Beruflich Dokumente

Kultur Dokumente

How Chin Engineering: Job Safety Analysis

Hochgeladen von

How Chin Engineering Sdn BhdOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

How Chin Engineering: Job Safety Analysis

Hochgeladen von

How Chin Engineering Sdn BhdCopyright:

Verfügbare Formate

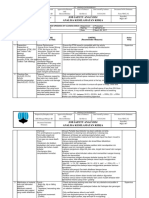

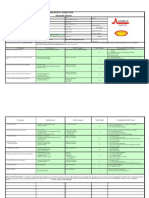

HOW CHIN ENGINEERING

Job Safety Analysis

JOB DESCRIPTION

TYPES OF WORK

: Welding works

LOCATION OF WORK: Workshop

REQUIRED PERSONAL PROTECTIVE EQUIPMENT

x

x

x

x

Safety Helmet

Safety Shoes / Boots

Safety Glasses

Face / Welding Shield

Goggles

Life Jackets

Cotton Gloves

Welding Gloves

Leather Gloves

Leather Apron

Gauntlets

Dust Mask

Work Vest

Safety Vest

Safety Harness / Belt

Face Mask

Ear Protection

Others (Specify): _________________

OTHER SAFETY EQUIPMENT / REQUIREMENTS

x

x

Fire Extinguisher

Gas Detector

Safety Signs

Barricades

Lifeline

N

o

Activity

( Job Steps )

1.

Work permit

from Client

to be

obtained.

Tag Out / Lock Out

Work Permit

Competency Certificate

Respirator

First Aid Equipment

Potential Hazard

Unauthorized

commencement of

works may result in

exposing workers

and or potential to

Control/ Recovery Measures

Authorized lead-operator / in-charge shall ensure obtaining and

maintaining valid work permit.

The worksite supervisor responsible for this activity has to check

the PPE of his staff to ensure that all required items are available

and properly used.

Responsib

le/ Action

By

Leadoperator

Supervisor

HOW CHIN ENGINEERING

harm or danger

Inform all workers regarding permit condition before work starts.

Worksite supervisor shall conduct toolbox talks about nature of

works and associated potential hazards and their essential

precautionary measure.

Follow mobilization schedule and arrange the required documents

to avoid any cause of delay.

Ensure that the pre task briefing is given out in a language

understood by the work force, have it translated.

Ask question regarding the briefing to get feedback from the staff,

this ensures full comprehension.

Issue required appropriate PPE and replace PPE that has signs of

defect.

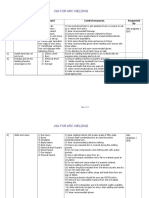

Pre-task

briefing

toolbox

talks.

Set up work

piece on fixture

The work force does

not understand the

pre task briefing

therefore does not

understand the

potential dangers

and control

measures to be

implemented. Some

of the workers could

be lacking PPE or

using defective PPE.

up

Strain/sprain from

heavy and/or

awkward

work piece

Foot injury from

dropping work

piece

Trip/fall in area

around

Arc Welding

workstation

Damage to work

piece

from incorrect set-

Use mechanical hoist or get assistance from co-worker to set-up/

adjust work piece

Wear recommended footwear. Ensure work piece is securely

clamped to fixture

Clean/clear work area/surfaces of unused tools/materials.

Remove dust/debris.

Work piece should be clean and secure to fixture

Wear recommended gloves when handling work pieces with

sharp edges

Use correct tool and wear recommended gloves

Supervisor

Workers

Supervisor

Workers

HOW CHIN ENGINEERING

Hand/finger

laceration

from edge of work

piece

Hand/finger

contusion

from tool slippage

while

tightening fixture

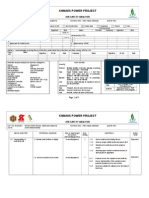

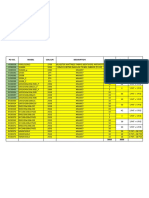

Install

electrode rod

into torch

Energize and

set Arc Welding

Machine

amperage/

current

Turn on gas

and set flow

(if applicable)

Hazard :

Electric shock/burn

from electrode rod

Hazard :

Electrical

shock/burn from

contact with

electrode rod

holder

Damage to

workpiece from

incorrect

amperage/current

Hazard :

Damage to

workpiece from

incorrect gas flow

rate

Bodily injury from

explosion of

Ensure Arc Welding machine power to arc is electrically deenergized when changing electrical rod

Supervisor

Ensure welding machine is properly grounded. Welder should be

insulated from live electrical parts and dry.

