Beruflich Dokumente

Kultur Dokumente

Cooke Lens Service Drawings Complete

Hochgeladen von

Darius WhiteCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cooke Lens Service Drawings Complete

Hochgeladen von

Darius WhiteCopyright:

Verfügbare Formate

2

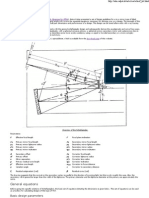

THIS IS A CAD DRAWING AND MUST NOT BE UPDATED BY HAND

DRG N0.

S4000-00034

FOCAL LENGTHS

MAIN LENS ASSEMBLY - SHOWN WITH OPTICAL

HOUSING ASSEMBLY REMOVED

VIEW SHOWING ASSEMBLY OF

FRONT AND REAR BEARING

ASSEMBLIES & IRIS STOPS.

T2 POSITION

M2x3 CH.HD

(3 OFF)

B

19

ADJUST TO CONTACT

STOP AT INFINITY

8

10

ITEM No.

VIEW SHOWING MOUNTING AND

ORIENTATION OF PL-MOUNT

M2x5 C'SK

(3 OFF)

M2.5x8 SKT

(8 OFF)

TORQUE TO

9 LBF-IN.

18 21 26 25

EL

18

25

32

40

50

75

100

CODE

QTY.

K501-1849

K501-1848

K501-1847

46-6897

46-6899

46-6939

46-6874

46-6835

46-6840

46-6841

46-6937

46-7116

46-7292

OPTICAL HOUSING ASSEMBLY

FRONT BEARING ASSEMBLY

REAR BEARING ASSEMBLY

CAM FOLLOWER ASSEMBLY

FRONT HOUSING

X

X

17

AV

14

DESCRIPTION

REAR HOUSING

FRONT COVER

X

X

IS

TR

IR

X

X

SCALE COVER

46-6931

FOCUS SCALE GEAR

46-6839

-

10

FOCUS CAM

46-6891

46-6892

46-6893

46-6894

46-6895

46-6896

X

X

X

M2x4 THIN HD.

(4 OFF)

M2.5x10 C'SK

(4 OFF)

T22 POSITION

M2x8 SKT HD

(6 OFF)

14 16 15 17

2

ASSEMBLE 2 OFF 45-10727 EACH END.

BEND DOWN 3mm OF LONG TANG ON 2

(OPPOSITE HANDS). LOCK WITH 2 FLAT

COMPONENTS. T2 STOP TO BE IN

CONTACT AT T2.

M2.5x16 C'SK

(4 OFF)

X

X

3

21

B

22 12 13 11

M2x3 NARROW

CH.HD (1 OFF)

LIGHTLY SMEAR CAM TRACK WITH

C40-0C128, (FINGREASE MP2/3)

ALL CLAMP RINGS TO BE SEALED WITH

SHELLAC OR BLACK PAINT ON FINAL

ASSEMBLY.

46-7114

11

BEARING COVER RING

46-6885

-

12

OUTER CLAMP RING

46-6883

-

13

INNER CLAMP RING

46-6884

-

14

IRIS SCALE GEAR

46-6875

-

15

IRIS FIDUCIAL RING

46-6886

-

16

IRIS BEARING

46-6878

17

PL MOUNT

46-6501

18

IRIS DRIVE PIN

45-10243

19

ADJUSTABLE STOP

C-O-001

20

FOCUS STOP

45-10167

21

IRIS STOP

45-10727

22

FOCUS BEARING

B640-870

23

FRONT LENS CAP

46-6938

24

REAR LENS CAP

46-6998

25

BACK FOCUS SHIM SET

46-6560

26

IRIS SHIM SET

46-6561

SHEET

OF

TITLE

OVERALL ASSEMBLY DRAWING

14mm - 100mm S4 LENSES

MATERIAL

FINISH

MACHINE FINISH

Unless otherwise stated

DRAWN BY

s4

DATE

27Sep96

ISSUE No.

DATE

10-02-00

16-02-00

CHANGE No.

0053

SECTION A-A

SECTION B-B - WITH FRONT BEARING

ASSEMBLY REMOVED

PART SECTION TO SHOW THE

MOUNTING OF THE FRONT

COVER TO THE FRONT

HOUSING

ALL OTHERS

14mm

18mm

25mm

M2 x 4

C'SK (2)

55

VIEW TO SHOW COMPLETED LENS ASSEMBLY

23

20

1.5 x 8 DOWEL

30

SHORTEN IRIS

FIDUCIAL RING TO

SET BACK FOCUS

FRONT LENS CAP

LOCATION

52.0

FLANGE BACK FOCUS

DAR 8.74

20

IMAGE PLANE

1.5 DOWEL

X 6 LONG (1)

- INSTALL

AS SHOWN.

THIS DRAWING COVERS THE

WHOLE OF THE S4 RANGE

- THE LENS SHOWN

IS THE 18mm LENS

SHIM FOR SETTING

IRIS DRIVE FEEL

REAR LENS

CAP LOCATION

24

APPROX SHORTENING

REQUIRED TO SET BACK

FOCUS

1.2 NOM

M2 HELICOIL

X 1D LONG (2)

OPTICAL

BACK FOCUS

7

M2.5x6 SKT(18,25)

M2.5x8 SKT(32 ON)

(4 OFF)

SECTION C-C

PART SECTION, WITH OUTER SLEEVES REMOVED

TO SHOW THE LOCATION AND ORIENTATION OF

THE FOCUS STOPS

2.5 x 6 DOWEL PINS (2) USED TO ENSURE

THAT THE CAM FOLLOWER ASSEMBLY CAN

BE REMOVED AND REPLACED REPEATABLY.

TO ADJUST WIDTH OF CAM FOLLOWER,

RELEASE SCREWS JOINING FOLLOWER

ADJUSTMENT PLATE TO FOLLOWER

SUPPORT BLOCK. SET WIDTH AS

REQUIRED AND RE-TIGHTEN SCREWS

SLOT IN FRONT

HOUSING

SLOT IN CAM

TO ASSEMBLE THE OPTICAL HOUSING INTO THE MAIN LENS ASSEMBLY:

1) REMOVE OUTER SLEEVES - FOCUS SCALE GEAR AND

SCALE COVER.

2) LOAD OPTICAL HOUSING ASSEMBLY INTO MAIN

LENS ASSEMBLY, WITH THE LOCATION FLAT FOR

THE CAM FOLLOWER ASSEMBLY IN LINE WITH THE

SLOT IN THE FRONT HOUSING

PILOT HOLES FOR PINS IN BRASS PLATE

MUST BE REAMED THROUGH ON ASSEMBLY.

FINAL HOLES MUST PROVIDE A GOOD LOCATION

FIT FOR CAM FOLLOWER, BUT MUST ALSO

ALLOW ASSEMBLY TO LIFT OFF EASILY.

VIEW TO SHOW SETTING OF IRIS DRIVE, BACK FOCUS

AND ASSEMBLY OF THE FOCUS STOPS.

TO SET IRIS DRIVE:

1) AXIAL PLAY FROM THE IRIS DRIVE TO BE MINIMISED

USING THE APPROPRIATE SHIM FROM THE IRIS SHIM SET.

TO SET BACK FOCUS:

1) AFTER SETTING THE IRIS DRIVE FEEL, LOAD THE OPTICAL

HOUSING INTO MAIN ASSEMBLY AND ATTACH THE CAM FOLLOWER.

STATUS

THE CAM TRACK MUST NOT BE HAND

FINISHED ON ASSEMBLY.

