Beruflich Dokumente

Kultur Dokumente

An1513 Application Note: Vipower: 30 W Smps Using Viper50A-E

Hochgeladen von

bookreader1968Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

An1513 Application Note: Vipower: 30 W Smps Using Viper50A-E

Hochgeladen von

bookreader1968Copyright:

Verfügbare Formate

AN1513

Application note

VIPower: 30 W SMPS using VIPer50A-E

Introduction

In a growing consumer market, cost effective solutions with good performances and

reliability able to meet energy saving international or local standards (Blue Angel) are

needed.

STMicroelectronics has, among its wide products portfolio, the VIPer product family offering

excellent solutions with all features to design SMPS suitable for consumer applications.

Thanks to the VIPower Technology, these devices combine on the same silicon chip a stateof-the-art PWM control circuit along with an optimized high voltage avalanche rugged

Vertical Power MOSFET.

The benefits obtained using these devices are:

Fewer components compared to a discrete solution

Less space on PCB

Simpler design phase

Automatic burst mode operation in standby for energy savings

Cost effective solution for SMPS

This document describes the results obtained from an off-line SMPS designed with

VIPer50A-E. It has been designed for European mains, providing 30 W on two outputs.

The main target of this application is total power consumption less than 1 W (Blue Angel

Norm) in standby mode delivering an output power of 400 mW.

September 2007

Rev 2

1/13

www.st.com

Contents

AN1513

Contents

1

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Full load test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Load step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Short circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Thermal test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2/13

AN1513

List of tables

List of tables

Table 1.

Table 2.

Table 3.

Table 4.

Table 5.

Table 6.

Table 7.

Table 8.

Electrical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Standby measurements at 65 mA on output 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Standby measurements at 65 mA on output 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Full load measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overvoltage measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Thermal measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Transformer specification and construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3/13

List of figures

AN1513

List of figures

Figure 1.

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Figure 6.

Figure 7.

Figure 8.

Figure 9.

4/13

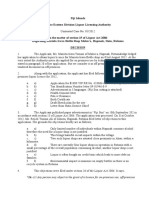

Electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Adjustment for frequency reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drain current at full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Voltage current at full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Load transient (Vout1, Vout2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Load transient (Vcomp, VDD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Short circuit (Vout1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Short circuit (Vout2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Transformer cross section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

AN1513

Schematic

Schematic

The power supply topology is a discontinuous current mode flyback converter, designed with

secondary feedback, optocoupler and TL431C. The output voltage regulation is performed

on the 6.5 V, so the output voltage 10 V can change according to the load applied on both

outputs.

To keep the drain voltage at a safe level and to meet the standby power specification, the

clamper used is a Transil 1.5KE220A instead of a classic R-C-D circuit. While the R-C-D

circuit dissipates energy in any load condition, the Transil dissipates energy only when the

drain voltage spike reaches its breakdown voltage. This consideration is important in order

to keep low consumption (<1 W) during standby operation mode.

A Zener diode is also connected to pin Comp for short circuit protection. This diode clamps

the voltage on pin Comp under the maximum value (4.5 V), reducing the maximum power

delivered by the SMPS.

During short circuit due to the short working time, the VDD voltage drops below the

undervoltage lockout threshold and the VIPer starts working in hiccup mode. Even if the

peak output current is higher than the nominal one, thanks to the on/off cycles, the average

current flowing in the shorted output components is kept under control at a safe value

avoiding diodes failure and any other damage to the circuit.

The output rectifiers are Schottky diodes for better efficiency thanks to their lower forward

voltage drop and negligible switching losses.

The output capacitors are low ESR type to minimize the output ripple and to manage the

RMS output ripple current.

Table 1.

Electrical specifications

Parameter

Value

Input voltage

European standard 230Vac15%

Output voltage 1

6,5 V3% at 2.5 A

Output voltage 2

10 V8% at 1.5 A

Standby consumption

<1 W

Efficiency

>80%

Max working ambient temperature

60C

5/13

Standby

AN1513

Standby

The first test performed is the measure of the power consumption during standby operation

mode as the main target of this application is consumption lower than 1 W. For better

accuracy, because the power level is very low, the power supply has been tested with a dc

voltage source.

