Beruflich Dokumente

Kultur Dokumente

Fulflo S Series Asme Code Filter Vessels

Hochgeladen von

Mario RendonOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fulflo S Series Asme Code Filter Vessels

Hochgeladen von

Mario RendonCopyright:

Verfügbare Formate

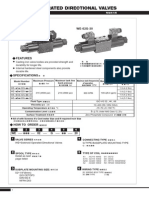

C-3070

Fulflo S Filter Vessels

Fulflo S Series ASME Code

Filter Vessels

Fulflo S Series Multi-Cartridge Filter

Vessels meet a broad range of liquid

and gas applications for flow rates up

to 2,040 gpm (7,720 lpm). All details

of design, materials, construction and

workmanship of the S vessel series

conform to ASME code.

The S Vessel Series accommodates

double-open-end (DOE) or singleopen-end (SOE) filter cartridges in

10 in, 20 in, 30 in and 40 in equivalents.

Benefits

Built in accordance with ASME boiler

and pressure vessel code

Available in 150 psi (10.3 bar) and

300 psi (20.7 bar) designs

Non-code design and construction

(parallel to code standards) available

Mechanical coverlifts standard on

most models

S85 and S102 feature hydraulic

coverlifts (available on all models as

an option)

Dual purpose cartridge seats for use

with double open end and 2-222

O-ring single open end cartridges

Buna-N O-ring closure seal provides

positive cover sealing.

Viton* elastomer, neoprene, ethylene

propylene rubber and fluoropolymer

elastomer O-rings are also available

for temperatures up to 500F (261C)

All S models feature swing bolts

with closures for quick cleaning and

servicing

Accepts double-open-end (DOE) or

single-open-end (SOE) cartridges

Applications

Liquid

Gas

Food & Beverage

Chemical Processes

Petrochemical

Paints & Coatings

Industrial

ENGINEERING YOUR SUCCESS.

125

Fulflo S Filter Vessels

150 psi (10.3 bar) Design Specifications

No. & Length Maximum Dimensions

Shipping

Model

of Cartridges Flow A

B

C

D

E

F

G

H

J

Weight

(in)

(gpm)

(lbs)

S25-3-4F

S25-4-6F

S35-3-4F

S35-3-6F

S35-4-6F

S40-3-6F

S52-3-4F

S52-3-6F

S52-4-8F

S85-3-8F

S85-4-8F

S102-3-8F

S102-4-8F

(25) 30

(25) 40

(35) 30

(35) 30

(35) 40

(40) 30

(52) 30

(52) 30

(52) 40

(85) 30

(85) 40

(102) 30

(102) 40

375

500

525

525

700

600

780

780

1040

1275

1700

1530

2040

55.88

69.75

58.19

58.19

68.25

60.25

63.69

63,69

73.69

67.25

73.63

68.63

79.94

26.00

26.00

29.25

29.25

29.25

30.75

33.38

33.38

33.38

39.75

39.75

42.25

42.25

18.06

18.06

20.06

20.06

20.06

22.06

24.06

24.06

24.06

30.06

30.06

32.06

32.06

15.50

16.50

16.50

16.50

16.50

18.00

20.50

20.50

20.50

24.00

24.00

23.63

23.63

28

31

31

31

31

32

34

34

34

40

40

41.25

41.25

5

5

5

5

5

5

5

5

5

6

6

6

6

20.44

22.25

22.56

22.56

22.56

23.31

27.56

27.56

27.56

31.50

31.50

31.69

31.69

17.76

17.76

19.77

19.77

19.77

21.70

23.72

23.72

23.72

29.81

29.81

31.81

31.81

4

6

4

6

6

6

4

6

6

8

8

8

8

515

540

640

645

695

810

855

865

900

1170

1200

1450

1600

Add 5 in to this dimension for hydraulic coverlift.

Inlet and outlet size standard ASA flanges.