3) THE CAM FOLLOWER WILL NOW BE POSITIONED EXACTLY

AT THE INFINITY POSITION OF THE CAM TRACK.

4) ENSURE THAT THE WHITE BACK FOCUS SHIM IS IN PLACE,

IN BETWEEN THE PL-MOUNT AND THE IRIS FIDUCIAL RING.

THE REMAINING SHIMS FROM THE BACK FOCUS SHIM SET

WILL BE SUPPLIED TO THE CUSTOMER.

4) LOWER CAM FOLLOWER ASSEMBLY INTO PLACE.

5) JOIN THE CAM FOLLOWER ASSEMBLY TO THE OPTICAL

HOUSING AS SHOWN.

3rd ANGLE PROJECTION

DRG. CONFORMS TO BS308

SCALE

1:1

DIMN IN

DRG SIZE

MM

A1

COOKE OPTICS LIMITED

5) SET THE OPTICAL BACK FOCUS AND SHORTEN THE IRIS

FIDUCIAL RING AS APPROPRIATE.

6) ADJUST THE WIDTH OF THE SLIDING PORTION OF

THE CAM FOLLOWER. THE CAM FOLLOWER SHOULD

SLIDE FREELY FROM END TO END OF THE SLOT IN

THE FRONT HOUSING, WITH NO TIGHT SPOTS AND

NO MORE THAN 0.02mm BACKLASH.

USED ON

2) WITH THE CAM FOLLOWER IN THE CAM-TRACK, FIX THE

POSITION OF THE FOCUS CAM, RELATIVE TO THE FRONT

HOUSING, WITH THE TOOLING PIN.

3) ROTATE CAM UNTIL THE SLOTS IN THE CAM AND

THE FRONT HOUSING LINE UP.

IRIS BEARINGS SUPPLIED

AS COMPLETE RING, CUT

ON ASSEMBLY JUNIOR

HACKSAW AND DE-BURR

ENDS ONLY.

SECTION D-D

SECTION A-A - VIEW WITH

OPTICAL HOUSING IN PLACE

VIEW TO SHOW THE ASSEMBLY OF THE OPTICAL

HOUSING INTO THE MAIN LENS ASSEMBLY, AND

THE FIXING OF THE CAM FOLLOWER ASSEMBLY.

TOOLING PIN

TO ALIGN FOCUS CAM

AND FRONT HOUSING

FOR ENGRAVING DETAIL

REFER TO ENGRAVING

DRAWING

LEICESTER ENGLAND

6) REMOVE THE TOOLING PIN AND REPLACE THE OUTER

SLEEVES.

Cooke Optics Ltd. 1998

TO SET THE FOCUS STOPS:

7) REPLACE OUTER SLEEVES AS REQUIRED

M2.5x6 CH.HD

(2 OFF)

1) THE FOCUS STOP WILL ALLOW THE FOCUS CAM TO ROTATE

300. AFTER SETTING THE BACK FOCUS, THE FOCUS STOP

SHOULD BE SET TO ALLOW NO FOCUS TRAVEL PAST INFINITY.

plotted by

DRG N0.

jlf

S4000-00034

24Mar99

SHEET

OF

THIS IS A CAD DRAWING AND MUST NOT BE UPDATED BY HAND

1

ASSEMBLY OF ZOOMCAM FOLLOWERS

B652-123 (2)

B606-65 (2)

BUILD UP "TRAVEL LIMIT STOPS" USING

3 LAYERS OF SELF ADHESIVE TAPE STUCK

TO BODY UNDER SPRINGS OF FOCUS CARRIAGE

STRIPS TO BE CUT TO LENGTHS OF RESPECTIVE

SPRINGS. TAPE CODE 6167-060118.

H45-4463 (2)

MUST RUN FREELY

D45-4464 (2)

SEAL WITH LOCTITE

222 ON FINAL

ASSEMBLY.

B604-945

INNER ZOOM

FOLLOWER

SECT. THRO. A FIXED FOLOWER.

B604-945

D45-5287 FOR H36-380

CARRIAGE, B616-784

FOR H36-724 CARRIAGE

B652-123 (2)

2:1

H45-4956

46-6757

D45-4954

SECT. A-A

FOCUS CARRIAGE ROLLERS

20-3881 (2)+B604-945 (2)

DRILL THRO. PILOT HOLES

INTO H46-4998 AND ASSEMBLE

PINS SEE NOTE 5

46-6972

D45-7446 (12)

D650-1124 (12)

45-10784 (12)

45-10785 (12)

ONE OF EACH AT

EACH END.

45-9992

45-9991

B45-7639 (3)

D680-102 (3)

D650-20026 (3)

H45-7716 (6)

4:1

D650-1125 (1)

A

D45-4449

45-9994

ASSEMBLY OF THE SPRINGS

SEE NOTE 7.

45-9993

H46-4999 + CEMENT B89-602 IN

POSITION WITH LOCTITE IS 12

46-7262

46-7263(2)

H46-3282

46-6746

46-6763

D650-1136(1)

46-6764

D650-11028(3)

B618-177 (6)

H36-724

46-6757

46-6766

D650-1223 (3)

Unless otherwise stated

45-10288

DRAWN BY

ppn

DATE

17Jan96

ISSUE No.

H45-8131

SET SO THAT RISE OF OUTER ZOOM CARRIAGE

MOVEMENT (NON LINEAR CAM) FROM ZERO RISE POINT

IS 0.7637 INCHES. LOCK FIRMLY WITH B659-140

(SPOT THRO. ONE TAPPED HOLE AND DRILL 1.4 x

2.2 DEEP INTO 46-6759) (APPLY LOCTITE 222)

THEN DRILL THRO. TWO DIAGONALLY OPPOSITE 1.50

HOLES IN H45-8131 INTO BODY AND FIT B604-2537

(2). WHEN SUITABLE CAM MOVEMENT HAS BEEN

ACHIEVED. FILL GAP BETWEEN C'SK HD. SCREW

AND SLOT WITH ACRULITE.

DATE

CHANGE No.

23-01-96

19-12-96

10-02-97

21-03-97

H5796

16-06-98

OC-0007

10-11-99

0055

H5727

H5766

FITTING OF FOCUS STOP

D650-1124 (1)

H45-4462

H45-7716 (11)

"C"

D650-1124 (2)

H46-4456 SEE NOTE 4 (A)

H46-4454 SEE INSET VEIW OF ADJUSTMENT

B640-374 (22)

H45-4461

H45-4459

"B"

45-10784 (22)

45-10785 (22)

ONE OF EACH AT

EACH END.

H46-4997

CEMENT ONTO

K599-1305

WITH INTERNAL

SHOULDER

TOUCHING GLASS

SHOULDER, USING

QUICK-SETTING

"ARALDITE"

4:1

GLASS CODES:

H45-4503

"Y"

H45-4502

H45-8071

B45-4494 CEMENT TO H45-4502 AND H45-8070

WITH BOSTIC CLEAR ADHESIVE.

H46-4998

K501-1530-01

D650-1324 (2)

D650-13202 (2)

46-6791 (1)

46-6792 (2)

B640-868

46-6785

D45-4455 (4)

D650-1323 (4)

20-3885 (3)

B45-7639 (3)

D680-102 (3)

B672-35 (3)

46-6787

D650-1223 (3)

5, SETTING OF FOCUS CAM FOLLOWER FOR POSITION;FIRST CLAMP 45-10606 ONTO H46-4998 WITH GAP "C" SET AT ZERO. PLACE UNIT

INTO LENS AND DETERMINE, FOR

FOCUS, DISTANCE "B" TO FRONT FACE OF

46-6789. REMOVE UNIT AND ADJUST GAP "C" TO MAKE "D" FROM GLASS APEX TO

SIDE OF B604-391, EQUAL TO 73.7-"B"(0.1). TIGHTEN 20-3881 SCREWS AND

DRILL FOR & FIT B604-945 (2).

