Beruflich Dokumente

Kultur Dokumente

WDD Wacholderbeer+Âl Alpha-Pinen, Schwarze 2012

Hochgeladen von

Томислав ГалавићOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WDD Wacholderbeer+Âl Alpha-Pinen, Schwarze 2012

Hochgeladen von

Томислав ГалавићCopyright:

Verfügbare Formate

Benedikt Schwarze, Daniel Meyer

OC-F-Practical course WS 2012/13

Steam distillation of juniper berry oil

Advanced practical course

for Organic Chemistry

WS 2012/13

Report

Steam distillation of juniper berry oil

from juniper berries

Leipzig, 6th November 2012

Supervisor: Prof. Dr. Sicker, M.Sc. Liang Xia

Intern: Benedikt Schwarze (2263057), Daniel Meyer (2258970)

Handover date: 06.11.2012

Benedikt Schwarze, Daniel Meyer

OC-F-Practical course WS 2012/13

Steam distillation of juniper berry oil

TABLE OF CONTENTS

1

Introduction.................................................................................................................................................................3

Experimental part ....................................................................................................................................................4

Analytical facts..........................................................................................................................................................4

Discussion...................................................................................................................................................................6

References .................................................................................................................................................................6

Appendix ......................................................................................................................................................................7

Benedikt Schwarze, Daniel Meyer

OC-F-Practical course WS 2012/13

Steam distillation of juniper berry oil

Juniper berry oil

1 INTRODUCTION

In this laboratory exercise juniper berry oil will be isolated by steam distillation from

juniper berries. This essential oil is a mix of fragrant compounds like -pinen, pinen, etc., which belong to the terpenes, the terpenoids and their oxygen containing

derivatives.

The direct distillation of juniper berries is impossible, because most compounds of

the oil have a high boiling point and would decompose under higher temperatures.

Therefore it is milder to use steam distillation to isolate the essential oil.

Steam distillation is a useful and selective separation process for temperature

sensitive volatile compounds that are not or only poorly miscible with water.

In our case the option of the live steam generation is used to generate steam from an

external steam source. The steam, which is conducted into the distilling pot, carries

the oils vapor into the distilling head and then into the condenser, where the oil and

water co-condense. This type of a so called azeotropic distillation only works

because of the fact that oil and water are immiscible and boil independent of each

other distillation.

[1][2]

Heating of such a mixture of two nearly immiscible liquids

forces each constituent to independently exert its own vapour pressure, in a manner

as if the other compound(s) were not existing. Continuous heating leads to a

temperature where the sum of the added single vapour pressure matches the

atmospheric pressure. With water as the main compound this boiling temperature is

close to 100 C, but always below. By this method, many hydrophobic but volatile

organic compounds can be selectively removed from their natural raw materials

distinctly below their own boiling points as pure liquids (e.g. -pinene which has a bp

of 155 C).

Benedikt Schwarze, Daniel Meyer

OC-F-Practical course WS 2012/13

Steam distillation of juniper berry oil

2 EXPERIMENTAL PART

200 g of intact juniper berries and 2000 mL water were put into a 4-L-triple-neckedflask. The distillation was stopped at an amount of 1500 mL of distillate, which was

extracted with 580 mL MTBE. The extract was dried and the solvent was removed

under reduced pressure (500 mbar, 40 C). The distillation yielded 250 mg of an

yellow-brown oil.

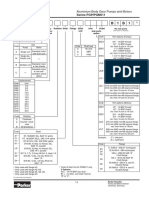

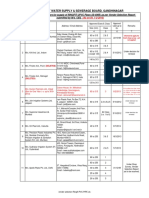

The setup for steam distillation looks like in figure 1.

Fig. 1: Still for steam distillation of juniper berries

[4]

3 ANALYTICAL FACTS

To roughly analyze the composition the essential oil a 1H-NMR-spectrum was taken.

Solvent: CDCl3

Mass: 50 mg

Test frequency: 300 MHz

Benedikt Schwarze, Daniel Meyer

OC-F-Practical course WS 2012/13

Steam distillation of juniper berry oil

Of course the oil is a mixture of many compounds, which are not all known. But the

main compound in the mixture is supposed to be -pinene. To proof this, a second

spectrum was taken of pure -pinene from our lab. The spectrum of -pinene was

taken from [6].

