Beruflich Dokumente

Kultur Dokumente

Hydraulic Design of An Aqueduct and Its Necessity in Rajouri Town in Jammu and Kashmir

Hochgeladen von

esatjournalsOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hydraulic Design of An Aqueduct and Its Necessity in Rajouri Town in Jammu and Kashmir

Hochgeladen von

esatjournalsCopyright:

Verfügbare Formate

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

HYDRAULIC DESIGN OF AN AQUEDUCT AND ITS NECESSITY IN

RAJOURI TOWN IN JAMMU AND KASHMIR

Yawar Mushtaq Raina1, Sajjad Ahmed2, Zuhaib Zahoor Shawl3, Ajaz Ahmed4

1

Junior Engineer Public Works (R & B) Department, Government of Jammu & Kashmir, India

yawarraina35@gmail.com

2, 3

Research Scholar, GIMT, Kurukshetra, Haryana, India

sajjadmughal40@gmail.com, zuhaibshawl@yahoo.in

4

Faculty, University Polytechnic, Baba Ghulam Shah Badshah University, Rajouri, Jammu & Kashmir, India

khanajaz00786@gmail.com

Abstract

Aqueduct is the Cross drainage arrangement which make the route of water from one side of drain to the other. Most of the

Rajouri town is hilly and semi-hilly belt. At Rajouri about 9000 hectares areas of land remain deprived of irrigation facilities.

The main aim of the paper is to present the hydraulic design of aqueduct proposed over Darhali River in Rajouri town and

explain as to why aqueduct was required in this area. To assist the growth of crops in areas adjoining to Darhali River

construction of Aqueduct from left bank to Right bank of River was projected. Aqueduct of 6 X 9.5m span was proposed to be

constructed. Substructure of the Aqueduct consists of the abutments, five piers and substructure of an R.C.C trough of internal

size 2.0m 2.3 m. Foundation of abutment and piers were escalated below the Scour depth level of 4m to avoid erosion and

consequent damage to the structure via silting and erosion. The estimated cost of the structure was near about 90 lacs. It was

found that rising of aqueduct structure shall boost farming in this area besides improving livelihood of respective land owners.

The overall irrigation system of the town shall improve by constructing such a structure which was dependent mostly on rainfall.

Keywords: Cross Drainage Works, Aqueduct, Rajouri, Canal, Drainage, Hydraulic Design, Irrigation

--------------------------------------------------------------------***---------------------------------------------------------------------1.

INTRODUCTION

Cross drainage works are the hydraulic structures which are

constructed to allow the passage of canal water from one

side of the drainage to the other (Punmia et al 2009). The

passage of canal water from one side to the other is done

either by allowing the water to go over the drainage or by

allowing it to go under the drainage water. Sometimes canal

water and the drainage cross each other at the same level

(Punmia et al & Garg 2009). Depending upon how canal

water crosses the drainage, cross drainage works are

classified into three types as: Canal over the drainage, Canal

under the drainage and canal at the same level as that of

drainage. When canal passes over the drainage, the cross

drainage works which are constructed are either Aqueduct

or syphon Aqueduct (Punmia et al & Garg 2009). When

canal is allowed to go under the drainage the cross drainage

works constructed are either Canal syphon or Super passage

(Arora , 2009). Sometimes canal and drainage water meet at

the same time. In that case level crossing is provided. The

relative bed levels, water levels, and discharge of the canal

and the drainage are the primary factors which govern and

dictate the type of cross drainage work. Aqueducts are

further classified as type I, type II and type III aqueduct.

Here type III aqueduct was provided because as the drainage

was very small drain.

The canal is diverged and then is allowed to pass the

drainage then this canal water ultimately benefits the land on

other side of the drainage( lacey, 1934). The canal water

passes through a trough which is generally an R.C.C or

steel. The section of canal normally is kept trapezoidal in

shape as it is best among hydraulic sections of lined canal

(Swamee et al 2000) .The construction of aqueduct is

similar to that of bridge (Chen & Duan, 2014, Punmia et al

& Garg 2009). Aqueduct consist of two parts sub structure

and super structure (Sharma and Sharma, 2008).

Substructure consists of piers, abutments, foundations

(Tonias 1994). Super structure consists of slab and trough

(Punmia et al & Garg 2009). However if possible these cross

drainage structures should be avoided. The aqueduct also

facilitates water transportation in developed countries

(Angelakis et al 2009) besides aiding the irrigation facilities.