8

1, REFER TO DRG. 100-6503 FOR FURTHER ASSEMBLY DETAILS

2, SPOT THROUGH TAPPED HOLE AND CONE DIMPLE 90 INTO MATING COMPONENT.

3, INITIAL CARRIAGE SETTINGS:

WITH ZOOM RING SET AT NARROW ANGLE END STOP, ADJUST H45-4956 AND

45-10323 ON THEIR CARRIAGES SO THAT:- (1)DEPTH TO REAR GLASS FROM

BACK FACE OF ZOOM UNIT BODY TO BE 16.34mm (RETURN TO THIS SETTING

AFTER ANY SEPARATION CHANGE). (2)DEPTH TO REAR GLASS OF MIDDLE (G3)

ZOOM SECTION FROM BACK FACE OF ZOOM UNIT BODY TO BE AS IN THE TABLE

FOR THE GLASS DESIGN LISTED.

4, SHORTENING:

(A) SHORTEN H46-4456 TO ACHIEVE SEPARATION "X" CORRECT TO DATA-SEE

TABLE. (MAY BE REVISED ON CHECKING FOCUS HOLDING THROUGH THE ZOOM

RANGE).(B) SHORTEN FRONT FACE OF 46-6972 TO GIVE SEPARATION "Y" OF

27.50mm. WITH LENS CORRECTLY SET AT THROUGHOUT ZOOM RANGE, AFTER ALL

ZOOM SEPARATIONS ARE FINALLY SET FOR TRACKING.

H36-380

H45-4447

46-6790

B618-177 (6)

46-6784

D650-1323 (4)

46-6789

B618-177 (4)

ASSEMBLY NOTES:

46-6765

D650-1223 (3)

D650-11310 (6)

46-6781

6, LUBRICATION:

LUBRICATE THE FOLLOWING SURFACES LIGHTLY WITH MTS 2000 GREASE CODE No

9103-19055

A) FOCUS FOLLOWER H45-7263.

B) CAM FOLLOWERS H45-4463, BORES ONLY.

C) OUTER FACES OF FOLLOWER BLOCKS AND SLIDING ZOOM FOLLOWERS H45-5292.

46-6790

45-9992

SECURE WITH

LOCTITE 601

H45-8070

46-6788

D650-1223 (4)

H46-5504

D650-1324 (2)

"G1": H99-1302,1303, K599-1305

H99-1306.

"G2": K599-812,814,H99-815.

"G3": H99-816, K599-818.

"G4": K599-820, H99-821.

H45-8069

"X"

"D"

46-6783

D650-1324 (4)

MACHINE FINISH

46-6769

D650-1223 (1)

H46-3288

ZOOM CARRIAGE ROLLERS

SCREW REAR RETAINING STRIP

46-6768 SECURELY IN PLACE

WITH D650-2026 (3).

H45-4501

45-10606

SEE NOTE 5

45-10786 (11)

SEAL OVER ENDS

WITH KWIKFIL TO

RETAIN.

FINISH

D650 -1128 (2)

B640-374 (12)

45-10786 (6)

SECURE ENDS WITH ARALDITE.

SEE PARTS LIST

46-6786

D650-1324 (4)

D650-1124 (1)

MATERIAL

ASSEMBLE D650-1325 (4) 0R -1326 (4) INTO EACH HOLE UNTIL IT TOUCHES

A 35 CUT-OUT IN END FACE OF H36-724. BY ROTATING THE HEADS OF TWO

DIAMETRICALLY OPPOSITE SCREWS SIMULTANEOUSLY IN OPPOSITE DIRECTIONS

SLIGHT MOVEMENTS OF REAR ZOOM CELL CAN BE EFFECTED IN ANY OF THE 4

DIRECTIONS SHOWN, UNTIL A POSITION IS ACHIEVED WHERE IMAGE AXIS

REMAINS STATIONARY WHEN TRACKING THROUGH ZOOM RANGE.

H45-7263

H45-7262

D680-102

OF

WITH ISOLATOR

AFTER FINAL TIGHTENING OF B653-116 SCREW FILL GAP WITH "ACRULITE"

B604-930 (4)

B604-391 RETAIN IN 45-10606 WITH

LOCTITE 638. ADJUST HEIGHT TO

MAX. WITHOUT FOULING TOP OF FOCUS

CAM SLOT.

SECT. THRO A SPRUNG FOLLOWER

SHEET

COOKE 18-100mm ZOOM & FOCUS

B

D650-1124 (2)

45-10288

D45-4951 (2)

K100-6513-01

ADJUSTMENT OF H46-4454 REAR ZOOM CELL

H45-5292 (2)

OUTER ZOOM

FOLLOWER

B639-405 (2)

ASSEMBLED INTO

H36-724

0.5

0.0

.EKAHS .XAM

DRG N0.

TITLE

REMOVE MATERIAL FROM

THIS FACE,SQUARE TO

TOP FACE,SO THAT LOWER

EDGE IS IN LINE WITH

BOTTOM EDGE OF CAM TO

0.5mm.

MACHINE OUTER EDGES

OF BLOCKS EQUALLY UNTIL

BLOCKS SLIDE FREELY IN

BODY 46-6759 WITH 0.02

B653-116 (4). TO BE SLACKENED OFF WHILE ADJUSTMENT "A" & "B" ARE CARRIED

OUT, THEN TIGHTENED TO GIVE LIGHT GRIP ONLY, AFTER EACH TRIAL STAGE OF

EACH ADJUSTMENT. FULLY TIGHTEN ONLY WHEN ADJUSTMENT IS COMPLETE.

20

45-10323

SEE NOTE 3

AFTER FINAL

SETTING, FILL

THE GAPS WITH

"ACRULITE".

"B" 653-101 (4)

ADJUST TO SET

OPTICAL TRUTH.

FILL WITH RED

PAINT AFTER

ADJUSTMENT.

46-6759

46-6767 (1)

46-6770 (2)

B640-867

STATUS

USED ON

8, ENGRAVING

ALL ZERO LINES FOR ALL SCALES (2 FOCUS, 2 ZOOM),PRE-ENGRAVE AT

COMPONENT STAGE.FRONT CELL MAIN INSCRIPTION ENGRAVED ACCORDING TO

PRODUCT CODE-SEE COMPONENT DRAWING 46-6782.

100-6503

3rd ANGLE PROJECTION

DRG. CONFORMS TO BS308

ALL OTHER ENGRAVING CARRIED OUT WHEN THE UNIT IS

ASSEMBLED TO AN APPROPRIATE REAR UNIT.

SCALE

9, ACCESSORIES.

PUT TO STOCK WITH K377-150-01 FRONT LENS CAP AND 3 OFF DRIVE

LEVERS K501-1835-01. IN CERTAIN CASES THE LENS IS ALSO SUPPLIED

WITH SPARE FOCUS SCALE RINGS-SEE PRODUCT CODE TABLE ON DRG.

100-6502

1:1

DIMN IN

DRG SIZE

MM

A1

OPTICS LIMITED

LEICESTER ENGLAND

7, SEALING:

ALL SCREWS TO BE SEALED WITH SHELLAC EXCEPT GRUB SCREWS WHICH ARE

TO BE SEALED WITH BLACK OR RED PAINT. NOTE: THE GRUB SCREWS WHICH

RETAIN 46-6785 AND 46-6786 MUST BE EASILY REMOVEABLE.