Fig. 2: - and -pinene

It is mainly hard to analyze the aliphatic part of the spectrum, since there is a mixture

of many compounds, whose signals overlap. Nonetheless there are specific shifts in

both the spectrum of the oil and the spectra of the pure pinenes.

Tab. 1: aliphatic shifts of the spectra

-pinene

-pinene

Juniper Berry Oil

=0.80 ppm

=0.70

=0.80

=1.30 ppm

=1.20

=1.20; =1.23

=1.60 ppm

=1.470

=1.60; =3.25

From the aliphatic part it is not obvious if only one or both pinenes are components of

the oil.

Hence the olefinic part of the spectrum has to be analyzed, since -pinene has only

one olefinic proton and -pinene has two.

Tab.2: olefinic shifts of the spectra

-pinene

-pinene

Juniper Berry Oil

=5.2 (s)

=4.6 (d)

=5.2 (s)

The olefinic part gives the information which is needed. For there is a singlet at a

chemical shift of 5.2 ppm in both the spectrum of -pinene and the juniper berry oil, it

is obvious that the one of the main components of the oil is -pinene.

In the spectrum of the oil there are some shifts in the aromatic part, which cannot be

interpreted. On principle, a gas chromatogram would give further informations.

Benedikt Schwarze, Daniel Meyer

OC-F-Practical course WS 2012/13

Steam distillation of juniper berry oil

4 DISCUSSION

The yield of 250 mg of juniper berry oil from 200 g juniper berries is rather small.

Hence the practical application has to be improved. The first idea is to reduce the

juniper berries to small pieces, so the steam can better release the essential oil

components, since there is no shell protecting fragrant compounds.

The second idea comes from the gin production. Some distillers dilute the spirit

alcohol with water to 45% (percentage by volume) and put it together with juniper

berries and other (!!) botanicals into a copper pot still for one day to one week so

the alcohol can absorb the flavors. This process is called maceration and gives low

quality gin. To complete the distillation process the grain distillate is heated up and

the volatile alcohol with the extracted flavors is collected at 86-89C.

Other distillers, who make superior quality gins, use the vaporization process. The

botanicals are placed in a copper basket or cheesecloth and suspended above the

alcohol in the pot still while the spirits are boiled. The vapor soak the contents of the

botanicals and transfer the flavor to the alcohol.[5] However, the intention for this

exercise was not to make gin, but to increase the number of steam distillation

examples. In this respect it was both interesting and sufficient for a first trail.

5 REFERENCES

[1] S. Hnig et al., Arbeitsmethoden in der organischen Chemie, 2006, Lehmanns

Media, S.110

[2] http://infohost.nmt.edu/~jaltig/SteamDistill.pdf (Stand: 05.11.2012)

[3] http://www.heilkraeuter.de/lexikon/wacholde.htm (Stand: 05.11.2012)

[4] Still by courtesy of S. Aurich, WDD Apparatur Kamille zu Chamazulen, 2008

[5] http://www.ehow.com/how-does_5453310_distillation-process-gin.html

(Stand: 05.11.2012)

[6] http://riodb01.ibase.aist.go.jp/sdbs/cgi-bin/direct_frame_top.cgi

(Stand: 05.11.2012)

Benedikt Schwarze, Daniel Meyer

OC-F-Practical course WS 2012/13

Steam distillation of juniper berry oil

6 APPENDIX

Spectrum of -pinene from the SDBS database (enclosed)

CAS-Registry-Number of -pinene: 7785-26-4

H-NMR-spectra of juniper berry oil (extra file)

H-NMR-spectra of - and -pinene (extra file)

Das könnte Ihnen auch gefallen

- The Beginner's Guide to Beer Brewing: Fundamentals Of Beer BrewingVon EverandThe Beginner's Guide to Beer Brewing: Fundamentals Of Beer BrewingNoch keine Bewertungen

- Steam Distillation of Cloves READ:Landgrebe 4 Ed .p160-161 (Section 7.6) and p369-371, 5 Ed. P 140-141 (Section 7.6) and P 321-322Dokument4 SeitenSteam Distillation of Cloves READ:Landgrebe 4 Ed .p160-161 (Section 7.6) and p369-371, 5 Ed. P 140-141 (Section 7.6) and P 321-322AeFondevillaNoch keine Bewertungen

- Bio-Based SolventsVon EverandBio-Based SolventsFrançois JérômeNoch keine Bewertungen

