Beruflich Dokumente

Kultur Dokumente

1976 BMW Split Housing

Hochgeladen von

vixentd0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

22 Ansichten5 SeitenSERVICE

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenSERVICE

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

22 Ansichten5 Seiten1976 BMW Split Housing

Hochgeladen von

vixentdSERVICE

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

714

Drive Axles

BMW SPLIT HOUSING

3.0 Seri

530i,

DESCRIPTION

Differential has hypoid type ting and pinion gear set, and

may have one of two clutch pack type limited sip units, Left

side of housing is the housing cover and must be removed to

expose carrier ossembly. Cover incorporates @ ball bearing

‘ond oil seal for left oxle flange, and @ bearing cone for the

left differential carrier bearing. Right carrier bearing and seol

‘ore incorporated in housing. The pinion gear is supported by

roller bearings ond prelocd is maintained by a collapsible

spacer.

AXLE RATIO & INDENTIFICATION

Ring ond pinion gear set with Klingelnberg tooth design, con

be identified by the letter "k” stamped on the head of the pi

rion gear; Gleason teeth are noted by an "H of F” stamping

To determine axle ratio, divide number of ring gear teeth by

number of pinion gear teeth. The number of teeth on ring and

pinion, ond the code for limited slip differential (S40), is

Stamped on right side of differential housing,

Ring Geor

“Oass

Standard Differential

Fig.

‘opr 200

Vom bm

OF}

go> 7 O

Pinion Geors

& fA,

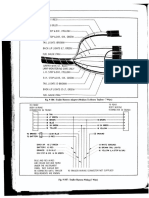

Exploded View of BMW Split Housing Differential

Sealing

Cover

Fig. 2. Exploded View of Half Shaft Constant Velosiy Joint

REMOVAL & INSTALLATION

DRIVE SHAFTS & UNIVERSAL JOINTS.

Remove drive shaft ofter removing retaining bolts from oxle

cond half shott flanges. Remove cover from joint housing and

snap ring from end of drive shaft. Remove clamps from boot

then press drive shaft fom joint. Remove dust boot. To install,

reverse removal procedure using sealer on boot-to-joint sur

foces, and install seal cover after packing joint with svitoble

‘grease

Housing

Pinion Gears

Four Pinion Type

Standard Differential

Beoring

‘Gears

Drive Axles

7-15

BMW SPLIT HOUSING (Cont.)

0

|

Thrust Washer

Housing

3 %.

Shotts

(o Lloiop ed

TYPE

ono. ®

DOG

\

t

Shims Cover

eS

in Gear

/ Dise

0)

0

t

Housing

O

2

Fig. 3 Exploded View of Type One and Type Two

Limited Slip Differentials

AXLE SHAFTS & BEARINGS.

Roise ond support vehicle. Remove wheel, drive shaft, axle

flange retoining nut, and using a puller, if required, remove

axle flange. Using soft headed mallet, drive axle shaft out of

housing. Drive out bearings ond seols, then remove spocer

sleeve ond shim, To install, reverse removal procedure noting

the following: Install outer bearing then determine distance

between outer races of inner and outer bearings. Measure

spacer and shim, then install spacer and a suitable shim that

will obtain the specified wheel bearing end ploy. Pack

bearings and new seals with suitable grease, then complete in

stallotion procedure

Fig. 4 Pulling Axle Drive Flange

‘ipo 0 200 a Rea

AXLE FLANGE, SEAL, & BEARING

Remove drive shoft. Hold axle flange using suitable too!

(7012) and remove fiange cetaining bolt, Using svitable puller

(7011-2) remove axle flange. Pry out oil seal and if required,

remove ball bearing on cover side, using suitable puller. To in:

all, reverse removal procedure alter packing bearing and/or

filling between sealing lips of seal with grease. Install seal

flush with housing or cover bore,

Fig. 5 Removing Axle Drive Flange Bearing

DIFFERENTIAL CARRIER ASSEMBLY

ENGI — Differential carrier can be removed from housing

with differential assembly installed in vehicle. After removing

‘oxle flanges, follow Differential Carrier, Disassembly and

‘Overhaul procedures, in this story.

7-16

Drive Axles

BMW SPLIT HOUSING (Cont.