"G2" DESIGN

"G3" DESIGN

"G4" DESIGN

001 TO 004 INCL.

001-004-006-007

001 TO 006 INCL.

DEPTH TO REAR OF "G3"

17.35 + G4 GLASS THICK.

SEPARATION "X"

58.04 + G3 THICK.

Cooke OPTICS Ltd. 1996

plotted by

jlf

DRG N0.

K100-6513-01

17Jun98

SHEET

OF

THIS IS A CAD DRAWING AND MUST NOT BE UPDATED BY HAND

D650-1028

D660-302(2).

CEMENT ONTO

D650-1028 BEFORE

ASSEMBLING SCREW

INTO 46-6760.

46-6760, RETAINED BY

D650-1128 (2)

DRG N0.

K100-6522-01

END OF HOOK

OF B616-774

46-6811

OF

TITLE

7.2 MA

SHEET

18-100 T3.0 REAR UNIT

D660-302 (4)

SECURE ONTO

D650-1128 WITH

CEMENT.

46-6761

END HOOK

OF B616-774

MATERIAL

H659-139

SEC B-B

D650-1128

SEC C-C

SCALE 2:1

SCALE 2:1

FINISH

46-6762

FOR FILTER HOLDER ASSY.

SEE DRG. K501-1443-01-Y

AND K501-1480-01-Y.

(SEE ALSO NOTE 3 BELOW)

A

B616-774

H46-4962

B604-956 INSERT TO

JUST CLEAR ROOT OF

THREAD.

H45-8437

H46-4963

D650-1035

MACHINE FINISH

H45-8438 SEAL WITH

ETCH BLACK

H46-4964

K599-1322

Unless otherwise stated

DRAWN BY

ppn

K503-3 (6)

B

DATE

K599-1318

5Jan96

ISSUE No.

K599-1320

C

FOCAL PLANE

IN AIR

H45-8038

D650-1028 (3)

DATE

CHANGE No.

26-01-96

19-12-96

H5727

29-04-97

H5895

87.51

87.49

D650-1028 (3)

H46-5513, FIXED INTO

RECESS OF 46-6762 WITH

D650-1124.

C

46-7157 FIT WHITE SHIM

SUPPLY REMAINING 8 SHIMS

IN PLASTIC BAG.

H46-4968

A

H46-4970 SHORTEN ON

ASSY. TO GIVE MIN

SHAKE OF 46-6811

NOTES

1, ASSEMBLY OF IRIS (A) BEFORE ASSEMBLING H46-4964 AND H46-4963,

CHECK THAT ALL HOLES AND SLOTS ARE FREE FROM BURRS, AND THAT

IRIS RIVETS ARE A FREE FIT; COMPONENTS TO BE THOROUGHLY CLEAN

AND DRY. (B) BEFORE ASSEMBLING B659-139 VIA SLOT IN 46-6762,

APPLY LOCTITE 222 SCREWLOCK SPARINGLY INTO TAPPED HOLE IN

H46-4964, (C) WITH B659-139 POSITIONED 1 FROM THE MAX.

APERTURE END OF THE IRIS SLOT, (THIS EQUALS 3/4mm ON THE

DIAMETER WHICH CARRIES THE IRIS SCALE ZERO LINES), ROTATE

H46-4963 UNTIL IRIS LEAVES TOUCH A PLUG OF 26.5mm DIA. THEN

TIGHTEN D650-1026 (3) SCREWS. APPLY SHELLAC TO HEADS OF THESE

SCREWS TO LOCK H46-4963 AGAINST ROTATION. (D) THE TWO T SCALES

ARE ENGRAVED WHEN THIS UNIT IS ASSEMBLED TO ZOOM UNIT SEE

100-6502 AND 100-6503.

2, B659-140. SCREW H46-4970 FIRMLY UP TO 46-6762 SHOULDER, PICK

UP TAPPED HOLE IN H46-4970 AND SPOT THROUGH INTO 46-6762.

DRILL 1.4 x 2.2 DEEP. CLEAN AWAY ALL SWARF AND FIT B659-140.

46-7156 SHORTEN TO GIVE

CORRECT BACK FOCUS - SEE

NOTE 4.

B659-140 (SEE NOTES)

3, FILTER HOLDER UNITS. CHECK THAT K501-1443-01 FILTER HOLDER SLIDES EASILY

INTO ITS SLOT BOTH WAYS ROUND, AND THAT WHEN THE FILTER SLOT COVER IS

ROTATED AGAINST ITS SPRING LOADING, THE FILTER HOLDER HANDLE SWINGS

EASILY INWARDS AND OUTWARDS WITHOUT JAMMING THE MOVEMENT OF THE COVER.

REPEAT THIS TEST FOR K501-1480-01 UNIT.

4, MECHANICAL BACK FOCUS. SHORTEN 46-7156 TO GIVE THE 87.51-87.49 DIMN

WHEN FITTED TO K100-6512-01 WITH WHITE SHIM FROM 46-7157 IN PLACE.

RETAIN WITH SCREWS D650-1028(2).

STATUS

USED ON

K100-6502

THESE COMPONENTS COMPRISE K598-235 GLASS SET

K100-6503

3rd ANGLE PROJECTION

DRG. CONFORMS TO BS308

SCALE

1:1

5, PLACING TO STOCK. PUT TO STOCK WITH REAR LENS CAP 77-135 FITTED AND

WITH IRIS CLOSED TO MIN. APERTURE AND L.H. END SEALED OFF.

H46-3641 ADAPTOR CLAMP RING SHOULD BE ASSEMBLED LOOSELY ONTO THREAD

OF H46-4970, AND BOTH FILTER HOLDERS, I.E K501-1443-01 AND K501-1480-01,

SHOULD ACCOMPANY EACH UNIT.

THESE COMPONENTS COMPRISE K510-977-01 GLASS BORING ASSY.

DIMN IN

DRG SIZE

MM

A2

OPTICS LIMITED

LEICESTER ENGLAND

Cooke OPTICS Ltd. 1991

plotted by

jlf

DRG N0.

K100-6522-01

12May97

SHEET

OF

THIS IS A CAD DRAWING AND MUST NOT BE UPDATED BY HAND

DRG N0.

SHEET

OF

K100-6571-01

B639-421

TITLE

B640/374

(2 PER ROLLER

ASSEMBLY).

ASSEMBLY NOTES

D650/1028(2)+

D680/102(2)

B672/35(2)

SYMBOLS:

A

*=CEMENT IN POSITION WITH HIGH STRENGTH LOCTITE

+=SECURE WITH LOCTITE SCREWLOC.

1. SETTING OF ZOOM CARRIAGE MOVEMENTS

BEFORE ASSEMBLING ZOOM DRIVE SLEEVE AND DRIVE PIN

MEASURE DOWN TO FRONT ZOOM CARRIAGE AT MAX. RISE ON

CAM SLOT (APPROX. 8 BEYOND REARMOST USED POINT).

ASSEMBLE DRIVE PIN AND STOPS AND SET REAR STOP SO THAT

FRONT ZOOM CARRIAGE IS 0.67 FORWARD FROM MAXIMUM

RISE POINT.

LOCATE 45-10786 IN POSITION BY BENDING D45/7446(2)

AS FOLLOWS: BEND OUTER EARS DOWN AT 45. BEND INNER

EARS AROUND 45-10786.

*B604/998(2)

APPLY ACRULITE INTO

GAPS AFTER SETTING.