Table 2.

Standby measurements at 65 mA on output 1

Vin

Iin

Vout1 at 65 mA

Vout2 at 0 mA

Pout

Pin

Efficiency

Switching

frequency

Vdc

mA

Vdc

Vdc

KHz

276

3.33

6.51

16.6

0.42

0.92

46

BURST

325

3.02

6.51

17.5

0.42

0.98

43

BURST

374

2.67

6.51

18.2

0.42

1.0

42

BURST

R6

6K8 1%

22K

10

R3

470R

IC3

TL431C

C15

R4

1K0

150nF

R5

C11

C12

2200uF-16V YXF 2200uF-16V YXF

STPS745F

D6

C6

2n2-Y2

6

C4

1nF

SOURCE

C14

22nF

COMP

DRAIN

D7

2.2nF

C13

22nF

C9

R1

15K

MOLEX

230Vac15%

C1

100nF

F1

FUSE 2A - 5*20

JP1

BZX79-4V3

VDD

OSC

R2

18R

VIPer50A-E

100nF

IC1

3

3

C2

IC2

TCDT1102G

MOUNTED ON HEAT SINK

100uF-50V YXF

C10

1N4148

2,2uH

D4

STTA106

D5

L2

47uF-400V

C5

D1

DF06M

4

L1

B82732- 27mH

4

1

D2

1.5KE220A

C3

1nF

6/13

R7

4K22 1%

RTN

+6.5V

11-12

STPS8H100CF

T1

010150W-C MAGNETICA

MOUNTED ON HEAT SINK

C7

C8

1000uF-25V YXF 1000uF-25V YXF

13-14

D3

MOUNTED ON HEAT SINK

RTN

+10V

Electrical schematic

Figure 1.

AN1513

Standby

The VIPer50A-E is designed to work in burst mode automatically when the power delivered

to the load becomes very low. The burst frequency and its duty-cycle depend on the

transformer parameters and the power delivered. The burst mode takes place when the

power transferred during the minimum on time is greater than the power required by the

load. This should increase the output voltage, but instead the control loop reacts by missing

some cycles. It is important to point out that during this working mode, the output voltage is

always perfectly under control. The result is a working mode where the effective duty-cycle

is much lower than the minimum under normal operation.

To further decrease the consumption during standby operation an additional test has been

done. Of course the burst mode has efficiency proportional to its working duty-cycle and to

work or not in burst mode is also dependent on the primary inductance of the transformer.

Sometimes it is difficult to optimize the primary inductance of the transformer and obtain an

efficient burst. The result can be just a few cycles missed and most of the pulses are

present at switching frequency. It can be an advantage to work at a lower fixed frequency,

giving up the burst operation mode. The network Q1, R8R10 decreases the frequency

sinking current from R1 (timing resistor) when pin Comp (5) is lower than 1.6 V. In this way

the charging current of C13 (timing capacitor) decreases and according to the law

Equation 1

VT = C

-------------I

the frequency starts to reduce until the minimum frequency is at standby load. In steady

state condition at full load the switching frequency has been set to around 70 KHz, while in

standby it is around 30 KHz.

Table 3.

Standby measurements at 65 mA on output 1

Vin

Iin

Vout1 at 65 mA

Vout2 at 0 mA

Pout

Pin

Efficiency

Switching

frequency

Vdc

mA

Vdc

Vdc

KHz

276

2.98

6.51

19.5

0.42

0.82

53

30

325

2.69

6.51

19.6

0.42

0.87

48

29

374

2.48

6.51

19.8

0.42

0.93

45

28

7/13

Full load test

AN1513

Full load test

The parameters checked at full load have been the efficiency and main working parameters

of the VIPer for system reliability. The minimum voltage has been set at 240Vdc considering

the minimum voltage ripple on the bulk capacitor when the power supply is connected to the

ac mains.

The drain voltage spike reaches its maximum value at full load and maximum input voltage.

