C116/A21.16

ANSI/AWWA C153/A21.53

ANSI/AWWA C153/A21.53

ANSI/AWWA C111/A21.10

ANSI/AWWA C111/A21.11

ENCASEMENT

Polyethylene Tube, 8 mill

thickness

ANSI/AWWA C105/A21.5

Page 1 of 3

PROJECT PIPING MATERIALS SPECIFICATION

PIPING SPECIFICATION

CLASS 125 DUCTILE IRON CEMENT MORTAR LINED

UNDETERMINED CORR. ALLOW.

UNDERGROUND FIRE WATER SERVICE (NFPA-24) UL/FM

200 PSIG @ 33F (0.56C) to 100F (38C) (Note 1, 2)

Piping Specification No: 12LB-XFZ-SJ

Status of this

specification:

TRIM &/OR SEAT

Clients Revised Spec

Clients Spec Rev. No.

Date:

BP Whiting Works, Fire Water Project, Whiting, Indiana

Jacobs Project Number: 58CV582T

TYPE OF

RATING & END STYLE BONNET

VALVE &

CONNECTION

OR

SIZE NPS

COVER

GATE VALVES

4 - 12

Class 125, FF,

NRS

Bolted

(250 psi rated

working

pressure)

New

PORT

OR

DISC

Ductile Iron, Resilient Full

Wedge, Fusion

Bonded Epoxy

Coated Inside &

Outside, NDZ Stem,

Open Left, w/ 2 sq.

nut, (use with Post

Indicator),

AWWA C515

VALVE

CODE

ASTM

SPEC

Z340AG-94A A-536

SEE

NOTES

1, 11

COMMENT

UL/ FM approved

Rated to 250 PSI

WWP

Recommended

Manufacturer and

Figure No. AFC

Series 2500 or

approved equal

FIRE PROTECTION EQUIPMENT

COMPONENT

DESCRIPTION

Hydrant

6 Main valve opening. American Darling Model B84B-BB UL/FM approved, with the following:

2 x 2.5 Threaded-on independent hose nozzle gate valves (NST) with cap & chain

2 x 4.5 Pumper nozzle (NST), Amlok, double set screw with cap & chain

Monitor spool elbow x 4 125# FF upper end

Operating nut (NS), open left with handwheel

6-0 Depth of trench

6 125# FF base inlet

Paint: chrome yellow

Monitor

Stang 22 BB3561 free standing elevated monitor, 360 horizontal motion, 45 vertical, cable operated fog nozzle P/N

4767AC 750 gpm, stainless steel control cables

Accessories for

TFT Z1121A Protector Monitor, 4 150# RF inlet, built-in off/on stainless steel ball valve, complete with TFT M-RF 1000

Monitor/Nozzle

gpm master stream nozzle

Page 2 of 3

PROJECT PIPING MATERIALS SPECIFICATION

PIPING SPECIFICATION

CLASS 125 DUCTILE IRON CEMENT MORTAR LINED

UNDETERMINED CORR. ALLOW.

UNDERGROUND FIRE WATER SERVICE (NFPA-24) UL/FM

200 PSIG @ 33F (0.56C) to 100F (38C) (Note 1, 2)

BP Whiting Works, Fire Water Project, Whiting, Indiana

Jacobs Project Number: 58CV582T

Piping Specification No: 12LB-XFZ-SJ

Status of this

specification:

New

Clients Revised Spec

Clients Spec Rev. No.

Date:

Notes:

1.

2.

All pipe and piping components shall be Factory Mutual/ Underwriter's Laboratory (UL/FM) approved.

Assembly & installation of boltless restrained pipe with field-lok 350 joints, flanges and fittings will be performed per NFPA-24 and

manufacturers recommended instructions.

3. The piping system to be a fully restrained field-lok 350 push-on joint system.

4. All exterior surface of Ductile iron Pipe shall be asphaltic coated one (1) mil average dry thickness (see ANSI/AWWA C110/A21.10 and

Cement-Mortar Lining per ANSI/AWWA C104/A21.4). Fittings to be Fusion Bonded Epoxy Coated interior and exterior per

ANSI/AWWA C116/A21.16 (Note: Based on availability, the fittings may be Cement Mortar lined per ANSI/AWWA C104/A21.4).

5. For soil corrosion protection, all under ground Ductile Iron pipe and fittings and other appurtenances, to be encased in loose

polyethylene wrap or tubes per ANSI/AWWA C105/A21.5. The installation procedure for the polyethylene encasement tube shall be in

accordance with applicable standard and the manufacturer's instructions.

