Beruflich Dokumente

Kultur Dokumente

Gujarat Technological University

Hochgeladen von

falgunOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gujarat Technological University

Hochgeladen von

falgunCopyright:

Verfügbare Formate

GUJARAT TECHNOLOGICAL UNIVERSITY

MECHANICAL ENGINEERING (19)

DESIGN FOR MANUFACTURING AND ASSEMBLY

SUBJECT CODE: 2181921

B.E. 8TH SEMESTER

Type of course: Under Graduate

Prerequisite: NIL

Rationale: The Design for Manufacturing and assembly is challenging subject, the aim of present course is

to introduce and aware students about the basic design process which based on different aspects of

manufacturing as well assembly. Student will have idea about different criteria made on design such as

machining and casting. They also have knowledge on Environment factors.

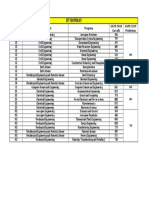

Teaching and Examination Scheme:

Teaching Scheme

T

P

Credits

C

Examination Marks

Theory Marks

Practical Marks

ESE

PA (M)

ESE (V)

PA

(E)

(I)

PA

ALA

ESE

OEP

70

20

10

30

0

20

Total

Marks

150

Content:

Sr.

No.

1

Content

Introduction:

General design principles for manufacturability: strength and

mechanical factors, mechanisms selection, evaluation method,

Process capability: Feature tolerances, Geometric tolerances,

Assembly limits, Datum features, and Tolerance stacks.

Factors Influencing form Design:

Working principle, Material, Manufacture, Design- Possible

solutions, Materials choice, Influence of materials on form

design, form design of Welded members, forgings and

castings.

Component Design-I:

Machining Consideration: Design features to facilitate

machining: drills, milling cutters, keyways, Doweling

procedures, counter sunk screws, Reduction of machined area,

simplification by separation, simplification by amalgamation,

Design for machinability, Design for economy, Design for

clampability, Design for accessibility, Design for assembly.

Component Design-II:

Casting Consideration: Redesign of castings based on parting

line considerations, Minimizing core requirements, machined

holes, redesign of cast members to obviate cores.

Identification of uneconomical design, Modifying the design,

group technology, Computer Applications for DFMA

Design for the Environment:

Introduction, Environmental objectives, Global issues,

Total

(Hours)

06

%

Weightage

15

08

15

10

25

10

25

10

20

Regional and local issues, Basic DFE methods, Design guide

lines, Example application, Lifecycle assessment, Basic

method, Environmentally responsible product assessment,

Weighted sum assessment method, Lifecycle assessment

method, Techniques to reduce environmental impact, Design

to minimize material usage, Design for disassembly, Design

for recyclability, Design for remanufacture, Design for energy

efficiency, Design to regulations and standards.

Total 44

100

Suggested Specification table with Marks (Theory):

Distribution of Theory Marks

R Level

U Level

5

10

A Level

20

N Level

20

E Level

5

C Level

10

Legends: R: Remembrance; U: Understanding; A: Application, N: Analyze and E: Evaluate C:

Create and above Levels (Revised Blooms Taxonomy)

Note: This specification table shall be treated as a general guideline for students and teachers. The actual

distribution of marks in the question paper may vary slightly from above table.

Reference Books:

1. Kevien Otto and Kristin Wood, Product Design. Pearson Publication, 2004.

2. Product design and development, by K.T. Ulrich and S.D. Eppinger, Tata McGraw Hill

3. Boothroyd, G, 1980 Design for Assembly Automation and Product Design. New York, Marcel

Dekker.

4. Bralla, Design for Manufacture handbook, McGraw Hill, 1999.

5. Boothroyd, G, Heartz and Nike, Product Design for Manufacture, Marcel Dekker, 1994.

6. Dickson, John. R, and Corroda Poly, Engineering Design and Design for Manufacture and

Structural Approach, Field Stone Publisher, USA, 1995.

7. Fixel, J. Design for the Environment McGraw Hill., 1996.

8. Graedel T. Allen By. B, Design for the Environment Angle Wood Cliff, Prentice Hall. Reason

Pub.1996.