- Formal Lab-Clove OilDokument7 SeitenFormal Lab-Clove OilMikeNoch keine Bewertungen

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerVon EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNoch keine Bewertungen

- Organic Chemistry Lab 2Dokument4 SeitenOrganic Chemistry Lab 2edmundhabboNoch keine Bewertungen

- Handbook of Enology, Volume 2: The Chemistry of Wine - Stabilization and TreatmentsVon EverandHandbook of Enology, Volume 2: The Chemistry of Wine - Stabilization and TreatmentsPascal Ribéreau-GayonNoch keine Bewertungen

- Distillation of GinDokument6 SeitenDistillation of GinJan Chester ChanNoch keine Bewertungen

- Synthesis of P2PDokument15 SeitenSynthesis of P2PRiki Mandol83% (24)

- BrewDokument17 SeitenBrewXeronadazero67% (3)

- Distillation of AlcoholDokument12 SeitenDistillation of Alcoholarturomarquezmaya5475Noch keine Bewertungen

- Banana Synthesis of EsterDokument53 SeitenBanana Synthesis of EsterChristianOngNoch keine Bewertungen

- Distillation 123Dokument12 SeitenDistillation 123Mukesh TiwariNoch keine Bewertungen

- Preparation of Banana FlavorsDokument8 SeitenPreparation of Banana Flavorsnathan3602Noch keine Bewertungen

- Project PPT 1Dokument22 SeitenProject PPT 1Swarnalatha Katta0% (1)

- Exp 6pcogDokument2 SeitenExp 6pcogJanice Malafu De GuiaNoch keine Bewertungen

- CHEM F110 - Lab Manual - Nov 5-2020Dokument45 SeitenCHEM F110 - Lab Manual - Nov 5-2020STUTI MATHUR100% (2)

- Isolation of Casein From Milk Aim: To Isolate CaseinDokument21 SeitenIsolation of Casein From Milk Aim: To Isolate CaseinK.Selvaraj79% (14)

- Exp 2-Dry FractionationDokument14 SeitenExp 2-Dry FractionationFfmohamad NAdNoch keine Bewertungen

- Synthesis of 2-NitropropeneDokument3 SeitenSynthesis of 2-NitropropeneVictor VikeneNoch keine Bewertungen

- AspirinDokument4 SeitenAspiringenelleestremos100% (1)

- Extraction of Oil From Eucalyptus Camadulensis Using Water Distillation MethodDokument6 SeitenExtraction of Oil From Eucalyptus Camadulensis Using Water Distillation MethodHatem ChouchaneNoch keine Bewertungen

- Skip To Main ContentDokument13 SeitenSkip To Main Contentleonardkigen100Noch keine Bewertungen

- Lab Session 2: Synthesis and Purification of Acetylsalicylic AcidDokument10 SeitenLab Session 2: Synthesis and Purification of Acetylsalicylic AcidBeatriz IzquierdoNoch keine Bewertungen

- Chemistry InvestigatoryDokument23 SeitenChemistry InvestigatoryAditi Goyal100% (3)

- Chemistry 125 Laboratory 11Dokument5 SeitenChemistry 125 Laboratory 11SmaeUBNoch keine Bewertungen

- Benzoic Acid LabDokument7 SeitenBenzoic Acid Labstephanie damajNoch keine Bewertungen

- Synthesis & Distillation of Isopentyl Acetate Using Acetic Acid and Isopentyl AlcoholDokument8 SeitenSynthesis & Distillation of Isopentyl Acetate Using Acetic Acid and Isopentyl AlcoholAlbert TorrezNoch keine Bewertungen

- Report On NeemDokument16 SeitenReport On Neemadityaksrivastava100% (1)

- Experiment 5: Simple Distillation ObjectiveDokument7 SeitenExperiment 5: Simple Distillation Objectiveshark eye67% (3)

- Saccharomyces Cerevisiae: Vinegar - Acetobacter CheeseDokument5 SeitenSaccharomyces Cerevisiae: Vinegar - Acetobacter CheeseArmanRenzTV0% (1)

- Exp 3 OtwwDokument3 SeitenExp 3 Otwwexpido tapologoNoch keine Bewertungen

- REPORT ON INDUSTRIAL ATTACHMENT AlphaDokument11 SeitenREPORT ON INDUSTRIAL ATTACHMENT AlphaOkorie VictorNoch keine Bewertungen