This spike is caused at turn-off by the energy stored in the primary leakage inductance of

the transformer during the Ton. This is the reason why it is recommended to design the

power transformer with a primary leakage inductance as low as possible. In addition a good

coupling between primary and secondaries improves total regulation, especially in SMPS

with more than one output.

Adjustment for frequency reduction

R1

15K

R2

18R

C9

R8

68K

Figure 2.

VDD

DRAIN

22nF

IC1

R10

Q1

OSC

18K

C13

VIPer50A-E

COMP

SOURCE

2.2nF

BC546

R9

15K

D7

C14

22nF

BZX79-4V3

Figure 3.

Drain current at full load

Figure 4.

Voltage current at full load

The maximum peak voltage measured on the drain is 642 V, thanks to the clamp

1.5KE220A. This value guarantees a reliable operation of VIPer with a good margin with

respect to the maximum BVDSS, which is 700 V. The VIPer is an avalanche rugged device

able to withstand a momentary energy peak caused by voltage greater than 700 V.

8/13

AN1513

Load step

The SMPS meets the specification with efficiency better than 80% at any input voltage

value, as shown in Table 4.

Table 4.

Full load measurements

Full load

Vin

Iin

Vdc

mA

Vdc

240

160

325

374

Vout1 at 2.5 A Vout2 at 1.5 A

Pout

Pin

Efficiency

Vdc

6.50

10.26

31.6

38.4

82.3

118

6.50

10.25

31.6

38.3

82.5

102

6.50

10.25

31.6

38.1

82.9

Load step

This SMPS has been designed to operate under two conditions: standby and full load. In

Figure 5 and Figure 6 show the outputs voltages during load steps from standby and full

load and vice versa. CHA is the resampling of Vout1 highlighting that no undershoot or

overshoot is present during load transient. The same test has been done to show the

behavior of the voltage on pins VDD and Comp.

Figure 5.

Load transient (Vout1, Vout2)

Figure 6.

Load transient (Vcomp, VDD)

9/13

Short circuit protection

AN1513

Short circuit protection

The SMPS is protected against short circuit on both outputs. The short circuit test has been

done with an active load for the complete input voltage range. As shown in Figure 7 and

Figure 8, taken at worst case at 374 Vdc, during short circuit on output1 or output 2, the

SMPS works in hiccup mode keeping the mean output current at a safe value for the

rectifiers, respectively at 3.3 A for output 1 and 2.2 A for output 2. Also the drain voltage

remains at a safe level during short circuit. To achieve these results a Zener diode has been

connected between pin Comp and Source of the VIPer. This Zener clamps the voltage on

pin Comp, limiting the maximum primary peak current. During short circuit the auxiliary

voltage is low because it is proportional to the output voltage. VDD drops under the low

threshold (8 V) blocking the VIPer and beginning the start up cycle. When C12 is charged at

11 V, the VIPer turns on again. It works as long as C12 is discharged to 8 V because the

auxiliary voltage, thanks to the reduced duty-cycle, is not capable of supplying the VIPer.

Figure 7.

Short circuit (Vout1)

Overvoltage protection

Figure 8.

Short circuit (Vout2)

Thanks to the VDD regulation capability, this SMPS is protected against secondary feedback

failure. If the secondary feedback loses control, the voltages increase. As the auxiliary

voltage is proportional to the outputs, VDD increases up to 13 V, which is the typical

regulation value for VIPer50A-E, so the VIPer takes control avoiding any damage to the

output capacitors and rectifiers. Table 5 gives the measurements in standby and at full load

with R6 removed from the board to simulate secondary feedback failure.

Table 5.

10/13

Overvoltage measurements

Operation mode

Vout1

Vout2

Standby

9.5V

22.5 V

Full load

7.2V

11.2 V

AN1513

Thermal test

Thermal test

For system reliability it is important to keep device temperature at a safe level, considering

the maximum ambient temperature especially when the board is inside a chassis. In Table 6

shows the temperatures measured on the SMPS after 4 hours of warm-up at full load at

nominal input voltage 230Vac: the results are compatible with robust design rules.

