Beruflich Dokumente

Kultur Dokumente

Standard and Codes

Hochgeladen von

Armin HeidariCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Standard and Codes

Hochgeladen von

Armin HeidariCopyright:

Verfügbare Formate

Standards and Codes

ANSI - American National Standards Institute

The American National Standards Institute - ANSI - is a private, non-profit organization that

administers and coordinates the U.S. voluntary standardization and conformity assessment

system.

ANSI provides a forum for development of American national standards from organizations as

ASME - American Society of Mechanical Engineers

NFPA - National Fire Protection Association and more,

and serves as a coordination point for national distribution of international standards issued from

organizations as

ISO - International Organization for Standardization,

DIN - Deutsches Institut fr Normung eV,

IEC - International Electro technical Commission and others.

Many of committees are chaired and sponsored by engineering societies such as

ASME - American Society of Mechanical Engineers and

IEEE - Institute of Electrical and Electronics Engineers.

Safety is the basic objective in the standards developed by ANSI. The ANSI standards include

prohibition for practices considered unsafe.

Some of the ANSI codes may eventually become known as ASME standards - as the ANSI B31

Pressure Piping Code is changed to ASME B31.

Standards and Codes

ASME - International Boiler and Pressure Vessel Code

The ASME - American Society of Mechanical Engineers - International Boiler and Pressure

Vessel Code is made of 11 sections and contains over 15 divisions and subsections.

Code Sections

I. Power Boilers

II. Materials

III. Rules for Construction of Nuclear Facility Components

IV. Heating Boilers

V. Nondestructive Examination

VI. Recommended Rules for the Care and Operation of Heating Boilers

VII. Recommended Guidelines for the Care of Power Boilers

VIII. Pressure Vessels

IX. Welding and Brazing Qualifications

X. Fiber-Reinforced Plastic Pressure Vessels

XI. Rules for In-service Inspection of Nuclear Power Plant Components

XII. Rules for Construction and Continued Service of Transport Tanks

I. Power Boilers

This Section provides requirements for all methods of construction of power, electric, and

miniature boilers; high temperature water boilers used in stationary service; and power boilers

used in locomotive, portable, and traction service. Requirements for: Boilers Fabricated by

Welding; Boilers Fabricated by Riveting (by reference only); Watertube Boilers; Firetube Boilers;

Feedwater Heaters; Miniature Boilers; Electric Boilers; Organic Fluid Vaporizer Generators.

Standards and Codes

This section provides requirements for all methods of construction of power, electric, and

miniature boilers; high temperature water boilers used in stationary service; and power boilers

used in locomotive, portable, and traction service. The rules are applicable to boilers in which

steam or other vapor is generated at a pressures exceeding 15 psig,

and high temperature water boilers intended for operation at pressures exceeding 160

psig and or temperatures exceeding 250 degree F.

Superheaters, economizers, and other pressure parts connected directly to the boiler without

intervening valves are considered as part of the scope of Section 1.

II. Materials

Part A-Ferrous Material Specifications

Part B-Nonferrous Material Specifications

Part C-Specifications for Welding Rods, Electrodes, and Filler Metals

Part D-Properties

III. Rules for Construction of Nuclear Facility Components

Subsection NCA - General Requirements for Divisions 1 and 2

DIVISION 1

Subsection NB- Class 1 Components

Subsection NC- Class 2 Components

Subsection ND- Class 3 Components

Subsection NE- Class MC Components

Subsection NF - Supports

Subsection NG - Core Support Structures

Subsection NH - Class 1 Components in Elevated Temperature Service

DIVISION 2

Code for Concrete Containments

Standards and Codes

DIVISION 3

Containments for Transportation and Storage

IV. Heating Boilers

This Subsection provides requirements for design, fabrication, installation and inspection of

steam generating boilers, and hot water boilers intended for low pressure service that are

directly fired by oil, gas, electricity, or coal. It contains appendices which cover approval of new

material, methods of checking safety valve and safety relief valve capacity, examples of

methods of checking safety valve and safety relief valve capacity, examples of methods of

calculation and computation, definitions relating to boiler design and welding, and quality control

systems.

V. Nondestructive Examination

Requirements and methods for nondestructive examination which are referenced and required

by other code Sections. It also includes manufacturer's examination responsibilities, duties of

authorized inspectors and requirements for qualification of personnel, inspection and

examination. Examination methods are intended to detect surface and internal discontinuities in

materials, welds, and fabricated parts and components. A glossary of related terms is included.

VI. Recommended Rules for the Care and Operation of Heating Boilers

General descriptions, terminology and operation guidelines applicable to steel and cast iron

boilers limited to the operating ranges of Section IV Heating Boilers. It includes guidelines for

associated controls and automatic fuel burning equipment. Illustrations show typical examples

of available equipment. Also included is a glossary of terms commonly associated with boilers,

controls, and fuel burning equipment.

VII. Recommended Guidelines for the Care of Power Boilers

Guidelines to promote safety in the use of stationary, portable, and traction type heating boilers.

The section provides guidelines to assist operators of power boilers in maintaining their plants

as safely as possible. Emphasis has been placed on industrial-type boilers because of their

extensive use. Contains Fuels for Routine Operation; Operating and Maintaining Boiler

Appliances; Inspection; Prevention of Direct Causes of Boiler Failure; Design of Installation;

Operation of Boiler Auxiliaries; Control of Internal Chemical Conditions

VIII. Pressure Vessels

Division 1 - Provides requirements applicable to the design, fabrication, inspection, testing, and

certification of pressure vessels operating at either internal or external pressures exceeding 15

psig.

Standards and Codes

Division 2 - Alternative Rules, provides requirements applicable to the design, fabrication,

inspection, testing, and certification of pressure vessels operating at either internal or external

pressures exceeding 15 psig.

Division 3 - Alternative Rules for Construction of High Pressure Vessels, provides requirements

applicable to the design, fabrication, inspection, testing, and certification of pressure vessels

operating at either internal or external pressures generally above 10,000 psi.

IX. Welding and Brazing Qualifications

Rules relating to the qualification of welding and brazing procedures as required by other Code

Sections for component manufacture. Covers rules relating to the qualification and requalification of welders, brazers, and welding and brazing operators in order that they may

perform welding or brazing as required by other Code Sections in the manufacture of

components. General Welding Requirements; Welding Procedure Qualifications; Welding

Performance Qualifications; Welding Data; Welding Forms; General Brazing Requirements;

Brazing Procedure Qualifications; Brazing Performance Qualifications; Brazing Data; Brazing

Forms.

X. Fiber-Reinforced Plastic Pressure Vessels

Requirements for construction of an FRP pressure vessel in conformance with a manufacturer's

design report. It includes production, processing, fabrication, inspection and testing methods

required for the vessel.

XI. Rules for In-service Inspection of Nuclear Power Plant Components

Rules for the examination, in-service testing and inspection, and repair and replacement of

components and systems in light-water cooled and liquid-metal cooled nuclear power plants.

XII. Rules for Construction and Continued Service of Transport Tanks

Requirements for construction and continued service of pressure vessels for the transportation

of dangerous goods via highway, rail, air or water at pressures from full vacuum to 3,000 psig

and volumes greater than 120 gallons.