Study Area

Rajouri used to be part of Poonch district but on 22

September1967. It was separated from poonch district and

on 1st January1968 it was officially declared as the separate

district covering an area equal to about 2630 sq km. Rajouri

is also known as Rajapuri or the land of kings. As per survey

of india Rajouri lies between latitudes 33000000&

33003520 North and longitudes 74800 & 744230

East. It is located at an elevation of about 562-4800m above

mean sea level and is surrounded by famous pir-panjal

hills.The river flowing through Rajouri town comes from

Darhal and Thanamandi, meeting each other near Darhali

Bridge at Kheora (Raina and Alam, 2014, Raina and Anjum

2015, Aslam et al, 2015), where the aqueduct is proposed to

be constructed. Temperature on the average varies from 7

_______________________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

213

IJRET: International Journal of Research in Engineering and Technology

degree Celsius to 40 degree Celsius but area is generally

cooler in winters. The average annual rainfall is 769 mm.

Figure 1 and 2 Shows map of Rajouri and its hydrogeology.

eISSN: 2319-1163 | pISSN: 2321-7308

of irrigation but they contribute in very little amount.

Irrigation in this area is also done mostly natural ways

which include rainfall the sources by which irrigation is

done in this area are given in table 2.

Figure-1 Map of Rajouri District, Jammu &

Kashmir, India (Source: Maps of India)

In the state Jammu and Kashmir district Rajouri is one of the

most important agricultural district having 7 blocks. Out of

the seven blocks of district Rajouri, Nowshera, Sunderbani,

Kalakote and Thanamandi are impotant agricarian blocks.

Wheat is the major Rabi crop but along with wheat, maize

and rice are the major Kharif crops grown in these blocks.

Rajouri town does not have well developed irrigation system

The per hectare yield of crops in this district is less as

compared to other parts of state due to high weed

infestations. Total area of the Rajouri is 253340 hectares of

which 52,973 hectares are cultivable (20%). Out of the

cultivable land, 7721 hectares is irrigated (about 14% of

cultivable area 3% of the total geographical area). Table 1

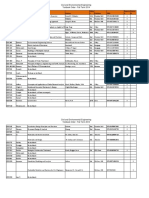

shows the crops grown in district Rajouri.

S.no

1

2

3

4

5

6

7

8

9

10

Table-1: Crops grown in district Rajouri.

Crop

Percentage(%age)

Rice

6

Bajra

0.25

Maize

46

Wheat

42.39

Barley

0.018

Millet

0.10

Pulses

0.43

Sugarcane

Fruit & Vegetables

0.069

Oil seeds

1.5

Most of the area is hilly and semi-hilly belt which is

deprived of irrigation facility. Ans and Rajal canal is the

only source of canal through which irrigation is done but

that covers area of Budhal division only irrigating only 660

hactares of land. Construction of aqueduct is under way in

Nowshera as well. Except canals wells also act as a source

Figure-2 Map of Rajouri District, Showing Hydrogeology,

(Source: Ground water information booklet Rajauri district)

Table 2 Irrigation by different sources

727 hectares

Net Area Irrigated

Canals

660 hectares

Wells

27 hectares

Other Sources

40 hectares

800 hectares

Gross Area Irrigated

Canals

680 hectares

Wells

50 hectares

Other Sources

70 hectares

Other then the above mentioned sources most of the paddy

area is irrigated through khuls in Thanna, Behrote, Palma

and sources of irrigation are Nullah Thanna, Nallah Ans,

River Rajauri and Nullah Kalakote. One more aqueduct is

proposed to be at kheora over Darhali River so that the land

which remains deprived of irrigation gets the necessary

water which not only will help in raising the crops but will

also improve the financial situation of many farmers.

Besides assisting the land owner.

2.

MATERIALS AND METHODS

The material used in the construction of aqueduct was

cement, course aggregate, sand, water and steel. Then the

hydraulic and structural was done though here only

hydraulic design is presented. Hydraulic design includes the

_______________________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

214

IJRET: International Journal of Research in Engineering and Technology

design canal section, determining the highest flood

discharge and highest flood level of the river, the design of

drainage waterway, design of canal waterway which

included design of transition and calculation of head losses

at critical sections was done. Besides this design of guide

banks, launching apron was also done. Scour depth was also

determined by formula recommended by Indian standard.

Structural design was done in accordance to IS 456:2000.

Design of transition was done using Mitra method (Vittal

and Chiranjeevi 1983), where as head losses were calculated

using Darcy (Moody,1944) and Mannings formula (Dooge,

1989).

eISSN: 2319-1163 | pISSN: 2321-7308

Table 3- Hydraulic design of Canal

Hydraulic Elements

Value

Bed width of canal

Canal Water depth

Bed Slope of the channel

Free board

Fully supply level

Full supply discharge

Canal bed level

Velocity

4m

2m

1 in 3110

0.3m

1002.685m

10 Cumecs

100.685m

0.8m/sec

Current meter was used to find out velocity of drainage.