Table 6.

Thermal measurements

Table 7.

Measure point

Temperature (C)

Ambient

25

VIPer50A-E

47

STPS8H100F

53

STPS745

58

1.5KE220A

84

STTA106

55

DFO6M

52

T1 Ferrite

53

Transformer specification and construction

Parameter

Primary inductance

Value

670 H 8%

58 TURNS

Winding output1

4 TURNS

Winding output2

6 TURNS

Auxiliary winding

6 TURNS

Primary leakage inductance

Figure 9.

12 H

1.8% of Lp

Core

EPCOS ETD29-N67

Code

B66358-G500-X67

Transformer cross section

11/13

Conclusion

AN1513

Conclusion

The main specification requirements of this application have been reached and thanks to

the VIPer features, it also has been demonstrated that a quite difficult task such as attaining

very low power consumption in standby is easily achievable.

Revision history

Table 8.

12/13

Document revision history

Date

Revision

Changes

04-Jan-2005

First issue

27-Sep-2007

The document has been reformatted

VIPer50A becomes VIPer50A-E

AN1513

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (ST) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to STs terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN STS TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USERS OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

13/13

Das könnte Ihnen auch gefallen

- LinuxCNC IntegratorDokument21 SeitenLinuxCNC IntegratorNguyễnNgọcMinhNoch keine Bewertungen

- Edu 637 Lesson Plan Gallivan TerryDokument11 SeitenEdu 637 Lesson Plan Gallivan Terryapi-161680522Noch keine Bewertungen

- Buck Za Led An2754Dokument20 SeitenBuck Za Led An2754JaskovskiNoch keine Bewertungen

- CD00252755 MR4030Dokument25 SeitenCD00252755 MR4030Heriberto Flores Ampie100% (1)

- Ice 2a265Dokument35 SeitenIce 2a265Marcio EmersonNoch keine Bewertungen

- ICE2XS01 G V2.1 30jun06Dokument24 SeitenICE2XS01 G V2.1 30jun06templpaNoch keine Bewertungen

- AN2252 Application NoteDokument21 SeitenAN2252 Application NoteAldemar Algarra GaitánNoch keine Bewertungen

- 4 X 50 W MOSFET Quad Bridge Power Amplifier: FeaturesDokument18 Seiten4 X 50 W MOSFET Quad Bridge Power Amplifier: FeaturesEderson MauriceiaNoch keine Bewertungen

- AN3172 Application Note: 19 V - 90 W Adapter With PFC For Laptop Computers Using The L6563H and L6599ADokument31 SeitenAN3172 Application Note: 19 V - 90 W Adapter With PFC For Laptop Computers Using The L6563H and L6599ARodrigo BonfanteNoch keine Bewertungen

- AN2317 Application Note: STPM01 Programmable, Single-Phase Energy Metering IC External CircuitsDokument27 SeitenAN2317 Application Note: STPM01 Programmable, Single-Phase Energy Metering IC External CircuitsJitender SharmaNoch keine Bewertungen

- TDA7384A: 4 X 42W Quad Bridge Car Radio AmplifierDokument14 SeitenTDA7384A: 4 X 42W Quad Bridge Car Radio Amplifierbeta2009Noch keine Bewertungen

- Constant Current From CV PDFDokument20 SeitenConstant Current From CV PDFxiliantonioNoch keine Bewertungen

- STM6315RDW13FDokument21 SeitenSTM6315RDW13FArunkumar PbNoch keine Bewertungen

- Data SheetDokument23 SeitenData Sheetmichaelliu123456Noch keine Bewertungen

- TDA7850Dokument18 SeitenTDA7850Ricardo AlfaroNoch keine Bewertungen

- DC Motor Speed Control BC201Dokument24 SeitenDC Motor Speed Control BC201ROSEMARIO PORFIRIONoch keine Bewertungen

- Eval6598 100wDokument24 SeitenEval6598 100wمجتبى مهند سمير عبد عليNoch keine Bewertungen

