Beruflich Dokumente

Kultur Dokumente

LoadCalcs PDF

Hochgeladen von

AnsarMahmoodOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

LoadCalcs PDF

Hochgeladen von

AnsarMahmoodCopyright:

Verfügbare Formate

Example Load and Rigging Calculations

This example provides the basic steps for performing load and rigging calculations. Bobs

Rigging & Crane Handbook (latest edition) or equivalent handbook should be used as reference.

1. Determine the total weight of the load and rigging through:

a. Documents, shipping labels, name plate

b. Information from a qualified person (engineer, designer)

c. Weigh the load

d. Calculate the load

2. Determine the required working load limit (WLL) of the crane/hoist. The WLL of the

weakest component must be sufficient to handle the load and associated rigging.

a. Determine the WLL of all hoist components and

b. Verify that the WLL is sufficient

3. Determine the WLL for all rigging components.

Example Problem:

A container filled with seawater is to be hoisted. Determine the following based on the diagram

below:

a. The weight of the container of seawater

b. The load on each of the sling legs

c. The size and type of eye bolt to be used

Page 1

August 2011, Rev. 1

Calculating the weight of the container:

Length (L) x Width (W) x Height (H) x Density = Weight.

The average density of seawater was determined to be 64 pounds per cubic foot. If uncertain,

always verify density and other factors or calculations with a knowledgeable/competent person.

3 x 3 x 2 x 64 lbs/ft3 = 18 ft3 x 64 lbs/ft3 = 1,152 lbs.

Calculating the load on each of the sling legs:

The vertical load for each sling = number of legs divided by the weight of the container

1,152 lbs divided by 3 legs* = Vertical load for each sling = 384 lbs

* Use 3 legs for the load

calculation. One leg is

generally balancing the

load and cannot be used

in load calculations.

Calculating the tension in each sling leg:

1/sin 450 x vertical load = sling tension. 1.414 x 384 lbs = 543 lbs

The tension in each sling leg is 543 lbs. NOTE: calculate sling tension using 1/sin of angle or

use Load Sling Factor from the applicable table in Bobs Rigging & Crane Handbook.

Page 2

August 2011, Rev. 1

Determining the size and type of eye bolt.

Always use forged, shoulder-type eye bolt for angular lifts.

De-rate eye bolt according to table:

For 450, the factor is 0.3

Direction

of Pull

Adjusted Working

Load Limit

(WLL)

45 Degrees

30% of WLL

90 Degrees

25% of WLL

Page 179 Bobs Rigging & Crane Handbook

Direction of pull = 450; therefore, de-rate eye bolt to 30% of WLL.

From Table 1, select an eye bolt where 0.3 x WLL is greater than 543 lbs.

From Table 1

Forged Eye Bolt

Size (inches)

1/4

Working Load

Limit (lbs)

500

5/16

800

3/8

1,200

1/2

2,200

5/8

3,500

A inch forged shoulder type eye bolt is the

best choice.

0.3 x 2,200 = 660 lbs, which is >543 lbs.

Page 179 Bobs Rigging & Crane Handbook

Rules of thumb:

Never rig below 300, which doubles the sling tension

450 or higher is preferred

600 is good

900 is best

Contact: EH&S Office, x3347.

Page 3

August 2011, Rev. 1

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Industrial Building, Design of Steel Structure Part 2, Types of LoadsDokument36 SeitenIndustrial Building, Design of Steel Structure Part 2, Types of LoadsRaju Sharma100% (3)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Jsa For KahsDokument3 SeitenJsa For Kahsfrancis_e_tan100% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Maestro Service Manual EnglishDokument38 SeitenMaestro Service Manual Englishanuraj patvardhanNoch keine Bewertungen

- DNV 2-7-3 2006Dokument22 SeitenDNV 2-7-3 2006thanhhai66Noch keine Bewertungen

- 2008-IADC Alerts PDFDokument66 Seiten2008-IADC Alerts PDFAnsarMahmood100% (1)

- Printable Daily PlannerDokument9 SeitenPrintable Daily PlannerDavid WatsonNoch keine Bewertungen

- Study GuideMobile CraneDokument30 SeitenStudy GuideMobile CraneegyinspectoryahooNoch keine Bewertungen

- TADANO - Service Operation Procedure - V06 OW-ENG-AML-F-00-0310-00 - enDokument86 SeitenTADANO - Service Operation Procedure - V06 OW-ENG-AML-F-00-0310-00 - enReinaldo Zorrilla100% (1)