ENLARGED VIEW AT "K"

SCALE 2:1

46-6619*

ASSEMBLE WITH

THE CUTOUT AT

THE BOTTOM.

H45/7292

45-10050

46-6617

D650/13202(3)

SEE NOTE 3

H616/875

46-6616

B659/140(3)

SEE NOTE 3

ROLLER ASSY

TYPE "Y"

46-6632

46-6630

H45/7311

D650/1028+

H45/7324+

ASSEMBLE INTO

REARMOST HOLE.

46-6625

B659/140(3)

SEE NOTE 3

D650/13202(3)

SEE NOTE 3

46-6624

H46/5818

SECTION "E-E"

17-06-97

H5963

30-09-97

OC-0006

15-06-98

OC-0007

04-11-99

H5727

H5895

0055

B659/140(3)

SEE NOTE 3

46-6850

SHORTEN AT STEP TO GIVE A GOOD

B659/140(2)

SMOOTH MOVEMENT OF IRIS GEAR

SEE NOTE 3

WITH MIN. SHAKE.

H46/6045.

ASSEMBLE INSERTS H45/8955(2)

AT REGION `I'*..

H99/1362

B618-126 (5)

(HELICOILS)

D650/1124(3)+

`I'

H99/1364

B639-402

H46/6226

`H'

D45/5521

K501/1043-01

G

H46/4576

46-6618

46-6614

D650/3535

SEE NOTE 3

ROLLER ASSY

TYPE "Y"

`H'

D650-11028

46-6620(2)

SHELLAC

ROTATE 46-6705 TO GIVE

AN OVER-RUN OF 0 TO 1

OF IRIS WHEN LEAVES ARE

TOUCHING A PLUG OF 26.91,

THEN TIGHTEN THE THREE

CH. HD. SCREWS.

H45/7459(3)

B672/35(3)

D650/1024(3)

45-10626

D650/3535 (3)

SEE NOTE 3

D650/1024(2)

H616/875

H45/7448 SHORTEN TO ACHIEVE SEPARATION `C'-SEE NOTE 2.

PARTIAL END VIEW SHOWING

RETAINING 0F 46-6705

H46/5821

K501-1830-01

B640-869

D650/1026(3)+

H45/7879(2)

H46/6047

D650/1024(2)

D650/1024(2)

H45/7454

(C) ITEMS ENGRAVED AT FINAL STAGES OF ASSEMBLY:

46-6621

H45/7751

FOCUS SCALES ON THE INTERCHANGEABLE RINGS 46-6621

SEE DRAWING 100-6561-01Sh2 FOR DETAILS

IDENTS (LAST 2 DIGITS OF SERIAL NO.) ON THE ABOVE

INTERCHANGEABLE RINGS.

SEE DRAWING 100-6561-01Sh1 FOR DETAILS.

T-SCALES ON 46-6629

SEE DRAWINGS 100-6561-01Sh3 FOR DETAILS.

H45/6976

D650/11014(2)

SHORTEN TO 1.85

SECTION "G-G"

B659/140(3)

SEE NOTE 3

(1 PLUS 1 SPARE) RETAINED BY D650/13202(4)

SEE NOTES ON ENGRAVING.

46-6622

B659-140(3)

SEE NOTE 3

WHEN DRILLING INTO 46-6618

ENSURE THAT DRILL MISSES

CAM TRACK.

5. ACCESSORIES

45-10614 CEMENT TO 46-7158

WITH LOCTITE HIGH STRENGTH

RETAINING COMPOUND

K599/1366

H45/7317

POSITION ON ASSY.

46-6705

H45/6978(2)

ONE EACH AT BOTH ENDS

OF 46-6632

H45/7287(2)

K501-1314-01

B604/998*

K99/0160

D45/7305(2)

H99/0158

K501-1873-01

(9 OFF)

H616/876

H45/7318+

6. FITTING OF 46-6625

ASSEMBLE WITH PARALLEL GAP TO 46-6624 (0.15 TO O.O5 WIDE)

LOCK IN PLACE WITH M2 GRUB SCREWS AND FIT B659/140(3)

AS INDICATED IN NOTE 3 ABOVE.

46-6628

D650/3535(3)

SEE NOTE 3

H45/7315*

46-6680

D650/1024(2)+

D45/5521

(1) OF (3)

7. FITTING OF 46-6629

D650/1136

D45/7276

RETAINED AS

SHOWN ABOVE

46-7158

.GNITTES LANIF TA ETILURCA

ASSEMBLE WITH PARALLEL GAP TO 46-6627 (0.15 TO 0.05 WIDE).

FIT D650/13202(3) AS INDICATED IN NOTE 3 ABOVE.

H99/1363, SHALLOW

CURVE TOWARDS H99/1364

H45/7293

H45/7454

12-05-97

(A) PRE-ENGRAVED COMPONENTS:

THE FOLLOWING LOOSE ITEMS MUST ACCOMPANY EACH

UNIT AS ACCESSORIES:

1 EXTRA FOCUS SCALE RING , ENGRAVED TO THE OPPOSITE

UNITS TO THE RING ON THE LENS, AND IDENTED.

K377/150-01 LENS CAP (FRONT).

K501-1835-01 X2 DRIVE LEVERS.

19-12-96

K599/1361

4. ENGRAVING.

22-03-96

H46/5819

B639/422(12)

(B) ITEMS ENGRAVED AT FIRST STAGES OF ASSEMBLY:

2.0

D45/7277

H46/5820

FOR D650/3535 SCREWS, DRILL 2.5 X 2.5 DEEP IN MATING PART.

NAME AND LENS SERIAL NO. ON 46-6614. NOTE THAT THIS MUST

MATCH THE SERIAL NO. ENGRAVED ON 46-6737 0F REAR UNIT.

SEE DRAWING 100-6561 FOR DETAILS.

CHANGE No.

46-6626

B618-177(6)

DATE

46-6629

D650/13202(3)

SEE NOTE 4 AND NOTE 7

H46/5816.

SHORTEN TO ACHIEVE

SEPN. `A' SEE NOTE 2

H45/7750

ENSURE THAT MATING PARTS ARE SHOULDERING UP TIGHTLY,

THEN PICK UP TAPPED HOLE AND SPOT THROUGH INTO MATING PART.

FOR D650/13202 GRUB SCREWS, DIMPLE 90. FOR B659/140

SCREWS,DRILL 1.4 X 2.2 DEEP IN MATING PART.

46-6849(2)

H46/6225

D650/1026(2)

D650/1026(2)

3. B659/140 SCREWS, D650/13202 GRUB SCREWS AND

D650-3535 HEX. SKT. SET SCREWS

THE FOLLOWING COMPONENTS ARE STOCKED AS ENGRAVED

ITEMS PRIOR TO ASSEMBLY:

46-6623 FOCUS ZERO RING (ZERO LINES)

46-6624 ZOOM SCALE ZERO RING (ZERO LINES)

46-6625 ZOOM GEAR RING (FOCAL LENGTH SCALES)

46-6627 IRIS SCALE ZERO RING (ZERO LINES)

45-9971

45-10049

46-6615

D650/13202(2)

SEE NOTE 3

H45/7752 ASSEMBLE WITH

TURNED UP END TOWARDS

FRONT OF LENS.

B604/998

H46/4466

46-6623

D650/13202(3)

SEE NOTE 3

46-6668

SHELLAC

5Feb96

ISSUE No.

46-6627

D650/13202(3)

SEE NOTE 3

D45/4455* CEMENT INTO FOCUS SCALE

RING WITH HEAD IN BORE.

