Beruflich Dokumente

Kultur Dokumente

G3520 Lehe2832 02 PDF

Hochgeladen von

Costas AggelidisOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

G3520 Lehe2832 02 PDF

Hochgeladen von

Costas AggelidisCopyright:

Verfügbare Formate

GAS GENERATOR SET

Natural Gas

Continuous

2055 ekW 60 Hz 1800 rpm

480 Volts

Image shown may not reflect actual package

Caterpillar is leading the power generation

market place with power solutions engineered

to deliver unmatched performance, reliability,

durability and cost-effectiveness.

BENEFITS

EMISSIONS

Meets most worldwide emissions requirements down

to 0.5 g/bhp-hr Nox level without after-treatment.

FULL RANGE OF ATTACHMENTS

Wide range of bolt-on system expansion

attachments, factory designed and tested

PROVEN SYSTEM

Fully prototype tested

Field proven in a wide range of applications worldwide

Certified torsional vibration analysis available

WORLDWIDE PRODUCT SUPPORT

Caterpillar dealers have over 1,600 dealer branch

stores operating in 200 countries.

Comprehensive post-sales support including

maintenance and repair agreements that a re-tailored

to your specific equipment application.

High skilled technicians are trained to service every

aspect of your electric power generation system.

The Cat SOSsm Service monitors and tracks internal

engine component condition providing the capability to

maximize product performance and minimizing

owning and operating costs.

LEHE2832-02

CAT G3520C GAS ENGINE

Robust high speed block design provides

prolonged life and lower owning and

operating costs.

Designed for maximum performance on

low pressure pipeline natural gas

Simple open chamber combustion system

for reliability and fuel flexibility

Leading edge technology in ignition system

and air/fuel ratio control for lower emission

and engine efficiency.

One electronic control module handles all

engine functions: ignition, governing,

air/fuel ratio control and engine protection

CAT SR4B GENERATOR

Designed to match performance and

output characteristics of Caterpillar gas

engines

Industry leading mechanical and electrical

design

High efficiency

CAT EMCP II+CONTROL PANEL

Simple user friendly interface and navigation

Digital monitoring, metering and protection

settings

Fully-featured power metering and protective

relaying

UL 508A Listed

Remote control and monitor capability options

Continuous 2055 ekW 60 Hz 1800 RPM 480V

Factory Installed Standard & Optional Equipment

System

Standard

Gas Engine Control Fuel/air ratio control;

Module (GECM)

Start/stop logic: gas purge cycle, staged shutdown;

Optional

Engine Protection System: detonation sensitive timing,

high exhaust temperature shutdown;

Governor: Transient richening and turbo bypass control;

Ignition.

Air Inlet

Two element, single-stage air cleaner with enclosure and

Air cleaner with precleaner; Mounting stand

service indicator

Control Panel

EMCP II+

Local alarm module; Remote annuciator;

Communications Module (PL1000T, PL1000E)

Synchronizing module; Engine failure relay

Cooling

Exhaust

Engine driven water pumps for jacket water and aftercooler;

Remote radiator for JW and SCAC circuits,

Jacket water and SCAC thermostats;

level switch included but not wired,

ANSI/DN customer flange connections for JW inlet and outlet

coolant level drain line with valves, fan with guard;

Cat flanges on SCAC circuit

Inlet/Outlet connections.

Dry exhaust manifolds, insulated and shielded;

Flange; Exhaust expander; Elbow; Flexible fitting;

Center section cooled turbocharger with Cat flanged outlet;

Muffler and spark-arresting muffler with companion

Individual exhaust port and turbocharger outlet wired to

flanges.

Integrated Temperature Sensing Module (ITSM) with GECM

providing alarms and shutdowns.

Fuel

Electronic fuel metering valve;

Fuel filter;

Throttle plate, 24V DC actuator, controlled by GECM;

Gas pressure regulator;

Fuel system is sized for 31.5 to 47.2 MJ/NM3 (800 to 1200

Gas shutoff valve, 24V, ETR (Energized-To-Run)

Btu/cu ft) dry pipeline natural gas with pressure of 10.2 to 34.5

kPa (1.5 to 5 psi) to the engine fuel control valve.