DIFFERENTIAL ASSEMBLY

Remove propeller shaft and drive shofts, tie drive shafts up out

‘of way. Support differential and remove bolts securing it 10

front brackets and rear support. Remove differential

‘ssembly. To install, reverse removal procedure, insuring rear

Support is strese free when installed

OVERHAUL

DISASSEMBLY

Differential Assembly ~ Remove differential assembly as

previously outlined and mount assembly in suitable holding

fixture. Drain oil and mark pinion shaft and companion flange

for reassembly reference. Remove inspection hole cover, mount

dial indicator in one cover bolt hole and check ring gear

backface runout and ring-to-pinian gear backlash. Check

{gear tooth contact pattern, IN@HTA— Refer fo Rear Axle Gear

Tooth Potters in this section. Remove axle flonges and side

cover, then remove differential carrier assembly. Proceed os

follows for standard or limited slip differential carrier die

cossembly.

Dial

Indicator

Fig. 6 Checking Ring Gear Backlash

Standard Differential Carrier (Two Pinion Type) —

Remove carrier bearings using suitable puller (Rolex LM

503349). Separate ring gear from carrier. Drive out pinion

shaft lock pin, remove pinion gears shaft and pinion gears,

then remove side gears with shims and thrust washers,

Standard Differential Carrier (Four Pinion Type) —

Remove carrier bearings using suitable puller (Rolex UM

503349). Separate carrier halfs and lift out pinion gears with

shafts, then remove side gears with shims and thrust washers.

Remove ring gear from carrier.

Limited Slip Differential Carrier ~ Remove cartier bearings

using suitable puller (Rolex LM 503349). Remove bolts secur.

ing case-to-ring gear flange (Type 1), or cover-to-case (Type

2), invert case and lift case off clutch and gear assembly.

Separate ring gear from flange. Remove clutch components

Lift off hub, remove side gear and one set of pinion gears.

Repeot procedure for other half of case.

cipro 200

Drive Pinion Gear - 1) Remove differential carrier os

previously described, then check pinion bearing prelood using

‘an inch pound torque wrench. Remove pinion flange nut lock

ring end using @ suitable Yoo! (7012) hold flange and remove

nut

Torque Wrench

Fig. 7 Checking Pinion Bearing Preload

2) Press pinion gear out, through flange ond housing, then

remove oil seal and front roller bearing, Using suitable puller

‘€1 (6053), remove pinion bearing outer cones from housing.

REASSEMBLY & ADJUSTMENT

Differential Assembly — Reverse disassembly procedure

noting the following checks and adjustments

Drive Pinion Bearing Preload — 1) If original ring and

pinion gear set is being installed, and gear tooth pattern and

pinion bearing preload was satisfactory at time of dis-

‘ossembly, install drive pinion gear using original shim and a

new collapsoble spacer, If a new gear set is being instlled,

determine correct size of shim to use in the following manner:

Drive pinion gears moy be stamped either "+1,2,3, etc", oF

"1,213, ete". Compore marks on tapered ends of old and

new gears. Subtract the two numbers. In relation to original

shim, a plus remainder means a thinner shim is required;

‘minus remainder means a thicker shim is required

Nur Collapsible Spacer

RES

Inner Bearing

Fig. 8 Sectional View of Drive Pinion Gear and

Bearing Assembly

Drive Axles

TAT

BMW SPLIT HOUSING (Cont.)

2) Remove then ceinstall pinion geor, using new shims)

collaproble spacer, cid seul os required. Install companion

flange and and nut and tighten nut to obtain specified drive

pinion bearing preload. I preload is exceeded, new

follopsible spacer must be installed, and this procedure

repeoted.