Maximum Operating Conditions

Material of

Construction

Maximum Operating

Maximum Design

Pressure (psi at 250F) Temperature

Carbon Steel

Carbon Steel

304 Stainless Steel

304 Stainless Steel

316 Stainless Steel

316 Stainless Steel

150 psi (10.3 bar)

300 psi (20.7 bar)

150 psi (10.3 bar)

300 psi (20.7 bar)

150 psi (10.3 bar)

300 psi (20.7 bar)

500F (260C)

500F (260C)

300F (150C)

300F (150C)

400F (204C)

400F (204C)

Operating temperature limited by standard gasket material

and exterior paint.

Ordering Information

Material

Design Series

Number of Columns

Cartridge Length (in)

No Symbol = Carbon Steel

4 = 304 Stainless Steel

6 = 316 Stainless Steel

HS = High Pressure

CS = Non-Code

25

35

40

52

85

102

3 30

4 = 40

Specifications are subject to change without notification.

*Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

Inlet/Outlet

Flange Size

4F = 4 in Flange

6F = 6 in Flange

8F = 8 in Flange

Coverlift Option

K1= Mechanical

K2 = Hydraulic

2007 Parker Hannifin

Process Advanced Filtration Inc.

All Rights Reserved

SPEC-C3070-Rev. A 01/08

ENGINEERING YOUR SUCCESS.

126

Das könnte Ihnen auch gefallen

- Halton fdb2Dokument4 SeitenHalton fdb2sbalan6949Noch keine Bewertungen

- MasterSeries 850 Specification SheetDokument2 SeitenMasterSeries 850 Specification SheetFEBCONoch keine Bewertungen

- L&T Gate Globe Check Valves API 602Dokument12 SeitenL&T Gate Globe Check Valves API 602Nilesh MistryNoch keine Bewertungen

- DeZURIK KCG Knife Gate ValvesDokument12 SeitenDeZURIK KCG Knife Gate ValvesKithkarnonNoch keine Bewertungen

- SAIL PRODUCT CATALOGUE 2010Dokument64 SeitenSAIL PRODUCT CATALOGUE 2010chandan139Noch keine Bewertungen

- 100G - 2100G ClavalDokument2 Seiten100G - 2100G Clavale1901bNoch keine Bewertungen

- Virgo Welded Valve BrochureDokument8 SeitenVirgo Welded Valve BrochureHerrera Jorge AgustínNoch keine Bewertungen

- Model 2100bDokument4 SeitenModel 2100bkeyur1109Noch keine Bewertungen

- High-Tech Block & Bleed ValvesDokument20 SeitenHigh-Tech Block & Bleed ValvesMayur PatelNoch keine Bewertungen

- TrelleborgDokument10 SeitenTrelleborgrofiqq4Noch keine Bewertungen

- BAGFLODokument68 SeitenBAGFLOAlicia ViridianaNoch keine Bewertungen

- Ansul Wheeled RedLine 150lb F-2002046Dokument4 SeitenAnsul Wheeled RedLine 150lb F-2002046German Duvan HernandezNoch keine Bewertungen

- EBARA Catalogue Fire PumpDokument14 SeitenEBARA Catalogue Fire PumpVanja Ivkovic100% (2)

- Cylinder and Container GuideDokument12 SeitenCylinder and Container GuideClaudio SantellanesNoch keine Bewertungen

- Valve Ari ArmaturenDokument16 SeitenValve Ari ArmaturenReza TambaNoch keine Bewertungen

- Check Horizontal PDFDokument2 SeitenCheck Horizontal PDFJorge CarionNoch keine Bewertungen

- ES B MarineDeckPenetrationsDokument2 SeitenES B MarineDeckPenetrationsBLUCHERNoch keine Bewertungen

- 13 - Solenoid Operated Directional Valve WE-SNSDokument16 Seiten13 - Solenoid Operated Directional Valve WE-SNSNookang SeaSunNoch keine Bewertungen