Course Outcome:

1. Students will have knowledge on design principles for manufacturability

2. Students will have knowledge Influencing factors on Design.

3. Students will have knowledge on Machining consideration while design.

4. Students will have knowledge on casting consideration while design.

5. Students will have knowledge on environment consideration while design.

6. Students will have ability to understand contemporary issues and their impact on design for

manufacturing and assembly.

List of Experiments:

1.

2.

3.

4.

5.

6.

Study and report on design principles for manufacturability

Study and report Influencing factors on Design.

Case study on Machining consideration

Case study on casting consideration

Case study on Life cycle assessment of product.

Case study on Environmental Aspects on Design of Product

Design based Problems (DP)/Open Ended Problem:

Case problems of design of product on different issues like: Machining, casting and Environment

List of Open Source Software/learning website:

http://www.nptel.ac.in

http://www.ocw.mit.edu

ACTIVE LEARNING ASSIGNMENTS: Preparation of power-point slides/Canvases/Drawing sheets

with different color pens for graphical representation of for better understanding theory and practical work

The faculty will allocate chapters/ parts of chapters to groups of students so that the entire syllabus to be

covered. The power-point slides should be put up on the web-site of the College/ Institute, along with the

names of the students of the group, the name of the faculty, Department and College on the first slide. The

best three works should submit to GTU.

Das könnte Ihnen auch gefallen

- J.B. Institute of Engineering and Technology: Course Code: C322 Finite Element MethodDokument82 SeitenJ.B. Institute of Engineering and Technology: Course Code: C322 Finite Element MethodGopinath GangadhariNoch keine Bewertungen

- EWY 100S Subject GuideDokument6 SeitenEWY 100S Subject GuideWilly K. Ng'etichNoch keine Bewertungen

- ME-406 Manufacturing and DesignDokument2 SeitenME-406 Manufacturing and DesignFaraz JamshaidNoch keine Bewertungen

- Vessel Fabrication Manual PDFDokument49 SeitenVessel Fabrication Manual PDFwalyat100% (2)

- Fabrication & Welding - Basic PrinciplesDokument49 SeitenFabrication & Welding - Basic Principlesjayapandis83100% (1)

- Chemical Process Plant Design and EconomicsDokument3 SeitenChemical Process Plant Design and Economics2020001873.gcetNoch keine Bewertungen

- Ed PDFDokument37 SeitenEd PDFStephen.KNoch keine Bewertungen

- Course File ContentDokument6 SeitenCourse File Contentswapnil kaleNoch keine Bewertungen

- Subject Description Form: Subject Code Subject Title Credit Value Level Pre-requisite/Co-requisite/Exclusion ObjectivesDokument3 SeitenSubject Description Form: Subject Code Subject Title Credit Value Level Pre-requisite/Co-requisite/Exclusion Objectiveschriswong2005Noch keine Bewertungen

- Assignment Brief-ENG2005 - (20-21)Dokument15 SeitenAssignment Brief-ENG2005 - (20-21)Ahmed ShaikhNoch keine Bewertungen

- CS10-1L SyllabusDokument6 SeitenCS10-1L SyllabusakladffjaNoch keine Bewertungen

- Industrial Course SyllabiDokument81 SeitenIndustrial Course SyllabiIbrahim AlhowaishNoch keine Bewertungen

- Outcome Based Engineering EducationDokument31 SeitenOutcome Based Engineering EducationfaridkhanNoch keine Bewertungen

- Cse205Dokument25 SeitenCse205Aman SinghNoch keine Bewertungen

- Gujarat Technological University: Design For Manufacturing and Assembly SUBJECT CODE:3710810Dokument2 SeitenGujarat Technological University: Design For Manufacturing and Assembly SUBJECT CODE:3710810Kartik ChauhanNoch keine Bewertungen

- Introduction To Engineering Design and Problem SolvingDokument244 SeitenIntroduction To Engineering Design and Problem SolvingVal RibeiroNoch keine Bewertungen

- Vausdha 2022-23 CircularDokument4 SeitenVausdha 2022-23 CircularAryanNoch keine Bewertungen