- Che2060 Distillation of Wine s16Dokument5 SeitenChe2060 Distillation of Wine s16Aaliyah MohamedNoch keine Bewertungen

- MEDICINAL CHEMISTRY-I - Practicals PDFDokument25 SeitenMEDICINAL CHEMISTRY-I - Practicals PDFAnit Dubey100% (1)

- Oil Tech Final PDFDokument22 SeitenOil Tech Final PDFRB CreationNoch keine Bewertungen

- HW0021 Manufacture of EthanolDokument5 SeitenHW0021 Manufacture of Ethanollily augustNoch keine Bewertungen

- Experiment 3 Isolating Clove OilDokument6 SeitenExperiment 3 Isolating Clove OilEmilio MolinaNoch keine Bewertungen

- Chm557 Laboratory Report: Experiment 4 The Aldol Condensation Reaction: Preparation of DibenzalacetoneDokument17 SeitenChm557 Laboratory Report: Experiment 4 The Aldol Condensation Reaction: Preparation of DibenzalacetonesyafNoch keine Bewertungen

- Experiment 1: Preparation of 2-Iodobenzoic Acid From Anthranilic Acid (2-Amino Benzoic Acid)Dokument11 SeitenExperiment 1: Preparation of 2-Iodobenzoic Acid From Anthranilic Acid (2-Amino Benzoic Acid)Sanjida Khandoker 1911009049Noch keine Bewertungen

- A PhenylacetoacetonitrileDokument4 SeitenA PhenylacetoacetonitrileNik OthmanNoch keine Bewertungen

- Esterification Reactions of VanilinDokument6 SeitenEsterification Reactions of Vanilinsarah amalinNoch keine Bewertungen

- Spicata Subsp. Insularis Essential Oils by Supercritical CO: Extraction and Isolation of Salvia Desoleana and MenthaDokument5 SeitenSpicata Subsp. Insularis Essential Oils by Supercritical CO: Extraction and Isolation of Salvia Desoleana and MenthaРусланNoch keine Bewertungen

- Chemical Industry 1Dokument17 SeitenChemical Industry 1xaliddiyareNoch keine Bewertungen

- AcetanilideDokument7 SeitenAcetanilideepsonme101Noch keine Bewertungen

- Bar ManualDokument45 SeitenBar Manualbagus wiraNoch keine Bewertungen

- DistillationDokument13 SeitenDistillationrijaNoch keine Bewertungen

- PLab EditedDokument7 SeitenPLab EditedChin RamosNoch keine Bewertungen

- Chem 305 Lab 5 Benzoil.Dokument4 SeitenChem 305 Lab 5 Benzoil.Gobe JamNoch keine Bewertungen

- Thermal Effects On Hydrothermal Biomass Liquefaction: # Humana Press Inc. 2008Dokument8 SeitenThermal Effects On Hydrothermal Biomass Liquefaction: # Humana Press Inc. 2008Amal ..Noch keine Bewertungen

- AlkylationDokument11 SeitenAlkylationZain Ul AbedinNoch keine Bewertungen

- CM134 1LDokument5 SeitenCM134 1LshellNoch keine Bewertungen

- Aldol Condensation Reaction Lab ReportDokument4 SeitenAldol Condensation Reaction Lab ReportAvril Watson100% (3)

- Piperidine SynthesisDokument4 SeitenPiperidine Synthesisjiskate77Noch keine Bewertungen

- Clove Oil Synthesis Organic ChemistryDokument8 SeitenClove Oil Synthesis Organic ChemistrynewswagNoch keine Bewertungen

- 3 Synthesis of AcetaminophenDokument6 Seiten3 Synthesis of AcetaminophenAashish GauravNoch keine Bewertungen

- Preparation of BiodieselDokument6 SeitenPreparation of Biodieselpranjal JaiswalNoch keine Bewertungen

- Exp 5 (Peroxide Value)Dokument7 SeitenExp 5 (Peroxide Value)eizat abasNoch keine Bewertungen

- CHM207 Lab Report Eks.2Dokument7 SeitenCHM207 Lab Report Eks.2Akmal HakimNoch keine Bewertungen

- Major Exam 2 ReviewerDokument7 SeitenMajor Exam 2 ReviewermauNoch keine Bewertungen

