Beruflich Dokumente

Kultur Dokumente

1975 BMW Courier

Hochgeladen von

vixentd0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten3 SeitenService manual

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenService manual

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten3 Seiten1975 BMW Courier

Hochgeladen von

vixentdService manual

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

Drive Axles 7.25

COURIER

DESCRIPTION

This oxle assembly incorporates a removable carrier

differential, having @ hypoid type ring and pinion gear set,

‘with the pinion being retained in the corrier by a companion

flonge ond nut. Semi-flooting axles are secured inthe housing

by the axle shait bearing retainers.

IDENTIFICATION

Only one type of axle assembly is used. Axle ratio for manual

transmission models is 4.11-1 and for automatic transmission

models is 4.65-1. This can be determined by dividing the

fnumber of teeth on ring gear by the number of eeth on the pi-

sion gear,

REMOVAL & INSTALLATION

AXLE SHAFTS & BEARINGS

Removal — After removing complete broke assembly

including nuts securing backing plate and bearing housings

‘xle housing, slide axle shaft out of housing. Remove inner ol

s20l from oxle shat, spread locking tabs on lock washer, then

‘hing @ suitable spanner (1721-4252) remove lock nut and

washer. Using o suitable puller (172J-1225), remove bearing

‘with housing from shalt. Remove bearing cup and outer seal

from bearing housing.

Installation — Using svitoble too! (172J-1177), install new

‘outer seal in bearing housing. Press or drive new bearing cup

into ttoiner sing table tool (1721-4252). Install broke

backing plate and bearing housing on axle shot, then posi-

tion bearing on axle shaft. Note — Insure bearing taper points

in the right direction. Slide a suitable tool (172)-4252-A) over

shaft, place axle shatt on end in press, and press bearing into

place. Install lock washer and nut, using spanner to tighten

‘ut. Install axle shaft and loosely assemble two bolts through

bearing housing and axle housing flange. Mount a dial in

dicator to backing plate so axle end play con be measured,

NOTE — IF both axles have been removed, check end play of

each shaft os itis installed. end play is not to specification,

‘odjustment is made by using appropriate shims between axl

housing flange and bearing housing. After correct end ploy

obtained, install and tighten as necessary, all remaining com

ponents

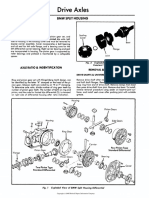

Side Gear

Thrust Washer

Raynor Prion Go

Thrust Block

VAX>

ie ag

— Carrier

Collapsible

Spacer

Co

Fig. 1 Exploded View of Courier Differential Assembly

‘ipo 200 Rapa ema Campa

7-26

Drive Axles

COURIER (Cont.)

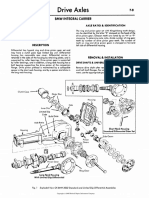

Axle Shaft

‘Adjusting Shim Oil Seal

1.

@®

Fig.2 Exploded View of Axle Assembly

DIFFERENTIAL CARRIER

Lock Nut

$1989

Bearing Housing

Removal ~ Roise and support vehicle, Drain lubricant from

differential, replace drain plug, then remove axle shafts as

previously outlined. Mark drive shaft and companion flange

‘ot differential for reference at time of reassembly, then

remove drive shaft, Remove carrier-to-housing retaining nuts,

then remove carrier from housing,

Installation — Reverse removal procedure using o suitable

szoler between the carrier and axle housing, and insure the

ive shatt-to-companion flange reference marks are aligned.

OVERHAUL

DISASSEMBLY

1) Remove differential carrier as previously outlined, then

‘mount carrier assembly in o wuitable holding fixture with ring

‘gear facing upward. Mount o dial indicator to carrier housing

‘and check fing gear runout for reference at time of

Feassembly. Also make a gear tooth contoct pattern check

Refer fo Rear Axle Gear Tooth Patterns inthis section.

Fig. 3 Checking Ring Gear Backface Runout

2) Punch mark differential bearing caps and adjusters for

reference at time of reassembly. Remove adjuster lock plates,

Loosen bearing cap nuts and back off adjusters using o

suitable spanner (172J-4067). NOTE — Adjuster on left hos

left hand thread. Remove nuts, bearing cops, and adjusters,

keeping each bearing cap with its own adjuster.