- Ideas To Consider For New Chemical Engineering Educators Senior DesignDokument11 SeitenIdeas To Consider For New Chemical Engineering Educators Senior DesignKaleab AndualemNoch keine Bewertungen

- Gujarat Technological University: W.E.F. AY 2018-19Dokument3 SeitenGujarat Technological University: W.E.F. AY 2018-19Pradeep SutharNoch keine Bewertungen

- Optimization TechniquesDokument3 SeitenOptimization Techniques2020001873.gcetNoch keine Bewertungen

- CHME 4703 SP2012 SyllabusDokument9 SeitenCHME 4703 SP2012 SyllabusFrank PiccirilloNoch keine Bewertungen

- Subject Description Form: Subject Code Subject Title Credit Value Level Pre-Requisite/ Co-Requisite/ ExclusionDokument89 SeitenSubject Description Form: Subject Code Subject Title Credit Value Level Pre-Requisite/ Co-Requisite/ ExclusionAnonymous 37PvyXCNoch keine Bewertungen

- Mp482 Product Development and Design (Careeryuga)Dokument2 SeitenMp482 Product Development and Design (Careeryuga)Subahani HaneefaNoch keine Bewertungen

- Gujarat Technological University: W.E.F. AY 2018-19Dokument3 SeitenGujarat Technological University: W.E.F. AY 2018-19Hardik SonvaneNoch keine Bewertungen

- ME493 - Special Topics in Materials and ManufacturingDokument2 SeitenME493 - Special Topics in Materials and ManufacturingFaraz JamshaidNoch keine Bewertungen

- Visvesvaraya Technological University, BelgaumDokument41 SeitenVisvesvaraya Technological University, BelgaumBen GeorgeNoch keine Bewertungen

- Become What You Want To Be: Unit GuideDokument6 SeitenBecome What You Want To Be: Unit GuideMq SharozNoch keine Bewertungen

- Design and Fabrication Project: L T P CDokument18 SeitenDesign and Fabrication Project: L T P CNellai RagulNoch keine Bewertungen

- An Integrated Concept To Prototype Capstone Design ExperienceDokument14 SeitenAn Integrated Concept To Prototype Capstone Design ExperienceKent DanielNoch keine Bewertungen

- Assessing Abet Outcomes Using Capstone Design CoursesDokument20 SeitenAssessing Abet Outcomes Using Capstone Design CoursesKaren Vanessa Castro MolinaNoch keine Bewertungen

- BMM 4623 Mechanical System Design - Rev01 July 31, 2013Dokument6 SeitenBMM 4623 Mechanical System Design - Rev01 July 31, 2013huszsNoch keine Bewertungen

- Eastern Mediterranean University Department of Industrial Engineering IENG484/MANE484 Quality Engineering Spring 2019-2020 Course OutlineDokument3 SeitenEastern Mediterranean University Department of Industrial Engineering IENG484/MANE484 Quality Engineering Spring 2019-2020 Course OutlineIlkin JafarovNoch keine Bewertungen

- Dmm-I Course File 2015Dokument56 SeitenDmm-I Course File 2015VeerendraChitturiNoch keine Bewertungen

- Certificate Level Stage II SyllabiDokument19 SeitenCertificate Level Stage II SyllabiAnuradha RumeshNoch keine Bewertungen

- Ppce SyllabusDokument3 SeitenPpce SyllabusVpr NaturalsNoch keine Bewertungen

- Module DDM 4214 - Design and Development 1Dokument2 SeitenModule DDM 4214 - Design and Development 1Kashyap SorathiyaNoch keine Bewertungen

- Tec Nyscate Design For ManufactureDokument43 SeitenTec Nyscate Design For ManufacturetnchsgNoch keine Bewertungen

- EE305 Course Project - Spring 2023Dokument8 SeitenEE305 Course Project - Spring 2023khan aliNoch keine Bewertungen

- MA2004 Engineering Materials and Manufacturing Processes 23082021Dokument7 SeitenMA2004 Engineering Materials and Manufacturing Processes 23082021Aloysius TobiasNoch keine Bewertungen

- ENGR 101 Syllabus Spring 2013 2014Dokument4 SeitenENGR 101 Syllabus Spring 2013 2014alishehadehNoch keine Bewertungen