Figure 3shows the current meter.

The hydraulic design of the Darhali Nallah over which this

canal will pass was done, in this design discharge and HFL

of the Nallah was determined by calculating the velocity of

river. The discharge was calculated using the continuity

equation of discharge by first determining the cross

sectional area which was 124.915m2calculated of the river

and then multiplying it by velocity which was found out by

current meter (Govers, 1992) and H.F.L was determined by

consulting the locals and taking data of past 50 years, details

of elements of drainage are shown in the table 4. The

average velocity of the drainage was found to be 5.70m/sec.

Slope was calculated from L-Section of the drainage, it was

found to be 3.86%. Canal bed level was 1000.685m and the

highest flood level (H.F.L) of drainage was 999.485m. So

Canal bed level was more than highest flood level (H.F.L)

of drainage, an aqueduct was proposed constructed. The

other design details of aqueduct are presented as follows

Figure 3: Current meter

Table 4- Design details of Darhali Nallah

A perfect current meter, whether mechanical or

electromagnetic, should react right away and time after time

to any change in water velocity, and should accurately

register the desired velocity component. Also it should be

sturdy, easily maintained, and simple to use Mechanical

current meters compute velocity by interpreting linear

motion into angular motion (Fulford et al 1994)

3.

RESULTS AND DISCUSSIONS

Design of Aqueduct

The design of Aqueduct includes hydraulic design and

structural design. Here only the hydraulic design is

presented.

Design of canal Section

The design of Aqueduct starts with the design of canal. A

canal a non-natural watercourse constructed to permit the

passage of boats or ships or to transmit water for irrigation.

Since the best cross section of the canal is trapezoidal for

lined canals (Swamee et al 2000), here the trapezoidal cross

section has been chosen. Applying the general method of

design of alluvial lined channels the constant width and

depth of alluvial canals with trapezoidal shape for a given

set of water discharge, channel slope, sediment size, and

side slope, F.S.L, Velocity etc are calculated (Chaang, 1980

and chitale, 1994). Table 3 shows Hydraulic design of Canal

Hydraulic Elements

Value

High flood discharge

712 Cumecs

Highest flood level

999.485m

Design of drainage Waterway

Waterway is defined as the canal, river or other water body

serving as a route or way of travel or transport (Broad,

1992) Table 5 shows some details of design of drainage

water way

Table 5: Design of drainage water way

62.5m

Total water way

Clear Water way

57.6m

Piers

5 nos of 1m each

Design of canal waterway

Canal waterway can be defined in a similar way as that of

drainage waterway

Transition design

Transition in channels is defined as the change in cross

section of canal (Punmia et al 2009, Garg 2009).Design of

transition in both expansion and contraction was done using

Mitras method and is shown in table 6

_______________________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

215

IJRET: International Journal of Research in Engineering and Technology

S.No

Table 6: Design of transitions

Design Feature

Value

Length of Expansion transition

3m

Length of Contraction transition

2m

Splay in Contraction

2:1

Splay in Expansion

3:1

Splay length in Contraction

5m

Splay length in Expansion

8m

eISSN: 2319-1163 | pISSN: 2321-7308

Head losses at various levels at different section

Head losses in the pipes and networks hydraulic delegate the

irreparable loss of pressure energy, that experience a liquid

or a gas as it passes through a conduit, or another fitting of

fluid network (Hooper, 1981).The head losses, reduced

levels and velocity of flow at different sections of canal

were calculated and are shown in table 7. The head losses

calculated at different sections as shown in table were

started from section 4-4. Initially trapezoidal section was

chosen and velocity was found out after calculating the cross

section elements. Then velocity head was calculated by

formula given by equation 1

Table 7- Head loses at Various sections of canals

R.L of bed was found out earlier and by adding depth of

canal water R.L of water surface was found. Total energy

line which is the sum of all the heads was found by adding

velocity head to R.L of water surface. Then we proceeded to

section 3-3 from here the canal gets expanded and hence

there will be loss of head due to expansion, calculated by

formula given by equation 2

Hc=0.5

V 22 V 21

(4)

2g

The complete details of the head losses and other features of

canal trough are given in figure 2

From section 3-3 to 2-2 there was head loss due to friction

which was calculated by Mannings formula given in

equation 3. Similarly reduced levels at this section were also

found out. From Section 2-2 to 1-1 the canal gets contracted

and as a result of that there will be head loss due to

contraction, which is calculated by formula given in

equation 4. Reduced levels were found in similar way.

Formulae used

H=V2/2g.

(1)

Where V is velocity of flow at that section and g is

acceleration due to gravity.

