Beruflich Dokumente

Kultur Dokumente

Paper About The Program Lincage

Hochgeladen von

Prot0nOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Paper About The Program Lincage

Hochgeladen von

Prot0nCopyright:

Verfügbare Formate

LINCAGES 2000 Latest Developments and Case Study

Yu, Ning. *

yuning@me.umn.edu

Erdman, Arthur G.

agerdman@umn.edu

Byers, Brandon P. _

byer0021@hotmail.com

Abstract

This paper introduces the latest development

of LINCAGES 2000, a mechanism design

software package available on Windows 9x/NT

and 2000. A case study of a motion generation

mechanism design using LINCAGES 2000 is

presented. Various design options are compared

and their advantages and disadvantages are

discussed. This software is proved to be a

powerful tool for mechanism synthesis and

analysis.

Introduction

A mechanism is a mechanical device that has

the purpose of transferring motion and/or force

from a source to an output [2]. Overall, the task

of a mechanism falls into one of the following

categories: motion, path and function generation.

A multiple-stage process of mechanical design is

required for mechanism design. Among these

stages, synthesis and analysis are two of the key

components. In short, synthesis generates the

optimal dimensional parameters for the

mechanism based on physical constrains and

design specifications. Analysis evaluates the

performance of the mechanism through

kinematics and dynamics and makes changes to

the mechanism as necessary. Traditionally, this

design process is done by intuition, experience,

and trial and error procedure. With the help of

computer aided mechanism design packages, the

work is greatly simplified and systemized.

Various mechanism design packages like

ADAMS [17], MINNSKETCH [12], AutoCAD

[14], IDEAS [18], Pro/E [15] have been

successfully used in academics and industry.

LINCAGES [6, 7, 8, 10, 11] developed in the

University of Minnesota, is a powerful tool for

the design of four-bar and six-bar planar

mechanisms using dyad equations in complex

*Graduate student, Department of Mechanical Engineering,

University of Minnesota, Minneapolis.

Professor, Department of Mechanical Engineering,

University of Minnesota, Minneapolis.

_Under graduate student, Department of Computer Science,

University of Minnesota, Minneapolis.

number forms and Burmester theory [1, 2],

LINCAGES 2000 provides three and fourprecision-position motion, path and function

synthesis. It also has basic analysis tools

providing velocity, acceleration and transmission

angle information simultaneously with the

synthesis process, thus providing evaluation of

the performance of ongoing designs. Users can

interactively change design parameters by direct

operation on the linkages or by using the

Solution Map to achieve different mechanism

types fulfilling the design specifications.

Analysis results dynamically change as design

parameters change. With the help of this

software package, traditional trail and error effort

in mechanism design process is greatly

decreased.

Latest development of LINCAGES

LINCAGES was first developed in the mid

70s in the University of Minnesota. Through the

past twenty years, LINCAGES has been ported

to various computer platforms such as

Macintosh, IRIX and DOS. New features have

been added based on feedback from academic

community and industry. The latest version is a

windows based LINCAGES 2000. This version

has a newly designed graphical user interface

(GUI) and an objectoriented synthesis engine. It

is developed using Visual C++ with MFC [16]

for Windows 9x, NT and 2000. Source code

control and bugs report systems with Perforce

[19] were used during the development.

Complete users help file and manual have been

added.

New features of LINCAGES-2000

3-point motion generator solution map

For four prescribed positions, the solution map

displays all the possible solutions in term of free

choices (e.g. dyads) as opposed to x-y

coordinates, as is done in the worksheet (the

main window which displays the current

linkage). Thus each axis of the map represents

one dyad of the four- bar. All possible four bar

mechanism that satisfy the design positions are

displayed by way of a color code according to

the type of four bar generated with those two

dyads. The Solution Map allows user to see all

the linkage solution possibilities at once, instead

of having to search for all of them in the

worksheet.

For a 3-point motion generator mechanism,

the number of free choices is increased and thus

the number of possible solutions is doubled. The

result is that given a prescribed dyad, there is

still a double infinity of solutions. These

solutions can be represented by a solution map.

The new version of LINCAGES 2000 displays

the map in the x; y worksheet coordinates.

To activate the solution map, one clicks the

solution map icon on the tool bar. User can drag

the ground pivot or moving pivot around. When

the left mouse button is pressed, LINCAGES

2000 will automatically generate a solution map

in the worksheet as background like figure 1. In

the figure, different regions with different colors

show the mechanism type when the dragged

pivot follow into them. User can use the analysis

tools at the same time to estimate the

performance of each design location

simultaneously.

Dynamic information display

When user moves mouse over objects such as

precision positions or linkage pivots, its

information is displayed at the bottom of the

window. The x; y coordinates of the mouse

cursor are also dynamically displayed.