Standards and Codes

ASME B31 - Standards of Pressure Piping

B31 Code for pressure piping, developed by American Society of Mechanical Engineers ASME, covers Power Piping, Fuel Gas Piping, Process Piping, Pipeline Transportation Systems

for Liquid Hydrocarbons and Other Liquids, Refrigeration Piping and Heat Transfer Components

and Building Services Piping. ASME B31 was earlier known as ANSI B31.

: ASME B31.1

: ASME B31.2

: ASME B31.3

: ASME B31.4

: ASME B31.5

: ASME B31.8

: ASME B31.9

: ASME B31.11

B31.1 - 2012 - Power Piping

Piping for industrial plants and marine applications. This code prescribes minimum requirements

for the design, materials, fabrication, erection, test, and inspection of power and auxiliary

service piping systems for electric generation stations, industrial institutional plants, central and

district heating plants.

The code covers boiler external piping for power boilers and high temperature, high pressure

water boilers in which steam or vapor is generated at a pressure of more than 15 PSIG; and

high temperature water is generated at pressures exceeding 160 PSIG and/or temperatures

exceeding 250 degrees F.

B31.2 - 1968 - Fuel Gas Piping

This has been withdrawn as a National Standard and replaced by ANSI/NFPA Z223.1, but B31.2

is still available from ASME and is a good reference for the design of gas piping systems (from

the meter to the appliance).

B31.3 - 2012 - Process Piping

Design of chemical and petroleum plants and refineries processing chemicals and

hydrocarbons, water and steam. This Code contains rules for piping typically found in petroleum

refineries; chemical, pharmaceutical, textile, paper, semiconductor, and cryogenic plants; and

related processing plants and terminals.

Standards and Codes

This Code prescribes requirements for materials and components, design, fabrication,

assembly, erection, examination, inspection, and testing of piping. This Code applies to piping

for all fluids including: (1) raw, intermediate, and finished chemicals; (2) petroleum products; (3)

gas, steam, air and water; (4) fluidized solids; (5) refrigerants; and (6) cryogenic fluids. Also

included is piping which interconnects pieces or stages within a packaged equipment assembly.

B31.4 - 2012 - Pipeline Transportation Systems for Liquid Hydrocarbons and Other

Liquids

This Code prescribes requirements for the design, materials, construction, assembly, inspection,

and testing of piping transporting liquids such as crude oil, condensate, natural gasoline, natural

gas liquids, liquefied petroleum gas, carbon dioxide, liquid alcohol, liquid anhydrous ammonia

and liquid petroleum products between producers' lease facilities, tank farms, natural gas

processing plants, refineries, stations, ammonia plants, terminals (marine, rail and truck) and

other delivery and receiving points.

Piping consists of pipe, flanges, bolting, gaskets, valves, relief devices, fittings and the pressure

containing parts of other piping components. It also includes hangers and supports, and other

equipment items necessary to prevent overstressing the pressure containing parts. It does not

include support structures such as frames of buildings, buildings stanchions or foundations

Requirements for offshore pipelines are found in Chapter IX. Also included within the scope of

this Code are:

(A) Primary and associated auxiliary liquid petroleum and liquid anhydrous ammonia

piping at pipeline terminals (marine, rail and truck), tank farms, pump stations, pressure

reducing stations and metering stations, including scraper traps, strainers, and prover

loop;

(B) Storage and working tanks including pipe-type storage fabricated from pipe and

fittings, and piping interconnecting these facilities;

(C) Liquid petroleum and liquid anhydrous ammonia piping located on property which

has been set aside for such piping within petroleum refinery, natural gasoline, gas

processing, ammonia, and bulk plants;

(D) Those aspects of operation and maintenance of liquid pipeline systems relating to

the safety and protection of the general public, operating company personnel,

environment, property and the piping systems.

B31.5 - 2013 - Refrigeration Piping and Heat Transfer Components

This Code prescribes requirements for the materials, design, fabrication, assembly, erection,

test, and inspection of refrigerant, heat transfer components, and secondary coolant piping for

temperatures as low as -320 deg F (-196 deg C), whether erected on the premises or factory

assembled, except as specifically excluded in the following paragraphs.

Standards and Codes

Users are advised that other piping Code Sections may provide requirements for refrigeration

piping in their respective jurisdictions.

This Code shall not apply to:

(a) any self- contained or unit systems subject to the requirements of Underwriters

Laboratories or other nationally recognized testing laboratory:

(b) water piping;

(c) piping designed for external or internal gage pressure not exceeding 15 psi (105 kPa)

regardless of size; or

(d) pressure vessels, compressors, or pumps,

but does include all connecting refrigerant and secondary coolant piping starting at the first joint

adjacent to such apparatus.

B31.8 - 2012 - Gas Transmission and Distribution Piping Systems

This Code covers the design, fabrication, installation, inspection, and testing of pipeline facilities

used for the transportation of gas. This Code also covers safety aspects of the operation and

maintenance of those facilities.

B31.8S - 2012 - Managing System Integrity of Gas Pipelines

This Standard applies to on-shore pipeline systems constructed with ferrous materials and that

transport gas.

Pipeline system means all parts of physical facilities through which gas is transported, including

pipe, valves, appurtenances attached to pipe, compressor units, metering stations, regulator

stations, delivery stations, holders and fabricated assemblies.

The principles and processes embodied in integrity management are applicable to all pipeline

systems. This Standard is specifically designed to provide the operator (as defined in section

13) with the information necessary to develop and implement an effective integrity management

program utilizing proven industry practices and processes.

The processes and approaches within this Standard are applicable to the entire pipeline system.

B31.9 - 2011 - Building Services Piping

This Code Section has rules for the piping in industrial, institutional, commercial and public

buildings, and multi-unit residences, which does not require the range of sizes, pressures, and

temperatures covered in B31.1.

Standards and Codes

This Code prescribes requirements for the design, materials, fabrication, installation, inspection,

examination and testing of piping systems for building services. It includes piping systems in the

building or within the property limits.

B31.11 - 2002 - Slurry Transportation Piping Systems

Design, construction, inspection, security requirements of slurry piping systems.

Covers piping systems that transport aqueous slurries of no hazardous materials, such as coal,

mineral ores and other solids between a slurry processing plant and the receiving plant.

B31.12 - 2011 - Hydrogen Piping and Pipelines

Gaseous and liquid hydrogen service and to pipelines in gaseous hydrogen service.

B31G - 2009 - Manual for Determining Remaining Strength of Corroded Pipelines

A supplement To B31 Code-Pressure Piping

Standards and Codes

10

ASME/ANSI B16 - Standards of Pipes and Fittings

The ASME - American Society of Mechanical Engineers - ASME/ANSI B16 Standards covers

pipes and fittings in cast iron , cast bronze, wrought copper and steel.

ASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged Fittings

This Standard for Classes 25, 125, 250 Cast Iron Pipe Flanges and Flanged Fittings covers:

(a) pressure-temperature ratings,

(b) sizes and method of designating openings of reducing fittings,

(c) marking,

(d) minimum requirements for materials,

(e) dimensions and tolerances,

(f) bolt, nut, and gasket dimensions and

(g) tests.