- 8200 8300 SRV CatalogDokument12 Seiten8200 8300 SRV CatalogwzuniniNoch keine Bewertungen

- BUL Marine 3000 - 0409Dokument4 SeitenBUL Marine 3000 - 0409Muhammad FerialNoch keine Bewertungen

- Rock Drilling Tools for Contractors and CorporationsDokument2 SeitenRock Drilling Tools for Contractors and CorporationsRonald OsorioNoch keine Bewertungen

- Tuberia Fibra de VidrioDokument0 SeitenTuberia Fibra de VidrioFernando Reyes GomezNoch keine Bewertungen

- Red Line Wheeled Extinguisher MODELS 150-D, 350-D: Data/SpecificationsDokument4 SeitenRed Line Wheeled Extinguisher MODELS 150-D, 350-D: Data/SpecificationsDnyaneshwarNoch keine Bewertungen

- Ss 01059 eDokument8 SeitenSs 01059 eDavid LapacaNoch keine Bewertungen

- GWC Valve International - Forged Steel Gate, Globe, and Check ValvesDokument28 SeitenGWC Valve International - Forged Steel Gate, Globe, and Check ValvesGWC Valve InternationalNoch keine Bewertungen

- Faslt 0020 enDokument6 SeitenFaslt 0020 enshashikanth79Noch keine Bewertungen

- Class 2500 Ball Valve Technical SpecsDokument4 SeitenClass 2500 Ball Valve Technical SpecsrsaimaheshNoch keine Bewertungen

- AAP S18 Butterfly Valves E2 SDokument9 SeitenAAP S18 Butterfly Valves E2 SPete KardumNoch keine Bewertungen

- fdb2 - Fire and Damper PDFDokument4 Seitenfdb2 - Fire and Damper PDFcandratrikusumaNoch keine Bewertungen

- Full Lift Spring Loaded Open PDFDokument4 SeitenFull Lift Spring Loaded Open PDFVenkatespatange RaoNoch keine Bewertungen

- Ball Valves - Metal SeatedDokument6 SeitenBall Valves - Metal Seatedmetasoniko2014Noch keine Bewertungen

- ASV 10 20 BrochureDokument8 SeitenASV 10 20 BrochureThomas Duane DavidsonNoch keine Bewertungen

- AL-BL Rotary Valve PDFDokument6 SeitenAL-BL Rotary Valve PDFIvanNoch keine Bewertungen

- CAST STEEL GATE VALVES UNDER 40 CHARACTERSDokument4 SeitenCAST STEEL GATE VALVES UNDER 40 CHARACTERSsghinausNoch keine Bewertungen

- Camara AnsulDokument4 SeitenCamara AnsulLuis del BarcoNoch keine Bewertungen

- Control Choke Valve 9000Dokument8 SeitenControl Choke Valve 9000sabi_shi100% (2)

- % Lighter: Air CylinderDokument34 Seiten% Lighter: Air CylinderRuri ApridianoNoch keine Bewertungen

- Dryplus 3Dokument10 SeitenDryplus 3sallehasanNoch keine Bewertungen

- Descote 2100BDokument4 SeitenDescote 2100BarrikanNoch keine Bewertungen

- Double Block Bleed TOSVDokument8 SeitenDouble Block Bleed TOSVplanet123Noch keine Bewertungen

- Bell & Gossett SuctionDiffusersDokument4 SeitenBell & Gossett SuctionDiffusersAnonymous 7xHNgoKE6eNoch keine Bewertungen

- Series 805YD Specification SheetDokument2 SeitenSeries 805YD Specification SheetFEBCONoch keine Bewertungen

- Solenoid Select ChartDokument47 SeitenSolenoid Select Chartسامح الجاسمNoch keine Bewertungen

- Es A Acv 605GS 605asDokument3 SeitenEs A Acv 605GS 605asWattsNoch keine Bewertungen