Inspect and replace cables, plugs and leads that show any signs

of defects. Wear recommended gloves and clothing.

Refer to Op Sheet and/or Shop Order for correct

amperage/current

Supervisor

Consult Op Sheet and/or Shop Order for correct flow rate

Practice caution around compressed gas cylinders. Protect gas

cylinders from excessive heat, mechanical shocks and arcs.

Ensure cylinder is insulated and fastened so it will not fall.

Do not use a compressed gas cylinder that appears to be

Supervisor

Workers

Workers

HOW CHIN ENGINEERING

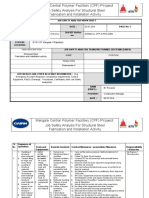

Weld

workpiece

Complete

welding

compressed gas

cylinder

Eye injury from

welding flash

and/or spatter

Burns from welding

spatter, UV/infrared

radiation and/or

electrical contact

Inhalation of

welding fumes or

asphyxiation from

displaced oxygen

Bodily injury from

condition or type of

work piece being

welded

Electrical shock

hazard

Hearing loss from

chronic exposure to

noisy machinery

Fire due to

combustible

material in welding

area

Hand/finger contact

burn from hot

electrode rod

Hazard :

Electrical

shock/burn or

damaged and/or defective.

Wear welding helmet with proper grade of filter plate.

Ensure flash curtains/barriers are used to protect

bystanders/observers--b) Wear recommended protective

clothing.

Ensure any exposed skin is covered during the welding process.

Do not wear metal jewelry and clothing with cuffs and/or pockets.

Stay a safe distance away from arc

Use local exhaust ventilation and a fan to maintain good air

circulation

Do not weld work piece unless it is properly cleaned

Ensure welding machine is properly grounded. Welder should be

insulated from live electrical parts and dry.

Do not weld when wet.

Inspect and replace cables, plugs and leads that show any signs

of defect.

Wear hearing protection

Remove any combustible material from the immediate welding

site.

Keep a fire extinguisher readily available.

When electrode rod gets too short, stop welding and restart with

a new electrode rod.

Wear recommended gloves

Supervisor

Ensure Arc Welding machine power to arc is electrically deenergized. When not in use electrode rod should be removed

Supervisor

Workers

HOW CHIN ENGINEERING

electrical contact

with conducting

objects, flammable

liquids and/or

compressed gas

cylinders due to

energized electrode

rod holder

9

Remove

workpiece from

fixture and

transport to

inspection

Hazard :

Strain/sprain from

heavy and/or

awkward workpiece

Foot injury from

dropping workpiece

Trip/fall in area

around Arc Welding

workstation

Hand/finger

laceration from

edge of workpiece

Hand/finger

contusion from tool

slippage

from holder and holder should be placed so it cannot make

electrical contact with conducting objects, flammable liquids

and/or compressed gas cylinders.

Workers

Use mechanical hoist or get assistance from co-workers to

transport workpiece

Wear recommended footwear. Ensure workpiece is securely

clamped to fixture

Clean/clear work area/surfaces of unused tools/materials.

Remove dust/debris regularly

Wear recommended gloves when handling workpieces with sharp

edges

Use correct tool and wear recommended gloves

Supervisor

Workers

Hazard :

Prepared By :

2016

Contractor / Contractor Representative

Reviewed By :

Lead-operator / In-charge

Date : 5 MAY

Das könnte Ihnen auch gefallen

- Manual Tig Welding (RRC) - Job ProcedureDokument3 SeitenManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JSA Word Construction of WorkshopDokument3 SeitenJSA Word Construction of Workshopgerard_borbonNoch keine Bewertungen

- Jsa Welding Cutting and Grinding at Closing AreaDokument7 SeitenJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- JSA Welding Confined SpaceDokument2 SeitenJSA Welding Confined Spacegkmlal100% (4)