ASME/ANSI B16.3 - 1998 - Malleable Iron Threaded Fittings

This Standard for threaded malleable iron fittings Classes 150, and 300 provides requirements

for the following:

(a) pressure-temperature ratings

(b) size and method of designating openings of reducing fittings

(c) marking

(d) materials

(e) dimensions and tolerances

(f) threading

(g) coatings

Standards and Codes

11

ASME/ANSI B16.4 - 1998 - Cast Iron Threaded Fittings

This Standard for gray iron threaded fittings, Classes 125 and 250 covers:

(a) pressure-temperature ratings

(b) size and method of designating openings of reducing fittings

(c) marking

(d) material

(e) dimensions and tolerances

(f) threading, and

(g) coatings

ASME/ANSI B16.5 - 1996 - Pipe Flanges and Flanged Fittings

The ASME B16.5 - 1996 Pipe Flanges and Flange Fittings standard covers pressuretemperature ratings, materials, dimensions, tolerances, marking, testing, and methods of

designating openings for pipe flanges and flanged fittings.

The standard includes flanges with rating class designations 150, 300, 400, 600, 900, 1500, and

2500 in sizes NPS 1/2 through NPS 24, with requirements given in both metric and U.S units.

The Standard is limited to flanges and flanged fittings made from cast or forged materials, and

blind flanges and certain reducing flanges made from cast, forged, or plate materials. Also

included in this Standard are requirements and recommendations regarding flange

bolting, flange gaskets, and flange joints.

ASME/ANSI B16.9 - 2001 - Factory-Made Wrought Steel Buttwelding Fittings

This Standard covers overall dimensions, tolerances, ratings, testing, and markings for wrought

factory-made buttwelding fittings in sizes NPS 1/2 through 48 (DN 15 through 1200).

ASME/ANSI B16.10 - 2000 - Face-to-Face and End-to-End Dimensions of Valves

This Standard covers face-to-face and end-to-end dimensions of straightway valves, and

center-to face and center-to-end dimensions of angle valves. Its purpose is to assure installation

interchangeability for valves of a given material, type size, rating class, and end connection

Standards and Codes

12

ASME/ANSI B16.11 - 2001 - Forged Steel Fittings, Socket-Welding and Threaded

This Standard covers ratings, dimensions, tolerances, marking and material requirements for

forged fittings, both socket-welding and threaded.

ASME/ANSI B16.12 - 1998 - Cast Iron Threaded Drainage Fittings

This Standard for cast iron threaded drainage fittings covers:

(a) size and method of designating openings in reducing fittings

(b) marking

(c) materials

(d) dimensions and tolerances

(e) threading

(f) ribs

(g) coatings

(h) face bevel discharge nozzles, input shafts, base plates, and foundation bolt holes

(see Tables 1 and 2).

ASME/ANSI B16.14 - 1991 - Ferrous Pipe Plugs, Bushings and Locknuts with Pipe

Threads

This Standard for Ferrous Pipe Plugs, Bushings, and Locknuts with Pipe Threads covers:

(a) pressure-temperature ratings:

(b) size;

(c) marking;

(d) materials;

(e) dimensions and tolerances;

(f) threading; and

(g) pattern taper.

Standards and Codes

13

ASME/ANSI B16.15 - 1985 (R1994) - Cast Bronze Threaded Fittings

This Standard pertains primarily to cast Class 125and Class 250 bronze threaded pipe fittings.

Certain requirements also pertain to wrought or cast plugs, bushings, couplings, and caps. This

Standard covers:

(a) pressure-temperature ratings;

(b) size and method of designating openings of reducing pipe fittings;

(c) marking;

(d) minimum requirements for casting quality and materials;

(e) dimensions and tolerances in U.S. customary and metric (SI) units;

(f) threading.

ASME/ANSI B16.18 - 1984 (R1994) - Cast Copper Alloy Solder Joint Pressure Fittings

This Standard for cast copper alloy solder joint pressure fittings designed for use with copper

water tube, establishes requirements for:

(a) Pressure-temperature ratings;

(b) Abbreviations for end connections;

(c) Sizes and method of designating openings of fittings;

(d) Marking;

(e) Material;

(f) Dimensions and tolerances; and

(g) Tests.

ASME/ANSI B16.20 - 1998 - Metallic Gaskets for Pipe Flanges-Ring-Joint, Spiral-Would,

and Jacketed

This standard covers materials, dimensions, tolerances, and markings for metal ring-joint

gaskets, spiral-wound metal gaskets, and metal jacketed gaskets and filler material. These

gaskets are dimensionally suitable for used with flanges described in the reference flange

standards ASME/ANSI B16.5, ASME B16.47, and API-6A. This standard covers spiral-wound

metal gaskets and metal jacketed gaskets for use with raised face and flat face flanges.

Replaces API-601 or API-601.

Standards and Codes

14

ASME/ANSI B16.21 - 1992 - Nonmetallic Flat Gaskets for Pipe Flanges

This Standard for nonmetallic flat gaskets for bolted flanged joints in piping includes:

(a) types and sizes;

(b) materials;

(c) dimensions and allowable tolerances.

ASME/ANSI B16.22 - 1995 - Wrought Copper and Copper Alloy Solder Joint Pressure

Fittings

The Standard establishes specifications for wrought copper and wrought copper alloy, solderjoint, seamless fittings, designed for use with seamless copper tube conforming to ASTM B 88

(water and general plumbing systems), B 280 (air conditioning and refrigeration service), and B

819 (medical gas systems), as well as fittings intended to be assembled with soldering materials

conforming to ASTM B 32, brazing materials conforming to AWS A5.8, or with tapered pipe

thread conforming to ASME B1.20.1. This Standard is allied with ASME B16.18, which covers

cast copper alloy pressure fittings. It provides requirements for fitting ends suitable for soldering.

This Standard covers:

(a) pressure temperature ratings;

(b) abbreviations for end connections;

(c) size and method of designating openings of fittings;

(d) marking;

(e) material;

(f) dimension and tolerances; and

(g) tests.

ASME/ANSI B16.23 - 1992 - Cast Copper Alloy Solder Joint Drainage Fittings (DWV)

The Standard establishes specifications for cast copper alloy solder joint drainage fittings,

designed for use in drain, waste, and vent (DWV) systems. These fittings are designed for use

with seamless copper tube conforming to ASTM B 306, Copper Drainage Tube (DWV), as well

as fittings intended to be assembled with soldering materials conforming to ASTM B 32, or

tapered pipe thread conforming to ASME B1.20.1. This standard is allied with ASME B16.29,

Wrought Copper and Wrought Copper Alloy Solder Joint Drainage Fittings - DWV. It provides

requirements for fitting ends suitable for soldering. This standard covers:

Standards and Codes

(a) description;

(b) pitch (slope);

(c) abbreviations for end connections;

(d) sizes and methods for designing openings for reducing fittings;

(e) marking;

(f) material; and

(g) dimensions and tolerances.

15

ASME/ANSI B16.24 - 1991 (R1998) - Cast Copper Alloy Pipe Flanges and Flanged Fittings

This Standard for Classes 25, 125, 250, and 800 Cast Iron Pipe Flanges and Flanged Fittings

covers:

(a) pressure temperature ratings,

(b) sizes and methods of designating openings for reduced fittings,

(c) marking,

(d) minimum requirements for materials,

(e) dimensions and tolerances,

(f) bolt, nut, and gasket dimensions, and

(g) tests.

ASME/ANSI B16.25 - 1997 - Buttwelding Ends

The Standard covers the preparation of butt welding ends of piping components to be

joined into a piping system by welding. It includes requirements for welding bevels, for

external and internal shaping of heavy-wall components, and for preparation of internal

ends (including dimensions and tolerances). Coverage includes preparation for joints

with the following.

