Beruflich Dokumente

Kultur Dokumente

Memor

Hochgeladen von

ntharyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Memor

Hochgeladen von

ntharyCopyright:

Verfügbare Formate

Enormous amounts of solid waste are generated every year in the United States an

d other

industrialized countries. These waste materials, in general, can be classi?ed in

to four major

categories: (1) municipal waste, (2) industrial waste, (3) hazardous waste, and

(4) lowlevel

radioactive

waste.

Table

17.1 lists the waste

material generated in 1984 in the United

States

in these four categories

(Koerner,

1994).

The waste materials generally are placed in land?lls. The land?ll materials inte

ract

with moisture received from rainfall and snow to form a liquid called leachate.

The chemical

composition of leachates varies

widely,

depending on the waste material involved.

Leachates are a main source of groundwater pollution; therefore, they must be co

ntained

properly in all land?lls, surface impoundments, and waste piles within some type

of liner

system. In the following sections of this chapter, various types of liner system

s and the

materials used in them are discussed.

Land?ll Liners Overview

Until about 1982, the predominant liner material used in land?lls was clay. Prop

er clay liners

have a hydraulic conductivity of about 10

7

cm/sec or less. In 1984, the U.S. Environmental

Protection Agency s minimum technological requirements for hazardous-waste land?ll

design

and construction were introduced by the U.S. Congress in Hazardous and Solid Was

te amendments.

In these amendments,

Congress stipulated that all new land?lls should have double

liners and systems for leachate collection and removal.

Compaction of Clay Soil for Clay Liner Construction

It was shown in Chapter 6 (Section 6.5) that, when a clay is compacted at a lowe

r moisture

content,

it possesses a ?occulent structure. Approximately at the optimum moisture

content of compaction, the clay particles have a lower degree of ?occulation. A

further

increase in the moisture content at compaction provides a greater degree of part

icle orientation;

however,

the dry unit weight decreases, because the added water dilutes the concentration

of soil solids per unit volume.

Figure 17.1 shows the results of laboratory compaction tests on a clay soil as w

ell as

the variation of hydraulic conductivity on the compacted clay specimens. From th

e laboratory

test results shown,

the following observations can be made:

1. For a given compaction effort, the hydraulic conductivity, k, decreases with

the

increase in molding moisture content, reaching a minimum value at about the

optimum moisture content (that is, approximately where the soil has a higher uni

t

weight with the clay particles having a lower degree of ?occulation). Beyond the

optimum moisture content, the hydraulic conductivity increases slightly.

2. For similar compaction effort and dry unit weight, a soil will have a lower h

ydraulic

conductivity when it is compacted on the wet side of the optimum moisture conten

t.

Benson and Daniel (1990) conducted laboratory compaction tests by varying

the size of clods of moist clayey soil. These tests show that, for similar compa

ction

effort and molding moisture content, the magnitude of k decreases with the decre

ase in

clod size.

In some compaction work in clayey soils, the compaction must be done in a manner

so that a certain speci?ed upper level of hydraulic conductivity of the soil is

achieved.

Examples of such works are compaction of the core of an earth dam and installati

on of clay

liners in solid-waste disposal sites.

To prevent groundwater pollution from leachates generated from solid-waste dispo

sal

sites,

the U.S. Environmental Protection Agency (EPA) requires that clay liners have

a hydraulic conductivity of 10

7

cm/sec or less. To achieve this value, the contractor must

ensure that the soil meets the following criteria (Environmental Protection Agen

cy, 1989):

1. The soil should have at least 20% ?nes (?ne silt and clay-sized particles).

2. The plasticity index (PI) should be greater than 10. Soils that have a PI gre

ater than

about 30 are dif?cult to work with in the ?eld.

3. The soil should not include more than 10% gravel-sized particles.

4. The soil should not contain any particles or chunks of rock that are larger t

han 25 to

50 mm (1 to 2 in.).

In many instances, the soil found at the construction site may be somewhat nonplastic. Such soil may be blended with imported clay minerals (like sodium bento

nite) to

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Fire Protection Hydraulic and Water Supply AnalysisDokument341 SeitenFire Protection Hydraulic and Water Supply AnalysisReza Akbar100% (4)

- P&G Questions and AnswersDokument12 SeitenP&G Questions and AnswersAryan KhanNoch keine Bewertungen

- Describe A Beautiful Place You Have Visited in Your CountryDokument3 SeitenDescribe A Beautiful Place You Have Visited in Your CountryAnh HoaiNoch keine Bewertungen

- Lending Hands To Someone Is Better Than Giving A DoleDokument3 SeitenLending Hands To Someone Is Better Than Giving A DoleBadri NathNoch keine Bewertungen