- An2359 Application Note: Double Output Buck-Boost Converter With Viperx2ADokument18 SeitenAn2359 Application Note: Double Output Buck-Boost Converter With Viperx2AYayan SukmaNoch keine Bewertungen

- 4 Watt Led Driver CircuitDokument17 Seiten4 Watt Led Driver CircuitNomade VoyageurNoch keine Bewertungen

- Viper 27Dokument31 SeitenViper 27javierrincon800Noch keine Bewertungen

- 502 Maqnual PDFDokument18 Seiten502 Maqnual PDFmantenimiento74Noch keine Bewertungen

- Ice 2 A 280Dokument36 SeitenIce 2 A 280Marimuthu RajNoch keine Bewertungen

- 71r3000 (Ref. HR 5097)Dokument40 Seiten71r3000 (Ref. HR 5097)payolin77Noch keine Bewertungen

- VNH2SP30 e PDFDokument33 SeitenVNH2SP30 e PDFservitecdjNoch keine Bewertungen

- Different Terms of LDO - TIDokument13 SeitenDifferent Terms of LDO - TIbkrebtelNoch keine Bewertungen

- 1HS01G PDFDokument18 Seiten1HS01G PDFAldo TonatoNoch keine Bewertungen

- TDA7388A: 4 X 42W Quad Bridge Car Radio AmplifierDokument13 SeitenTDA7388A: 4 X 42W Quad Bridge Car Radio AmplifierJuan de la RosaNoch keine Bewertungen

- Ucc3842 App Note PDFDokument19 SeitenUcc3842 App Note PDFRakesh RakeeNoch keine Bewertungen

- Denison Ec01 A10Dokument17 SeitenDenison Ec01 A10Margaret DaughertyNoch keine Bewertungen

- Scea 030 ADokument17 SeitenScea 030 ACarlos EstevesNoch keine Bewertungen

- LAW 420 LAW 520: Service ManualDokument46 SeitenLAW 420 LAW 520: Service ManualquangppNoch keine Bewertungen

- Dla001d L6599DDokument36 SeitenDla001d L6599DBRIGHT_SPARK50% (6)

- 2.5A Output Current Gate Driver Optocoupler: Features DescriptionDokument11 Seiten2.5A Output Current Gate Driver Optocoupler: Features DescriptiononafetsNoch keine Bewertungen

- CD 00279018Dokument25 SeitenCD 00279018hsyntunaNoch keine Bewertungen

- VIPower: VIPer22A Dual Output Reference Board 90 To 264 VAC Input, 10W OutputDokument20 SeitenVIPower: VIPer22A Dual Output Reference Board 90 To 264 VAC Input, 10W OutputLullaby summerNoch keine Bewertungen

- AN4214 Application Note: High Power Factor Flyback Converter Using The L6564Dokument37 SeitenAN4214 Application Note: High Power Factor Flyback Converter Using The L6564GreenoceanNoch keine Bewertungen

- VIPER17LN-Fixed Frequency 6W High Performance Off Line High Voltage Converter-STDokument33 SeitenVIPER17LN-Fixed Frequency 6W High Performance Off Line High Voltage Converter-STbookreader1968Noch keine Bewertungen

- Evaluation Board For Off-Line Forward Converter Based On L5991Dokument25 SeitenEvaluation Board For Off-Line Forward Converter Based On L5991Grzegorz WegnerNoch keine Bewertungen

- Lbs PDFDokument20 SeitenLbs PDFthy thy thyNoch keine Bewertungen

- 1Dokument5 Seiten1Prajnyajit MohantyNoch keine Bewertungen

- Improved High-Voltage Resonant Controller: FeaturesDokument31 SeitenImproved High-Voltage Resonant Controller: Featuressontuyet82Noch keine Bewertungen

- Tda 2005Dokument25 SeitenTda 2005John CruzNoch keine Bewertungen

- KBRG 212d Thruhole ManualDokument17 SeitenKBRG 212d Thruhole ManualJulio FerminNoch keine Bewertungen