(a) no backing rings;

(b) split or non continuous backing rings;

(c) solid or continuous backing rings;

Standards and Codes

(d) consumable insert rings;

(e) gas tungsten are welding (GTAW) of the root pass. Details of preparation for any

backing ring must be specified in ordering the component.

16

ASME/ANSI B16.26 - 1988 - Cast Copper Alloy Fittings for Flared Copper Tubes

This standard for Cast Copper Alloy Fitting for Flared Copper Tubes covers:

(a) pressure rating;

(b) material;

(c) size;

(d) threading;

(e) marking.

ASME/ANSI B16.28 - 1994 - Wrought Steel Buttwelding Short Radius Elbows and Returns

This Standard covers ratings, overall dimensions, testing, tolerances, and markings for wrought

carbon and alloy steel buttwelding short radius elbows and returns. The term wrought denotes

fittings made of pipe, tubing, plate, or forgings.

ASME/ANSI B16.29 - 1994 - Wrought Copper and Wrought Copper Alloy Solder Joint

Drainage Fittings (DWV)

The standard for wrought copper and wrought copper alloy solder joint drainage fittings,

designed for use with copper drainage tube, covers:

(a) Description,

(b) Pitch (slope),

(c) Abbreviations for End Connections,

(d) Sizes and Method of Designating Openings for Reducing Fittings,

(e) Marking,

(f) Material,

(g) Dimensions and Tolerances.

Standards and Codes

17

ASME/ANSI B16.33 - 1990 - Manually Operated Metallic Gas Valves for Use in Gas Piping

Systems Up to 125 psig

General This Standard covers requirements for manually operated metallic valves sizes NPS

1.2 through NPS 2, for outdoor installation as gas shut-off valves at the end of the gas service

line and before the gas regulator and meter where the designated gauge pressure of the gas

piping system does not exceed 125 psi (8.6 bar). The Standard applies to valves operated in a

temperature environment between .20 degrees F and 150 degrees F (.29 degrees C and 66

degrees C). Design This Standard sets forth the minimum capabilities, characteristics, and

properties, which a valve at the time of manufacture must possess, in order to be considered

suitable for use in gas piping systems.

ASME/ANSI B16.34 - 1996 - Valves - Flanged, Threaded, and Welding End

This standard applies to new valve construction and covers pressure-temperature ratings,

dimensions, tolerances, materials, nondestructive examination requirements, testing, and

marking for cast, forged, and fabricated flanged, threaded, and welding end, and wafer or

flangeless valves of steel, nickel-base alloys, and other alloys shown in Table 1. Wafer or

flangeless valves, bolted or through-bolt types, that are installed between flanges or against a

flange shall be treated as flanged end valves.

ASME/ANSI B16.36 - 1996 - Orifice Flanges

This Standard covers flanges (similar to those covered in ASME B16.5) that have orifice

pressure differential connections. Coverage is limited to the following:

(a) welding neck flanges Classes 300, 400, 600, 900, 1500, and 2500

(b) slip-on and threaded Class 300

Orifice, Nozzle and Venturi Flow Rate Meters

ASME/ANSI B16.38 - 1985 (R1994) - Large Metallic Valves for Gas Distribution

The standard covers only manually operated metallic valves in nominal pipe sizes 2 1/2 through

12 having the inlet and outlet on a common center line, which are suitable for controlling the

flow of gas from open to fully closed, for use in distribution and service lines where the

maximum gage pressure at which such distribution piping systems may be operated in

accordance with the code of federal regulations (cfr), title 49, part 192, transportation of natural

and other gas by pipeline; minimum safety standard, does not exceed 125 psi (8.6 bar). Valve

seats, seals and stem packing may be nonmetallic.

Standards and Codes

18

ASME/ANSI B16.39 - 1986 (R1998) - Malleable Iron Threaded Pipe Unions

This Standard for threaded malleable iron unions, classes 150, 250, and 300, provides

requirements for the following:

(a) design

(b) pressure-temperature ratings

(c) size

(d) marking

(e) materials

(f) joints and seats

(g) threads

(h) hydrostatic strength

(i) tensile strength

(j) air pressure test

(k) sampling

(l) coatings

(m) dimensions

ASME/ANSI B16.40 - 1985 (R1994) - Manually Operated Thermoplastic Gas

The Standard covers manually operated thermoplastic valves in nominal sizes 1.2 through 6 (as

shown in Table 5). These valves are suitable for use below ground in thermoplastic distribution

mains and service lines. The maximum pressure at which such distribution piping systems may

be operated is in accordance with the Code of Federal Regulation (CFR) Title 49, Part 192,

Transportation of Natural and Other Gas by Pipeline; Minimum Safety Standards, for

temperature ranges of .20 deg. F to 100 deg. F (.29 deg. C to 38 deg. C). This Standard sets

qualification requirements for each nominal valve size for each valve design as a necessary

condition for demonstrating conformance to this Standard. This Standard sets requirements for

newly manufactured valves for use in below ground piping systems for natural gas [includes

synthetic natural gas (SNG)], and liquefied petroleum (LP) gases (distributed as a vapor, with or

without the admixture of air) or mixtures thereof.

Standards and Codes

19

ASME/ANSI B16.42 - 1998 - Ductile Iron Pipe Flanges and Flanged Fittings, Classes 150

and 300

The Standard covers minimum requirements for Class 150 and 300 cast ductile iron pipe

flanges and flanged fittings. The requirements covered are as follows:

(a) pressure-temperature ratings

(b) sizes and method of designating openings

(c) marking

(d) materials

(e) dimensions and tolerances

(f) blots, nuts, and gaskets

(g) tests

ASME/ANSIB16.44 - 1995 - Manually Operated Metallic Gas Valves for Use in House

Piping Systems

This Standard applies to new valve construction and covers quarter turn manually operated

metallic valves in sizes NPS 1/2-2 which are intended for indoor installation as gas shutoff

valves when installed in indoor gas piping between a gas meter outlet & the inlet connection to a

gas appliance.

ASME/ANSI B16.45 - 1998 - Cast Iron Fittings for Sovent Drainage Systems

The Standard for cast iron drainage fittings used on self-aerating, one-pipe Solvent drainage

systems, covers the following:

(a) description

(b) sizes and methods for designating openings for reducing fittings

(c) marking

(d) material

(e) pitch

(f) design

(g) dimensions and tolerances

Standards and Codes

20

(h) tests

ASME/ANSI B16.47 - 1996 - Large Diameter Steel Flanges: NPS 26 through NPS 60

This Standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking,

and testing for pipe flanges in sizes NPS 26 through NPS 60 and in ratings Classes 75,

150,0300, 400, 600, and 900. Flanges may be cast, forged, or plate (for blind flanges only)

materials. Requirements and recommendations regarding bolting and gaskets are also included.

ASME/ANSI B16.48 - 1997 - Steel Line Blanks

The Standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking,

and testing for operating line blanks in sizes NPS 1/2 through NPS 24 for installation between

ASME B16. 5 flanges in the 150, 300, 600, 900, 1500, and 2500 pressure classes.