Head due to expansion, calculated by formula

32 42

He = 0.3

(2)

Head loss due to friction from section 3-3 to 2-2 there is

which was calculated by

H2=

N2V2 L

4

R 3

(3)

Where N is Mannings coefficient R is hydraulic radius V is

velocity of flow and L is length of the canal waterway

Head loss due to contraction, which is calculated by formula

Figure 4- Head losses and R. Ls at different sections

Design of Guide banks

They are provided to prevent the river from damaging

railway formation, bridges and cross drainage or any other

hydraulic structure (Przedwojski, 1995).

First of all length of Guide bank and radius of curved head

both at the upstream and downstream end of the aqueduct

were determined and are shown in the table 8. The cross

sectional details of guide banks are given in table 9 and

figure 4.

_______________________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

216

IJRET: International Journal of Research in Engineering and Technology

Table 8: Length and radius of curved head of guide banks

Side of

Length of Radius of

Sweep

aqueduct

guide

curved

angle

bank(m)

head(m)

Up stream

78.13

34

130

Down stream

15.63

17

60

Table 9: The cross sectional details of guide banks

999.485m

H.F.L at aqueduct site

Free board

1.5m

Top level of guide bank

1000.985m

River bed level

993.985m

Guide bank height above river bed 7m

The water face of the shank was pitched with one man stone

weighing 0.4 to 0.5 KN The rear slope of the shank was

provided with vegetal cover. This was done for slope

protection. Volume of stone required for pitching was found

out to be 8.46m3.Thickness of launching apron at the inner

and outer edge was found out to be 1m and 1.5m

respectively. Figure 4 shows cross section and plan of guide

bunds

Fig 5 -Cross section of curved portion of Bund

eISSN: 2319-1163 | pISSN: 2321-7308

Table 10: Scour depth and apron at various sections

Section

Scour Width of

depth launching

below Apron

river

(m)

bed

(m)

At the river bed from nose of the 4

1.2

guide bank and H.F.L

At the river bed at the transition

from nose to straight portion

and H.E.L

At the Shank of the guide bank and

H.F.L

0.8

1.6

0.8

1.6

CONCLUSION

The design of aqueduct was done and it was found that it is

of great importance especially in areas like this where

irrigation is done only by natural means and to some extent

by wells. Rising of aqueduct structure shall boost farming in

this area besides improving livelihood of respective land

owners as 9000 hectares of land was found to remain

deprived of irrigation. Aqueduct of 6 X 9.5m span was

proposed to be constructed. Substructure of the Aqueduct

consists of the abutments, five piers and substructure of an

R.C.C trough of internal size 2.0m 2.3 m. Foundation of

abutment and piers were escalated below the Scour depth of

4m level to avoid erosion and consequent damage to the

structure. Span of the aqueduct was 57.6m.The estimated

cost of the structure was near about 90 lacs that was the only

difficulty found that the project is pretty costly. Crops like

rice wheat maize etc will grow by assistance of this

aqueduct.

REFRENCES

Fig 6- Plan of guide bunds.

Design of Launching Apron and Scour depth calculation

Scour depth is the depth upto which soil erodes river bed

(Lim, 1997). It is helpful in designing the foundation of a

cross drainage work as the silting problems are controlled

(Olsen, 1998). Scour depth at various sections and details of

apron are tabulated in table 10. After that design of apron

was done

[1]. Punmia, B. C., Pande Brij Basi Lal, Ashok Kumar Jain,

and Arun Kumar Jain. Irrigation and water power

engineering. Laxmi Publications, Ltd., 2009.

[2]. Garg, Santosh Kumar. Irrigation engineering and

hydraulic structures. Khanna publishers, 2009.

[3]. Lacey, Gerald. "Uniform Flow in Alluvial Rivers and

Canals.(Includes Appendices)."

[4]. Angelakis, A. N., D. Koutsoyiannis, B. A. Stewart, and

T. A. Howell. "Encyclopedia of Water Science."

(2003).

[5]. Swamee, Prabhata K., Govinda C. Mishra, and Bhagu

R. Chahar. "Minimum cost design of lined canal

sections." Water Resources Management 14, no. 1

(2000): 1-12.

[6]. Chen, Wai-Fah, and Lian Duan, eds. Bridge

Engineering Handbook: Construction and Maintenance.

CRC press, 2014.

[7]. Sharma, R. K., and T. K. Sharma. Irrigation

engineering. S. Chand, 2008.

_______________________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

217

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

[8]. Tonias

DE.

Bridge

Engineering.

Design,

Rehabilitation, and Maintenance of Modern Highway

Bridges. 1994.

[9]. Ground water information booklet Rajauri district,

jammu and kashmir, north western Himalayan region

Jammu, November 2009.