- 2794 990 RevADokument36 Seiten2794 990 RevAgovindarulNoch keine Bewertungen

- 60W1 ApplicationNotes v01 - 00 ENDokument36 Seiten60W1 ApplicationNotes v01 - 00 ENorkun burkayNoch keine Bewertungen

- L 6599 DDokument36 SeitenL 6599 DVidal VelasquezNoch keine Bewertungen

- $ Power Supply DesignDokument164 Seiten$ Power Supply Designquangntn88Noch keine Bewertungen

- UCC39421 3.3-V SEPIC Evaluation Board: User's GuideDokument7 SeitenUCC39421 3.3-V SEPIC Evaluation Board: User's GuidebensumbbNoch keine Bewertungen

- BTS50080-1TMB: Smart High-Side Power Switch Profet One ChannelDokument27 SeitenBTS50080-1TMB: Smart High-Side Power Switch Profet One Channelbünyamin altunNoch keine Bewertungen

- Tda 7388Dokument11 SeitenTda 7388Lucas Meister BarichelloNoch keine Bewertungen

- dm00044787 19 V 90 W Adapter With PFC For Laptop Computers Using The l6563h and l6699 StmicroelectronicsDokument40 Seitendm00044787 19 V 90 W Adapter With PFC For Laptop Computers Using The l6563h and l6699 StmicroelectronicssacralNoch keine Bewertungen

- LinuxCNC IntegratorDokument21 SeitenLinuxCNC IntegratormilknaniNoch keine Bewertungen

- KBMM DC Drive Series ManualDokument32 SeitenKBMM DC Drive Series ManualKBElectronicsincNoch keine Bewertungen

- Summary ClockDokument39 SeitenSummary ClockmikcomiNoch keine Bewertungen

- AN3159 Application Note: STEVAL-ILH005V2: 150 W HID Electronic BallastDokument36 SeitenAN3159 Application Note: STEVAL-ILH005V2: 150 W HID Electronic BallastAstin R. MartinezNoch keine Bewertungen

- Power Electronics Design: A Practitioner's GuideVon EverandPower Electronics Design: A Practitioner's GuideBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Variable Speed Pumping: A Guide to Successful ApplicationsVon EverandVariable Speed Pumping: A Guide to Successful ApplicationsBewertung: 3 von 5 Sternen3/5 (2)

- M890 ManualDokument4 SeitenM890 Manualbookreader1968Noch keine Bewertungen

- Tidu227 PDFDokument11 SeitenTidu227 PDFbookreader1968Noch keine Bewertungen

- MJH11017, MJH11019, MJH11021 (PNP) MJH11018, MJH11020, MJH11022 (NPN) Complementary Darlington Silicon Power TransistorsDokument8 SeitenMJH11017, MJH11019, MJH11021 (PNP) MJH11018, MJH11020, MJH11022 (NPN) Complementary Darlington Silicon Power Transistorsbookreader1968Noch keine Bewertungen

- Obsolete Product(s) - Obsolete Product(s) : Control Circuit For Switch Mode Power Supplies Using Mos TransistorsDokument7 SeitenObsolete Product(s) - Obsolete Product(s) : Control Circuit For Switch Mode Power Supplies Using Mos Transistorsbookreader1968Noch keine Bewertungen

- Tda2614 CNV 2Dokument11 SeitenTda2614 CNV 2octalmNoch keine Bewertungen

- Practical Magnetic Design: Inductors and Coupled Inductors: Power Supply Design SeminarDokument23 SeitenPractical Magnetic Design: Inductors and Coupled Inductors: Power Supply Design Seminarbookreader1968Noch keine Bewertungen

- AP9T15GHDokument4 SeitenAP9T15GHbookreader1968Noch keine Bewertungen

- BU931Dokument13 SeitenBU931anon_136451958Noch keine Bewertungen

- En An Ce / Co Nti Nu Ed: Silicon PNP Epitaxial Planar Type DarlingtonDokument4 SeitenEn An Ce / Co Nti Nu Ed: Silicon PNP Epitaxial Planar Type Darlingtonbookreader1968Noch keine Bewertungen