- JSA For Cutting, Grinding and WeldingDokument4 SeitenJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Crane JSADokument5 SeitenCrane JSAKritsada Tiwutanon100% (1)

- Jsa For Arc WeldingDokument3 SeitenJsa For Arc Weldingtnssbhaskar100% (5)

- JSA #19 Grinding, Welding, Gas CuttingDokument2 SeitenJSA #19 Grinding, Welding, Gas CuttingSubham Sohal100% (1)

- JSA Formet New Structural Steel ErectionDokument11 SeitenJSA Formet New Structural Steel Erectionsakthi venkatNoch keine Bewertungen

- JSA Electrical WiringDokument10 SeitenJSA Electrical WiringWeru Morris100% (1)

- JSA Fitting and Welding Work For Pipe Trench InstalationDokument6 SeitenJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Job Safety Analysis Worksheet: Yes NoDokument8 SeitenJob Safety Analysis Worksheet: Yes NoBorislav VulićNoch keine Bewertungen

- JSA NO 2-Piling WorkDokument3 SeitenJSA NO 2-Piling WorkKarthik GanesanNoch keine Bewertungen

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDokument4 SeitenMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- Jsa For Weld and GrindingDokument6 SeitenJsa For Weld and GrindingTanzeel LiaqatNoch keine Bewertungen

- Jsa-Jha For Using of Hand ToolsDokument2 SeitenJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDokument9 SeitenHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDokument4 SeitenJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Jsa For WeldingDokument2 SeitenJsa For WeldingMohamed Samir50% (2)

- JSA For Welding GrindingDokument7 SeitenJSA For Welding GrindingBabar78% (9)

- JHA Welding & Grinding Work Rev 001Dokument6 SeitenJHA Welding & Grinding Work Rev 001Jeremia Samosir100% (2)

- 1 Scaffolding WorkDokument27 Seiten1 Scaffolding WorkKhuda BukshNoch keine Bewertungen

- JSA Erection of Steel StructureDokument9 SeitenJSA Erection of Steel StructureLuqman Osman77% (13)

- Job Safety Analysis: Job Title: Installing Pneumatic Rubber FenderDokument3 SeitenJob Safety Analysis: Job Title: Installing Pneumatic Rubber FenderIhwan AsrulNoch keine Bewertungen

- Jsa For Piping and Erection RevisedDokument1 SeiteJsa For Piping and Erection RevisedDr AnwarNoch keine Bewertungen

- JSA HandToolsDokument2 SeitenJSA HandToolsCristina Rican100% (3)

- JSA For Fab Erec of STRL Steel StackDokument5 SeitenJSA For Fab Erec of STRL Steel StackkrishnakumarNoch keine Bewertungen

- R1937-JSA-004 Job Safety Analysis For Pipe PullDokument3 SeitenR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNoch keine Bewertungen

- Lifting Operatio in Progress PDFDokument1 SeiteLifting Operatio in Progress PDFsubhanmusadiq100% (1)

- JSA # 3 Column ErectionDokument6 SeitenJSA # 3 Column ErectionRaghava Richhu100% (2)

- Jsa General HousekeepingDokument2 SeitenJsa General HousekeepingHow Chin Engineering Sdn Bhd44% (9)

- JSA-010 Excavation Sampling PDFDokument5 SeitenJSA-010 Excavation Sampling PDFArgaYurIstiawanNoch keine Bewertungen

- 1installation of Steel Structures JHA 1 (06!06!2015)Dokument33 Seiten1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- Jsa For The Installation of I EamDokument5 SeitenJsa For The Installation of I EamMohammed MinhajNoch keine Bewertungen

- JSA G20 Scaffolding (Erection, Dismantling)Dokument4 SeitenJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- JHA Manual HandlingDokument5 SeitenJHA Manual HandlingFatin Zulkifli100% (1)

- Job Hazard AnalysisDokument10 SeitenJob Hazard AnalysisDave ImpresoNoch keine Bewertungen

- JSA WeldingDokument2 SeitenJSA WeldingSigint Sides0% (3)

- JSA For Working at HeightDokument2 SeitenJSA For Working at HeightXUE JIANNoch keine Bewertungen