D45/5521

D650/1024(2)+

tja

DRAWN BY

DATE

H45/7281

D650/11014(6)

B639/422(12)

H45/7453

H45/7453

MACHINE FINISH

Unless otherwise stated

SEPN.`A'. SHORTEN H46/5816 TO GIVE AX. SEPN. BETWEEN

H99/1362 AND H99/1363 OF 14.050.05 AT INFINITY FOCUS.

SECTION THROUGH ROLLER ASSEMBLY

(2 X SIZE)

K501-1043

SEPN.`B'. 80.51 NOMINAL AT INFINITY FOCUS AND REARMOST

ZOOM POSITION (REFERANCE ONLY).

FINISH

ENLARGED VIEW AT "J" SHOWING CONSTRUCTION AND RETAINING OF ROLLER ASSEMBLIES.

H46-4471*

SHORTEN TO

12.5 LG.

NOTE:

FOR 1/2 INCREASE IN ROTATION OF DRIVE SLEEVE THE FRONT

ZOOM TRAVEL INCREASES BY 0.35 AND THE REAR ZOOM TRAVEL

DECREASES BY 0.02

SEPN.`D'. SHORTEN H45/7450 TO GIVE 2.23 FROM APEX OF

K599/1366 TO IRIS FACE OF 46-6705, WITH ZOOM AT REAR

END OF TRAVEL.

ROLLER ASSY. SHOWN IS TYPE `X'

(OCCURS AT 8 POSITIONS).

FOR ASSY TYPE `Y' (OCCURING IN

4 POSITIONS AS SHOWN IN SECTION

VIEWS `E-E' AND `G-G'), USE

H45/7326 TYRE & D45-7327 SPACERS.

FOR SPRING-LOADED ASSYS. USE THRUST SPACER H45/7457(2)

TRAVEL OF ZOOM CARRIAGES SHOULD THEN BE:

FRONT ZOOM CARRIAGE 79.43

REAR ZOOM CARRIAGE 14.68

SEPN.`C'. AFTER SETTING SEPN.`D', SHORTEN H45/7448 TO

GIVE 4.99 AX. SEPN. BETWEEN K99/0160 AND K599/1366, WITH

ZOOM AT REAR END OF TRAVEL.

NOTE:

D650/1124(2)

TOTAL OF 8

H46/4471*

25-250 T3.7 COOKE

MATERIAL

H45/7716

H45/7295(2)*

ON THE REAR ZOOM CARRIAGE ADJUST THE FOLLOWER BLOCK SO

THAT TRAVEL FROM MAXIMUM RISE POINT BACK TO THE REAR STOP

IS 16.28.

2. AXIAL SEPARATIONS

H45/7301

D45/7446(2)

TOTAL OF 8

H45/7296(2)

H45/7294.

ROTATE TO GIVE

FREE WITHOUT SHAKE,

SLIDING FIT OF

H45/7296 BLOCKS.

ZOOM AND FOCUS UNIT FOR

ROLLER ASSEMBLIES TO RUN CONCENTRIC

TO SPINDLE WITHIN 0.03mm T.I.R.

45-9907

H45/7306

SEAL WITH

ETCH BLACK

H46/5822

STATUS

H45/7438 (REAR SPRING)

H45/7440 (FRONT SPRING)

H45/8769

46-6681

D650/3535(3)

SEE NOTE 3

H45/7439(2)

D45/7280

D650/1124(8)+

(USE D650/1333(3)

INITIALLY)

100-6561

3rd ANGLE PROJECTION

H45/8768

D650/10013(3)

PART SECTION "F-F"

USED ON

DRG. CONFORMS TO BS308

SCALE

ENLARGED VIEW AT "M" (2 X SIZE)

1:1

DIMN IN

DRG SIZE

MM

A0

H45/7450. SHORTEN TO ACHIEVE SEPARATION `D'

.2 ETON EES

OPTICS LIMITED

LEICESTER ENGLAND

PART SECTION `H-H'

Cooke Optics Ltd. 1998

plotted by

DRG N0.

jlf

K100-6571-01

22Jun98

SHEET

OF

THIS IS A CAD DRAWING AND MUST NOT BE UPDATED BY HAND

DRG N0.

K100-6581-01

SHEET

OF

TITLE

REAR UNIT FOR 25-250 T3.7

COOKE 25-250

ACRULITE POTTING COMPOUND

MATERIAL

ACRULITE POTTING COMPOUND

M2 X 4 SL.CH.SCR.

D650-1224 4 OFF.

M2 X 6 SL.CH.SCR.

D650-1026 4 OFF.

DOWEL PIN 2 X 10

B604-2524 2 OFF.

DOWEL PIN 2 X 8

B604-2560 2 OFF.

FINISH

SECTION B-B

SECTION D-D

SECTION C-C

SECTION E-E

MACHINE FINISH

Unless otherwise stated

D650-13202(3)

DIMPLE 46-6740

90

tja

21Dec95

ISSUE No.

D650-1038 (6)

4 OFF

B659/140 (2). SEE NOTE 2.

M2 X 8

D650-1028

DATE

CHANGE No.

22-3-96

24-04-97

H5895

20-04-99

OC-0034

05-11-99

0055

D650-20312 (5)

H45/8913

H45/8761

DRAWN BY

DATE

H99/1386

D

46-7157 (WHITE SHIM)

H45/8762

H45/8765

H45/8763

H45/8764 (ASSEMBLE WITH PARTING-OFF

RECESS INWARDS)

B604/956. INSERT TO JUST CLEAR

ROOT OF THREAD.

K599/1372.

SHALLOW CURVE

TOWARDS K599/1369.

H99/1367

K599/1374

K599/1369

E

46-7156

H99/1368, DEEP CURVE

TOWARDS K599/1369.

4 OFF

M2 X 8

D650-1028

46-6740

FOCAL PLANE IN AIR

46-6737

87.500.01

46-6738

46-5810

46-6580

SECTION A-A

46-6741

46-6739

ASSEMBLY NOTES

1. ENGRAVING OF SERIAL NUMBER. AS FIRST OPERATION, ENGRAVE

LENS SERIAL NUMBER AS SHOWN ON DRAWING 100-6561 ON THIS

FACE.

2. B659/140 PINS. SCREW H46/5810 FIRMLY UP TO 46-6739 END

FACE. PICK UP TAPPED HOLE IN H46/5810 AND SPOT THROUGH

INTO 46-6739. DRILL 1.4 X 2.2 DEEP. CLEAN AWAY ALL SWARF

AND FIT B659/140.

STATUS

USED ON

1656-001

3rd ANGLE PROJECTION

DRG. CONFORMS TO BS308

SCALE

2:1

3. MECHANICAL BACK FOCUS. SHORTEN COLLAR 46-7156 TO GIVE

THE 87.500.01 DIMENSION WITH WHITE SHIM FROM SHIM SET

INSTALLED AND THE REAR UNIT FITTED TO K100-6571 ZOOM

AND FOCUS UNIT. PUT REMAINING 8 SHIMS FROM SET IN

POLYTHENE BAG AND SUPPLY WITH LENS.

4. ACCESSORIES. ASSEMBLE H46/3641 ADAPTOR CLAMP RING LOOSELY

ONTO THREAD OF H46/5810, THEN 77/300 LENS CAP ONTO H46/3641.

DIMN IN

DRG SIZE

MM

A2

OPTICS LIMITED

LEICESTER ENGLAND

Cooke OPTICS Ltd. 1998

plotted by

jlf

DRG N0.