- Inte Na Nce / Dis Con Tinu Ed: Silicon NPN Triple Diffusion Planar Type DarlingtonDokument4 SeitenInte Na Nce / Dis Con Tinu Ed: Silicon NPN Triple Diffusion Planar Type Darlingtonbookreader1968Noch keine Bewertungen

- Silicon PNP Darlington Power Transistors: Savantic Semiconductor Product SpecificationDokument3 SeitenSilicon PNP Darlington Power Transistors: Savantic Semiconductor Product Specificationbookreader1968Noch keine Bewertungen

- Silicon NPN Triple Diffusion Planar Type Darlington: Power TransistorsDokument3 SeitenSilicon NPN Triple Diffusion Planar Type Darlington: Power Transistorsbookreader1968Noch keine Bewertungen

- Inte Na Nce / Dis Con Tinu Ed: Silicon NPN Triple Diffusion Planar Type DarlingtonDokument4 SeitenInte Na Nce / Dis Con Tinu Ed: Silicon NPN Triple Diffusion Planar Type Darlingtonbookreader1968Noch keine Bewertungen

- MC 1496Dokument13 SeitenMC 1496Avishek BiswasNoch keine Bewertungen

- SLVA797Dokument6 SeitenSLVA797bookreader1968Noch keine Bewertungen

- En An Ce / Co Nti Nu Ed: Silicon PNP Epitaxial Planar Type DarlingtonDokument4 SeitenEn An Ce / Co Nti Nu Ed: Silicon PNP Epitaxial Planar Type Darlingtonbookreader1968Noch keine Bewertungen

- SLYT675Dokument32 SeitenSLYT675bookreader1968Noch keine Bewertungen

- SLYT674Dokument6 SeitenSLYT674bookreader1968Noch keine Bewertungen

- SNVA761Dokument18 SeitenSNVA761bookreader1968Noch keine Bewertungen

- SLVA730Dokument12 SeitenSLVA730bookreader1968Noch keine Bewertungen

- SLVA773Dokument8 SeitenSLVA773bookreader1968Noch keine Bewertungen

- Fundamentals of On-Resistance in Load Switches: Application ReportDokument9 SeitenFundamentals of On-Resistance in Load Switches: Application Reportbookreader1968Noch keine Bewertungen

- SLVA812Dokument7 SeitenSLVA812bookreader1968Noch keine Bewertungen

- SLUA787Dokument5 SeitenSLUA787bookreader1968Noch keine Bewertungen

- Switching Power Supply Topology Voltage Mode vs. Current ModeDokument4 SeitenSwitching Power Supply Topology Voltage Mode vs. Current Modennpatel1990Noch keine Bewertungen

- SLUP079Dokument46 SeitenSLUP079bookreader1968Noch keine Bewertungen

- Switching Regulator Fundamentals: Application ReportDokument28 SeitenSwitching Regulator Fundamentals: Application Reportbookreader1968Noch keine Bewertungen

- Switching Regulator Fundamentals: Application ReportDokument28 SeitenSwitching Regulator Fundamentals: Application Reportbookreader1968Noch keine Bewertungen

- SLYU032Dokument9 SeitenSLYU032bookreader1968Noch keine Bewertungen

- Magnetic Properties of CoreDokument10 SeitenMagnetic Properties of CoreSBalamurughanNoch keine Bewertungen

- Zeb OSARSInstallDokument128 SeitenZeb OSARSInstallThien TranNoch keine Bewertungen

- Elite 08Dokument96 SeitenElite 08Razza WilliNoch keine Bewertungen

- UTAR Convocation Checklist For Graduands Attending Convocation (March 2019) - 1Dokument5 SeitenUTAR Convocation Checklist For Graduands Attending Convocation (March 2019) - 1JoyleeeeeNoch keine Bewertungen

- Summer 2019 - OSD Exam Paper MS - FINALDokument13 SeitenSummer 2019 - OSD Exam Paper MS - FINALAsifHossainNoch keine Bewertungen

- Status of Implementation of Prior Years' Audit RecommendationsDokument10 SeitenStatus of Implementation of Prior Years' Audit RecommendationsJoy AcostaNoch keine Bewertungen