- About Axial Displacement Pump A4VSoDokument68 SeitenAbout Axial Displacement Pump A4VSomrkadu_61Noch keine Bewertungen

- Vctds-02233 Model 171c (Asme) - enDokument12 SeitenVctds-02233 Model 171c (Asme) - enDGWNoch keine Bewertungen

- Kitz Gate ValveDokument28 SeitenKitz Gate ValvemohamedfirozNoch keine Bewertungen

- Kit 11011Dokument28 SeitenKit 11011Reza VakilNoch keine Bewertungen

- Forged Steel Valves PDFDokument12 SeitenForged Steel Valves PDFDiwakar NigamNoch keine Bewertungen

- KGV Bi MDokument3 SeitenKGV Bi MArmando Palacios EscuderoNoch keine Bewertungen

- Basket StrainersDokument15 SeitenBasket StrainersYarlagadda Harsha VardhanNoch keine Bewertungen

- Flowserve Lined Flush BottomDokument32 SeitenFlowserve Lined Flush BottomDevdatt WaghuleNoch keine Bewertungen

- Pqs BC 150 Lbs Con Ruedas MODELO 150-C PDFDokument4 SeitenPqs BC 150 Lbs Con Ruedas MODELO 150-C PDFtremendousNoch keine Bewertungen

- Pqs BC 150 Lbs Con Ruedas MODELO 150-CDokument4 SeitenPqs BC 150 Lbs Con Ruedas MODELO 150-CtremendousNoch keine Bewertungen

- High-Performance GM LS-Series Cylinder Head GuideVon EverandHigh-Performance GM LS-Series Cylinder Head GuideBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Southern Marine Engineering Desk Reference: Second Edition Volume IVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INoch keine Bewertungen

- ENG Planche Workout Sample - PDF by Andrea LarosaDokument6 SeitenENG Planche Workout Sample - PDF by Andrea LarosaMario Rendon100% (1)

- Calisthenics Muscle Building ProgramDokument6 SeitenCalisthenics Muscle Building ProgramKaMcIaK 1997100% (3)

- BeyondX RepDokument114 SeitenBeyondX RepRicardo E Arrieta CNoch keine Bewertungen

- King of Weighted Calisthenics Test DayDokument3 SeitenKing of Weighted Calisthenics Test DayMario RendonNoch keine Bewertungen

- Stevereevesinspiredworkout 1Dokument1 SeiteStevereevesinspiredworkout 1Mario RendonNoch keine Bewertungen

- BODYWEIGHT BODYBUILDING by Alexander IronDokument26 SeitenBODYWEIGHT BODYBUILDING by Alexander IronMario Rendon100% (1)

- 50 High Calorie Meal RecipesDokument51 Seiten50 High Calorie Meal RecipesMario Rendon100% (1)

- BodyweightTraining PlanDokument14 SeitenBodyweightTraining PlanMario RendonNoch keine Bewertungen

- Progressions Bae-Sic: Strength Standards and Progressions For Basic Ring & Bodyweight MovementsDokument21 SeitenProgressions Bae-Sic: Strength Standards and Progressions For Basic Ring & Bodyweight MovementsMario Rendon100% (1)

- Custom Calisthenics Program Michael WoerdmanDokument19 SeitenCustom Calisthenics Program Michael WoerdmanMurat KadayıfçıNoch keine Bewertungen

- Daisy Ridley 0Dokument1 SeiteDaisy Ridley 0Mario Rendon100% (1)

- Scottherman 0 PDFDokument1 SeiteScottherman 0 PDFMario RendonNoch keine Bewertungen

- Calisthenics 30 Minutes To Ripped - Get Your Dream Body Fast With Body Weight Exercises Today by Cathy HarwellDokument45 SeitenCalisthenics 30 Minutes To Ripped - Get Your Dream Body Fast With Body Weight Exercises Today by Cathy HarwellMario Rendon100% (1)