ASME/ANSI B16.49 - 2000 - Factory-Made Wrought Steel Buttwelding Induction Bends for

Transportation and Distribution Systems

This Standard covers design, material, manufacturing, testing, marking, and inspection

requirements for factory-made pipeline bends of carbon steel materials having controlled

chemistry and mechanical properties, produced by the induction bending process, with or

without tangents. This Standard covers induction bends for transportation and distribution piping

applications (e.g., ASME B31.4, B31.8, and B31.11) Process and power piping have differing

requirements and materials that may not be appropriate for the restrictions and examinations

described herein, and therefore are not included in this Standard.

Standards and Codes

21

API - American Petroleum Institute

The American Petroleum Institute - API - represents more than 400 members involved in the oil

and natural gas industry.

Over 900 API standards serve as the basis for API quality programs covering production

material and lubricants, and certification programs for storage tanks, pressure vessels, and

piping inspectors. API publish recommended practices, research reports, and specifications on

pipelines, valves, offshore structures, oil-spill response procedures, environmental protection,

exploration, facility management and much more.

The API membership work is organized in

the API upstream segment

the API downstream segment

the API marine segment

the API pipeline segment

Popular Titles from API

Some popular titles from API are

API Publication 4721

Analytical Detection and Quantification Limits: Survey of State and Federal Approaches

API 526

Flanged Steel Pressure Relief Valves

API 620

Design and Construction of Large, Welded, Low-Pressure Storage Tanks

API RP 1007

Loading and Unloading of MC 306 / DOT 406 Cargo Tank Motor Vehicles

ANSI/API 1104

Welding of Pipelines and Related Facilities

API 650

Welded Steel Tanks for Oil Storage

Standards and Codes

API 653

Tank Inspection, Repair, Alteration, and Reconstruction

API 5L

Specification for Line Pipe

API SPEC 6A

Specification for Wellhead and Christmas Tree Equipment

API 5CT

Specification for Casing and Tubing (U.S. Customary Units)

API RP 7G

Recommended Practice for Drill Stem Design and Operation Limits

22

Standards and Codes

23

API - Valve Standards

Valve standards from API - the American Petroleum Institute:

API SPEC 6D

Specification for Pipeline Valves. API Specification 6D is an adoption of ISO 14313:

1999, Petroleum and Natural Gas Industries-Pipeline Transportation Systems-Pipeline

Valves. This International Standard specifies requirements and gives recommendations

for the design, manufacturing, testing and documentation of ball, check, gate and plug

valves for application in pipeline systems.

API 526

Flanged Steel Pressure Relief Valves. The standard is a purchase specification for

flanged steel pressure relief valves. Basic requirements are given for direct springloaded pressure relief valves and pilot-operated pressure relief valves as follows: orifice

designation and area; valve size and pressure rating, inlet and outlet; materials;

pressure-temperature limits; and center-to-face dimensions, inlet and outlet.

API 527

Seat Tightness of Pressure Relief Valves R(2002). Describes methods of determining

the seat tightness of metal- and soft-seated pressure relief valves, including those of

conventional, bellows, and pilot-operated designs.

ANSI/API STD 594

Check Valves: Flanged, Lug, Wafer and Butt-welding. API Standard 594 covers design,

material, face-to-face dimensions, pressure-temperature ratings, and examination,

inspection, and test requirements for two types of check valves.

API 598

Valve Inspection and Testing. The standard covers inspection, supplementary

examination, and pressure test requirements for both resilient-seated and metal-to-metal

seated gate, globe, plug, ball, check, and butterfly valves. Pertains to inspection by the

purchaser and to any supplementary examinations the purchaser may require at the

valve manufacturer's plant.

ANSI/API 599

Metal Plug Valves - Flanged, Threaded and Welding Ends. A purchase specification that

covers requirements for metal plug valves with flanged or butt-welding ends, and ductile

iron plug valves with flanged ends, in sizes NPS 1 through NPS 24, which correspond to

nominal pipe sizes in ASMEB36.10M. Valve bodies conforming to ASME B16.34 may

have flanged end and one butt-welding end. It also covers both lubricated and

nonlubricated valves that have two-way coaxial ports, and includes requirements for

valves fitted with internal body, plug, or port linings or applied hard facings on the body,

body ports, plug, or plug port.

Standards and Codes

24

ANSI/API 600

Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas Industries - Modified

National Adoption of ISO 10434:1998.

API 602

Compact Steel Gate Valves - Flanged, Threaded, Welding, and Extended-Body Ends.

The standard covers threaded-end, socket-welding-end, butt-welding-end, and flangedend compact carbon steel gate valves in sizes NPS4 and smaller.

ANSI/API 603

Corrosion-Resistant, Bolted Bonnet Gate Valves - Flanged and Butt-Welding Ends. The

standard covers corrosion-resistant bolted bonnet gate valves with flanged or butt-weld

ends in sizes NPS 1/2 through 24, corresponding to nominal pipe sizes

in ASME B36.10M, and Classes 150, 300, and, 600, as specified in ASME B16.34.

ANSI/API 607

Fire Test for Soft-Seated Quarter Turn Valves. The standard covers the requirements for

testing and evaluating the performance of straightway, soft-seated quarter-turn valves

when the valves are exposed to certain fire conditions defined in this standard. The

procedures described in this standard apply to all classes and sizes of such valves that

are made of materials listed in ASME B16.34.

API 609

Butterfly Valves: Double Flanged, Lug- and Wafer-Type. The standard covers design,

materials, face-to-face dimensions, pressure-temperature ratings, and examination,

inspection, and test requirements for gray iron, ductile iron, bronze, steel, nickel-base

alloy, or special alloy butterfly valves that provide tight shutoff in the closed position and

are suitable for flow regulation.

API 6FA

Specification for Fire Test for Valves. The standard covers the requirements for testing

and evaluating the performance of API Spec 6A and Spec 6D valves when exposed to

specifically defined fire conditions.

API 6FC

Fire Test for Valve with Automatic Backseats. The standard covers the requirements for

testing and evaluating the performance of API Spec 6A and Spec 6D valves with

automatic backseats when exposed to specifically defined fire conditions.

API 6RS

Referenced Standards for Committee 6, Standardization of Valves and Wellhead

Equipment.

API 11V6

Design of Continuous Flow Gas Lift Installations Using Injection Pressure Operated

Valves. The standard sets guidelines for continuous flow gas lift installation designs

using injection pressure operated valves.

Standards and Codes

25

ANSI/API RP 11V7

Recommended Practice for Repair, Testing, and Setting Gas Lift Valves. The standard

applies to repair, testing, and setting gas lift valves and reverse flow (check) valves.

API 520-1

Sizing, Selection, and Installation of Pressure-Relieving Devices in Refineries: Part I Sizing and Selection. The recommended practice applies to the sizing and selection of

pressure relief devices used in refineries and related industries for equipment that has a

maximum allowable working pressure of 15 psig (1.03 bar g or 103 kPa g) or greater.

API 520-2

Recommended Practice 520: Sizing, Selection, and Installation of Pressure-Relieving

Devices in Refineries-Part II, Installation. The recommended practice covers methods of

installation for pressure-relief devices for equipment that has a maximum allowable

working pressure of 15 psig (1.03 bar g or 103 kPa g) or greater. It covers gas, vapor,

steam, two-phase and incompressible fluid service.

ANSI/API 574

Inspection Practices for Piping System Components. The standard covers the inspection

of piping, tubing, valves (other than control valves) and fittings used in petroleum

refineries.

ANSI/API 576

Inspection of Pressure Relieving Devices. The recommended practice describes the

inspection and repair practices for automatic pressure-relieving devices commonly used

in the oil and petrochemical industries.