3) itt out differential assembly keeping each bearing outer

race with its own bearing. To remove differential bearings, use

9 suitable puller (170P-4221). Remove bolts and locks retain-

ing ring gear to case, then remove ring gear. Drive out

differential pinion shaft lock pin and remove pinion shaft and

thrust block. Rotate pinion gears 90 degrees ond remove

them, Lift out differential side gears along with their thrust

washers

Fig. 4 Removing Differential Bearings

Fig. 5 Removing Pinion Shaft Lock Pin

4) Hold pinion gear companion flange and remove nut, then

the flange. Remove drive pinion and rear bearing. NOTE ~ It

‘required, use soft headed mallet to top pinion gear from cate,

‘and guide pinion out fo avoid damage to gear teeth, Remove

collapsible spacer, oil seal and front bearing. Remove pinion

bearing races from carrier using a drift in the slots provided.

Remove bearing from pinion gear using a suitable tool (172)

4630) ond remove shim from pinion gear,

REASSEMBLY & ADJUSTMENT

Case Assembly 1) If original ring ond pinion gear set is

being installed, use original shim between bearing and pinion

head. If a new gear sets being installed, determine the size of

shim to use in the following manner: Drive pinions may be

stomped either "41,23" or "— 1,2,3", or they may be un-

marked. Compare marks on topered ends of old and new

Drive Axles

7-27

COURIER (Cont.)

‘gers. Subtract the two numbers. A plus remainder means to

Install @ thinner shim than the original. A minus remainder

means to install a thicker shim thon the original. Ifthe numb

is the same on both geots or if both gears are unmarked, ure

the original shim. NOTE — Shims are available in thicknesses

from 120" to .135" (3.048 mm to 3.429 mm) in increments of

001" (.025 mm)

2) Using suitoble driver (1725-4616) install pinion gear

bearing races. Install selected thim on pinion gear then install

bearing on pinion using suitable tool (170P-4625) and o press

Install pinion gear ond bearing in carrier followed by the

collapsible spacer, front bearing, oll seal and companion

flange. Install, But do not tighten, companion flange nut

Fig. 6 Instlling Drive Pinion Bearing Races

{3} Using an inch pound torque wrench on companion flange

nut, rotate pinion gear and note drag of oil seal. Remove inch

pound torque wrench and stort tightening nut. As nut is

Tightened, keep checking rotating torque with inch pound

torque wrench. When nut is tightened to 145 foot pounds

(20.0 mkg) minimum and rotating torque is 11.3-15.6 INCH

pounds (13-18 ckg) plus the oil seal drag, preload is correct

NOTE ~ If preload is exceeded, install new collapsible spacer

cond repeat procedure. Do not backoff nut to obtain preload.

Differential Assembly — Reverse disassembly procedure

noting the following checks and adjustments.

‘Side-to-Pinion Gear Backlash — After installing side ond

Pinion gears, insert pinion shaft, without thrust block, into its

proper postion. Check sidetorpinion ‘gear backlash. If

bbocklash exceeds .008"(.20 mm), refer fo table and install op-

propriate side gear thrust washers to obtain the correct

backlash. Remove pinion shat, then reinstall it with the thrust

block.

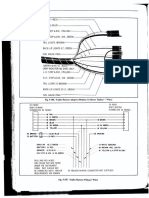

Side Gear Thrust Washers

LD. Mark Thickness

— 063" (1.6 mm)

7. : : 067" (1.7 mm)

8 O71" (1.8 mm)

‘completely assembled and installed in carrier, snug bearing

cop nuts. Turn adjusters, using spanner, until bearings are

properly seated ond end play is eliminated with a sight

‘omount of ring-o-drive pinion gear backlash, Slightly tighten

fone bearing cap nut on each side, Mount dial in

corrier flange with indicator plunger set at @ right ongle to

ring gear teeth. Check ring-to-drive pinion gear backlash ot

four or five points around ring gear. Turn both adjusters

equally 10 obtain specified backlash. Proceed by setting

differential bearing preload.

Fig. 7 Checking Ring-to-Pinion Geor Backlash

Differential Bearing Preload ~ Taking core not to disturb

ting-to-drive pinion gear backlash, set preload using a dial in-

dicotor as shown in illustration. Alter seting preload, tighten

beoring cap nuts and complete assembly procedure.

Fig. 8 Checking Differential Bearing Preload

‘AXLE ASSEMBLY SPECIFICATIONS.