- Heko KatalogDokument2 SeitenHeko KatalogТомислав ГалавићNoch keine Bewertungen

- Katalog Skladistenjeiprerada enDokument2 SeitenKatalog Skladistenjeiprerada enТомислав ГалавићNoch keine Bewertungen

- Anker International PLCDokument29 SeitenAnker International PLCТомислав ГалавићNoch keine Bewertungen

- Logistic Tables and Prices FFHDokument3 SeitenLogistic Tables and Prices FFHТомислав ГалавићNoch keine Bewertungen

- First Fruit 2013-2014Dokument1 SeiteFirst Fruit 2013-2014Томислав ГалавићNoch keine Bewertungen

- Price List of Horeca Frozen Bakery ProductsDokument1 SeitePrice List of Horeca Frozen Bakery ProductsТомислав ГалавићNoch keine Bewertungen

- The Origins of Mythology PDFDokument43 SeitenThe Origins of Mythology PDFТомислав Галавић100% (1)

- Price For Buyer SA (ExW SRB)Dokument1 SeitePrice For Buyer SA (ExW SRB)Томислав ГалавићNoch keine Bewertungen

- Accessories and Important Guidelines When Using Wi-PourDokument1 SeiteAccessories and Important Guidelines When Using Wi-PourТомислав ГалавићNoch keine Bewertungen

- Siemens Engineering Manual V7Dokument338 SeitenSiemens Engineering Manual V7Jeremy Branch100% (2)

- Magneto Hydro Dynamics PresentationDokument19 SeitenMagneto Hydro Dynamics PresentationVipul GuptaNoch keine Bewertungen

- Production of Isopropyl Palmitate-Experimental StudiesDokument12 SeitenProduction of Isopropyl Palmitate-Experimental Studiesikaw_3Noch keine Bewertungen

- User'S Manual: Capstone MicroturbineDokument56 SeitenUser'S Manual: Capstone MicroturbinemassimocalviNoch keine Bewertungen

- Comfort and Performance Your Customers DemandDokument18 SeitenComfort and Performance Your Customers Demandgizex2013Noch keine Bewertungen

- Using Dapper Asynchronously inDokument1 SeiteUsing Dapper Asynchronously inGiovani BrondaniNoch keine Bewertungen

- AHRLACDokument18 SeitenAHRLACVictor Pileggi100% (1)

- Sjoblom, J. - Handbook of Emulsion Technology PDFDokument731 SeitenSjoblom, J. - Handbook of Emulsion Technology PDFdcharlies92% (13)

- Kathir CollegeDokument3 SeitenKathir Collegeshanjuneo17Noch keine Bewertungen

- ENOVIA V6 Product PortfolioDokument32 SeitenENOVIA V6 Product PortfolioARUN PATILNoch keine Bewertungen

- Creating REST API Using NodeJS and Consuming in AngularJSDokument8 SeitenCreating REST API Using NodeJS and Consuming in AngularJSserignemodouNoch keine Bewertungen

- D 2510 - 94 R98Dokument3 SeitenD 2510 - 94 R98David Cazorla100% (1)

- HiraDokument30 SeitenHiravijay kumar singhNoch keine Bewertungen

- Woson 23 Litre B Class Touch AutoclaveDokument2 SeitenWoson 23 Litre B Class Touch AutoclaveBashar MohammadNoch keine Bewertungen

- Sewer Connection Application Guidance PDFDokument7 SeitenSewer Connection Application Guidance PDFSamuel FuentesNoch keine Bewertungen

- ElectronicsDokument3 SeitenElectronicsashishkumar218Noch keine Bewertungen

- RT 8090 TDokument40 SeitenRT 8090 TManuel100% (1)

- Marine Lubricants Equivalents List: Sae 50 TBN 57 Sae 50 TBN 55 Sae 40 TBN 60 Sae 50 TBN 50 Sae 50 TBN 55Dokument3 SeitenMarine Lubricants Equivalents List: Sae 50 TBN 57 Sae 50 TBN 55 Sae 40 TBN 60 Sae 50 TBN 50 Sae 50 TBN 55spyros_peiraiasNoch keine Bewertungen

- Delhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeyDokument6 SeitenDelhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeySumukh MullangiNoch keine Bewertungen

- FL-02-01 PM SheetDokument12 SeitenFL-02-01 PM SheetBikas SahaNoch keine Bewertungen