ANSI/API 608

Metal Ball Valves - Flanged and Butt-Welding Ends. The standard covers Class 150 and

Class 300 metal ball valves that have either butt-welding or flanged ends and are for use

in on-off service.

Standards and Codes

26

ASTM International

ASTM International, originally known as the American Society for Testing and Materials (ASTM),

is one of the largest voluntary standards development organizations in the world - a trusted

source for technical standards for materials, products, systems, and services.

The standards includes test procedures for determining or verifying characteristics as chemical

composition, measuring performance. The standards cover refined materials as steel and basic

products as machinery and fabricated equipment.

The ASTM standards are published in a set of 67 volumes in 16 sections:

Volume 00.01 - Subject Index - Alphanumeric List

Sections and Volumes

The ASTM Standards are organized in the Sections and Volumes

Section 1 - Iron and Steel Products

Section 2 - Nonferrous Metal Products

Section 3 - Metals Test Methods and Analytical Procedures

Section 4 - Construction

Section 5 - Petroleum Products, Lubricants, and Fossil Fuels

Section 6 - Paints, Related Coatings, and Aromatics

Section 7 - Textiles

Section 8 - Plastics

Section 9 - Rubber

Section 10 - Electrical Insulation and Electronics

Section 11 - Water and Environmental Technology

Section 12 - Nuclear, Solar, and Geothermal Energy

Section 13 - Medical Devices and Services

Standards and Codes

Section 14 - General Methods and Instrumentation

Section 15 - General Products, Chemical Specialties, and End Use Products

27

where each Section contains of several volumes.

Section 1 - Iron and Steel Products

Volume 01.01 - Steel Piping, Tubing, Fittings

This volume features standards for various types of steel pipe which specify requirements for

high-temperature service, ordinary use, and special applications such as fire protection use.

Specifications for steel tubes list standard requirements for boiler and super heater tubes,

general service tubes, still tubes in refinery service, heat exchanger and condenser tubes,

mechanical tubing, and structural tubing. Steel casting specifications call out the standard

properties for valves, flanges, fittings, and other pressure containing parts for high-temperature

and low-temperature service. Also in this volume, are specifications that cover black, plain end

steel pipe for use in the conveyance of fluids under pressure.

Volume 01.02 - Ferrous Castings; Ferroalloys

Volume 01.03 - Steel - Plate, Sheet, Strip, Wire; Stainless Steel Bar

Volume 01.04 - Steel - Structural, Reinforcing, Pressure Vessel, Railway

Volume 01.05 - Steel - Bars, Forgings, Bearing, Chain, Springs

Volume 01.06 - Coated Steel Products

Volume 01.07 - Ships and Marine Technology

Volume 01.08 - Fasteners

Section 2 - Nonferrous Metal Products

Volume 02.01 - Copper and Copper Alloys

Volume 02.02 - Aluminum and Magnesium Alloys

Volume 02.03 - Electrical Conductors

Volume 02.04 - Metals: Nickel, Cobalt, Lead, Tin, Zinc, Cadmium, Precious, Reactive,

Refractory Metals and Alloys; Materials for Thermostats, Electrical Testing and

Resistance, Contacts, Connectors

Standards and Codes

28

Volume 02.05 - Metallic and Inorganic Coatings; Metal Powders; Sintered P/M Structural

Parts

Section 3 - Metals Test Methods and Analytical Procedures

Volume 03.01 - Metals - Mechanical Testing; Elevated and Low-Temperature Tests;

Metallography

Volume 03.02 - Wear and Erosion; Metal Corrosion

Volume 03.03 - Nondestructive Testing

Volume 03.04 - Magnetic Properties

Volume 03.05 - Analytical Chemistry for Metals, Ores, and Related Materials (I): E 32 to

E 1724

Volume 03.06 - Analytical Chemistry for Metals, Ores, and Related Materials (II): E356 to

latest; Molecular Spectroscopy; Surface Analysis

Section 4 - Construction

Volume 04.01 - Cement, Lime; Gypsum

Volume 04.02 - Concrete and Aggregates

Volume 04.03 - Road and Paving Materials; Vehicle-Pavement Systems

Volume 04.04 - Roofing, Waterproofing, and Bituminous Materials

Volume 04.05 - Chemical-Resistant Nonmetallic Materials; Vitrified Clay Pipe; Concrete

Pipe; Fiber-Reinforced Cement Products; Mortars and Grouts; Masonry

Volume 04.06 - Thermal Insulation; Environmental Acoustics

Volume 04.07 - Building Seals and Sealants; Fire Standards; Dimension Stone

Volume 04.08 - Soil and Rock (I): D 420 to D 5779

Volume 04.09 - Soil and Rock (II): D 5780 - latest; Geosynthetics

Volume 04.10 - Wood

Volume 04.11 - Building Construction

Volume 04.12 - Building Constructions (II): E 1672 - latest; Property Management

Systems

Standards and Codes

29

Volume 04.13 - Geosynthetics

Section 5 - Petroleum Products, Lubricants, and Fossil Fuels

Volume 05.01 - Petroleum Products and Lubricants (I): D 56 - D 2596

Volume 05.02 - Petroleum Products and Lubricants (II): D 2597 - D 4927

Volume 05.03 - Petroleum Products and Lubricants (III): D 4928 - D 5950

Volume 05.04 - Petroleum Products and Lubricants (IV): D 5966 - latest

Volume 05.05 - Test Methods for Rating Motor, Diesel, and Aviation Fuels; Catalysts;

Manufactured Carbon and Graphite Products

Volume 05.06 - Gaseous Fuels, Coal and Coke

This volume features gaseous fuels, and coal and coke. Under Gaseous Fuels, tables and

practices fix standard procedures for sampling and calculating thermo physical properties. In

addition, several tests define methods for analyzing the properties of gaseous fuels. And under

Coal and Coke, tests and practices establish procedures for evaluating properties of coal and

coke such as dustiness, moisture content, plastic properties, and sulphur content.

Section 6 - Paints, Related Coatings, and Aromatics

Volume 06.01 - Paint - Tests for Chemical, Physical, and Optical Properties; Appearance

Volume 06.02 - Paint - Products and Applications; Protective Coatings; Pipeline Coatings

Volume 06.03 - Paint - Pigments, Drying Oils, Polymers, Resins, Naval Stores, Cellulosic

Esters, and Ink Vehicles

Volume 06.04 - Paint - Solvents; Aromatic Hydrocarbons

Section 7 - Textiles

Volume 07.01 - Textiles (I): D76 - D3218

Volume 07.02 - Textiles (II): D3333 - latest

Section 8 - Plastics

Volume 08.01 - Plastics (I): D 256 - D 2343

Volume 08.02 - Plastics (II): D 2383 - D 4322

Standards and Codes

Volume 08.03 - Plastics (III): D 4329 - latest

Volume 08.04 - Plastic Pipe and Building Products

30

Section 9 - Rubber

Volume 09.01 - Rubber, Natural and Synthetic -- General Test Methods; Carbon Black

Volume 09.02 - Rubber Products, Industrial - Specifications and Related Test Methods:

Gaskets; Tires

Section 10 - Electrical Insulation and Electronics

Volume 10.01 - Electrical Insulation (I): D 69 - D 2484

Volume 10.02 - Electrical Insulation (II): D 2518 - latest

Volume 10.03 - Electrical Insulating Liquids and Gases; Electrical Protective Equipment