- Type SAP Usage / Definition Example Procurement RotablesDokument4 SeitenType SAP Usage / Definition Example Procurement Rotablessabya1411Noch keine Bewertungen

- Nishat ISDokument11 SeitenNishat ISSaeed MahmoodNoch keine Bewertungen

- Murugan Temple of North America: Ahkpuf F Gankd - FZGJP JizDokument8 SeitenMurugan Temple of North America: Ahkpuf F Gankd - FZGJP JizOurMuruganTempleNoch keine Bewertungen

- 95 IDokument17 Seiten95 IsvishvenNoch keine Bewertungen

- Property DigestDokument9 SeitenProperty DigestJoy OrenaNoch keine Bewertungen

- SK Memorandum of AgreementDokument3 SeitenSK Memorandum of AgreementNORZEN LAGURANoch keine Bewertungen

- PD Download Fs 1608075814173252Dokument1 SeitePD Download Fs 1608075814173252straulleNoch keine Bewertungen

- Safety Manual For DumperDokument9 SeitenSafety Manual For DumperHimanshu Bhushan100% (1)

- CASE DIGEST: Teodoro Acap Vs CA, Edy Delos Reyes G.R. No. 118114 December 7, 1995 (251 SCRA 30) (Yellow Pad Digest)Dokument7 SeitenCASE DIGEST: Teodoro Acap Vs CA, Edy Delos Reyes G.R. No. 118114 December 7, 1995 (251 SCRA 30) (Yellow Pad Digest)Laiza MayNoch keine Bewertungen

- Contribution of Science and Technology To National DevelopmentDokument2 SeitenContribution of Science and Technology To National DevelopmentAllan James DaumarNoch keine Bewertungen

- Is LNG Still Competitive With Other Liquid Fuels?: Proceedings, Ascope'97 ConferenceDokument18 SeitenIs LNG Still Competitive With Other Liquid Fuels?: Proceedings, Ascope'97 Conferencemanolo8catalanNoch keine Bewertungen

- However, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To PrescriptionDokument7 SeitenHowever, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To Prescriptionkemsue1224Noch keine Bewertungen

- Slates Cembrit Berona 600x300 Datasheet SirDokument2 SeitenSlates Cembrit Berona 600x300 Datasheet SirJNoch keine Bewertungen

- 14.quality of Life in Patients With Recurrent AphthousDokument7 Seiten14.quality of Life in Patients With Recurrent AphthousCoste Iulia RoxanaNoch keine Bewertungen

- Bank Details and Payment MethodsDokument1 SeiteBank Details and Payment Methodsetrit0% (1)

- Aga 11Dokument7 SeitenAga 11elijbbNoch keine Bewertungen

- MyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerDokument1 SeiteMyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerGeanina OlteanuNoch keine Bewertungen

- in Re Irava Bottle ShopDokument10 Seitenin Re Irava Bottle ShopCYMON KAYLE LubangcoNoch keine Bewertungen

- Pmgsy Unified BSR December 2019 PDFDokument87 SeitenPmgsy Unified BSR December 2019 PDFRoopesh Chaudhary100% (1)

- METHODOLOG1Dokument3 SeitenMETHODOLOG1Essa M RoshanNoch keine Bewertungen

- Assessment Task 1: Written Questions 1. Identify and Describe Five Common Components of A Business PlanDokument6 SeitenAssessment Task 1: Written Questions 1. Identify and Describe Five Common Components of A Business PlanJoanne Navarro AlmeriaNoch keine Bewertungen

- Introduction To MAX InternationalDokument48 SeitenIntroduction To MAX InternationalDanieldoeNoch keine Bewertungen

- Royal Classic e BrochureDokument14 SeitenRoyal Classic e Brochureidreesali8654Noch keine Bewertungen

- 5 GR No. 93468 December 29, 1994 NATU Vs TorresDokument9 Seiten5 GR No. 93468 December 29, 1994 NATU Vs Torresrodolfoverdidajr100% (1)