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Dokument7 SeitenPG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksNoch keine Bewertungen

- RequirementsDokument18 SeitenRequirementsmpedraza-1Noch keine Bewertungen

- Sewerage & Sewage Treatment PlantDokument26 SeitenSewerage & Sewage Treatment PlantSyed ZamanNoch keine Bewertungen

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDokument11 Seiten4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- Islamic Law - WaterDokument12 SeitenIslamic Law - WaterAnum FaheemNoch keine Bewertungen

- Esquema Elétrico NGD 9.3Dokument2 SeitenEsquema Elétrico NGD 9.3LuisCarlosKovalchuk100% (1)

- Electro Magnetic Induction PDFDokument28 SeitenElectro Magnetic Induction PDFPuran BistaNoch keine Bewertungen

- Crankshaft Position (CKP) Sensor: 1F2-12 M161 Engine ControlsDokument6 SeitenCrankshaft Position (CKP) Sensor: 1F2-12 M161 Engine ControlsKukuh SeptiantoNoch keine Bewertungen

- GWSSB Vendor List 19.11.2013Dokument18 SeitenGWSSB Vendor List 19.11.2013sivesh_rathiNoch keine Bewertungen

- Apqp - DR SHFTDokument60 SeitenApqp - DR SHFTrajesh5000100% (2)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterVon EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterBewertung: 3.5 von 5 Sternen3.5/5 (487)

- Magnolia Table, Volume 3: A Collection of Recipes for GatheringVon EverandMagnolia Table, Volume 3: A Collection of Recipes for GatheringBewertung: 4.5 von 5 Sternen4.5/5 (4)

- The Obesity Code: Unlocking the Secrets of Weight LossVon EverandThe Obesity Code: Unlocking the Secrets of Weight LossBewertung: 4 von 5 Sternen4/5 (6)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldVon EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldBewertung: 3.5 von 5 Sternen3.5/5 (5)

- Sully: The Untold Story Behind the Miracle on the HudsonVon EverandSully: The Untold Story Behind the Miracle on the HudsonBewertung: 4 von 5 Sternen4/5 (103)

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingVon EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingBewertung: 4 von 5 Sternen4/5 (9)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomVon EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomBewertung: 4 von 5 Sternen4/5 (1)

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyVon EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyBewertung: 4 von 5 Sternen4/5 (11)

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideVon EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideBewertung: 4 von 5 Sternen4/5 (6)

- The End of Craving: Recovering the Lost Wisdom of Eating WellVon EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellBewertung: 4.5 von 5 Sternen4.5/5 (82)

- The Fabric of Civilization: How Textiles Made the WorldVon EverandThe Fabric of Civilization: How Textiles Made the WorldBewertung: 4.5 von 5 Sternen4.5/5 (58)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookVon EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyVon EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyBewertung: 4 von 5 Sternen4/5 (1)

- Mexican Today: New and Rediscovered Recipes for Contemporary KitchensVon EverandMexican Today: New and Rediscovered Recipes for Contemporary KitchensBewertung: 4 von 5 Sternen4/5 (6)

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthVon EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthBewertung: 2 von 5 Sternen2/5 (1)

- Hero Found: The Greatest POW Escape of the Vietnam WarVon EverandHero Found: The Greatest POW Escape of the Vietnam WarBewertung: 4 von 5 Sternen4/5 (19)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingVon EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingBewertung: 4 von 5 Sternen4/5 (3)

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingVon EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingNoch keine Bewertungen

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoVon EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoNoch keine Bewertungen

- Authentic Mexican: Regional Cooking from the Heart of MexicoVon EverandAuthentic Mexican: Regional Cooking from the Heart of MexicoNoch keine Bewertungen

- Trisha's Kitchen: Easy Comfort Food for Friends & FamilyVon EverandTrisha's Kitchen: Easy Comfort Food for Friends & FamilyBewertung: 4 von 5 Sternen4/5 (5)

- Glucose Goddess Method: A 4-Week Guide to Cutting Cravings, Getting Your Energy Back, and Feeling AmazingVon EverandGlucose Goddess Method: A 4-Week Guide to Cutting Cravings, Getting Your Energy Back, and Feeling AmazingBewertung: 5 von 5 Sternen5/5 (61)

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayVon EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayBewertung: 4 von 5 Sternen4/5 (4)