Generator

SR4B generator, includes:

Medium and high voltage generators and attachments

Caterpillar's Digital Voltage Regulator (CDVR) with 3-phase

Low voltage extension box; Cable access box;

sensing and KVAR/PF control; Reactive droop;

Air filter for generator; Bearing temperature detectors;

Bus bar connections; Winding temperature detectors;

Manual voltage control; European bus bar.

Anti-condensation space heater.

Governing

Electronic speed governor as part of GECM;

Woodward load sharing module

Electronically-controlled 24V DC actuator connected to

throttle shaft.

Ignition

Electronic Ignition System controlled by GECM;

Individual cylinder Detonation Sensitive Timing (DST)

Lubrication

Lubricating oil; Gear type lube oil pump; Oil filter, filler and dipsticOil level regualtor; Prelube pump;

Mounting

330 mm structural steel base (for low and medium voltage units);

Integral lube oil cooler; Oil drain valve; Crankcase breather.

Positive crankcase ventilation system

Spring-type anti-vibration mounts (shipped loose)

Starting / Charging 24V starting motors; Battery with cables and rack (shipped looseCharging alternator; Battery charger;

Battery disconnect switch;

Oversized battery; Lacket water heater;

60A, 24V charging alternator (standard on 60Hz 1800rpm only)

General

LEHE2832-02

Paint -- Caterpillar Yellow except rails & radiators;

Crankcase explosion relief valve;

Damper guard.

Engine barring group;

Operation and Maintenance Manuals; Parts Book.

EEC D.O.I and other certifications

Continuous 2055 ekW 60 Hz 1800 RPM 480V

SPECIFICATIONS

CAT GAS ENGINE

CAT EMCPII+ CONTROL PANAL

G3520C SCAC 4-stroke-cycle watercooled gas engine

* Power by 24 volts DC

Number of Cylinders ------------------------------------------V20

* NEMA 12, IP44 dust-proof enclosure

Bore --- mm (in) ------------------------------------------------170 (6.7)

* Lockable hinged door

Stroke --- mm (in) ----------------------------------------------190 (7.5)

* Single-location customer connection

Displacement --- L (cu in) -----------------------------------86.3 (5266)

* Auto start/stop control switch

Compression Ratio -------------------------------------------11.3:1

* Voltage adjustment potentiomenter

Aspiration -------------------- Turbocharged Separate Circuit Aftercooled

* True RMS AC metering, 3 phase

Cooling Type ---- Two stage aftercooler, JW + O/C + A/C 1 combined

* Pruge cycle and staged shutdown logic

Fuel System ------------------------------------------------------ Low Pressure

* Digital indication for:

Governor Type ------------------------------------------ Electronic (ADEM * III)

RPM

Operating hours

CAT SR4B GENERATOR

Oil pressure

Frame size -------------------------------------------------------827

Coolant temperature

Excitation ------------------------------------------------------ Permanent Magnet

DC voltage

Pitch ---------------------------------------------------------------0.667

L-L volts, L-N volts, phase amps, Hz,

Number of poles -----------------------------------------------4

ekW, kVA, kVAR, kWhr, %kW, pf

Number of bearings ------------------------------------------2

System diagnostic codes

Number of leads -----------------------------------------------6

* Shutdown with indicating lights;

Insulation --------------------------------------------------------Class H

Low oil pressure

IP rating ------------------------------------------------------------ Drip proof IP22

High coolant temperature

Alignment --------------------------------------------------------Pilot shaft

High oil temperature

Overspeed capability -- % of rated ------------------------125%

Overspeed

Waveform deviation line to line, no load ------------------ less than 2.0%

Overcrank

Paralleling kit droop transformer --------------------------Standard

Emergency stop

Voltage regulator -----------------------------------------------CDVR

High inlet air temperature (for TA engine only)

Voltage regulation ---------------------------------------------+/- 0.5%

Detonation sensitive timing (for LE engine only)

Telephone Influence Factor (TIF) --------------------------- less than 50

* Programmable protective relaying functions:

Total Harmonic Distortion (THD) --------------------------- less than 3.0%

Under / Over voltage

Under / Over frequency

Consult your Caterpillar dealer for available voltage

Overcurrent

Reverse power

* Spare indicator LEDs

* Spare alarm/shutdown inputs

Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

LEHE2832-02

Continuous 2055 ekW 60 Hz 1800 RPM 480V

TECHNICAL DATA

G3520C Gas Generator Set

Emission level (NOx)