Volume 10.04 - Electronics (I)

Volume 10.05 - Electronics (II)

Section 11 - Water and Environmental Technology

Volume 11.01 - Water (I)

Volume 11.02 - Water (II)

Volume 11.03 - Atmospheric Analysis; Occupational Health and Safety; Protective

Clothing

Volume 11.04 - Environmental Assessment; Hazardous Substances and Oil Spill

Responses; Waste Management

Volume 11.05 - Biological Effects and Environmental Fate; Biotechnology; Pesticides

Section 12 - Nuclear, Solar, and Geothermal Energy

Volume 12.01 - Nuclear Energy (I)

Volume 12.02 - Nuclear Energy (II), Solar, and Geothermal Energy

Section 13 - Medical Devices and Services

Volume 13.01 - Medical Devices; Emergency Medical Services

Standards and Codes

31

Section 14 - General Methods and Instrumentation

Volume 14.01 - Healthcare Informatics

Volume 14.02 - General Test Methods; Forensic Sciences; Terminology; Conformity

Assessment; Statistical Methods

Volume 14.03 - Temperature Measurement

Volume 14.04 - Laboratory Apparatus; Degradation of Materials; SI; Oxygen Fire Safety

Section 15 - General Products, Chemical Specialties, and End Use Products

Volume 15.01 - Refractories; Activated Carbon; Advanced Ceramics

Volume 15.02 - Glass; Ceramic Whitewares

Volume 15.03 - Space Simulation; Aerospace and Aircraft; High Modulus Fibers

Volume 15.04 - Soaps and Other Detergents; Polishes; Leather; Resilient Floor

Coverings

Volume 15.05 - Engine Coolants; Halogenated Organic Solvents and Fire Extinguishing

Agents; Industrial and Specialty Chemicals

Volume 15.06 - Adhesives

Volume 15.07 - Sport Equipment; Safety and Traction for Footwear; Amusement Rides;

Consumer Products

Volume 15.08 - Sensory Evaulation; Vacuum Cleaners; Security Systems; Detention

Facilities; Food Service Equipment

Volume 15.09 - Paper; Packaging; Flexible Barrier Materials; Business Imaging Products

Standards and Codes

32

DIN - Deutsches Institut fr Normung

DIN - Deutsches Institut fr Normung, the German Institute for Standardization, is a nongovernmental organization recognized by the German government as the national standards

body and represents German interests at international and European level.

DIN Standards promote rationalization, quality assurance, safety, and environmental protection

as well as improving communication between industry, technology, science, government and the

public domain. Standards work is carried out by 26,000 external experts serving as voluntary

delegates in more than 4,000 committees. Draft standards are published for public comment,

and all comments are reviewed before final publication of the standard. Published standards are

reviewed for continuing relevance every five years, at least.

The over 12,000 DIN standards cover a wide range of topics including: physical quantities and

units, fasteners, water analysis, building and civil engineering (including building materials,

construction contract procedures (VOB), soil testing, corrosion protection of steel structures),

materials testing (testing machines, plastics, rubber, petroleum products, semiconductors), steel

pipes, machine tools, twist drills, roller and ball bearings, and process engineering. DIN

Handbooks (covering subjects such as mechanical engineering, fasteners, steel, steel pipes,

and welding), and most DIN standards are available as English versions, or as English

translations.

DIN standards designation

The designation of a DIN standard shows its origin (# denotes a number):

DIN # is used for German standards with primarily domestic significance or designed as

a first step toward international status

E DIN # is a draft standard and

DIN V # is a preliminary standard

DIN EN # is used for German edition of European standards

DIN ETS # is used for standards prepared by European Telecommunications Standards

Institute

DIN ISO # is used for German edition of ISO standards

DIN EN ISO # is used if the standard as also been adopted as a European standard

Standards and Codes

33

Examples - DIN Standards

DIN 75078-1 Motor vehicle for the transport of persons with reduced mobility - Part 1:

Terms and definitions, requirements, tests

DIN V 4108-4 Thermal insulation and energy economy in buildings - Part 4:

Hygrothermal design values

DIN EN 126 Multifunctional controls for gas burning appliances

DIN EN ISO 10042 Welding - Arc-welded joints in aluminum and its weldable alloys Quality levels for imperfections (ISO/DIS 10042:2004)

Standards and Codes

34

BSi - British Standards institute

British Standards institute is the National Standards Body of the UK, responsible for facilitating,

drafting, publishing and marketing British Standards and other guidelines. British Standards

provides UK industry and other stakeholders with their major access to and influence on

standardization, both in the European arena (with CEN, CENELEC and ETSI) and

internationally (with ISO and IEC).

Standards Developments Committees

Representations are sought from many spheres including: consumer organizations; professional

institutions; certification, testing and inspection bodies; educational establishments; research

organizations; UK notified bodies; enforcement bodies and government departments.

Over 15,000 British Standard publications have been published, all falling in one of the following

standards programmes:

Building and Civil Engineering

Materials and Chemicals

Engineering

Electro technical

Consumer Products and Services

Healthcare

Management Systems

DISC (Information Technology)

Numbering British Standards

The British Standards are titled

BS XXX:Year Title

where

XXX is the number of the standard

Standards and Codes

Popular Titles from BSi

Some of the most popular titles from BSi:

BS 8888:2002 Technical product documentation (TPD). Specification for defining,

specifying and graphically representing products

BS PD 5500:2003 Specification for unfired fusion welded pressure vessels

BS EN 10255:2004 Non-alloy steel tubes suitable for welding or threading

BS EN ISO 9001:2000 Quality management systems. Requirements

BS EN ISO 9004:2000 Quality management systems. Guidelines for performance

improvements

BS 5839-1:2002 Fire detection and alarm systems for buildings. Code of practice for

system design, installation, commissioning and maintenance

BS EN ISO 10012:2003 Measurement management systems. Requirements for

measurement processes and measuring equipment

BS EN ISO 19011:2002 Guidelines for quality and/or environmental management

systems auditing

BS EN ISO 14001:1996 Environmental management systems. Specification with

guidance for use

BS 5266-1:1999 Emergency lighting. Code of practice for the emergency lighting of

premises other than cinemas and certain other specified premises used for

entertainment

BS 7671:2001 Requirements for electrical installations. IEE Wiring Regulations.

Sixteenth edition

35

Standards and Codes

36

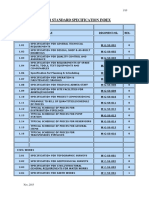

IPS (IRANIAN PETROLEUM STANDARS)

:

(E)

(M) /

(C)

(I)

(D)

(G)

:

(IN)

(SF)

(EL)

(AR)

(ME)

(TP)

(CE) /

(GN)

(PR)

(PI)

(PM)

(TC)

Valve Specifications

American Petroleum Institute

API

API

API

API

API

API

API

API

Q1 Specification for quality programs

6D Specification for pipeline valves

6FA Fire test for valves

598 Valve inspection and testing

600 Steel gate valves, flanged and buttwelding ends, bolted and pressure seal bonnets

602 Compact steel gate valves flanged, threaded, welding, and extended body ends

607 Fire test for soft seated quarter turn valves

608 Metal ball valves flanged and butt welding ends

Standards and Codes

37

American Society of Mechanical Engineers/

American National Standards Institute

ASME/ANSI B16.34 Valves flanged, threaded and welding end

ASME/ANSI B16.5 Pipe flanges and flanged fittings

ASME/ANSI B16.10 Face-to-face and end-to-end dimensions of valves

ASME/ANSI B16.11 Forged fittings, socket-welding and threaded

ASME/ANSI B16.25 Buttwelding ends

ASME/ANSI B16.47 Large diameter steel flanges

Note: This specification for flanges larger than 24 replaces MSS SP-44 and API 605 with the

designations of Series A (MSS SP-44) and Series B (API 605).