- Production Drawing Practice Lab ManualDokument52 SeitenProduction Drawing Practice Lab ManualoutlanderNoch keine Bewertungen

- BCS Course SyllabusDokument65 SeitenBCS Course SyllabuskasunNoch keine Bewertungen

- Syllabus F 23Dokument4 SeitenSyllabus F 23Mrwan ThabetNoch keine Bewertungen

- Vardhaman College of Engineering: (Autonomous)Dokument20 SeitenVardhaman College of Engineering: (Autonomous)SureshKumar550Noch keine Bewertungen

- Engineering Design SyllabusDokument49 SeitenEngineering Design SyllabusanandandmeenaNoch keine Bewertungen

- Seider (2015) - Guide To Teaching Design With Internet Links - 3rd EdDokument64 SeitenSeider (2015) - Guide To Teaching Design With Internet Links - 3rd Edvazzoleralex6884Noch keine Bewertungen

- CHE 425 622 F15 Intro SheetDokument4 SeitenCHE 425 622 F15 Intro SheetjohnNoch keine Bewertungen

- ME3450 Syllabus 2011 Fall v3Dokument7 SeitenME3450 Syllabus 2011 Fall v3petkirstNoch keine Bewertungen

- CAD Lab Course File 2019-20 (RTU OLD)Dokument58 SeitenCAD Lab Course File 2019-20 (RTU OLD)sandeep kumar kumawatNoch keine Bewertungen

- Course Syllabus: Cebu Technological University Ctu-Main CampusDokument5 SeitenCourse Syllabus: Cebu Technological University Ctu-Main CampusRicson BondadNoch keine Bewertungen

- CHE 482 Chemical Process Design II - Tentative Syllabus - AYMDokument8 SeitenCHE 482 Chemical Process Design II - Tentative Syllabus - AYMLarry WhitleyNoch keine Bewertungen

- Syllabus CIMDokument72 SeitenSyllabus CIMArUnIzzSrkNoch keine Bewertungen

- Important Notice: Design and Technology 6043 GCE O Level 2007Dokument16 SeitenImportant Notice: Design and Technology 6043 GCE O Level 2007mstudy123456Noch keine Bewertungen

- Electrical Measurements and Instrumentation KG ReddyDokument158 SeitenElectrical Measurements and Instrumentation KG Reddyabhaymehta67Noch keine Bewertungen

- Course Outline - Plant Design Project SKKK 4824 1415-2Dokument7 SeitenCourse Outline - Plant Design Project SKKK 4824 1415-2Firdaus AzizanNoch keine Bewertungen

- DFMDokument7 SeitenDFMaraz_1985Noch keine Bewertungen

- B48BE Student Guide v2Dokument26 SeitenB48BE Student Guide v2Farid AliyevNoch keine Bewertungen

- The Exam Will Come From Handouts, Power Point Presentations, Notes, Home Works, and Class ActivitiesDokument11 SeitenThe Exam Will Come From Handouts, Power Point Presentations, Notes, Home Works, and Class Activitiesapi-270387817Noch keine Bewertungen

- EeescehemeDokument4 SeitenEeescehemebharathgkNoch keine Bewertungen

- 2013-2014 Eee Consoldate 9.10.2014Dokument448 Seiten2013-2014 Eee Consoldate 9.10.2014satish reddyNoch keine Bewertungen

- JVD Verfication Students For Six Step ValidationDokument3 SeitenJVD Verfication Students For Six Step ValidationBOPPAIPURAM SACHIVALAYAMNoch keine Bewertungen

- Engineering Management - Activity 1 - Reaction PaperDokument4 SeitenEngineering Management - Activity 1 - Reaction PaperMoises BuenafeNoch keine Bewertungen

- Application LetterDokument2 SeitenApplication LetterJhay-ar MiguelNoch keine Bewertungen

- FINAL School of Engineering 2014Dokument84 SeitenFINAL School of Engineering 2014Nimra Naveed ShaikhNoch keine Bewertungen

- Selection of Material Handling EquipmentDokument6 SeitenSelection of Material Handling EquipmentAkif ZubairNoch keine Bewertungen