- JSA - Structural Steel Fabrication and Installation WorksDokument3 SeitenJSA - Structural Steel Fabrication and Installation Workssakthi venkatNoch keine Bewertungen

- JHA Civil WorksDokument2 SeitenJHA Civil Worksethelchudi100% (11)

- Pa Hsec 02 040 002 F03Dokument4 SeitenPa Hsec 02 040 002 F03Abdul KhaliqNoch keine Bewertungen

- SOP Erection TC PDFDokument3 SeitenSOP Erection TC PDFRashidi RahmanNoch keine Bewertungen

- Jsa CraneDokument3 SeitenJsa Cranenattwa201075% (24)

- Job Safety AnalysisDokument3 SeitenJob Safety AnalysisBhisamS SallehNoch keine Bewertungen

- Steel Erection JSADokument5 SeitenSteel Erection JSASalah Abd Eldayem100% (1)

- Job Safety Analysis Sheet: FacilityDokument1 SeiteJob Safety Analysis Sheet: Facilitywahyu nugrohoNoch keine Bewertungen

- Job Hazard Analysis Welding Operations: Job Title: Work Place LocationDokument18 SeitenJob Hazard Analysis Welding Operations: Job Title: Work Place Locationmuhammad imtiaz100% (1)

- Job Safety Analysis PlumbersDokument5 SeitenJob Safety Analysis Plumbersallen2912100% (1)

- Jha of PaintingDokument3 SeitenJha of PaintingAllan Camacho Regalado100% (1)

- ULSADO-JSA-Demolation Existing Concrete FoundationDokument2 SeitenULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- JSA-Steel Structure Erection-NDokument4 SeitenJSA-Steel Structure Erection-NVivek Naik100% (2)

- 6.0 ISOLATION JSA CONCRETE WORK HanesDokument7 Seiten6.0 ISOLATION JSA CONCRETE WORK HanesMc Loki100% (3)

- JSA Steel Erection ManliftsDokument1 SeiteJSA Steel Erection Manliftsrudygoot100% (1)

- Welding WorkDokument1 SeiteWelding WorkGudduNoch keine Bewertungen

- JSA-Manual Lifting of MaterialsDokument3 SeitenJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- Jsa Copper Grounding at Fire PumpDokument5 SeitenJsa Copper Grounding at Fire PumpHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Job Hazard Analysis For Desalination of First Effect RetubingDokument7 SeitenJob Hazard Analysis For Desalination of First Effect Retubingmc chesterNoch keine Bewertungen

- Haz Repair&MaintDokument29 SeitenHaz Repair&MaintSANJAY PANDYANoch keine Bewertungen

- Skylift CHECKLISTDokument1 SeiteSkylift CHECKLISTEmmie Van Halen100% (2)

- Gas TestingDokument1 SeiteGas TestingHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Skylift CHECKLISTDokument1 SeiteSkylift CHECKLISTEmmie Van Halen100% (2)

- Jsa Installing BracketDokument3 SeitenJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Jsa PolypipeDokument2 SeitenJsa PolypipeHow Chin Engineering Sdn BhdNoch keine Bewertungen

- How Chin Engineering: Job Safety AnalysisDokument5 SeitenHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Jsa Dismantling The Wooden Framework-NewDokument3 SeitenJsa Dismantling The Wooden Framework-NewHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Jsa Copper Grounding at Fire PumpDokument5 SeitenJsa Copper Grounding at Fire PumpHow Chin Engineering Sdn BhdNoch keine Bewertungen

- JSA Teflon - U BoltDokument3 SeitenJSA Teflon - U BoltHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Jsa General HousekeepingDokument2 SeitenJsa General HousekeepingHow Chin Engineering Sdn Bhd44% (9)

- Jsa Welding Diesel PipelineDokument3 SeitenJsa Welding Diesel PipelineHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Jsa Pipe Cutting at Fire PumpDokument5 SeitenJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNoch keine Bewertungen

- JSA Ceiling Access by LadderDokument3 SeitenJSA Ceiling Access by LadderHow Chin Engineering Sdn BhdNoch keine Bewertungen