Enhanced object operation

User can perform more operations on drawn

objects. One can copy and delete imported

Windows OLE objects. When zoom function is

used, drawn/imported objects also zoom with the

same ratio as linkage itself.

A case study of mechanism design

using LINCAGES 2000

Dr Michael McCarthy from University of

California, Irvine, proposed the following design

challenge for software vendors. Its a motion

generation problem with 11 prescribed precision

positions (figure2).

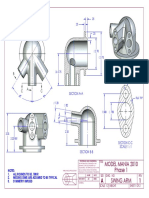

Figure 2: Design positions

Figure 1: 3pt motion solution map

Ability to change synthesis precision

Base on the problem being solved, different

design precision may be required. New release of

LINCAGES 2000 enables user to specify

synthesis precision by changing the number of

points Burmester curve solutions displays and

solution map resolution. This ability is especially

usefully when doing 4-point synthesis.

Our goal is to design a simple 4 bar linkage to

provide as close approximation to these positions

as possible. With LINCAGES 2000, we can

specify at most 4 precision positions, so we need

to select the four precision positions from the 11

prescribed positions. It is decided the first

position, the last position and the top most

position are the most important positions (in

yellow color in the design positions figure). The

4th precision positions will be chosen from the

remaining ones. To start the solution process,

one creates a new four-point motion design file,

imports the design position graph (in BMP

format), and adjusts the scale and location of the

coordinate system to match the imported graph.

Next, we drag the 4 precision position points

(little box with numbers) to the specific design

position and adjust the orientation of each

position (the straight line attached to each little

box). The solution map is opened by clicking

the solution map icon. After a short

investigation, the third position from the left is

chosen as another precision position because it

gives the solution map with the biggest solution

area. The cross-hair in solution map (figure 3) is

dragged while watching the change of

mechanism in the main worksheet. When the

solution is close to a local optimum (using

measures like pivot locations, mechanism type,

match of all non-specified positions), the pivots

on the input or output link are dragged in the

main window to fine-tune the path of tracer point

on the couple until it reaches a best solution

(figure 4).

Figure 5: position checking

Figure 6: position checking

Figure 3: Solution map

Linkage pivots location information is

available by clicking the linkage information

icon on the toolbar (figure 7). This linkage is a

crank-rocker mechanism. (Input link has full

rotation, which is desirable for using a motor as

driver)

Figure 4: Solution to design positions

Figure 7: Linkage information

We can now reshape the coupler to include

the moving object, and use animation to verify

each design position. The solution was generated

very quickly as a very good match for all the

design positions (figure 4, 5). Is this the best

design? Well, best depends on other

considerations that were not specified! This

design, however, very closely matches all 11

positions.

The transmission angle plot is shown in figure

8, which suggests a lower than desirable range

between about 10 to 70 degree of input rotation.

Figure 8: Transmission angle

It is found transmission angles fall under 20

degrees. This is usually not acceptable because

small transmission angle will affect the smooth

operation of the mechanism.

Angular velocity and acceleration are shown

in figure 9 and 10.

Figure 11: Alternative solution with better

transmission angle

The three-position motion generation option is

another design strategy available in the software.

Since the real goal is to match 11 positions, we

would tend to first use the four-position option as

was done above.

Figure 12 shows a solution that resulted in a

short design exercise with 3 prescribed positions.

The advantage here of many more available

solutions is over shadowed by the performance

of the mechanism being further away from

matching all 11 positions.

Figure 9: Angular velocity

Figure 12: 3-position motion generation

Figure 10: Angular acceleration

If we desire to have a design with better

transmission angles, we can have transmission

angle graph open, while synthesizing the

mechanism. One design with minimum

transmission angle greater than 20 degree is

shown in figure 11. The tracer point curve of this

design doesnt match all the design positions as

well as the other solution. It is found the design

positions on the left side causes the transmission

angle problem. As usual, there is some trade off

to make in satisfying multiple design constrains.

Figure 13 shows the solution map

superimposed on the 3 specified design

positions. This is a different solution than shown

in figure 12. For one fixed dyad position (upper

right), the map is generated for the other (input)

dyad. Notice that the ground pivot had been

placed in the green region, which guarantees a

crank-rocker solution.

Figure 13:Solution Map for 3-position option

Scope for Future Work

The current LINCAGES 2000 release saves

documents in a standard binary format for

Microsoft Foundation Classes documents.

Changing to STEP standard compatible format is

under consideration. This will enable

LINCAGES to exchange files with other CAD

software package like ADAMS. This will greatly

expand the use of LINCAGES 2000 in other

domains.

Kinetostatic and dynamic analysis may be also

the future feature of LINCAGES.