- 40 High Calorie Shakes and SmoothiesDokument25 Seiten40 High Calorie Shakes and SmoothiesMario RendonNoch keine Bewertungen

- Hybrid Leave The Gym Behind PDFDokument18 SeitenHybrid Leave The Gym Behind PDFMario RendonNoch keine Bewertungen

- Adoniscreedinspired PDFDokument1 SeiteAdoniscreedinspired PDFMario Rendon100% (1)

- The Tools You Need To Build The Body You Want: Paul Rudd Inspired Workout: Over 40 & Ripped Like The Ant-ManDokument1 SeiteThe Tools You Need To Build The Body You Want: Paul Rudd Inspired Workout: Over 40 & Ripped Like The Ant-ManMario RendonNoch keine Bewertungen

- Davebautista PDFDokument1 SeiteDavebautista PDFMario RendonNoch keine Bewertungen

- Tom Hardy Inspired Work OutDokument1 SeiteTom Hardy Inspired Work OutMario RendonNoch keine Bewertungen

- Dumbbell Barbell HomeDokument1 SeiteDumbbell Barbell HomeMario RendonNoch keine Bewertungen

- Workoutsforwomen2bodyweightcircuits PDFDokument1 SeiteWorkoutsforwomen2bodyweightcircuits PDFMario RendonNoch keine Bewertungen

- Brielarsoninspiredworkout 0Dokument1 SeiteBrielarsoninspiredworkout 0Mario RendonNoch keine Bewertungen

- Frankdumbbellonly PDFDokument1 SeiteFrankdumbbellonly PDFMario RendonNoch keine Bewertungen

- The Tools You Need To Build The Body You Want: 4 Week Complete Kettlebell Ab & Core WorkoutDokument1 SeiteThe Tools You Need To Build The Body You Want: 4 Week Complete Kettlebell Ab & Core WorkoutMario RendonNoch keine Bewertungen

- Drop 5 System: 4 Day Home Muscle Building Plan: The Tools You Need To Build The Body You WantDokument1 SeiteDrop 5 System: 4 Day Home Muscle Building Plan: The Tools You Need To Build The Body You WantMario RendonNoch keine Bewertungen

- The Tools You Need To Build The Body You Want: Field Manual: A Training Guide For Those With Little Time & EquipmentDokument1 SeiteThe Tools You Need To Build The Body You Want: Field Manual: A Training Guide For Those With Little Time & EquipmentMario RendonNoch keine Bewertungen

- 6 Exercise Home Dumbbell LegsDokument1 Seite6 Exercise Home Dumbbell LegsMario RendonNoch keine Bewertungen

- Core Strength Fat BurnDokument1 SeiteCore Strength Fat BurnMario RendonNoch keine Bewertungen

- Faststart3dayhomekettlebellwomen PDFDokument1 SeiteFaststart3dayhomekettlebellwomen PDFMario RendonNoch keine Bewertungen

- Take It To The StairsDokument1 SeiteTake It To The StairsMario RendonNoch keine Bewertungen

- November 2017 (v1) QP - Paper 4 CIE Chemistry IGCSEDokument16 SeitenNovember 2017 (v1) QP - Paper 4 CIE Chemistry IGCSEGhulam Mehar Ali ShahNoch keine Bewertungen

- Bearing From Copper AlloyDokument7 SeitenBearing From Copper AlloyPhung Tuan AnhNoch keine Bewertungen

- CCUS technologies activities in France: Focus on industriesDokument21 SeitenCCUS technologies activities in France: Focus on industriesGaurav MishraNoch keine Bewertungen

- Hawaii Hotel Performance by WeekDokument1 SeiteHawaii Hotel Performance by WeekHonolulu Star-AdvertiserNoch keine Bewertungen

- Schools Division of Roxas CityDokument4 SeitenSchools Division of Roxas CityHuge Propalde EstolanoNoch keine Bewertungen