ide-to-Pinion Gear Backlash (Standard Differentials) —

Install two pinion gears with shaft and one side gear. Mount

diol indicotor to carrier so plunger contacts side gear. Force

side geor hard against pinion gears, zero indicator, then force

side gear hard against cose. With proper shim and thrust

washer, backlash should be as specified, and preload of all

three geors should not exceed specified volue. Repeat

procedure on opposite side (with second set of pinions on four

Pinion type), then retoin side gears pressed outward against

Corrier s0 axle flange retoining bolts can later be installed

Dial

Indicator

a

Fig. 9 Checking Side-to-Pinion Gear Backlash

Clutch Assembly End Play (Type 1 Limited Slip

Differential) ~ Assemble clutch assembly without ring gear

or case. Apply 220 psi (15.5 kg/sq. em) to one end of

‘ssembly. Measure from inner surface of flange to top surface

fof spacer ring. Measure depth of case. If clutch assembly-to

housing end play isnot to specification, adjust by using thicker

or thinner inner clutch ise

Apply Pressure

Clutch

‘Assembly

Measure Depth

Fig. 10 Measuring Type 1 Clutch Assembly Installed Height

With Pressure Applied

cipro 200

Clutch Assembly End Play (Type 2 Limited Slip

Differential) ~ Without using the four small diameter thrust

Mathers two smo spring washers, or two. large. spring

“roshers assemble clutch onsembly in houting. Compare depth

SF hovsing cover thron srfoce ond thickness of forge spring

wother, to. dstonce between edge of hovsing. ond cuter

Clutch die. inall suitable large oping wathers 0. obfon

specitied end ploy. WIGHA ~ If excessive end play nists,

iBrker outer loch diss moy be insted

‘Measure Here

Fig. 11 Measuring Type 2 Clutch Assembly Installed Height

Checking Pinion Gear Torque (Limited Slip Differentials)

="With differential carrier assembled, install oxle flanges in

corrier. Clamp one flange in vise and using and INCH pound

torque wrench (Type 1), ar foot pound torque wrench (Type

2), turn other flange. If rotating torque of side and pinion

‘gears is not to specification, install thicker or thinner cose

cover-to-lutch assembly thrust washers

Clamp Here Torque Wrench

= os

Fig. 12 Checking Pinion Gear Torque on Limited

Slip. Differential

Differential Bearing Preload — Install one shim behind

carrier bearing outer cone in side cover, Install bearing cone

using svitable tool (6053). Install drive flange bolt, without

flange, soit contacts pinion gear shaft. Install carrer in hous

ing and tighten cover retoining bolts. Check preload by tur

ning flange belt using on INCH pound torque wench, When

cover bolts ore torqued to specification, measure gap between

cover and housing using a feeler gauge. If preload is low

than specified, shims must be thicker than gop; if preload is

higher thon specified, shim thickness behind cone must be less

than gop between cover ond housing. Install required shims

7-18

Drive Axles

BMW SPLIT HOUSING ( Cont.)

1 bearing cone in cover. Heat ring gear 10 176-212°F,

ring gear on corrier using locking compound on bolts

‘ond install carrer in housing. Check Ring-to-Drive Pinion Gear

oe

Fig. 13. Making Measurement for Establishing Shim Pack

for Differential Beoring Prelood

ion Gear Backlash ~ With differential

beoring preload set, remove inspection hole cover, mount dil

inicotor in one cover bolt hole, and check ingo-piion gear

backlash. Check ring gear tooth contect pattern, BUSIE,

Refer to Reor Axle Gear Tooth Patterns in this section, While

maintaining established shim thickness, move shims behind

Fig. 14 Sectional View Showing Ring Geor Backlash

‘Shim Locations

Cipro 200 me

carrier beoring outer cones, (rom one side to the othe os

setting

hecessary, 10 obtain proper contact pattern. At

backlash, complete differential reassembly procedure.

AXLE ASSEMBLY SPECIFICATIONS.

Application Specification

Wheel Bearing End Play. 002.004" (.05-.10 mm)

Differential Pinion Rotating Torque (At Flange)

Standard

2 Pinion Type 8:15 ft Ibs. (1.0-2.0 mkg)

4 Pinion Type. 11-18 ft Ibs. (1.5-2.5 mkg)

Limited Slip

Type 1 (Max.) 43 INCH Ibs. (50 cmkg)

Type 2(Min.) 36 ft Ibs. (5 mkg)

{002.004",05:.10 mm)

(002-,004"(.06-.11 mm)

‘Axle Drive Flange End Play

Ring-to-Pinion Gear Backlash

Pinion Geor Bearing Preload

Without Seo! (Max).

With Oil Seal (Max.)

Clutch Assembly-to-Case End Play

26 INCH Ibs. (30 cmkg)

2BINCH Ibs. (32 emks)

Type? {004..008" (.1-.2 mm)

Type2 (004.016! (1-.4 mm)

Differential Bearing

Preload 12-14 INCH Ibs. (14-16 emkg)

TIGHTENING SPECIFICATIONS

Application Fr Lbs. (Mkg)

Housing Cover Bolts,

Ring Geor-to:Carrier Bolts

Drive Pinion Flange Nut.