Conclusions

This paper introduced the latest development

of LINCAGES 2000 and some of its new

features. A case study of designing a motion

generation mechanism using LINCAGES 2000

is presented. Even though the four-position

option was preferred here, other problems may

be easier to solve in the three-position or sketch

option. The power of the software is proved by

its quick solution to synthesis problems and its

analysis functions. Once the precision positions

were imported into the software, the solution

shown in figure 4 took about 10 minutes.

Acknowledgement

We thank the Greenfield Coalition Project

Focus (National Science Foundation) and

University of Minnesota for their support in the

project. We would also give thanks to Troy

Giese, a graduate student in Department of

Mechanical Engineering in the University of

Minnesota, Minneapolis. Without his relentless

effort this would not have been achieved.

References

[1] Erdman, Arthur G., Sandor, George N.,

Mechanism Design: Analysis and Synthesis,

Volume 1, Prentice Hall, 1997.

[2] Sandor, George N., Erdman, Arthur G.,

Mechanism Design: Analysis and Synthesis,

Volume 2, Prentice Hall, 1984.

[3] Chase, Thomas R., Erdman, Arthur G., Riley,

Ronald D., Improved Center-point Curve

Generation Techniques for Four-Precision

Position Synthesis Using the Complex Number

Approach, Transaction of the ASME Journal of

Mechanisms, Transmissions, and Automation in

Design, 1984, pp 1-7.

[4] Erdman, Arthur G., Loerch, F. M., Sandor,

George N., On the Existense of Circle-Point and

Center-Point for Three Precision Point Dyad

Synthesis, ASME Journal of Mechanical Design,

Vol 101, No. 4, pp554-562, October 1979.

[5] Erdman, Arthur G., Three and Four

Precision Point Kinematic Synthesis of Planar

Linkages, Mechanism and Machine Theory, Vol.

16, pp227-245, 1981.

[6] Erdman, Arthur G., Gustafson, J.,

LINCAGES-A Linkage Interactive Computer

Analysis and Graphically Enhanced Synthesis

Package, ASME Paper No. 77-DTC-5, Chicago,

Illinois.

[7] Chidambaran, Narayanan C., Erdman, Arthur

G., LINCAGES 2000 Mechanism Design

Software, Sixth Applied Mechanisms and

Robotics Conference, Dec 1999, Cincinnati.

[8] Erdman, Arthur G., Riley, Donald R.,

Computer Aided Linkage Design Using the

LINCAGES Package, ASME paper No. 81DET-121, 1981.

[9] Hunt, L., Erdman, Arthur G., Riley, Donald

R., MicroLINCAGES: Microcomputer Synthesis

and Analysis of Planar Linkages, Processing of

the Seventh OSU Applied Mechanisms

Conference, Dec 1981.

[10] Harber, M., Erdman, Arthur G., Riley,

Donald R., LINCAGES Package Enhancements:

A New Method of Three Design Position

Synthesis, Proceedings of the Ninth Applied

Mechanisms Conference, Vol. 1, Paper II.A-VI,

Kansas City, Missouri, October 28-30, 1985.

[11] Kota, S., Peterson, R., Erdman, Arthur G.,

Riley, Donald R., LINCAGES, Four-Bar

Synthesis and Analysis Package, Update and

Additions, Proceedings of the Ninth Applied

Mechanisms Conference, Vol. 1, Paper III.A-III,

Kansas City, Missouri, October 28-30, 1985.

[12] Ho, C., Erdman, Arthur G., Riley, Donald

R., MINNSKETCH: A Graphic Kinematic and

Dynamic Analysis Tool for Planar Mechanism

Design, 1994 ASME Mechanisms Conference,

Minneapolis, MN, September 11-14, 1994. In

Proceedings of Machine Elements and Machine

Dynamics, ASME, DE-vol. 71, pp 401-412,

1994

[13] Cheng, P. M., Erdman, Arthur G., Rizq, R.,

k

M Circle-An Interactive Computer Graphics

Design Tool to Solve the Generalized Three

Position Synthesis Problem, 1994 ASME

Mechanisms Conference, Minneapolis, MN,

September 11-14, 1994. In Proceedings of

Mechanism Synthesis and Analysis, De-vol. 70,

pp273-280, 1994.

[14] AutoDesk Inc., http://www.autodesk.com/.

[15] Parametric Technology Corporation,

http://www.ptc.com/.

[16] Microsoft Inc., http://www.microsoft.com/.

[17]

Mechanical

Dynamics

Inc.,

http://www.adams.com/.

[18] Structural Dynamics Research Corporation,

http://www.sdrc.com/.