ASME B31.3 Chemical plant and petroleum refinery piping

ANSI B31.4 Liquid petroleum transportation piping system

ANSI B31.8 Gas transmission and distribution piping system

Manufacturers Standardization Society of the Valves and Fittings

Industry

MSS SP-25 Standard marking system for valves, fittings, flanges and unions

MSS SP-55 Quality standard for steel castings for valves, flanges, and fittings, and other piping

components visual method

MSS SP-70 Cast iron gate valves, flanged and threaded ends

MSS SP-71 Cast iron swing check valves, flanged and threaded ends

MSS SP-79 Socket-welding reducer inserts

MSS SP-80 Bronze gate, globe, angle and check valves

MSS SP-83 Class 3000 steel pipe unions, socket-welding and threaded

MSS SP-85 Cast iron globe and angle valves, flanged and threaded ends

National Association of Corrosion Engineers

NACE MR0175 Standard material requirements for sulfide stress cracking resistant metallic materials

for oilfield equipment.

British Standards Institute

BSI 1414 Steel wedge gate valves (flanged and butt welding ends) for the petroleum, petrochemical,

and allied industries

BSI 1868 Steel check valves (flanged and butt welding ends) for the petroleum, petrochemical, and

allied industries

BSI 1873 Steel globe and globe stop and check valves (flanged and butt welding ends) for the

petroleum, petrochemical, and allied industries

BSI 5352 Steel wedge gate, globe and check valves 50 mm and smaller for the petroleum,

petrochemical, and allied industries

Standards and Codes

International Organization for Standardization

ISO 9001/9002 Quality system Model for Quality Assurance

38

Das könnte Ihnen auch gefallen

- 6 Pipeline and Production Hipps Chris CurranDokument16 Seiten6 Pipeline and Production Hipps Chris CurranTHETHINHNoch keine Bewertungen

- 6 Pipeline and Production Hipps Joan Hall PDFDokument8 Seiten6 Pipeline and Production Hipps Joan Hall PDFArmin HeidariNoch keine Bewertungen

- SCH - Piping HandbookDokument25 SeitenSCH - Piping HandbookArmin HeidariNoch keine Bewertungen

- Letter FittingDokument2 SeitenLetter FittingArmin HeidariNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Rpdir-L12 Shielding WebDokument73 SeitenRpdir-L12 Shielding WebWiie ArdiNoch keine Bewertungen

- MeasurementDokument4 SeitenMeasurementJemason100% (1)

- Budget of Lesson Science 9Dokument14 SeitenBudget of Lesson Science 9Hezl Valerie ArzadonNoch keine Bewertungen

- Control of Surface Defects On plasma-MIG Hybrid Welds in Cryogenic Aluminum AlloysDokument14 SeitenControl of Surface Defects On plasma-MIG Hybrid Welds in Cryogenic Aluminum AlloysKaushik SenguptaNoch keine Bewertungen

- Exhaust ManifoldDokument5 SeitenExhaust ManifoldDeepak Chachra100% (1)

- Sany HBT8018C-5S (T3) Trailer Pump - 004118Dokument2 SeitenSany HBT8018C-5S (T3) Trailer Pump - 004118اهى عيشه وبن عشها just a lifeNoch keine Bewertungen

- Transformer REFDokument4 SeitenTransformer REFs_banerjeeNoch keine Bewertungen

- Unidad de Potencia Hidraulica Hycon HPP13 FlexDokument9 SeitenUnidad de Potencia Hidraulica Hycon HPP13 FlexJorge Diaz Nestor MonsalveNoch keine Bewertungen

- Fire Pump Installation GuideDokument3 SeitenFire Pump Installation GuideJeff D. AgustinNoch keine Bewertungen

- EXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSUREDokument44 SeitenEXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSURESite EngineeringtiaNoch keine Bewertungen

- Introduction to Distillation and Flash DistillationDokument19 SeitenIntroduction to Distillation and Flash DistillationSalman HaniffaNoch keine Bewertungen

- Flux and Refining Agent InjectionDokument1 SeiteFlux and Refining Agent InjectionСтанислав ПодольскийNoch keine Bewertungen

- Boundary Layer ThicknessDokument23 SeitenBoundary Layer ThicknessPridhar ThiagarajanNoch keine Bewertungen

- ZhangDokument21 SeitenZhangjajajaja21Noch keine Bewertungen

- DC Machine Theory and Transformer PrinciplesDokument32 SeitenDC Machine Theory and Transformer PrinciplesPolireddi Gopala KrishnaNoch keine Bewertungen

- Krff302ess01 Tech Sheet - w10787422 - Rev CDokument10 SeitenKrff302ess01 Tech Sheet - w10787422 - Rev CJesikaGomezSaavedraNoch keine Bewertungen

- Lab 5Dokument9 SeitenLab 5Cem UsmangilNoch keine Bewertungen

- Water Standard Specification Index As On Dec 2015Dokument10 SeitenWater Standard Specification Index As On Dec 2015afp15060% (1)

- Safety LOPADokument28 SeitenSafety LOPAnandorg1113100% (1)

- 3512TA - 1000kVA - LV - Spec Sheet PDFDokument5 Seiten3512TA - 1000kVA - LV - Spec Sheet PDFavinash_1229Noch keine Bewertungen

- Genie GTH 4013Dokument202 SeitenGenie GTH 4013Sam Manutenção100% (2)

- Quality Policy and Quality ObjectivesDokument2 SeitenQuality Policy and Quality ObjectivesrabiulfNoch keine Bewertungen

- LHCb Seminar on New Physics SearchesDokument32 SeitenLHCb Seminar on New Physics SearchesdedeNoch keine Bewertungen

- General Principles of Freeze Drying (The Lyophilization Process)Dokument9 SeitenGeneral Principles of Freeze Drying (The Lyophilization Process)Shefali PawarNoch keine Bewertungen

- Fluid MechDokument10 SeitenFluid MechPrasant KumarNoch keine Bewertungen

- All Terrain Vehicle Wiring PDFDokument3 SeitenAll Terrain Vehicle Wiring PDFVINAY KUMARNoch keine Bewertungen

- Acoustic Variables - Kasia's E-PortfolioDokument2 SeitenAcoustic Variables - Kasia's E-Portfoliomuhammad ShoaibNoch keine Bewertungen

- New Tutorial 2 Solution On ThermodynamicsDokument7 SeitenNew Tutorial 2 Solution On ThermodynamicsNaveed AhmadNoch keine Bewertungen

- Design and implementation of a solar-powered electric smart benchDokument7 SeitenDesign and implementation of a solar-powered electric smart benchAmir KalčoNoch keine Bewertungen

- SAES-R-004 Sanitary SewersDokument27 SeitenSAES-R-004 Sanitary SewersWaqar AhmedNoch keine Bewertungen