(©.002-.004"(.05-.10 mm)

Axle Shatt Endplay

.0075-.0083" 19-21 mm)

19:t0-Pinion Gear Backiosh

Ring Gear Backface Runout (Max.). .003" (.08 mm)

Differential Bearing Preload 10045" (.11 mm)

© If both shotts were removed, end play of first shaft in

solled should be .026-033" (.65-44 mm).

TIGHTENING SPECIFICATIONS

FF. Ub. (mkg)

41-49 (5.76.8)

1216(1.7-22)

12:16(17-22)

40-45 (55-6.2)

145-250 20-248)

Application

Differential Bearing Cop Bolts...

Carier-to-Axle Housing Nuts

Axle Shatt Bearing Retoiner Bots.

Ring Gear-to-Case Bolts

Companion Flange Nut

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- CK30 WM 00 GeneralDokument54 SeitenCK30 WM 00 GeneralvixentdNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- B44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFDokument158 SeitenB44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFvixentdNoch keine Bewertungen

- CK30 WM 03 ClutchDokument16 SeitenCK30 WM 03 ClutchvixentdNoch keine Bewertungen

- 1977 BMW Integral CarrierDokument3 Seiten1977 BMW Integral CarriervixentdNoch keine Bewertungen

- BSA InstructionDokument55 SeitenBSA InstructionvixentdNoch keine Bewertungen

- CK30 WM 02 EngineDokument62 SeitenCK30 WM 02 EnginevixentdNoch keine Bewertungen

- 1955 56 57 SpecsDokument9 Seiten1955 56 57 SpecsvixentdNoch keine Bewertungen

- 1977 BMW Split HousingDokument5 Seiten1977 BMW Split HousingvixentdNoch keine Bewertungen

- 1975 BMW Split HousingDokument5 Seiten1975 BMW Split HousingvixentdNoch keine Bewertungen

- 1974 BMW Capri 1971-74Dokument3 Seiten1974 BMW Capri 1971-74vixentdNoch keine Bewertungen

- 1976 BMW Split HousingDokument5 Seiten1976 BMW Split HousingvixentdNoch keine Bewertungen

- 1975 BMW Integral CarrierDokument5 Seiten1975 BMW Integral CarriervixentdNoch keine Bewertungen

- 1976 BMW Integral CarrierDokument5 Seiten1976 BMW Integral CarriervixentdNoch keine Bewertungen

- 1974 Austin Marina 1973-74Dokument3 Seiten1974 Austin Marina 1973-74vixentdNoch keine Bewertungen

- 1982 All Others Multiplex TypeDokument2 Seiten1982 All Others Multiplex TypevixentdNoch keine Bewertungen

- 1974 Austin Sprite 1968-70Dokument3 Seiten1974 Austin Sprite 1968-70vixentdNoch keine Bewertungen

- 1972 American Motors 1968-74 All Models PDFDokument2 Seiten1972 American Motors 1968-74 All Models PDFvixentdNoch keine Bewertungen

- 1972 All Manufacturers 1971-73 All Models PDFDokument3 Seiten1972 All Manufacturers 1971-73 All Models PDFvixentdNoch keine Bewertungen

- 1972 All Manufacturers 1972-73 All ModelsDokument3 Seiten1972 All Manufacturers 1972-73 All ModelsvixentdNoch keine Bewertungen

- 1974 Al All ModelsDokument1 Seite1974 Al All ModelsvixentdNoch keine Bewertungen

- 05 NCFDokument12 Seiten05 NCFvixentdNoch keine Bewertungen

- 1982 All Others LiftgateDokument2 Seiten1982 All Others LiftgatevixentdNoch keine Bewertungen

- 1972 American Motors 1968-74 All Models PDFDokument2 Seiten1972 American Motors 1968-74 All Models PDFvixentdNoch keine Bewertungen

- 1972 All Manufacturers 1974 All ModelsDokument4 Seiten1972 All Manufacturers 1974 All ModelsvixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 08Dokument94 Seiten78 Olds CSMCHPT 08vixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 09Dokument64 Seiten78 Olds CSMCHPT 09vixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 07Dokument325 Seiten78 Olds CSMCHPT 07vixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 07Dokument325 Seiten78 Olds CSMCHPT 07vixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 10Dokument10 Seiten78 Olds CSMCHPT 10vixentdNoch keine Bewertungen