[10]. Raina, Y.M. & Alam, P. (2014):Wastewater Treatment

and Management in Rural areas - A Case Study of

Rajouri District, Jammu and Kashmir, India,

International Journal of Development Research, 4 (11),

2266-2269.

[11]. Raina, YM & Anjum, F. (2015): Analysis and Effect of

Plastic and Biomedical waste on Rajouri Town, Jammu

and Kashmir, India International Journal of Innovative

Research

in

Science,Engineering

and

Technology,4(6),3904-3909.

[12]. Aslam, Z., Raina, Y. M., & Mohiuddin, I (2015).

Characterization of Wastewater in Rajouri Town,

Jammu And Kashmir, India, International journal of

Engineering research and applications , 5(10),pp 69-79

[13]. Dooge, J. C. I. "Manning Formula in Context." (1989).

[14]. Moody, L. F. (1944). Friction factors for pipe flow.

Trans. Asme, 66(8), 671-684.

[15]. Vittal, Nandana, and V. V. Chiranjeevi. "Open channel

transitions: Rational method of design." Journal of

Hydraulic Engineering 109, no. 1 (1983): 99-115.

[16]. Standard, I., Plain and reinforced concretecode of

practice. New Delhi: Bureau of Indian Standards

2000.

[17]. Chang HH. Stable alluvial canal design. Journal of the

Hydraulics Division. 1980 May;106(ASCE 15420).

[18]. Board, Marine. Shiphandling simulation: Application

to waterway design. National Academies Press, 1992.

[19]. Fulford JM, Thibodeaux KG, Kaehrle WR.

Comparison of current meters used for stream gaging.

Fundamentals and advancements in hydraulic

measurements and experimentation. 1994 Aug 1:37685.

[20]. Chitale, S. V. "Lacey divergence equations for alluvialcanal design." Journal of Hydraulic Engineering 120,

no. 11 (1994): 1320-1326.

[21]. Chitale SV. Shape and size of alluvial canals. Journal

of Hydraulic Engineering. 1976 Jul;102(7):1003-11.

[22]. Govers G. Relationship between discharge, velocity

and flow area for rills eroding loose, nonlayered

materials. Earth surface processes and landforms. 1992

Aug 1;17(5):515-28.

[23]. Hooper WB. The 2-K Method Predicts Head Losses in

Pipe Fittings. Chemical Engineering. 1981 Jan 1;

88(17):96-100.

[24]. Przedwojski, Bogusaw, R. Bazejewski, and Krystian

W. Pilarczyk. River training techniques: fundamentals,

design and applications. AA Balkema, 1995.

[25]. Lim, Siow-Yong. "Equilibrium clear-water scour

around an abutment." Journal of Hydraulic Engineering

123, no. 3 (1997): 237-243.

[26]. Olsen, Nils RB, and Hilde M. Kjellesvig. "Threedimensional numerical flow modeling for estimation of

maximum local scour depth." Journal of Hydraulic

Research 36, no. 4 (1998): 579-590.

_______________________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

218

Das könnte Ihnen auch gefallen

- Irrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsVon EverandIrrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsNoch keine Bewertungen

- Hydraulic Design of An Aqueduct and Its Necessity in Rajouri Town in Jammu and KashmirDokument7 SeitenHydraulic Design of An Aqueduct and Its Necessity in Rajouri Town in Jammu and KashmirSUSHEEL KUMAR KANAUJIYANoch keine Bewertungen

- Hydraulic Design of An Aqueduct and Its Necessity in Rajouri Town in Jammu and KashmirDokument7 SeitenHydraulic Design of An Aqueduct and Its Necessity in Rajouri Town in Jammu and KashmirPeter ValentineNoch keine Bewertungen

- Implementation of Infrastructure Projects: 1.1 River RaviDokument37 SeitenImplementation of Infrastructure Projects: 1.1 River RaviNavit MahajanNoch keine Bewertungen

- Jwarp 2013062614443433Dokument11 SeitenJwarp 2013062614443433timesave240Noch keine Bewertungen

- Planning of River Inter - Linking Canal System Between Shetrunji River and Dhatarwadi River, Saurashtra, India, Using Remote Sensing and GISDokument7 SeitenPlanning of River Inter - Linking Canal System Between Shetrunji River and Dhatarwadi River, Saurashtra, India, Using Remote Sensing and GISIJSTENoch keine Bewertungen

- Kalpasar Presentation - Final PDFDokument39 SeitenKalpasar Presentation - Final PDFkc_p2150% (2)

- Irrigation Engineering CE-408 (2+1) : Engr. Afzal AhmedDokument36 SeitenIrrigation Engineering CE-408 (2+1) : Engr. Afzal AhmedNoman khanNoch keine Bewertungen