- JSA Concereting and PaintingDokument4 SeitenJSA Concereting and PaintingHow Chin Engineering Sdn BhdNoch keine Bewertungen

- How Chin Engineering: Job Safety AnalysisDokument6 SeitenHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNoch keine Bewertungen

- He Dressmaking10 Quarter4 Module 1Dokument18 SeitenHe Dressmaking10 Quarter4 Module 1Titser Ramca100% (3)

- PutDokument7 SeitenPutwhite elephant0% (1)

- Play Ready Steady GoDokument3 SeitenPlay Ready Steady GoRosa GuindosNoch keine Bewertungen

- Vocab Basics U3Dokument1 SeiteVocab Basics U3Aura VargasNoch keine Bewertungen

- 15 CopiiDokument4 Seiten15 CopiiOana Puf-CraciunNoch keine Bewertungen

- Emotional BrandingDokument15 SeitenEmotional BrandingAakash PareekNoch keine Bewertungen

- In A German Pension, by Katherine Mansfield - 2Dokument5 SeitenIn A German Pension, by Katherine Mansfield - 2kbm marocNoch keine Bewertungen

- Euromonitor Retailing in The UsDokument33 SeitenEuromonitor Retailing in The UsShriniket PatilNoch keine Bewertungen

- Packing List 11th ContainerDokument7 SeitenPacking List 11th ContainerswatiNoch keine Bewertungen

- Inventory Control & ManagementDokument17 SeitenInventory Control & ManagementPrakash KcNoch keine Bewertungen

- Summer InternshipDokument61 SeitenSummer InternshipParul Jaiswal0% (1)

- Fashion White PaperDokument9 SeitenFashion White Paperapi-491113890Noch keine Bewertungen

- NEMO Product Workbook 2012 (Excerpt)Dokument21 SeitenNEMO Product Workbook 2012 (Excerpt)ba1084100% (1)

- L.L.Bean Factory List: Parent Company Facility Name Facility Address Province/State CountryDokument10 SeitenL.L.Bean Factory List: Parent Company Facility Name Facility Address Province/State CountrygowriNoch keine Bewertungen

- Mossy Cowl ADokument3 SeitenMossy Cowl AJill KrahlingNoch keine Bewertungen

- DMSDokument79 SeitenDMSkundan0% (1)

- PatternsDokument16 SeitenPatternsabigail_baker_50% (1)

- Karnataka PDFDokument1.848 SeitenKarnataka PDFSushant nayarNoch keine Bewertungen

- Chapyer 01 Modern Distillation TechniquesDokument20 SeitenChapyer 01 Modern Distillation TechniquesYezdi Solaina100% (3)

- Consumer Behaviour at The Food Market: September 2012Dokument9 SeitenConsumer Behaviour at The Food Market: September 2012colin23Noch keine Bewertungen

- A Project Report On E-Commerce Sales and Operations Through MarketplaceDokument38 SeitenA Project Report On E-Commerce Sales and Operations Through MarketplaceAmit JaiswatNoch keine Bewertungen

- BL (La Mejor)Dokument1 SeiteBL (La Mejor)Niquilinsebas100% (1)

- 9775c Bistro2 - Service Manual PDFDokument47 Seiten9775c Bistro2 - Service Manual PDFdanielradu27Noch keine Bewertungen

- Resume 2 Daniel PoweDokument1 SeiteResume 2 Daniel Poweapi-490401372Noch keine Bewertungen

- Corporate ListDokument111 SeitenCorporate ListmayajogiNoch keine Bewertungen

- Invoice 2019 12 2537Dokument1 SeiteInvoice 2019 12 2537nguywdrtffdNoch keine Bewertungen

- Hong Kong 13 Eating - v1 - m56577569830511158Dokument17 SeitenHong Kong 13 Eating - v1 - m56577569830511158theo_31Noch keine Bewertungen

- US Allergen ChartDokument4 SeitenUS Allergen ChartCassandra HonsonNoch keine Bewertungen

- Bahasa Inggris 7Dokument6 SeitenBahasa Inggris 7Abdul KadirNoch keine Bewertungen

- Physical and Chemical Changes WorksheetDokument4 SeitenPhysical and Chemical Changes Worksheetapi-307565882100% (1)