6. All system should be flushed in accordance with the following minimum preferred flow rates:

NPS 4 400gpm,

NPS 6 900gpm,

NPS 8 1600gpm,

NPS 14 and larger 4500gpm.

7. Gaskets for Ductile iron piping and fittings to be furnished by manufacturer and shall be packed separately.

8. Gasket lubricant to be compatible with gasket material and furnished by the pipe manufacturer.

9. Mechanical joint retainer glands to be used on all M.J. connections. Retainer glands to be "Mega-Lug retainer glands" by 'EBBA' Iron or

equal.

10. This Standard is to be used in conjunction with the following standards and codes:

a. ANSI/AWWA C150/A21.50 - Thickness Design of Ductile-Iron Pipe

b. ANSI/AWWA C151/A21.51 - Ductile Iron Pipe, Centrifugally Cast for Water

c. ANSI/AWWA C110/A21.10 - Ductile Iron and Gray-Iron Fittings,3 in. through 48 in. for water

d. ANSI/AWWA C111/A21.11 - Rubber-Gasket joints for Ductile-Iron Pressure pipe and fittings

e. ANSI/AWWA C105/A21.5 - Polyethylene Encasement for Ductile-Iron pipe systems

f.

ANSI/AWWA C104 /A21.4 - Cement-Mortar Lining for Ductile-Iron Pipe and fittings for Water.

g. ANSI/AWWA C116/A21.16 Protective Fusion-Bonded Epoxy Coatings for the Interior and Exterior Surfaces of DuctileIron

and Gray-Iron fittings for Water Supply Service.

h. AWWA C600 - Installation of Ductile-Iron Water Main and their appurtenances

i.

NFPA24 - Standard for the Installation of Private Fire Service Mains and Their Appurtenances

11. Valve Rated to 250 psi WWP, UL/FM, Epoxy Coated, Open Left (use with post indicator), (valve code suffix, option-94A).

12. Any thrust block requirement to be evaluated based on soil conditions or at change in direction.

Page 3 of 3

Das könnte Ihnen auch gefallen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Von EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Noch keine Bewertungen

- 094135-PE-SPC-001 Piping Material Specification-REV 4Dokument76 Seiten094135-PE-SPC-001 Piping Material Specification-REV 4thongpvgas100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- A Guide to Ship Repair Estimates in Man-hoursVon EverandA Guide to Ship Repair Estimates in Man-hoursBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Marketing Measurement Done RightDokument16 SeitenMarketing Measurement Done RightWasim Ullah0% (1)

- 15-1-6 - Chilled Water Piping SystemDokument10 Seiten15-1-6 - Chilled Water Piping Systemfarshan296015Noch keine Bewertungen

- Jacobs (HPCL) Standard On Pressure Vessel & He PDFDokument52 SeitenJacobs (HPCL) Standard On Pressure Vessel & He PDFAnit100% (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerVon EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerBewertung: 5 von 5 Sternen5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyVon EverandPipeline and Energy Plant Piping: Design and TechnologyBewertung: 5 von 5 Sternen5/5 (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- Welding QuestionsDokument10 SeitenWelding Questionsbalakumar rajaram100% (1)

- Writing Short StoriesDokument10 SeitenWriting Short StoriesRodiatun YooNoch keine Bewertungen

- BOQ For Solar Water HeatersDokument2 SeitenBOQ For Solar Water Heaterssolpower_epl100% (2)

- GRP Pipe For SeawaterDokument22 SeitenGRP Pipe For Seawatersethu1091100% (2)

- Hot Tap CalculationDokument20 SeitenHot Tap Calculationsurekha_ahireNoch keine Bewertungen

- PROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01Dokument7 SeitenPROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01mihahudeaNoch keine Bewertungen

- BOQDokument2 SeitenBOQManish Goyal100% (1)

- AdweaDokument12 SeitenAdweaUnni Cyriac100% (1)

- Spec EarthingDokument9 SeitenSpec EarthingsbpathiNoch keine Bewertungen

- Di Pipes AuhDokument22 SeitenDi Pipes AuhMaged SamirNoch keine Bewertungen

- Valve Procurement SpecsDokument39 SeitenValve Procurement Specsjoseph.maquez24100% (2)

- Review of Related Literature and Related StudiesDokument23 SeitenReview of Related Literature and Related StudiesReynhard Dale100% (3)

- Project Standards and Specifications Pipeline Construction Rev01Dokument15 SeitenProject Standards and Specifications Pipeline Construction Rev01hiyeonNoch keine Bewertungen