Aftercooler SCAC (Stage 2)

Package Performance (1)

Power Rating @ 0.8 pf (w/ 2 water pumps and w/o fan)

Power Rating @ 0.8 pf (w/ 2 water pumps and w/o fan)

Power Rating @ 1.0 pf (w/ 2 water pumps and w/o fan)

Electric Efficiency @ 1.0 pf (ISO 3046/1) (2)

Mechanical Power (w/ 2 water pumps and w/o fan)

Fuel Consumption (3)

100% load w/o fan

75% load w/o fan

50% load w/o fan

Altitude Capability (4)

At 25 Deg C (77 Deg F) ambient, above sea level

Cooling System

Ambient air temperature

Jacket water temperature ( Maximum outlet )

Exhaust System

Combustion air inlet flow rate

Exhaust stack gas temperature

Exhaust gas flow rate

Exhaust flange size ( internal diameter )

Heat Rejection (5)

Heat rejection to jacket water and oil cooler and AC - Stage

Heat rejection to AC - Stage 2

Heat rejection to exhaust (LHV to 350 Deg F)

Heat rejection to exhaust (LHV to 120 Deg C)

Heat rejection to atmosphere from engine

Heat rejection to atmosphere from generator

Generator

Frame

Temperature rise

Motor starting capability @ 30% voltage dip (6)

Lubrication System

Standard sump refill with filter change

Emissions (7)

NOx @ 5% O2 (dry)

CO @ 5% O2 (dry)

THC @ 5% O2 (dry)

NMHC @ 5% O2 (dry)

Exhaust O2 (dry)

LEHE2832-02

DM 3194

mg/N.M3

Deg C

g/bhp-hr

Deg F

446

54

DM 3195

1.0

130

ekW Continuous

kVA Continuous

ekW Continuous

%

bkW

bhp

2154

NM3/hr

NM3/hr

NM3/hr

553

432

303

20 619

16 079

11 276

976

3200

scf/hr

scf/hr

scf/hr

ft

Deg C

Deg C

NM3/min

Deg C

NM3/min

mm

kW

kW

kW

kW

kW

kW

221

54

2055

2569

2100

38.4

0.5

130

2055

2569

2100

37.4

2889

2154

2889

567

443

310

21 146

16 495

11 571

976

3200

Deg F

Deg F

25

90

77

194

25

90

SCFM

Deg F

CFM

in

158

487

168

360

6097

909

16 714

14

167

478

176

360

6410

893

17 348

14

1187

144

1230

1455

154

69

67 467

8167

69 984

82 818

8763

3924

1239

161

1250

1487

154

69

70 479

9150

71 169

84 640

8763

3924

Btu/min

Btu/min

Btu/min

Btu/min

Btu/min

Btu/min

77

194

827

Deg C

Deg F

105

skVA

L

mg/N.M3

mg/N.M3

mg/N.M3

mg/N.M3

221

105

5226

221

5226

gal

541

143

541

143

g/bhp-hr

g/bhp-hr

g/bhp-hr

g/bhp-hr

446

1051

1789

269

1

2.36

4.01

0.61

221

946

2137

321

0.5

2.14

4.83

0.73

1.77

9.9

Continuous 2055 ekW 60 Hz 1800 RPM 480V

DEFINITIONS AND CONDITIONS

(1) Continuous --- Maximum output available for an unlimited time

Ratings are based on pipeline natural gas having a Low Heat Value

(LHV) of 35.6 MJ/NM3 (905 Btu/ft3) and 80 Caterpillar Methane Number.

For values in excess of altitude, ambient temperature, inlet/exhaust restriction,

or different from the conditions listed, contact your local Caterpillar dealer.

(2) Efficiency of standard generator is used. For higher efficiency generators, contact

your local Caterpillar dealer.

(3) Ratings and fuel consumption are based on ISO3046/1 standard reference conditions of

25 deg C (77 deg F) of ambient temperature and 100 kPa (29.61 in Hg) of total barometic

pressure, 30% relative humidity with 0, +5% fuel tolerance.

(4) Altitude capability is based on 2.5 kPa air filter and 5.0 kPa exhaust stack restrictions.

(5) Heat Rejection --- Values based on nominal data with fuel tolerence of +/-2.5% and

2.5 kPa inlet and 5.0 kPa exhaust restrictions.