- Software Engineering - Unit - 1Dokument22 SeitenSoftware Engineering - Unit - 1Naveen IdxNoch keine Bewertungen

- A PJ Abdul Kal Am Technological UniversityDokument1 SeiteA PJ Abdul Kal Am Technological UniversityManoj Ravindranath0% (1)

- Wenzel Shapetracer GB 01 20ab11Dokument1 SeiteWenzel Shapetracer GB 01 20ab11irinaNoch keine Bewertungen

- Inplant Training Companies For Cse Students in TrichyDokument2 SeitenInplant Training Companies For Cse Students in TrichyshreesiddhiNoch keine Bewertungen

- Application of Costing System in The Small and Medium Sized Enterprises (SME) in TurkeyDokument1 SeiteApplication of Costing System in The Small and Medium Sized Enterprises (SME) in TurkeySantosh DeshpandeNoch keine Bewertungen

- Philoshopy of Science DesaisdmDokument6 SeitenPhiloshopy of Science DesaisdmDesa Ikhlas ShoburoNoch keine Bewertungen

- Engineering ManagementDokument36 SeitenEngineering ManagementAllysa Marie Cabral100% (2)

- Development of Low-Cost Portable Hand Exoskeleton For Assistive and Rehabilitation PurposesDokument14 SeitenDevelopment of Low-Cost Portable Hand Exoskeleton For Assistive and Rehabilitation Purposesgil lerNoch keine Bewertungen

- Iit Bombay PDFDokument1 SeiteIit Bombay PDFJainam JoshiNoch keine Bewertungen

- Engineer N Society SlideDokument22 SeitenEngineer N Society SlideMohd ShafiqNoch keine Bewertungen

- Mechanical CADD CourseDokument8 SeitenMechanical CADD CourseCadd CentreNoch keine Bewertungen

- Space Agencies & Research InstitutesDokument5 SeitenSpace Agencies & Research InstitutesMeera Priyaa0% (1)

- SQL Exercises Using The Postgresql DbmsDokument15 SeitenSQL Exercises Using The Postgresql DbmsSteliosDoumasNoch keine Bewertungen

- Daftar PustakaDokument2 SeitenDaftar PustakadamayNoch keine Bewertungen

- Jurnal Indonesia Terindeks WoSDokument22 SeitenJurnal Indonesia Terindeks WoSIslahuddinNoch keine Bewertungen

- Pakistan Science Innovation ReviewDokument139 SeitenPakistan Science Innovation ReviewTayyab HussainNoch keine Bewertungen

- Electrical Engineer PLC Programmer in Greenville Spartanburg SC Resume James WasnessDokument1 SeiteElectrical Engineer PLC Programmer in Greenville Spartanburg SC Resume James WasnessJamesWasnessNoch keine Bewertungen

- Introduction To Optimization: MIT and James Orlin ©2003 1Dokument39 SeitenIntroduction To Optimization: MIT and James Orlin ©2003 1john tylerNoch keine Bewertungen

- Analisis Kemampuan Koneksi Matematis Berdasarkan NCTM (National Council of Teachers of Mathematics) Siswa SMK Kelas Xi Jurusan Multimedia Pada Pokok Bahasan Hubungan Antar GarisDokument9 SeitenAnalisis Kemampuan Koneksi Matematis Berdasarkan NCTM (National Council of Teachers of Mathematics) Siswa SMK Kelas Xi Jurusan Multimedia Pada Pokok Bahasan Hubungan Antar GarisChoi HyunsukNoch keine Bewertungen

- Dbms Unit 4.2Dokument60 SeitenDbms Unit 4.2X BoyNoch keine Bewertungen

- LabVIEW BrochureDokument8 SeitenLabVIEW Brochuremaxellligue5487Noch keine Bewertungen

- Resume Eng Yalitza Torres Perez-2016Dokument1 SeiteResume Eng Yalitza Torres Perez-2016rocollNoch keine Bewertungen

- A Method For Analysing Delay Duration Considering Lost Productivity Through Construction Productivity Data ModelDokument9 SeitenA Method For Analysing Delay Duration Considering Lost Productivity Through Construction Productivity Data ModelAnonymous p2cFoXbjDNoch keine Bewertungen