- Module 1Dokument3 SeitenModule 1Anonymous jhhtrnfNoch keine Bewertungen

- Processing Cacao Pod Husk into Low-Methoxyl PectinDokument9 SeitenProcessing Cacao Pod Husk into Low-Methoxyl PectinEmmanuel PlazaNoch keine Bewertungen

- Payslip 11 2020Dokument1 SeitePayslip 11 2020Sk Sameer100% (1)

- Doble M4000 User GuideDokument204 SeitenDoble M4000 User GuidePablo Toro Lopez100% (1)

- Experimental Animals Used in Pharmacology: RabbitDokument8 SeitenExperimental Animals Used in Pharmacology: RabbitDAMBALENoch keine Bewertungen

- Methyldopa Drug DataDokument3 SeitenMethyldopa Drug DataLaurel Joshua Reyes DauzNoch keine Bewertungen

- Discipline and Ideas in Applied Social Science Quarter 1 - Module 5: The Clientele and Audiences in Counseling and The Counseling ProcessesDokument17 SeitenDiscipline and Ideas in Applied Social Science Quarter 1 - Module 5: The Clientele and Audiences in Counseling and The Counseling ProcessesBenilda Pensica SevillaNoch keine Bewertungen

- Complete Your Summer Sculpt Calendar WorkoutsDokument1 SeiteComplete Your Summer Sculpt Calendar WorkoutsSmarauza TinyNoch keine Bewertungen

- Power Quality SolutionDokument40 SeitenPower Quality Solutionshankar ammantryNoch keine Bewertungen

- Week 3. DIASDokument14 SeitenWeek 3. DIASJaymie NeriNoch keine Bewertungen

- Ds 1018Dokument2 SeitenDs 1018Ramesh ChandNoch keine Bewertungen

- MR Safe Conditional PDFDokument4 SeitenMR Safe Conditional PDFAKSNoch keine Bewertungen

- Handbook of Heterogeneous Catalytic Hydrogenation For Organic Synthesis 2001 2Dokument747 SeitenHandbook of Heterogeneous Catalytic Hydrogenation For Organic Synthesis 2001 2Purna Bhavnari75% (4)

- Tinnitus Causes and TreatmentDokument3 SeitenTinnitus Causes and TreatmentTinnituscausesandtreatment Tinnituscausesandtreatment100% (1)

- Raising Indigenous Chickens in UgandaDokument9 SeitenRaising Indigenous Chickens in Ugandashemks79% (38)

- I-WEB - Com.vn Manual 498031910Dokument94 SeitenI-WEB - Com.vn Manual 498031910IBJSC.comNoch keine Bewertungen

- Level I Questions Thermal and Infrared Testing Method: Southern Inspection ServicesDokument8 SeitenLevel I Questions Thermal and Infrared Testing Method: Southern Inspection Servicesprabhakaran.SNoch keine Bewertungen

- ATEX Guidelines for the Valve IndustryDokument49 SeitenATEX Guidelines for the Valve Industryio1_roNoch keine Bewertungen

- Rock CycleDokument30 SeitenRock CycleDenny PrawiraNoch keine Bewertungen

- RescueLogicCutSheet Full Bleed 2 PDFDokument2 SeitenRescueLogicCutSheet Full Bleed 2 PDFStevenNoch keine Bewertungen

- Nutritional Assessment Form of ChildrenDokument6 SeitenNutritional Assessment Form of ChildrenBisakha Dey100% (2)

- Laboratory Notebook: Aquatic Ecology and ResourcesDokument7 SeitenLaboratory Notebook: Aquatic Ecology and ResourcesAireen Diamsim MaltoNoch keine Bewertungen

- The Bondage of Sin Edward WelchDokument8 SeitenThe Bondage of Sin Edward Welchandrés_torres_58Noch keine Bewertungen

- Valve Manual Pocket EditionDokument23 SeitenValve Manual Pocket EditionBùi Cảnh Trung100% (1)