(6) Assume synchronous driver

(7) Emissions data measurements are consistent with those described in EPA CFR

40 Part 89 Subpart D & E and ISO8178-1 for measuring HC, CO, PM, NOx. Data shown

is based on steady state engine operating conditions of 25 deg C (77 deg F), 96.28 kPa

(28.43 in Hg) and fuel having a LHV of 35.6 MJ/NM3 (905 Btu/cu ft) and 80 Caterpillar

Methane Number at 101.60 kPa (30.00 in Hg) absolute and 0 deg C (32 deg F).

Emission darta shown is subject to instrumentation, measurement, facility, and engine

fuel system adjustment.

LEHE2832-02

Continuous 2055 ekW 60 Hz 1800 RPM 480V

DIMENSIONS

Package Dimensions

Length

6367.1 mm

Width

1996.5

250.67 in

78.6

Height

2340.4 mm

92.14 in

Shipping Weight

18 350 kg

40 437 lb

Note: Do not use for installation design.

See general dimension drawings

for detail ( Drawing # 234-1955 ).

Performance Number: DM3194, DM3195

Feature Code: 520GE10

Generator Arrangement: 144-1828

Information contained in this publication may be considered confidential. Discretion is recommended when distributing.

Materials and specifications are subject to change without notice. CAT, CATERPILLAR, their respective logos,

Caterpillar Yellow and the POWER EDGE trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

http://www.cat-electricpower.com/

U.S. Sourced

LEHE2832-02 (09/08)

LEHE2832-02

2008 Caterpillar

All Rights Reserved.

Printed in U.S.A.

Das könnte Ihnen auch gefallen

- Operation Maintenance G-3500 3rcDokument116 SeitenOperation Maintenance G-3500 3rcJorge Enrique Fuentes MarinNoch keine Bewertungen

- 1.3.1. LEHE1448-02r - G3512HDokument7 Seiten1.3.1. LEHE1448-02r - G3512HJuan Valdivieso100% (2)

- G3520C Series Gas EngineDokument47 SeitenG3520C Series Gas Engineammargakhar100% (2)

- Caterpillar XQ80 Towable Diesel Generator SetDokument5 SeitenCaterpillar XQ80 Towable Diesel Generator SetMacAllister MachineryNoch keine Bewertungen

- REHS1438-09 Installation and Initial Start-Up Procedure For G3500C and G3500E Generator Set Engines PDFDokument52 SeitenREHS1438-09 Installation and Initial Start-Up Procedure For G3500C and G3500E Generator Set Engines PDFvoivod667% (3)

- Generator Output Power SensorDokument11 SeitenGenerator Output Power SensorHugo CiprianiNoch keine Bewertungen

- CAT - 3516H Diagnostic CapabilitiesDokument2 SeitenCAT - 3516H Diagnostic Capabilitieswagner_guimarães_1100% (1)

- Varistor - Test (GZP)Dokument3 SeitenVaristor - Test (GZP)Hugo CiprianiNoch keine Bewertungen

- CAT - G3516H Configuration Parameters - 3516HDokument1 SeiteCAT - G3516H Configuration Parameters - 3516Hwagner_guimarães_1Noch keine Bewertungen

- Power System - Fast Training ProgramDokument44 SeitenPower System - Fast Training ProgramMohammed Elbadri100% (1)

- Datasheet G3516 1200 RPMDokument4 SeitenDatasheet G3516 1200 RPMVerita SanjuánNoch keine Bewertungen

- CAT - 3516H Engine OverspeedsDokument3 SeitenCAT - 3516H Engine Overspeedswagner_guimarães_1Noch keine Bewertungen

- EMCP IVR ConnectionDokument4 SeitenEMCP IVR ConnectionHachimou Rohingya RoufaiNoch keine Bewertungen

- Gen Control Paralleling SystemDokument4 SeitenGen Control Paralleling SystemSunny KumarNoch keine Bewertungen

- 9 - Gas A&I G3500-G3300 Ignition, Starting and Engine Protection SystemsDokument37 Seiten9 - Gas A&I G3500-G3300 Ignition, Starting and Engine Protection Systemsosama100% (2)

- Cat G3520C Engine Coal Mine GasDokument6 SeitenCat G3520C Engine Coal Mine GasJSH100Noch keine Bewertungen