- Assessment of Surface Water Quality Using Qual2k Software: A Case Study of River Yamuna, IndiaDokument9 SeitenAssessment of Surface Water Quality Using Qual2k Software: A Case Study of River Yamuna, IndiaCarlosNoch keine Bewertungen

- tmp7BF TMPDokument12 Seitentmp7BF TMPFrontiersNoch keine Bewertungen

- The Lining of Irrigation CanalsDokument30 SeitenThe Lining of Irrigation CanalsGonzalo López0% (1)

- Various Conventional Water Recharging Systems and Conservation StructuresDokument9 SeitenVarious Conventional Water Recharging Systems and Conservation StructuresmayankNoch keine Bewertungen

- Project Report New Okhla BarrageDokument85 SeitenProject Report New Okhla BarrageAbhishek Koul100% (2)

- Financial BidDokument285 SeitenFinancial BidGoodwillNoch keine Bewertungen

- Wainganga Report (Previous Project)Dokument124 SeitenWainganga Report (Previous Project)Jagadish_2Noch keine Bewertungen

- CH 1Dokument16 SeitenCH 1Fozia SamoonNoch keine Bewertungen

- Kalisindh Chambal River Linking CanalDokument9 SeitenKalisindh Chambal River Linking CanalSrihariKyatamNoch keine Bewertungen

- Narmada Bachao AndolanDokument3 SeitenNarmada Bachao AndolanAaesta PriyestaNoch keine Bewertungen

- Godavari River Water Sharing AccordDokument6 SeitenGodavari River Water Sharing AccordN. Sasidhar100% (1)

- Civil Engineering - Water Resource Engineering IntroductionDokument23 SeitenCivil Engineering - Water Resource Engineering IntroductionVilly L.100% (3)

- Development of Synthetic Unit Hydrograph at Kakkadavu Dam: Azhar HusainDokument12 SeitenDevelopment of Synthetic Unit Hydrograph at Kakkadavu Dam: Azhar HusainSebas Miles MoraNoch keine Bewertungen

- Flood Control by Reservoir Operation ForDokument6 SeitenFlood Control by Reservoir Operation ForJohn Christian Rey CelizNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument20 SeitenDisclosure To Promote The Right To InformationgayalamNoch keine Bewertungen

- Site Visit ReportDokument10 SeitenSite Visit ReportKushal ThakkarNoch keine Bewertungen

- Sardar Sarovar Narmada DamDokument32 SeitenSardar Sarovar Narmada DamBindu SravaniNoch keine Bewertungen

- Use of Rubber Dam in Tapi River Front Development at Surat City April 2012 2959815456 1404022Dokument3 SeitenUse of Rubber Dam in Tapi River Front Development at Surat City April 2012 2959815456 1404022A-35 Jalay MakwanaNoch keine Bewertungen

- Irrigation Engineering CE-408 (2+1)Dokument63 SeitenIrrigation Engineering CE-408 (2+1)Umer Waheed50% (2)

- Water: Study On Backwater E Project Under DiDokument20 SeitenWater: Study On Backwater E Project Under DiAnde BhanuNoch keine Bewertungen

- Sukhhar Barrage - Previous Studies - ME - Ver. 1Dokument29 SeitenSukhhar Barrage - Previous Studies - ME - Ver. 1zarifkheroNoch keine Bewertungen

- Industrial Training Report DraftDokument27 SeitenIndustrial Training Report DraftAbhinav VermaNoch keine Bewertungen

- Par-Tapi-Narmada Link Project EIA PDFDokument83 SeitenPar-Tapi-Narmada Link Project EIA PDFsumitNoch keine Bewertungen

- Patel, D., Srivastava, P., Singh, S. K., Prieto, C., & Han, D. (2018)Dokument8 SeitenPatel, D., Srivastava, P., Singh, S. K., Prieto, C., & Han, D. (2018)Prithu RajNoch keine Bewertungen

- Technical Visit To Polavaram-1.ioopp PDFDokument15 SeitenTechnical Visit To Polavaram-1.ioopp PDFkesapragada naga mounikaNoch keine Bewertungen

- Narmada Bachao AndolanDokument6 SeitenNarmada Bachao AndolanManish ChandranNoch keine Bewertungen

- Cooum RiverDokument235 SeitenCooum RiverSuma ManthaNoch keine Bewertungen

- Geomorphic Study IJREISS 2228 51109Dokument7 SeitenGeomorphic Study IJREISS 2228 51109VikasNoch keine Bewertungen

- Application of 1-D Hec-Ras Model in Design of ChannelsDokument5 SeitenApplication of 1-D Hec-Ras Model in Design of ChannelsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNoch keine Bewertungen