- Resources and Development NotesDokument10 SeitenResources and Development NotesKushan MittalNoch keine Bewertungen

- Unesco Technical PapersDokument315 SeitenUnesco Technical PapersGerardo Maximiliano Medina QuiñonesNoch keine Bewertungen

- Unit 3 - HoaDokument8 SeitenUnit 3 - HoaTan NguyenNoch keine Bewertungen

- (Cidam) : Earth and Life ScienceDokument7 Seiten(Cidam) : Earth and Life ScienceJake UrbiNoch keine Bewertungen

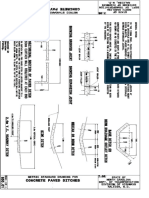

- Concrete Paved DitchesDokument1 SeiteConcrete Paved DitchesNikola ArsovskiNoch keine Bewertungen

- Floating Bodies - Adrian LahoudDokument13 SeitenFloating Bodies - Adrian LahoudblacksunNoch keine Bewertungen

- Social EnterprisesDokument3 SeitenSocial Enterprisesgelay.gonz8223Noch keine Bewertungen

- AGS-HK (2005b) - Ground Investigation Guidelines 04.7 - Karst in Hong KongDokument2 SeitenAGS-HK (2005b) - Ground Investigation Guidelines 04.7 - Karst in Hong KongramatrisNoch keine Bewertungen

- Engineers India LTD Campus: Integrated Design TeamDokument1 SeiteEngineers India LTD Campus: Integrated Design Teamm aNoch keine Bewertungen

- Caustic - Soda - Chlor - Alkali - IndustryDokument13 SeitenCaustic - Soda - Chlor - Alkali - Industryphat nguyenNoch keine Bewertungen

- Review Paper On Water Pumping System Using Windmill: International Research Journal of Engineering and Technology (IRJET)Dokument4 SeitenReview Paper On Water Pumping System Using Windmill: International Research Journal of Engineering and Technology (IRJET)MeleseNoch keine Bewertungen

- HPP750eco: Constant Climate ChamberDokument5 SeitenHPP750eco: Constant Climate ChamberArslan SamraNoch keine Bewertungen

- The Construction Contractor'S W Aste Management Plan: Optimizing Control and CostDokument10 SeitenThe Construction Contractor'S W Aste Management Plan: Optimizing Control and CostKaung Zaw HeinNoch keine Bewertungen

- Eco-Tourism in IndiaDokument12 SeitenEco-Tourism in IndiaPrasun PalNoch keine Bewertungen

- Land Acquisition and Diversion of Forest Land - Effective Socio-Economic Surveys and Due Diligences For Project PlanningDokument384 SeitenLand Acquisition and Diversion of Forest Land - Effective Socio-Economic Surveys and Due Diligences For Project PlanningSabyasachi Naik (Zico)Noch keine Bewertungen

- HSE Manual: Top Drive Drilling EquipmentDokument16 SeitenHSE Manual: Top Drive Drilling EquipmentHayLenLeeNoch keine Bewertungen

- DR Manoj Tourism Think India Pub FULLDokument9 SeitenDR Manoj Tourism Think India Pub FULLTakhmina SharopovaNoch keine Bewertungen

- Cynthia Villar Vs ReclamationDokument3 SeitenCynthia Villar Vs Reclamationtito bogs100% (1)

- A Coast Is A Region Where The Land Meets The The SeaDokument2 SeitenA Coast Is A Region Where The Land Meets The The SeaPrashant SinghalNoch keine Bewertungen

- Study of An Ecosystem Serrano Micah JacksonDokument8 SeitenStudy of An Ecosystem Serrano Micah JacksonApril Faye de la CruzNoch keine Bewertungen

- Environmental Engineering Updated Midterm ReviewerDokument8 SeitenEnvironmental Engineering Updated Midterm ReviewerLiug Vic Franco B. CajuraoNoch keine Bewertungen

- GMP TD Ar FPL 11033Dokument1 SeiteGMP TD Ar FPL 11033Sammy NguyenNoch keine Bewertungen

- LaĜardeno Introduction EN V1Dokument5 SeitenLaĜardeno Introduction EN V1Md.Hafijur Rahman TarafderNoch keine Bewertungen

- Holiday AssignmentDokument3 SeitenHoliday AssignmentnavneetNoch keine Bewertungen

- Science 9 ODL IDEA L5 Week 8 PRINTEDDokument3 SeitenScience 9 ODL IDEA L5 Week 8 PRINTEDClarice Jenn Malto50% (2)

- Degradation of MaterialsDokument29 SeitenDegradation of MaterialsAdrish NaskarNoch keine Bewertungen