- Installation of The Generator and Control Panel Components For Dynamic Gas BlendingDokument49 SeitenInstallation of The Generator and Control Panel Components For Dynamic Gas Blendingالمهندسوليدالطويل100% (1)

- CDVR General InformationDokument6 SeitenCDVR General InformationTTIBCCANoch keine Bewertungen

- 3500B and 3500B High Displacement Generator Sets Electrical SystemDokument2 Seiten3500B and 3500B High Displacement Generator Sets Electrical SystemAliHabesNoch keine Bewertungen

- G3520 SLD PDFDokument43 SeitenG3520 SLD PDFdanielh776100% (4)

- DYN110754 Technical Bulletin PDFDokument6 SeitenDYN110754 Technical Bulletin PDFMaksim PanfilovNoch keine Bewertungen

- Waukesha Gas Engines: WarningDokument3 SeitenWaukesha Gas Engines: WarningdfmolinaNoch keine Bewertungen

- Avr MX321Dokument3 SeitenAvr MX321Ahmad ArpaniNoch keine Bewertungen

- Ajax Igtb Electronic GovernorDokument2 SeitenAjax Igtb Electronic GovernorAnonymous CD0suI9Noch keine Bewertungen

- Cat 3520 Gas EngineDokument3 SeitenCat 3520 Gas EngineJafarShojaNoch keine Bewertungen

- Emcp II For MuiDokument208 SeitenEmcp II For MuiDiego Morales100% (1)

- 3412 - 810kVA PrimeDokument6 Seiten3412 - 810kVA PrimeCharl PietersenNoch keine Bewertungen

- Cat Electronic Technician 2019A v1.0 Configuration: Parameter ValueDokument3 SeitenCat Electronic Technician 2019A v1.0 Configuration: Parameter ValueMohamed Mohamed100% (1)

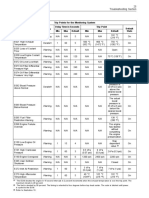

- Troubleshooting G3516 Fuel MeteringDokument16 SeitenTroubleshooting G3516 Fuel Meteringwagner_guimarães_1100% (3)

- Fuel Rate Scaling (Fuel Correction Factor) - Diesel FuelDokument1 SeiteFuel Rate Scaling (Fuel Correction Factor) - Diesel Fuelvictor.ciprianiNoch keine Bewertungen

- 500 - SET19294-03-Generator Technical SpecificationDokument20 Seiten500 - SET19294-03-Generator Technical SpecificationAndres DNoch keine Bewertungen

- P-530 G3516BDokument5 SeitenP-530 G3516Bmuhammad arifNoch keine Bewertungen

- Exciter Field - Cat GeneratorDokument5 SeitenExciter Field - Cat Generatorwagner_guimarães_10% (1)

- AVR 380 ManualDokument14 SeitenAVR 380 Manualkazishah100% (1)

- CAT 3516 B and 3516 B High Displacement EnginesDokument1 SeiteCAT 3516 B and 3516 B High Displacement EnginesHemant RasamNoch keine Bewertungen

- Cat 3516Dokument4 SeitenCat 3516Muhammad IshfaqNoch keine Bewertungen

- Caterpillar - 3412 - 750kVADokument2 SeitenCaterpillar - 3412 - 750kVAPrashant NaikNoch keine Bewertungen

- CAT - G3516H System Overview PDFDokument3 SeitenCAT - G3516H System Overview PDFwagner_guimarães_1100% (1)

- CAT - G3516H Exhaust Temperature - Test PDFDokument14 SeitenCAT - G3516H Exhaust Temperature - Test PDFwagner_guimarães_1Noch keine Bewertungen

- Alteradores MarathonDokument8 SeitenAlteradores MarathonSalineñoApasionadoNoch keine Bewertungen

- 16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Dokument16 Seiten16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Ahmed Said GhonimyNoch keine Bewertungen

- g3520c Spec Sheet (Lehe2834)Dokument4 Seiteng3520c Spec Sheet (Lehe2834)Qamar Akhtar100% (3)

- Datasheet QSX15G9Dokument3 SeitenDatasheet QSX15G9walsystem22100% (2)

- SR5 Generators For C175-16Dokument14 SeitenSR5 Generators For C175-16Mounir SerguineNoch keine Bewertungen