K100-6581-01

20Apr99

SHEET

OF

Das könnte Ihnen auch gefallen

- Welding - Principles and Practices (5th Ed) (Gnv64)Dokument1.146 SeitenWelding - Principles and Practices (5th Ed) (Gnv64)Chandra Sekhar83% (12)

- Peter Bondanella The Films of Federico FelliniDokument221 SeitenPeter Bondanella The Films of Federico Felliniaedicofidia100% (2)

- American Woodworker No 171 April-May 2014Dokument76 SeitenAmerican Woodworker No 171 April-May 2014Darius White75% (4)

- American Woodworker No 170 February-March 2014Dokument76 SeitenAmerican Woodworker No 170 February-March 2014Darius White100% (1)

- Aspheric Lens Design PDFDokument1 SeiteAspheric Lens Design PDFJhon Cena100% (1)

- Panavision LensesDokument48 SeitenPanavision Lensesraviitherising100% (1)

- Diseño y Fabricación de Hologramas Con MatlabDokument273 SeitenDiseño y Fabricación de Hologramas Con MatlabEder Manuel Alfaro Alfaro estNoch keine Bewertungen

- Conventional and Unconventional Contact Lens Manufacturing SystemsDokument15 SeitenConventional and Unconventional Contact Lens Manufacturing SystemsCristi MocanNoch keine Bewertungen

- OpticStudio GettingStarted PDFDokument223 SeitenOpticStudio GettingStarted PDFRaj HimanshuNoch keine Bewertungen

- Cricut For Beginners by Elisa RussellDokument227 SeitenCricut For Beginners by Elisa RussellDarius White80% (5)

- 66 EasyDokument10 Seiten66 EasyDarius WhiteNoch keine Bewertungen

- Basics of Image Processing and AnalysisDokument175 SeitenBasics of Image Processing and AnalysisVikrant ViksNoch keine Bewertungen

- Asphere Design For DummiesDokument20 SeitenAsphere Design For DummiesMiguel AlejandroNoch keine Bewertungen

- Beam ExpanderDokument12 SeitenBeam ExpanderRio Ananda PutraNoch keine Bewertungen

- 2009 Class Summary Essay - Vineeth AbrahamDokument40 Seiten2009 Class Summary Essay - Vineeth AbrahamRachel OnealNoch keine Bewertungen

- Cult Classic Third Party LensesDokument64 SeitenCult Classic Third Party LensesazamamaNoch keine Bewertungen

- Tolerance On Material Inhomogenity and Surface Irregularity - Wen RuiDokument14 SeitenTolerance On Material Inhomogenity and Surface Irregularity - Wen RuiKrishna ReddyNoch keine Bewertungen

- CollimatorDokument5 SeitenCollimatorskc3128Noch keine Bewertungen

- Aspheric Lens Design PDFDokument1 SeiteAspheric Lens Design PDFAnonymous HGOomkn69Noch keine Bewertungen

- Diffractive Optics From Holo /or: Services & CapabilitiesDokument4 SeitenDiffractive Optics From Holo /or: Services & Capabilitiesasdfasdfsharklasers100% (1)

- Laser Beam Expanders Basics and Applications: Vision System Vision SystemDokument6 SeitenLaser Beam Expanders Basics and Applications: Vision System Vision SystemAtul SharmaNoch keine Bewertungen

- 521.tutorial - Zemax Tolerancing - HaynesDokument10 Seiten521.tutorial - Zemax Tolerancing - Haynesodane3113Noch keine Bewertungen

- Eastern Bloc New PDFDokument33 SeitenEastern Bloc New PDFkurageartNoch keine Bewertungen

- Schiefspiegler ToolkitDokument5 SeitenSchiefspiegler ToolkiteolocosNoch keine Bewertungen

- Plastic OpticsDokument35 SeitenPlastic Opticskerbla100% (1)

- Designing A Double-Gauss Lens, The Hard Way: David Shafer David Shafer Optical Design Fairfield, CT, 06824 #203-259-1431Dokument22 SeitenDesigning A Double-Gauss Lens, The Hard Way: David Shafer David Shafer Optical Design Fairfield, CT, 06824 #203-259-1431resuscitatNoch keine Bewertungen

- DLP System OpticsDokument26 SeitenDLP System OpticsAnonymous kg7YBMFHNoch keine Bewertungen

- LensDesign PDFDokument61 SeitenLensDesign PDFGerardo Angel GentileNoch keine Bewertungen

- Optics of LithographyDokument143 SeitenOptics of LithographyChang MingNoch keine Bewertungen

- The Iris DiaphragmDokument8 SeitenThe Iris DiaphragmRandy WigginsNoch keine Bewertungen

- Zemax in GeneralDokument31 SeitenZemax in GeneralgordansimNoch keine Bewertungen

- AberrationDokument16 SeitenAberrationPaul G Paul100% (1)

- Aspheric Lenses Design PDFDokument9 SeitenAspheric Lenses Design PDFTuan Do100% (1)

- 2013 Benz ManualDokument22 Seiten2013 Benz ManualArif MohammadNoch keine Bewertungen

- Beam ExpandersDokument4 SeitenBeam ExpandersVaBi LeftNoch keine Bewertungen

- Fabrication of Freeform OpticsDokument3 SeitenFabrication of Freeform Opticskndprasad01100% (1)

- Sampled Imaging Systems: Analysis and Evaluation ofDokument20 SeitenSampled Imaging Systems: Analysis and Evaluation ofSurajit AcharyaNoch keine Bewertungen

- Collimation Instructions APMAPOBino Version 1 3Dokument7 SeitenCollimation Instructions APMAPOBino Version 1 3aandrassyNoch keine Bewertungen

- OptiFDTD TutorialsDokument36 SeitenOptiFDTD TutorialsDr-Mandeep SinghNoch keine Bewertungen

- Simulation of Wave Front Propagation With ZEMAX: Sara Casalbuoni and Rasmus Ischebeck DesyDokument48 SeitenSimulation of Wave Front Propagation With ZEMAX: Sara Casalbuoni and Rasmus Ischebeck DesyZeynep Nilüfer Güven ÖztürkNoch keine Bewertungen

- Perfect Optical Alignment Made SimpleDokument15 SeitenPerfect Optical Alignment Made SimplewaltermannNoch keine Bewertungen

- The Importance of Induced Aberrations in The Correction of Secondary ColorDokument11 SeitenThe Importance of Induced Aberrations in The Correction of Secondary ColorDannyNoch keine Bewertungen

- SOLIGOR Lens CompendiumDokument7 SeitenSOLIGOR Lens CompendiumpeterNoch keine Bewertungen

- Defence Space Optics BrochureDokument4 SeitenDefence Space Optics BrochureRavishankarNoch keine Bewertungen

- Vacuum Coating of Plastic OpticsDokument15 SeitenVacuum Coating of Plastic OpticsSasiKumar PetchiappanNoch keine Bewertungen

- Tutorial On ZemaxDokument10 SeitenTutorial On Zemaxms_geoNoch keine Bewertungen

- Lens Selection Gaussian Beam OpticsDokument2 SeitenLens Selection Gaussian Beam Opticskwinters2015Noch keine Bewertungen

- Anamorficos PanavisionDokument7 SeitenAnamorficos PanavisionBlas De LezoNoch keine Bewertungen

- Lens History by ZEISS Planar en - CLB - 40 PDFDokument12 SeitenLens History by ZEISS Planar en - CLB - 40 PDFkfranovskyNoch keine Bewertungen

- Getting Started With ZEMAXDokument66 SeitenGetting Started With ZEMAXReno Kyu Young ChoiNoch keine Bewertungen

- Lens CoatingDokument43 SeitenLens CoatingjorgeNoch keine Bewertungen

- Optical GlassDokument181 SeitenOptical GlassHunter Moon100% (1)