[19]

Perforce

Software,

Inc.,

http://www.perforce.com

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- PHYS132 Formula SheetDokument12 SeitenPHYS132 Formula SheetMuhammad IshtiaqNoch keine Bewertungen

- B 29 - 14Dokument4 SeitenB 29 - 14ruben carcamoNoch keine Bewertungen

- BS en Iso 8990 - 1996Dokument27 SeitenBS en Iso 8990 - 1996danielNoch keine Bewertungen

- Penetration TestDokument5 SeitenPenetration TestU Mad BRoNoch keine Bewertungen

- Biler 2006 PDFDokument68 SeitenBiler 2006 PDFProt0nNoch keine Bewertungen

- 2011 Fsae RulesDokument130 Seiten2011 Fsae RulesvinitkatiraNoch keine Bewertungen

- GoldpassDokument3 SeitenGoldpassProt0nNoch keine Bewertungen

- 36estimator LOCKEDDokument4 Seiten36estimator LOCKEDProt0nNoch keine Bewertungen

- 1 FSA+Dealer+Eng ItaDokument144 Seiten1 FSA+Dealer+Eng ItaProt0nNoch keine Bewertungen

- RTD Studies in PFRDokument13 SeitenRTD Studies in PFRSiddarthNoch keine Bewertungen

- Curved BeamDokument85 SeitenCurved Beamanon_651663167Noch keine Bewertungen

- Beams Free Transverse Vibrations of Nano-To-Micron Scale:, 2977-2995 2006 Mingtian XuDokument20 SeitenBeams Free Transverse Vibrations of Nano-To-Micron Scale:, 2977-2995 2006 Mingtian XuEric AmbroziniNoch keine Bewertungen

- Laws of Motion MCQs Sheet 1Dokument6 SeitenLaws of Motion MCQs Sheet 1eka123100% (1)

- Lock ShimDokument3 SeitenLock ShimJulie WeiNoch keine Bewertungen

- 3D ExerciseDokument1 Seite3D ExerciseRashiqah RazlanNoch keine Bewertungen

- Jurnal Peledakan TambangDokument8 SeitenJurnal Peledakan TambangSyafril MaidiNoch keine Bewertungen

- Fourth Quarter ExaminationDokument10 SeitenFourth Quarter ExaminationJay Ronnie PranadaNoch keine Bewertungen

- Π HistoryDokument5 SeitenΠ Historydbest12Noch keine Bewertungen

- Phase 1Dokument1 SeitePhase 1Gilberto Perez HernandezNoch keine Bewertungen

- June 2014 (R) QP - Unit 1 Edexcel Physics A-LevelDokument28 SeitenJune 2014 (R) QP - Unit 1 Edexcel Physics A-LevelArun MosesNoch keine Bewertungen

- Hw3 Chap4 SolutionDokument13 SeitenHw3 Chap4 Solutioncoasterfan13100% (1)

- Pumps and Hydraulic CheckDokument67 SeitenPumps and Hydraulic CheckNivas SadhasivamNoch keine Bewertungen

- Lecture 3 - Chapter 3 (Modeling in The Time Domain)Dokument57 SeitenLecture 3 - Chapter 3 (Modeling in The Time Domain)Jessiedee Mark GingoNoch keine Bewertungen

- Fountain: Date: 08-Apr-18Dokument20 SeitenFountain: Date: 08-Apr-18MikhaelA.RodriguezNoch keine Bewertungen

- Design of A Magnetic Levitation Control System PDFDokument5 SeitenDesign of A Magnetic Levitation Control System PDFEliel Marcos RomanciniNoch keine Bewertungen

- Marksheet PDFDokument1 SeiteMarksheet PDFDurjoy DasNoch keine Bewertungen

- Megger OTS100 AFDokument5 SeitenMegger OTS100 AFneerajaNoch keine Bewertungen

- Quantitative Application of UV-Visible SpectrosDokument7 SeitenQuantitative Application of UV-Visible SpectrosRoshan Mohammad100% (1)

- Experiment No 7-MQCDokument7 SeitenExperiment No 7-MQCArvind Bhosale100% (1)

- COMAC Method Damage DetectionDokument15 SeitenCOMAC Method Damage DetectionJuanNoch keine Bewertungen

- Makalah Perkerasan LanjutDokument22 SeitenMakalah Perkerasan LanjutHana M'wf CiieManroeNoch keine Bewertungen

- Axisymm TutorialDokument15 SeitenAxisymm Tutorialmudur6Noch keine Bewertungen

- BITSAT From Brilliant TutorialsDokument46 SeitenBITSAT From Brilliant TutorialsAbhay Kumar Nayak100% (1)

- Soil Structure and FabricDokument33 SeitenSoil Structure and FabricVigknaraja JagathesanNoch keine Bewertungen

- Tesla 09Dokument41 SeitenTesla 09William NormanNoch keine Bewertungen