- MK V Simplex Architecture: RS232 To Plant Ethernet To Plant RS232 To PlantDokument20 SeitenMK V Simplex Architecture: RS232 To Plant Ethernet To Plant RS232 To PlantHeryanto SyamNoch keine Bewertungen

- Cat 3516B-2250 enDokument1 SeiteCat 3516B-2250 enMohammed JassimNoch keine Bewertungen

- Low PowerPoor or No Response To ThrottleDokument5 SeitenLow PowerPoor or No Response To ThrottleAxel G.FloresNoch keine Bewertungen

- 1221 - 1010KVA DG Set SpecificationDokument36 Seiten1221 - 1010KVA DG Set SpecificationKhiem Le100% (1)

- Fuel SystemDokument1 SeiteFuel SystemJamil Ahmed100% (1)

- JMS 612 GS-N.L: Jenbacher Gas EnginesDokument4 SeitenJMS 612 GS-N.L: Jenbacher Gas EngineshadNoch keine Bewertungen

- Dief ControllerDokument1 SeiteDief ControllerMohammad HazbehzadNoch keine Bewertungen

- Manual Partes PCC 3201 VATIOTROMDokument60 SeitenManual Partes PCC 3201 VATIOTROMEdgarNoch keine Bewertungen

- DVR WiringDokument12 SeitenDVR WiringHalit YalçınkayaNoch keine Bewertungen

- g3520c Im Natural Gas For 1966Dokument6 Seiteng3520c Im Natural Gas For 1966Pankaj KambleNoch keine Bewertungen

- Gas EngineDokument6 SeitenGas EngineMRizwanSadiq313Noch keine Bewertungen

- G3508 - 600kvaDokument7 SeitenG3508 - 600kvaJim Patrick ChombaNoch keine Bewertungen

- Genset - 2MVA-5Dokument6 SeitenGenset - 2MVA-5Shawn ZadehNoch keine Bewertungen

- Genset - 2MVA-2Dokument6 SeitenGenset - 2MVA-2Shawn ZadehNoch keine Bewertungen

- Catalogo Generador Cat 3512Dokument6 SeitenCatalogo Generador Cat 3512pamg50% (1)

- G3516 (975 Ekw 1218 kVA)Dokument7 SeitenG3516 (975 Ekw 1218 kVA)Antwon CharlesNoch keine Bewertungen

- XERVON Up2date 01 2014 ENG FinalDokument32 SeitenXERVON Up2date 01 2014 ENG FinalCostas AggelidisNoch keine Bewertungen

- Asset Integrity Management Petroleum Industry: For TheDokument4 SeitenAsset Integrity Management Petroleum Industry: For TheCostas AggelidisNoch keine Bewertungen

- 9 PIM Forum: 15 - 17 March 2016, Berlin, GermanyDokument6 Seiten9 PIM Forum: 15 - 17 March 2016, Berlin, GermanyCostas AggelidisNoch keine Bewertungen

- Inspection of Subsea Pipelines and Offshore Tubular StructuresDokument6 SeitenInspection of Subsea Pipelines and Offshore Tubular StructuresCostas AggelidisNoch keine Bewertungen

- Za ZN LL3 IGn CL Cy 6 W JT 7 H WW RG Hgy K882 QL SLX0 C CEDokument20 SeitenZa ZN LL3 IGn CL Cy 6 W JT 7 H WW RG Hgy K882 QL SLX0 C CECostas AggelidisNoch keine Bewertungen

- Xervon: Your Experts For Specialty Surface CoatingsDokument5 SeitenXervon: Your Experts For Specialty Surface CoatingsCostas AggelidisNoch keine Bewertungen

- Hazop Training GuideDokument9 SeitenHazop Training GuideAdyBorsosNoch keine Bewertungen

- FLAME 2013 Brochure UpdatedDokument12 SeitenFLAME 2013 Brochure UpdatedCostas AggelidisNoch keine Bewertungen

- Workshop: Application of Fit-for-Purpose Smart Technology To Improve Mature Assets WorkshopDokument5 SeitenWorkshop: Application of Fit-for-Purpose Smart Technology To Improve Mature Assets WorkshopCostas AggelidisNoch keine Bewertungen

- Oral Program Final PDFDokument7 SeitenOral Program Final PDFCostas AggelidisNoch keine Bewertungen

- Conference Details Athens 010816Dokument14 SeitenConference Details Athens 010816Costas AggelidisNoch keine Bewertungen