- Electrical SafetyDokument27 SeitenElectrical SafetyAnsarMahmoodNoch keine Bewertungen

- TEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Dokument8 SeitenTEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Haymanot BaynesagnNoch keine Bewertungen

- BASF SOP - Crane and Rigging ProcedureDokument7 SeitenBASF SOP - Crane and Rigging ProcedureDavid O'Brien100% (1)

- Crane Load D Mag PDFDokument50 SeitenCrane Load D Mag PDFrahul ranjanNoch keine Bewertungen

- Method Statement For Cranage & LiftingDokument6 SeitenMethod Statement For Cranage & Liftingadeniyi abiolaNoch keine Bewertungen

- Sinopec Engineering PresentationDokument83 SeitenSinopec Engineering Presentationstavros7Noch keine Bewertungen

- Electrical SafetyDokument45 SeitenElectrical SafetyAnsarMahmoodNoch keine Bewertungen

- Rima Rolamentos Versão1 PDFDokument114 SeitenRima Rolamentos Versão1 PDFCarlos Alberto de OliveiraNoch keine Bewertungen

- TEREXDokument10 SeitenTEREXYew LimNoch keine Bewertungen

- DS350GM Service Handbook PDFDokument63 SeitenDS350GM Service Handbook PDFmekanicobucaro100% (2)

- Leading Safety at WorkDokument16 SeitenLeading Safety at Worksgrsaya711Noch keine Bewertungen

- MM 122 - UnitizationDokument5 SeitenMM 122 - UnitizationRoselyn Balio-an100% (1)

- Norsok R-005 Nov. 2008Dokument60 SeitenNorsok R-005 Nov. 2008Eyoma EtimNoch keine Bewertungen

- Manitowoc 222exbDokument36 SeitenManitowoc 222exbrenatoxtrNoch keine Bewertungen

- ENISA Incident Management GuideDokument110 SeitenENISA Incident Management Guidejakle100% (1)

- Interpersonal SkillsDokument26 SeitenInterpersonal SkillsAnsarMahmoodNoch keine Bewertungen

- Scba 1010Dokument31 SeitenScba 1010AnsarMahmoodNoch keine Bewertungen

- Action PlanDokument2 SeitenAction PlanAnsarMahmoodNoch keine Bewertungen

- TNI TemplateDokument15 SeitenTNI TemplateAnsarMahmoodNoch keine Bewertungen

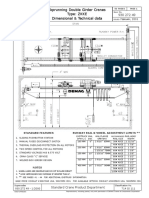

- 12 - D - 000 Motorized Rail Trolley - Without CraneDokument6 Seiten12 - D - 000 Motorized Rail Trolley - Without CraneAnsarMahmoodNoch keine Bewertungen

- 2011-08 Rig 1 Drift Eyes English Learning PDFDokument1 Seite2011-08 Rig 1 Drift Eyes English Learning PDFAnsarMahmoodNoch keine Bewertungen

- Awad AshrafDokument82 SeitenAwad AshrafAnsarMahmoodNoch keine Bewertungen

- Step-By-Step Guide RM LT 51Dokument57 SeitenStep-By-Step Guide RM LT 51AnsarMahmoodNoch keine Bewertungen

- PrintDokument5 SeitenPrintAnsarMahmoodNoch keine Bewertungen

- 2010-10-04 Alert-Drill Pipe PDFDokument1 Seite2010-10-04 Alert-Drill Pipe PDFAnsarMahmoodNoch keine Bewertungen

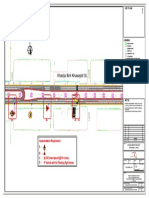

- TTCP at Pier 107 (Night Closure)Dokument1 SeiteTTCP at Pier 107 (Night Closure)AnsarMahmoodNoch keine Bewertungen

- Eib Ua Og Wells Appalachia - MTC - Worker Struck by Sling During Lift 05-Aug-11 PDFDokument1 SeiteEib Ua Og Wells Appalachia - MTC - Worker Struck by Sling During Lift 05-Aug-11 PDFAnsarMahmoodNoch keine Bewertungen

- Angola Mechanical Lifting Live & Learn 11 Aug 2011Dokument1 SeiteAngola Mechanical Lifting Live & Learn 11 Aug 2011AnsarMahmoodNoch keine Bewertungen