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Dokument6 SeitenPCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroNoch keine Bewertungen

- ALN FP ESA MEC SPC 2201 - 2B6B.1 Piping Materials SupplementDokument327 SeitenALN FP ESA MEC SPC 2201 - 2B6B.1 Piping Materials Supplementahmed.njahNoch keine Bewertungen

- SS EN 1991-1-1-2008 (2017) - PreviewDokument16 SeitenSS EN 1991-1-1-2008 (2017) - PreviewNg SHun JieNoch keine Bewertungen

- Asme Section Ii A Sa-179 Sa-179m PDFDokument4 SeitenAsme Section Ii A Sa-179 Sa-179m PDFHyunjong MoonNoch keine Bewertungen

- Asme Section II A Sa-179 Sa-179mDokument4 SeitenAsme Section II A Sa-179 Sa-179mAnonymous GhPzn1xNoch keine Bewertungen

- Water SystemDokument9 SeitenWater SystemArun GuptaNoch keine Bewertungen

- Fire Supperssion StandpipesDokument15 SeitenFire Supperssion StandpipesMohammad Sadik0% (1)

- 1 - Firewater Piping Spec - DIDokument2 Seiten1 - Firewater Piping Spec - DISuezie Iella100% (1)

- UtilitiesDokument31 SeitenUtilitiesjia wangNoch keine Bewertungen

- Goyen 25BW3-CNBNT Solenoid ValveDokument10 SeitenGoyen 25BW3-CNBNT Solenoid ValvejadetorresNoch keine Bewertungen

- 22 11 17 - Gas Pipe and AppurtenancesDokument7 Seiten22 11 17 - Gas Pipe and AppurtenancesTeguh SetionoNoch keine Bewertungen

- 240K C2 CS 50 009 0TDokument78 Seiten240K C2 CS 50 009 0TYeims LozanoNoch keine Bewertungen

- T1 Orbital Welding of DuplexSSDokument9 SeitenT1 Orbital Welding of DuplexSSssmith2007Noch keine Bewertungen

- Firewater Piping Spec - DIDokument2 SeitenFirewater Piping Spec - DIvaradarajNoch keine Bewertungen

- 22 05 14Dokument8 Seiten22 05 14Story LoveNoch keine Bewertungen

- Modular Condenser Replacement at Ano-1 Solves Operating Problems and Improves PerformanceDokument9 SeitenModular Condenser Replacement at Ano-1 Solves Operating Problems and Improves Performancelifemillion2847Noch keine Bewertungen

- Ipc2012 90738Dokument11 SeitenIpc2012 90738Marcelo Varejão CasarinNoch keine Bewertungen

- 1113 DWSDWSDDokument53 Seiten1113 DWSDWSDenjoygurujiNoch keine Bewertungen

- NL Master Specification Guide For Public Funded Buildings: Re-Issued 2017/05/31Dokument8 SeitenNL Master Specification Guide For Public Funded Buildings: Re-Issued 2017/05/31Aijo JustineNoch keine Bewertungen

- HEP-23-02-232105 Mech Systems PipingDokument14 SeitenHEP-23-02-232105 Mech Systems Pipingsenseiann.eslNoch keine Bewertungen

- Cathodic Protection Specification - Takoradi Oil Terminal 27.02.2018 rv1 PDFDokument12 SeitenCathodic Protection Specification - Takoradi Oil Terminal 27.02.2018 rv1 PDFRaynus Arhin100% (1)

- Directive056 ConversionCalculatorDokument16 SeitenDirective056 ConversionCalculatorAnonymous KpVxNXsNoch keine Bewertungen

- Section 21 11 00Dokument10 SeitenSection 21 11 00Ismail MohammadNoch keine Bewertungen

- SF - Piped Utilities - Basic Materials and MethodsDokument11 SeitenSF - Piped Utilities - Basic Materials and MethodsMuwafaq_mibNoch keine Bewertungen

- HVAC Ducts and CasingsDokument10 SeitenHVAC Ducts and CasingsmanikantanNoch keine Bewertungen

- Hydronic PipingDokument11 SeitenHydronic PipingLjubomir DjurinNoch keine Bewertungen

- SampleDokument8 SeitenSamplearavindNoch keine Bewertungen

- IGS-M-PL-027 (0) 1388 : ApprovedDokument9 SeitenIGS-M-PL-027 (0) 1388 : ApprovedMamadNoch keine Bewertungen