- ICR DailySchedule 08122020Dokument4 SeitenICR DailySchedule 08122020Costas AggelidisNoch keine Bewertungen

- The Society of Rheology: 91 Annual Meeting Program and AbstractsDokument170 SeitenThe Society of Rheology: 91 Annual Meeting Program and AbstractsCostas AggelidisNoch keine Bewertungen

- Scientific Program HSR 2019Dokument5 SeitenScientific Program HSR 2019Costas AggelidisNoch keine Bewertungen

- Maini 06 Phil Trans Modeling PhysiologyDokument8 SeitenMaini 06 Phil Trans Modeling PhysiologyCostas AggelidisNoch keine Bewertungen

- ProgramOverview ICR2020-01122020Dokument1 SeiteProgramOverview ICR2020-01122020Costas AggelidisNoch keine Bewertungen

- Raleigh Convention Center, Raleigh, North Carolina: The Society of Rheology 91 Annual MeetingDokument12 SeitenRaleigh Convention Center, Raleigh, North Carolina: The Society of Rheology 91 Annual MeetingCostas AggelidisNoch keine Bewertungen

- Symposium Programme: 14th Fundamental Research Symposium St. Anne's College, Oxford 13-18 September 2009Dokument3 SeitenSymposium Programme: 14th Fundamental Research Symposium St. Anne's College, Oxford 13-18 September 2009Costas AggelidisNoch keine Bewertungen

- Civic Architecture For The Athens 2004 Olympic Games: Miltos KatsarosDokument1 SeiteCivic Architecture For The Athens 2004 Olympic Games: Miltos KatsarosCostas AggelidisNoch keine Bewertungen

- SoR Abst 19aDokument170 SeitenSoR Abst 19aCostas AggelidisNoch keine Bewertungen

- Properties of Carbopol Solutions As Models For Yield-Stress FluidsDokument5 SeitenProperties of Carbopol Solutions As Models For Yield-Stress FluidsCostas AggelidisNoch keine Bewertungen

- Steen 09 Pnas Capillary Based Switchable AdhesionDokument5 SeitenSteen 09 Pnas Capillary Based Switchable AdhesionCostas AggelidisNoch keine Bewertungen

- Oppong 06 Pre Microrheology Ys GelDokument9 SeitenOppong 06 Pre Microrheology Ys GelCostas AggelidisNoch keine Bewertungen

- Steen 09 Pnas Capillary Based Switchable AdhesionDokument5 SeitenSteen 09 Pnas Capillary Based Switchable AdhesionCostas AggelidisNoch keine Bewertungen

- Say That A Single Tone Played On The Organ or Harpsichord Sounds PassionateDokument9 SeitenSay That A Single Tone Played On The Organ or Harpsichord Sounds PassionateVaizal AndriansNoch keine Bewertungen

- A Quantitative Approach To Evolution of Music and PhilosophyDokument22 SeitenA Quantitative Approach To Evolution of Music and PhilosophyCostas AggelidisNoch keine Bewertungen

- Fauré and French Musical Aesthetics: Carlo CaballeroDokument23 SeitenFauré and French Musical Aesthetics: Carlo CaballeroCostas AggelidisNoch keine Bewertungen

- BIGAND Et Al (2005) Multidimensional Scaling of Emotional Responses To Music - The Effect of Musical Expertise and of The Duration of The ExcerptsDokument27 SeitenBIGAND Et Al (2005) Multidimensional Scaling of Emotional Responses To Music - The Effect of Musical Expertise and of The Duration of The Excerptsarnould massartNoch keine Bewertungen

- Fauré and French Musical Aesthetics: Carlo CaballeroDokument23 SeitenFauré and French Musical Aesthetics: Carlo CaballeroCostas AggelidisNoch keine Bewertungen

- Wells Integrity Management Training Course PDFDokument4 SeitenWells Integrity Management Training Course PDFCostas AggelidisNoch keine Bewertungen

- Jathroper Charcoal As Alternative Heat Source. Clyde2Dokument29 SeitenJathroper Charcoal As Alternative Heat Source. Clyde2Charles Jebb Belonio JuanitasNoch keine Bewertungen

- Nanotechnology Applications in Automobiles ComprehensivereviewofexistingdataDokument6 SeitenNanotechnology Applications in Automobiles ComprehensivereviewofexistingdataMadhav ManmayNoch keine Bewertungen