- Is 7114 1973Dokument15 SeitenIs 7114 1973praveena61Noch keine Bewertungen

- Drainage in Dehradun CityDokument2 SeitenDrainage in Dehradun CityAchal GargNoch keine Bewertungen

- I J E S M: Nternational Ournal of Ngineering Ciences & AnagementDokument3 SeitenI J E S M: Nternational Ournal of Ngineering Ciences & AnagementAdithya DasNoch keine Bewertungen

- Is.6966.1.1989. Hydraulic Design Indian StandardDokument19 SeitenIs.6966.1.1989. Hydraulic Design Indian StandarderamitdhanukaNoch keine Bewertungen

- Bridges Failures in Extreme Flood EventsDokument10 SeitenBridges Failures in Extreme Flood EventsFinney WilsonNoch keine Bewertungen

- 2D Flood Simulation and Development of Flood Hazard Map by Using Hydraulic ModelDokument11 Seiten2D Flood Simulation and Development of Flood Hazard Map by Using Hydraulic ModelKIM ElsaNoch keine Bewertungen

- Environmental Impact Assessment Case Study ON Sardar Sarovar DamDokument18 SeitenEnvironmental Impact Assessment Case Study ON Sardar Sarovar Damsachin100% (2)

- Rubber Balloon Barrage Project Over The River TapiDokument27 SeitenRubber Balloon Barrage Project Over The River Tapinikunj64508Noch keine Bewertungen

- Fund A Metal of HydrologyDokument15 SeitenFund A Metal of Hydrologyelephant111Noch keine Bewertungen

- Tehri Ganga IrrigationDokument14 SeitenTehri Ganga Irrigationdmsouthasia100% (1)

- What Is My WorkDokument7 SeitenWhat Is My Workharshit kumawatNoch keine Bewertungen

- Ce12b1014 IgnpDokument19 SeitenCe12b1014 IgnpPremKumarNoch keine Bewertungen

- Ashish Yadav ReportDokument16 SeitenAshish Yadav ReportSatzya SiinghNoch keine Bewertungen

- IHS Report NikhilDokument10 SeitenIHS Report NikhilAditya SutarNoch keine Bewertungen

- NIH - SW - Hydrological Assessment of Ungauged CatchmentsDokument452 SeitenNIH - SW - Hydrological Assessment of Ungauged CatchmentsBalaji AngamuthuNoch keine Bewertungen

- Rain Water Harvesting Around Ramtek Area (Pertaining To Dudhala Lake)Dokument5 SeitenRain Water Harvesting Around Ramtek Area (Pertaining To Dudhala Lake)IJIERT-International Journal of Innovations in Engineering Research and TechnologyNoch keine Bewertungen

- Hydraulic Structures For Flow Diversion & StorageDokument30 SeitenHydraulic Structures For Flow Diversion & StorageIanleft9100% (1)

- Jodhpur Sewerage SystemDokument14 SeitenJodhpur Sewerage SystemKanishk BhattNoch keine Bewertungen

- What Is Dam ?Dokument23 SeitenWhat Is Dam ?Ashu PawarNoch keine Bewertungen

- Eia - Sigandhur BridgeDokument28 SeitenEia - Sigandhur BridgesathyamreNoch keine Bewertungen

- Ijett V47P253Dokument7 SeitenIjett V47P253SutrisnoNoch keine Bewertungen

- PTE 3 Week Study ScheduleDokument3 SeitenPTE 3 Week Study ScheduleesatjournalsNoch keine Bewertungen

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDokument7 SeitenAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsNoch keine Bewertungen

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDokument4 SeitenAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsNoch keine Bewertungen

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDokument6 SeitenAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsNoch keine Bewertungen

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFDokument6 SeitenAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsNoch keine Bewertungen

- A Servey On Wireless Mesh Networking ModuleDokument5 SeitenA Servey On Wireless Mesh Networking ModuleesatjournalsNoch keine Bewertungen

- A Review Paper On Smart Health Care System Using Internet of ThingsDokument5 SeitenA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNoch keine Bewertungen

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDokument9 SeitenA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsNoch keine Bewertungen

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDokument3 SeitenA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsNoch keine Bewertungen

- A Review On Fake Biometric Detection System For Various ApplicationsDokument4 SeitenA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNoch keine Bewertungen

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDokument6 SeitenA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNoch keine Bewertungen

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Dokument3 SeitenA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsNoch keine Bewertungen

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDokument8 SeitenA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNoch keine Bewertungen

- Module 10 Pipes in Series and Parallel Reservoir ProblemsDokument18 SeitenModule 10 Pipes in Series and Parallel Reservoir ProblemsAragones, Trisha Marie CNoch keine Bewertungen

- Types and Sizes of RebarsDokument17 SeitenTypes and Sizes of RebarsWyncie CariñoNoch keine Bewertungen