- Zernike Wavefront AberrationsDokument26 SeitenZernike Wavefront AberrationsgastromonoNoch keine Bewertungen

- CODE V Optical Design Software: Design, Optimize and Fabricate Reliable Imaging OpticsDokument8 SeitenCODE V Optical Design Software: Design, Optimize and Fabricate Reliable Imaging OpticsDeaw EggTofuNoch keine Bewertungen

- (Optical Sciences and Applications of Light) Sun, Haiyin - Lens Design - A Practical guide-CRC Press (2017)Dokument374 Seiten(Optical Sciences and Applications of Light) Sun, Haiyin - Lens Design - A Practical guide-CRC Press (2017)Vivian Amos100% (1)

- En CLB41 Nasse LensNames DistagonDokument15 SeitenEn CLB41 Nasse LensNames DistagonseifadiazNoch keine Bewertungen

- Design of Basic Double Gauss LensesDokument11 SeitenDesign of Basic Double Gauss LensesHarry H LeeNoch keine Bewertungen

- Precision Injection MoldingDokument6 SeitenPrecision Injection MoldingLeonardo Falcão Macedo LimaNoch keine Bewertungen

- Light Microscopy and Digital ImagingDokument301 SeitenLight Microscopy and Digital ImagingBrandon ScottNoch keine Bewertungen

- The Cooke Triplet and Tessar LensesDokument42 SeitenThe Cooke Triplet and Tessar Lensesomega776Noch keine Bewertungen

- Analytical Study and Optical Design of Offner Based Hyperspectral Imager in Vnir RegionDokument69 SeitenAnalytical Study and Optical Design of Offner Based Hyperspectral Imager in Vnir RegionTanushrii RameshNoch keine Bewertungen

- Ray Optics by SenjicsDokument49 SeitenRay Optics by SenjicssenjicsNoch keine Bewertungen

- Notebook E - OpticsDokument66 SeitenNotebook E - Opticsapi-26183506Noch keine Bewertungen

- Zemax Tutorial V03Dokument15 SeitenZemax Tutorial V03vlavanyakumarNoch keine Bewertungen

- Gearbox AssemblyDokument1 SeiteGearbox AssemblyIan AsNoch keine Bewertungen

- Cylinder Liner ProjectionDokument4 SeitenCylinder Liner ProjectionFernando Daniel Saez VillarrealNoch keine Bewertungen

- MLNX VPI WinOF Release Notes Rev 5.19 For Windows Server 2016Dokument30 SeitenMLNX VPI WinOF Release Notes Rev 5.19 For Windows Server 2016Darius WhiteNoch keine Bewertungen

- CineAsset V1Dokument2 SeitenCineAsset V1Darius WhiteNoch keine Bewertungen

- Dolby CineAsset Player - ProductSheetDokument2 SeitenDolby CineAsset Player - ProductSheetDarius WhiteNoch keine Bewertungen

- American Woodworker - July 2014Dokument68 SeitenAmerican Woodworker - July 2014skruzo100% (5)

- QuantelRio Release Notes V4.4.1Dokument17 SeitenQuantelRio Release Notes V4.4.1Darius WhiteNoch keine Bewertungen

- ZPL Vol1 PDFDokument428 SeitenZPL Vol1 PDFDarius WhiteNoch keine Bewertungen

- Angst Lightingdesign MeerDokument1 SeiteAngst Lightingdesign MeerDarius WhiteNoch keine Bewertungen

- Alignment Using A Wobbulator PDFDokument10 SeitenAlignment Using A Wobbulator PDFAdinei HamradioNoch keine Bewertungen

- Fundacion Juan March - Julia Margaret Cameron PDFDokument166 SeitenFundacion Juan March - Julia Margaret Cameron PDFmoises_generNoch keine Bewertungen

- This Demonstration Covers The Usage of V-Ray Render Elements in Adobe PhotoshopDokument15 SeitenThis Demonstration Covers The Usage of V-Ray Render Elements in Adobe PhotoshopBartek BanterNoch keine Bewertungen

- Application FormDokument1 SeiteApplication FormAkshat AtrayNoch keine Bewertungen

- Information For Authors of Papers ACSDokument21 SeitenInformation For Authors of Papers ACSsouvenirsouvenirNoch keine Bewertungen

- Inglese 1Dokument2 SeitenInglese 1Cristian BraccialeNoch keine Bewertungen

- Geetika Das: Career ObjectivesDokument3 SeitenGeetika Das: Career ObjectivesSuman DasNoch keine Bewertungen

- Et Cetera DiscordiaDokument126 SeitenEt Cetera DiscordiakesherNoch keine Bewertungen

- Sun ScopeDokument3 SeitenSun ScopeJimNoch keine Bewertungen

- Yale Film Analysis WebsiteDokument5 SeitenYale Film Analysis WebsiteizmcnortonNoch keine Bewertungen

- My Dark Love (I'm A Vampire. So What., # 1)Dokument31 SeitenMy Dark Love (I'm A Vampire. So What., # 1)Ali Mac Novels88% (8)

- Aina Smart MirrorDokument25 SeitenAina Smart Mirrorsrinivas.sNoch keine Bewertungen

- Modo Servicio Bizhub C250 y C252Dokument5 SeitenModo Servicio Bizhub C250 y C252Miki Perez WarNoch keine Bewertungen

- MTV-Editing and Its Influence On Modern CinemaDokument12 SeitenMTV-Editing and Its Influence On Modern CinemaVanessa SpindigNoch keine Bewertungen

- Module 3-Answer KeyDokument15 SeitenModule 3-Answer Keyarmykrs_100% (2)

- PIVview v30 ManualDokument78 SeitenPIVview v30 ManualMartino Ermacora100% (1)

- Taking The Extra Out of The Extraordinary Mortensen JerslevDokument29 SeitenTaking The Extra Out of The Extraordinary Mortensen Jerslevdavid santiago uscamaita del castilloNoch keine Bewertungen

- Intro (The Basics) : Basic FactsDokument14 SeitenIntro (The Basics) : Basic FactsPedro BenitezNoch keine Bewertungen

- Knoll Light Factory ManualDokument59 SeitenKnoll Light Factory ManualNatalie WilliamsNoch keine Bewertungen

- Art V Porn V Religion The Weston Worlds Miss UnderstandingDokument22 SeitenArt V Porn V Religion The Weston Worlds Miss UnderstandingPhotoStu SmileNoch keine Bewertungen

- Sporting Optics, The Gun Digest Book of - Ocr PDFDokument308 SeitenSporting Optics, The Gun Digest Book of - Ocr PDFv133543250% (2)

- Multimedia ElementsDokument13 SeitenMultimedia ElementsRoderickParboTiriNoch keine Bewertungen

- Wisteria Portfolio Issue Tomek CiesielskiDokument26 SeitenWisteria Portfolio Issue Tomek CiesielskiGREENBOOKFACTORYNoch keine Bewertungen

- Seminar Report Liquid LensDokument27 SeitenSeminar Report Liquid LensTanmoy Tatwadarshi50% (2)

- Microscopy: Fig. 1: Principle of Compound Light Microscope and Phase - Contrast MicrosDokument6 SeitenMicroscopy: Fig. 1: Principle of Compound Light Microscope and Phase - Contrast MicrosTrần Vĩnh Bảo NgọcNoch keine Bewertungen

- Canon Pixma Mg4270 Mg2270 PR EngDokument8 SeitenCanon Pixma Mg4270 Mg2270 PR EngDocMasterNoch keine Bewertungen