- DR Engp 1.1 R13Dokument2.070 SeitenDR Engp 1.1 R13Revair CostaNoch keine Bewertungen

- PPP WHADokument3 SeitenPPP WHAMartin Roberto GarciaNoch keine Bewertungen

- Part 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsDokument16 SeitenPart 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsNelson VargasNoch keine Bewertungen

- SECTION 22 11 00 Facility Water Distribution: Based On DFD Master Specification Dated 10/10/17Dokument12 SeitenSECTION 22 11 00 Facility Water Distribution: Based On DFD Master Specification Dated 10/10/17Juan CarloNoch keine Bewertungen

- Concast WPS - REV-01Dokument28 SeitenConcast WPS - REV-01meena34Noch keine Bewertungen

- Volume - 4Dokument72 SeitenVolume - 4Arunkumar AdikesavanNoch keine Bewertungen

- Design Standard Gas Piping For Laboratory Facilities: Revisions LogDokument3 SeitenDesign Standard Gas Piping For Laboratory Facilities: Revisions LogZineddine ALICHENoch keine Bewertungen

- 15510Dokument13 Seiten15510uddinnadeemNoch keine Bewertungen

- Equipment SpecificationDokument8 SeitenEquipment SpecificationPraveen ChandrakarNoch keine Bewertungen

- Specification - Pipes FlangesDokument3 SeitenSpecification - Pipes FlangesAco CvijeticNoch keine Bewertungen

- Webinar Landing Pages BlyDokument49 SeitenWebinar Landing Pages BlyalphahotelbravoNoch keine Bewertungen

- Blues O MaticDokument3 SeitenBlues O MaticalphahotelbravoNoch keine Bewertungen

- Takamine 2way Trussrod PDFDokument1 SeiteTakamine 2way Trussrod PDFalphahotelbravoNoch keine Bewertungen

- Takamine 2-Way Trussrod PDFDokument1 SeiteTakamine 2-Way Trussrod PDFalphahotelbravoNoch keine Bewertungen

- K-1 Operating ManualDokument140 SeitenK-1 Operating ManualMichael Zhang100% (2)

- VQ IoT (Low-Res Spreads)Dokument23 SeitenVQ IoT (Low-Res Spreads)alphahotelbravoNoch keine Bewertungen

- Certification Body Application Form 2016 0Dokument2 SeitenCertification Body Application Form 2016 0alphahotelbravoNoch keine Bewertungen

- Bosch DA-70 Iron InstructionsDokument20 SeitenBosch DA-70 Iron InstructionsalphahotelbravoNoch keine Bewertungen

- 15 Secretos Personas Altas Productivas PDFDokument11 Seiten15 Secretos Personas Altas Productivas PDFALIANZA BOLDNoch keine Bewertungen

- 18 Secrets WorkbookDokument19 Seiten18 Secrets WorkbookalphahotelbravoNoch keine Bewertungen

- 18 Secrets WorkbookDokument19 Seiten18 Secrets WorkbookalphahotelbravoNoch keine Bewertungen

- Scotland's Future - The Constitutional Report CardDokument52 SeitenScotland's Future - The Constitutional Report CardalphahotelbravoNoch keine Bewertungen

- Bro Cyber Essentials Certification BodiesDokument2 SeitenBro Cyber Essentials Certification BodiesalphahotelbravoNoch keine Bewertungen

- Ce Illustrative Questionnaire Web VersionDokument8 SeitenCe Illustrative Questionnaire Web VersionalphahotelbravoNoch keine Bewertungen

- Bosch DA-70 Iron InstructionsDokument20 SeitenBosch DA-70 Iron InstructionsalphahotelbravoNoch keine Bewertungen

- 41Dokument3 Seiten41alphahotelbravoNoch keine Bewertungen

- How Do You Get Your Employees To Do What You Hired Them To DoDokument4 SeitenHow Do You Get Your Employees To Do What You Hired Them To DoalphahotelbravoNoch keine Bewertungen

- 18 Secrets WorkbookDokument19 Seiten18 Secrets WorkbookalphahotelbravoNoch keine Bewertungen

- Report Talent Acquisition Candidates View 2016Dokument8 SeitenReport Talent Acquisition Candidates View 2016alphahotelbravoNoch keine Bewertungen

- Bosch DA-70 Iron InstructionsDokument20 SeitenBosch DA-70 Iron InstructionsalphahotelbravoNoch keine Bewertungen

- Elap Engineering REGReport - UserID-100068401 - 01377278 - 280211083959Dokument11 SeitenElap Engineering REGReport - UserID-100068401 - 01377278 - 280211083959alphahotelbravoNoch keine Bewertungen