Drive Shaft-to-Drive Flange Baits

15.18 (22.5)

‘696-111.(13-15)

11105)

86-74 9-10)

Drive Shaft-to-Anle Flange Bolts 47-52 (6.47.1)

Differential Corrier Cover Bolts. 15.18 (2.25)

Axle Flange Nut 295-332 (40-45)

Differential-to-Reor Insviotor

Differential-to-Front Supports

© = "Using Locktte 240 oF 276.

53:59(7.2-8)

49-55 (6.7-7.5)

Das könnte Ihnen auch gefallen

- 1955 56 57 SpecsDokument9 Seiten1955 56 57 SpecsvixentdNoch keine Bewertungen

- 1977 BMW Integral CarrierDokument3 Seiten1977 BMW Integral CarriervixentdNoch keine Bewertungen

- CK30 WM 03 ClutchDokument16 SeitenCK30 WM 03 ClutchvixentdNoch keine Bewertungen

- CK30 WM 02 EngineDokument62 SeitenCK30 WM 02 EnginevixentdNoch keine Bewertungen

- B44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFDokument158 SeitenB44, B25, C25 Series 1967 Workshop Manual 00-4136 X PDFvixentdNoch keine Bewertungen

- BSA InstructionDokument55 SeitenBSA InstructionvixentdNoch keine Bewertungen

- CK30 WM 00 GeneralDokument54 SeitenCK30 WM 00 GeneralvixentdNoch keine Bewertungen

- 1977 BMW Split HousingDokument5 Seiten1977 BMW Split HousingvixentdNoch keine Bewertungen

- 1975 BMW CourierDokument3 Seiten1975 BMW CouriervixentdNoch keine Bewertungen

- 1975 BMW Integral CarrierDokument5 Seiten1975 BMW Integral CarriervixentdNoch keine Bewertungen

- 1975 BMW Split HousingDokument5 Seiten1975 BMW Split HousingvixentdNoch keine Bewertungen

- 1976 BMW Integral CarrierDokument5 Seiten1976 BMW Integral CarriervixentdNoch keine Bewertungen

- 1974 Austin Sprite 1968-70Dokument3 Seiten1974 Austin Sprite 1968-70vixentdNoch keine Bewertungen

- 1974 BMW Capri 1971-74Dokument3 Seiten1974 BMW Capri 1971-74vixentdNoch keine Bewertungen

- 1972 All Manufacturers 1971-73 All Models PDFDokument3 Seiten1972 All Manufacturers 1971-73 All Models PDFvixentdNoch keine Bewertungen

- 1972 American Motors 1968-74 All Models PDFDokument2 Seiten1972 American Motors 1968-74 All Models PDFvixentdNoch keine Bewertungen

- 1972 American Motors 1968-74 All Models PDFDokument2 Seiten1972 American Motors 1968-74 All Models PDFvixentdNoch keine Bewertungen

- 1974 Austin Marina 1973-74Dokument3 Seiten1974 Austin Marina 1973-74vixentdNoch keine Bewertungen

- 1974 Al All ModelsDokument1 Seite1974 Al All ModelsvixentdNoch keine Bewertungen

- 05 NCFDokument12 Seiten05 NCFvixentdNoch keine Bewertungen

- 1972 All Manufacturers 1974 All ModelsDokument4 Seiten1972 All Manufacturers 1974 All ModelsvixentdNoch keine Bewertungen

- 1982 All Others Multiplex TypeDokument2 Seiten1982 All Others Multiplex TypevixentdNoch keine Bewertungen

- 1982 All Others LiftgateDokument2 Seiten1982 All Others LiftgatevixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 07Dokument325 Seiten78 Olds CSMCHPT 07vixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 08Dokument94 Seiten78 Olds CSMCHPT 08vixentdNoch keine Bewertungen

- 1972 All Manufacturers 1972-73 All ModelsDokument3 Seiten1972 All Manufacturers 1972-73 All ModelsvixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 07Dokument325 Seiten78 Olds CSMCHPT 07vixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 09Dokument64 Seiten78 Olds CSMCHPT 09vixentdNoch keine Bewertungen

- 78 Olds CSMCHPT 10Dokument10 Seiten78 Olds CSMCHPT 10vixentdNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)