- June 2018 QP - Paper 1 OCR (A) Chemistry AS-LevelDokument24 SeitenJune 2018 QP - Paper 1 OCR (A) Chemistry AS-LevelRunNoch keine Bewertungen

- Chemistry Notes VtuDokument160 SeitenChemistry Notes VtuNarayan S. Burbure67% (3)

- Pyramid Magazine 3/34Dokument36 SeitenPyramid Magazine 3/34John Daker100% (2)

- Forced Draft Combustion Vs Natural Draft Combustion: December 2017Dokument10 SeitenForced Draft Combustion Vs Natural Draft Combustion: December 2017Suyash KumarNoch keine Bewertungen

- MSDS Jeelate Sles-60Dokument6 SeitenMSDS Jeelate Sles-60Carmel PahugotNoch keine Bewertungen

- DRRR g1 PDFDokument39 SeitenDRRR g1 PDFxyreneNoch keine Bewertungen

- Group 1Dokument16 SeitenGroup 1Abdul QayyumNoch keine Bewertungen

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDokument20 SeitenUniversity of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456Noch keine Bewertungen

- Aiaa 45148 268Dokument6 SeitenAiaa 45148 268Kiran ManoharanNoch keine Bewertungen

- Combustion ChambersDokument81 SeitenCombustion ChambersRavikumar Ningachar0% (1)

- Predicting CO and NOx Emissions From Gas Turbines - Novel Data and A Benchmark PEMS (#662444) - 894203 PDFDokument14 SeitenPredicting CO and NOx Emissions From Gas Turbines - Novel Data and A Benchmark PEMS (#662444) - 894203 PDFAlya Khairunnisa RizkitaNoch keine Bewertungen

- And Their Application Areas: SensorsDokument31 SeitenAnd Their Application Areas: SensorsKapil VenkatNoch keine Bewertungen

- Emission Control On IC EngineDokument18 SeitenEmission Control On IC Enginetarunskumar89% (19)

- Harley Davidson MaintenanceDokument52 SeitenHarley Davidson MaintenanceUrsbaumT100% (6)

- Taller CombustionDokument1 SeiteTaller CombustionAlexanderCáceresCalderón100% (1)

- HINO Riel Comun J08C-J05C (Ingles)Dokument29 SeitenHINO Riel Comun J08C-J05C (Ingles)Carlos Pabon Salom100% (1)

- A Summary of Six Case StudiesDokument12 SeitenA Summary of Six Case StudiesKaliyaperumal KalamegamNoch keine Bewertungen

- Chem e CarDokument4 SeitenChem e CarJOSHIRA LAURA DIAZNoch keine Bewertungen

- Safety: Hazards of Air and OxygenDokument68 SeitenSafety: Hazards of Air and OxygenTomasz31-5Noch keine Bewertungen

- CDU 03 CO ControlDokument19 SeitenCDU 03 CO Controlrvkumar61Noch keine Bewertungen

- Capstone - Chapter 1 + Chapter 2Dokument99 SeitenCapstone - Chapter 1 + Chapter 2Surthi BathumalaiNoch keine Bewertungen

- Air Around UsDokument2 SeitenAir Around UsAnonymous 8VJhV1eI2yNoch keine Bewertungen

- Safety Measures in Pharmaceutical IndustriesDokument31 SeitenSafety Measures in Pharmaceutical Industriesabdullah18oowNoch keine Bewertungen

- Sheet 04 - ICE CombustionDokument3 SeitenSheet 04 - ICE CombustionMahmoud El-halwagyNoch keine Bewertungen

- ESM PresentationDokument30 SeitenESM Presentationnicol_sgNoch keine Bewertungen

- Energy Audit Case Study PDFDokument34 SeitenEnergy Audit Case Study PDFRakesh SharmaNoch keine Bewertungen

- Safety Standard For Vehicle Mounted Forklift Trucks: ANSI/ITSDF B56.14-2015Dokument44 SeitenSafety Standard For Vehicle Mounted Forklift Trucks: ANSI/ITSDF B56.14-2015alexdaniel26Noch keine Bewertungen

- City of Portland Complaint FinalDokument39 SeitenCity of Portland Complaint FinalNEWS CENTER MaineNoch keine Bewertungen