- Edinburgh Airport Summer Destination GuideDokument14 SeitenEdinburgh Airport Summer Destination GuidealphahotelbravoNoch keine Bewertungen

- Impeller Velocity TrianglesDokument2 SeitenImpeller Velocity TrianglesLorettaMayNoch keine Bewertungen

- ENGLISH 4 (General & Specific Sentence, Main Idea & Key Sentence) )Dokument3 SeitenENGLISH 4 (General & Specific Sentence, Main Idea & Key Sentence) )Analiza Dequinto BalagosaNoch keine Bewertungen

- Unseen Passage 2Dokument6 SeitenUnseen Passage 2Vinay OjhaNoch keine Bewertungen

- Program Logic FormulationDokument69 SeitenProgram Logic FormulationIan OffemariaNoch keine Bewertungen

- WHITE TOWN GROUP-4 FinalDokument112 SeitenWHITE TOWN GROUP-4 Finalaswath manojNoch keine Bewertungen

- Chapter 3 Mine Ventialtion ProblemDokument3 SeitenChapter 3 Mine Ventialtion ProblemfahimNoch keine Bewertungen

- Srinivasa Ramanujan - Britannica Online EncyclopediaDokument2 SeitenSrinivasa Ramanujan - Britannica Online EncyclopediaEvariste MigaboNoch keine Bewertungen

- Crusher 4Dokument39 SeitenCrusher 4kediliterapiNoch keine Bewertungen

- Part 1. Question 1-7. Complete The Notes Below. Write NO MORE THAN THREE WORDS AND/OR A NUMBER For Each AnswerDokument13 SeitenPart 1. Question 1-7. Complete The Notes Below. Write NO MORE THAN THREE WORDS AND/OR A NUMBER For Each Answerahmad amdaNoch keine Bewertungen

- Lecture 5: Triangulation Adjustment Triangulation: in This Lecture We Focus On The Second MethodDokument5 SeitenLecture 5: Triangulation Adjustment Triangulation: in This Lecture We Focus On The Second MethodXogr BargarayNoch keine Bewertungen

- Federal Government Employees Housing FoundationDokument2 SeitenFederal Government Employees Housing FoundationMuhammad Shakil JanNoch keine Bewertungen

- Celestino vs. CIRDokument6 SeitenCelestino vs. CIRchristopher d. balubayanNoch keine Bewertungen

- Light Dimmer CircuitsDokument14 SeitenLight Dimmer CircuitskapilasriNoch keine Bewertungen

- Memo ALS Literacy MappingDokument4 SeitenMemo ALS Literacy MappingJEPH BACULINANoch keine Bewertungen

- Ijrpr2741 Study On Investor Perception Towards Stock Market InvestmentDokument19 SeitenIjrpr2741 Study On Investor Perception Towards Stock Market InvestmentAbhay RanaNoch keine Bewertungen

- Full Download Human Biology 11th Edition Starr Solutions ManualDokument35 SeitenFull Download Human Biology 11th Edition Starr Solutions Manualsheathe.zebrinny.53vubg100% (41)

- p1632 eDokument4 Seitenp1632 ejohn saenzNoch keine Bewertungen

- Presentation 1Dokument22 SeitenPresentation 1AILYN PECASALESNoch keine Bewertungen

- E Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersDokument13 SeitenE Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersRichard VillanuevaNoch keine Bewertungen

- Damask: by ChenoneDokument17 SeitenDamask: by ChenoneYasir IjazNoch keine Bewertungen

- Evolution of Strategic HRM As Seen Through Two Founding Books A 30TH Anniversary Perspective On Development of The FieldDokument20 SeitenEvolution of Strategic HRM As Seen Through Two Founding Books A 30TH Anniversary Perspective On Development of The FieldJhon Alex ValenciaNoch keine Bewertungen

- Review Problems On Gas TurbineDokument9 SeitenReview Problems On Gas TurbinejehadyamNoch keine Bewertungen

- Market Challengers StrategiesDokument19 SeitenMarket Challengers Strategiestobbob007100% (20)

- Esp Kelompok 2Dokument19 SeitenEsp Kelompok 2Taufiq DiNoch keine Bewertungen

- Bill - AKIJDokument3 SeitenBill - AKIJm.tanjil2005Noch keine Bewertungen

- VDRL - Press. GaugesDokument9 SeitenVDRL - Press. GaugesSourav RayNoch keine Bewertungen