- 75 December Brent Bravo Parted Drill Pipe 752626 PDFDokument1 Seite75 December Brent Bravo Parted Drill Pipe 752626 PDFAnsarMahmoodNoch keine Bewertungen

- EIB OG-Wells-US-Magnolia NM-Substructure Pin Falls To Ground 1 Dec 2010 PDFDokument1 SeiteEIB OG-Wells-US-Magnolia NM-Substructure Pin Falls To Ground 1 Dec 2010 PDFAnsarMahmoodNoch keine Bewertungen

- Platform Felt Down While Reeving Drilling Line: Access LadderDokument2 SeitenPlatform Felt Down While Reeving Drilling Line: Access LadderAnsarMahmoodNoch keine Bewertungen

- LIST of LAWSDokument4 SeitenLIST of LAWSAnsarMahmoodNoch keine Bewertungen

- Eib Ua Og Wells Can Deep Basin - NM - Drop From Height-Picker Fast Line Weight 29-July 2011 PDFDokument1 SeiteEib Ua Og Wells Can Deep Basin - NM - Drop From Height-Picker Fast Line Weight 29-July 2011 PDFAnsarMahmoodNoch keine Bewertungen

- 76 December S711 - Sling Damaged While Picking Up Casing Joint 757999 PDFDokument1 Seite76 December S711 - Sling Damaged While Picking Up Casing Joint 757999 PDFAnsarMahmoodNoch keine Bewertungen

- Electrical SafetyDokument23 SeitenElectrical SafetyAnsarMahmoodNoch keine Bewertungen

- Nebosh D GuideDokument25 SeitenNebosh D GuideAnsarMahmoodNoch keine Bewertungen

- Incident Accident Reporting1062Dokument11 SeitenIncident Accident Reporting1062AnsarMahmoodNoch keine Bewertungen

- Report WritingDokument12 SeitenReport WritingSreekanth RaveendranNoch keine Bewertungen

- Controllers and Controller StationsDokument65 SeitenControllers and Controller StationsLucian ChorusNoch keine Bewertungen

- 888 SeriesDokument4 Seiten888 SeriesAntonio ArellanoNoch keine Bewertungen

- Luffing Mechanism 4th LectureDokument3 SeitenLuffing Mechanism 4th LectureMataifa emmanuelNoch keine Bewertungen

- Construction Planning and Implementation Using ANSI/TIA-322 and ANSI/ASSE A10.48Dokument43 SeitenConstruction Planning and Implementation Using ANSI/TIA-322 and ANSI/ASSE A10.48KemoH0% (1)

- Gantry Crane 511-512 Series Owners ManualDokument32 SeitenGantry Crane 511-512 Series Owners ManualAndi Mohamad FahrulNoch keine Bewertungen

- Zx10 ST Hoist d3050Dokument92 SeitenZx10 ST Hoist d3050roberto fuentealba godoyNoch keine Bewertungen

- KRA 1.4 Plant and EquipmentDokument13 SeitenKRA 1.4 Plant and EquipmentSubburajMechNoch keine Bewertungen

- SL6000 LC PDFDokument64 SeitenSL6000 LC PDFJavier PáezNoch keine Bewertungen

- View - File Value EngineeringDokument24 SeitenView - File Value EngineeringmagdyamdbNoch keine Bewertungen

- 1-1 2018-03-29 Operating Instructions Silo - Arctic EK-SiloDokument23 Seiten1-1 2018-03-29 Operating Instructions Silo - Arctic EK-SiloVali BobNoch keine Bewertungen

- Peerless Custom LiftingDokument100 SeitenPeerless Custom LiftingRony MedinaNoch keine Bewertungen

- Sandeep K. Pawar: A4-502, Mangeshi Sahara, Madhavkunj, Chikanghar, Kalyan (W) - 421301Dokument3 SeitenSandeep K. Pawar: A4-502, Mangeshi Sahara, Madhavkunj, Chikanghar, Kalyan (W) - 421301Sandeep PawarNoch keine Bewertungen

- 12-Zoomlion 70t Crawler Crane Specs - v2.4Dokument2 Seiten12-Zoomlion 70t Crawler Crane Specs - v2.4Athul BabuNoch keine Bewertungen

- Instruction Manual: LKH Centrifugal PumpDokument70 SeitenInstruction Manual: LKH Centrifugal PumpService CTANoch keine Bewertungen