- Geon™ Vinyl Fittings M1000: Polyone CorporationDokument3 SeitenGeon™ Vinyl Fittings M1000: Polyone CorporationJames FaunceNoch keine Bewertungen

- Analisa Pekerjaan WaterproofingDokument2 SeitenAnalisa Pekerjaan WaterproofingNurfandy Dewanto100% (9)

- Flow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical StudyDokument6 SeitenFlow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical Studyho_afsharNoch keine Bewertungen

- Wall CladdingDokument24 SeitenWall CladdingRemya R. KumarNoch keine Bewertungen

- 40rr 2pDokument12 Seiten40rr 2pAlejandro Castillo100% (1)

- Rate - ErectionDokument1 SeiteRate - ErectionAnjum JauherNoch keine Bewertungen

- Geotech Report 520Dokument27 SeitenGeotech Report 520Ramakrishna RaoNoch keine Bewertungen

- Drilling Engineering Lab Funnel Viscosity Test: Experiment NO. 4Dokument8 SeitenDrilling Engineering Lab Funnel Viscosity Test: Experiment NO. 4Nasih AhmadNoch keine Bewertungen

- Drymet LFDokument6 SeitenDrymet LFHenrique SantosNoch keine Bewertungen

- Final Exam Ce 1351 PDFDokument1 SeiteFinal Exam Ce 1351 PDFJustine Joy De LeonNoch keine Bewertungen

- The Ritz-Carlton MEP April 18Dokument86 SeitenThe Ritz-Carlton MEP April 18yiuloi997023Noch keine Bewertungen

- Method Statement - FA Silo-12.69m LVLDokument5 SeitenMethod Statement - FA Silo-12.69m LVLArunkumarNoch keine Bewertungen

- Flare Boom Engineering - Failure - DrillSafeDokument11 SeitenFlare Boom Engineering - Failure - DrillSafeAndrey RogozhaNoch keine Bewertungen

- Fall 2014 Textbook Fall 2014Dokument2 SeitenFall 2014 Textbook Fall 2014Tabish IslamNoch keine Bewertungen

- Composite Floor - FlavsDokument5 SeitenComposite Floor - FlavszewilkNoch keine Bewertungen

- Module 1 Introduction To Civil EngineeeringDokument6 SeitenModule 1 Introduction To Civil EngineeeringMadhavan SowrirajanNoch keine Bewertungen

- Surface Vehicle Information: Rev. AUG2002Dokument29 SeitenSurface Vehicle Information: Rev. AUG2002Julio Herrera VenegasNoch keine Bewertungen

- T - Thermanit 22 - 09 - de - en - 5Dokument1 SeiteT - Thermanit 22 - 09 - de - en - 5brayanNoch keine Bewertungen

- W3 Deep FoundationDokument42 SeitenW3 Deep FoundationTeoh Zhi TongNoch keine Bewertungen

- Bridge Bearing Replacement Using Flat JacksDokument9 SeitenBridge Bearing Replacement Using Flat JacksKamal AlkurdiNoch keine Bewertungen

- 19 - Heating and Ventilating Systems - HVACDokument6 Seiten19 - Heating and Ventilating Systems - HVACJoshua EvansNoch keine Bewertungen

- Neptune Benson ANTI VORTEX PLATES Tech DataDokument1 SeiteNeptune Benson ANTI VORTEX PLATES Tech DatasyedahmedsabirNoch keine Bewertungen

- Design Calculations For The Dome Structure-Type 1Dokument6 SeitenDesign Calculations For The Dome Structure-Type 1msiddiq1100% (2)

- Pipelines 2015 - Recent Advances in Underground Pipeline Engineering and Construction - Proceedings of The Pipelines 2015 Conference, August 23-26, 2015, Baltimore, MarylandDokument1.935 SeitenPipelines 2015 - Recent Advances in Underground Pipeline Engineering and Construction - Proceedings of The Pipelines 2015 Conference, August 23-26, 2015, Baltimore, MarylandmabroukNoch keine Bewertungen

- Tabussum PDFDokument330 SeitenTabussum PDFMisael AlejandroNoch keine Bewertungen

- Design of Square Footing (With or Without Moment)Dokument13 SeitenDesign of Square Footing (With or Without Moment)Ella Clent moralesNoch keine Bewertungen

- Guide For Installing RTR Pipe Courtesy Bondstrand For InfoDokument4 SeitenGuide For Installing RTR Pipe Courtesy Bondstrand For InfoHafiz Ali Alvi100% (1)

- Combined & Separate Sewer SystemsDokument9 SeitenCombined & Separate Sewer SystemsKhairylle JuanNoch keine Bewertungen