Beruflich Dokumente

Kultur Dokumente

SEA TRIAL Procedure (Rev1)

Hochgeladen von

Rahmat WahyuOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SEA TRIAL Procedure (Rev1)

Hochgeladen von

Rahmat WahyuCopyright:

Verfügbare Formate

Institute of Marine Engineering, Science and Technology (ImarEst)

Prepared by Hari Prastowo - Jurusan Teknik Sistem Perkapalan ITS

Tanggal 14 -feb-13

Date

Hal

1 of 9

Page

WORKING INSTRUCTION

SEA TRIAL PROCEDURE

No. Revisi

Rev. Number

I. TESTS AND SEA TRIAL CONDITION

1. KINDS OF TEST:

a.

Starting Test

b.

Stop Inertia Test

c.

Progressive speed trials

d.

Crash Stop astern and Crash stop ahead test.

e.

Turning test

f.

Zigzag Maneuvering test

g.

Steering Gear test

h.

Anchoring test

i.

Black Out

j.

Endurance Test

k.

Noise and Local Vibration

l.

Fire Fighting Equipment test (additional)

m. Life Saving Appliances Test (additional)

2. SEA TRIAL CONDITION

a.

Ballast Condition.

The vessel is to be ballasted to the full displacement corresponding to the . Meter

(mld) draught in sea water.

b.

Draft Measurement.

Prior to sea trial, ships drafts (fore, mid ships (p & s), and aft) shall be measured at

the draft marks by eye in the presence of owners representative. Items to measure

are:

i.

Draft reading at fore, aft, and sb & ps mid ship.

ii.

Specific gravity of sea water

c.

Life saving appliances check.

In order to ensure the safety for all persons on board, thorough checks shall be

carried out to the life saving appliances prior to sea trial.

II. TEST ITEMS FOR THE SEA TRIAL

1. STARTING TEST

a.

Procedure:

Starting test to be carried out as per Class Rules for starting system of the main

engine. For reversible engine, the staring system shall capable for 12 times start,

whereas for non-reversible engine for 6 times.

For electric starter, the starting system is to be confirmed to start as engine

manufacturer guidance.

b.

Items of Measurement:

i.

Total number of starting.

ii.

Functional test confirmation.

01

Institute of Marine Engineering, Science and Technology (ImarEst)

Prepared by Hari Prastowo - Jurusan Teknik Sistem Perkapalan ITS

Tanggal 14 -feb-13

Date

Hal

2 of 9

Page

WORKING INSTRUCTION

SEA TRIAL PROCEDURE

No. Revisi

Rev. Number

.

2. MAGNETIC COMPASS ADJUSTMENT

The adjustment of magnetic compass shall be carried out prior to sea trial according

to standard from technical engineer and certified on behalf of the government.

3. STOP INERTIA TEST

a.

Purpose:

To measure required time and distance from the time that ME (full throttle position)

to be stopped up to the vessels speed reaching to two (2) knots.

b.

Procedure:

While the vessel is running ahead at MCR (100% engine load, or 100% Rpm), the

main engine to be stopped until the vessel reach two (2) knots speed

c.

Item to be Measured:

i.

Vessels speed before the main engine to be stopped (at full-throttle or at

100% load or at 100% rpm).

ii.

Time required until vessel speed reaching 2 knots after main engine to be

stopped.

iii.

Advance distance from full speed to 2 knots speed (at stopped main engine

condition).

iv. Wind speed, wind direction, and sea condition.

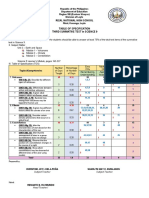

4. PROGRESSIVE SPEED TRIALS

a.

Purpose:

The test to be carried out with the engine load progressively increased in order to

settle the relation between vessels speed and engine loads.

b.

Place:

On the availably safe sea area.

c.

Procedure:

Progressive speed trials are to be carried out at the following engine load:

Engine Load Engine Power

Engine Rpm

Run between Mile posts

25 %

As calculation

As on panel

One double run

50 %

As calculation

As on panel

One double run

75 %

As calculation

As on panel

One double run

100 %

As calculation

As on panel

One double run

*) The measurement may differ subject to Maker and Class recommendation

d.

Items of Measurement:

i.

Vessels speed

ii.

Main Engine parameters; Rpm, Throttle position, and other necessary items

for Main Engine performance.

iii.

Weather, sea state condition, relative velocity, direction of wind, and depth of

sea.

5. CRASH STOP AHEAD and CRASH STOP ASTERN:

a.

Purpose;

To prove that the Main Engine is suitable for ships emergency stop, and to

measure the time and distance between points of the order of astern / ahead under

headway until Rpm becomes steady.

01

Institute of Marine Engineering, Science and Technology (ImarEst)

Prepared by Hari Prastowo - Jurusan Teknik Sistem Perkapalan ITS

Tanggal 14 -feb-13

Date

Hal

3 of 9

Page

b.

WORKING INSTRUCTION

SEA TRIAL PROCEDURE

No. Revisi

Rev. Number

Procedure:

i.

Stop Astern Test:

While the vessel is running ahead at 100 % Main Engine load (corresponding

to its MCR) the Main Engine is then ordered to reverse its RPM from initial

rpm until the RPM is reaching steady.

ii.

Handling the Main Engine for Stop Astern Test:

Procedure of the test is according to the followings:

No

Command

Speed Control handle

Start ahead

100 % load

Order to start

the Stop

Astern Test

For Conventional

Shafting: Stop the ME,

change to the reversed

Rpm, start the engine,

increase rpm

progressively to the

MCR.

Stop test

For Steerable Rudder

Propeller: Move the SRP

handle from 0 o gradually

up to reaching 180 o

For Conventional

Shafting: Stop the ME,

change the rpm to the

initial Rpm,

Rpm Control Dial for ME

To reach steadily at

MCR rpm ahead

To reach reversed rpm

steadily at MCR astern

(referring to the Engine

Maker)

Until 0 rpm

For Steerable Rudder

Propeller (SRP): Move

the SRP handle from 0 o

gradually up to reaching

180

c.

Items to measure:

i.

Measurement on Stop Astern Test:

Vessels speed each 10 second interval by Speed Log on the wheel

house.

Vessels heading angle each 10 second interval by Gyro compass.

ME rpm each 10 second interval correspondingly.

Wind direction and velocity, weather state, and sea depth at the

beginning of the test.

Time elapsed from signal full-astern to the complete stop, i.e. from the

Main engine to be stopped engine begins to rotate astern up to

the vessel is completely stopped.

ii.

Measurement on Stop Ahead Test:

01

Institute of Marine Engineering, Science and Technology (ImarEst)

Prepared by Hari Prastowo - Jurusan Teknik Sistem Perkapalan ITS

Tanggal 14 -feb-13

Date

Hal

4 of 9

Page

WORKING INSTRUCTION

SEA TRIAL PROCEDURE

No. Revisi

Rev. Number

Vessels speed each 10 second interval by Speed Log on the wheel

house.

Vessels heading angle each 10 second interval by Gyro compass.

ME rpm each 10 second interval correspondingly.

Wind direction and velocity, weather state, and sea depth at the

beginning of the test.

Time elapsed from signal full-ahead to the complete stop, i.e. from the

Main engine to be stopped engine begins to rotate ahead up to the

vessel is completely stopped.

6. TURNING TEST

a. Purpose:

To examine the vessels turning maneuverability, maximum advance, and maximum

tactical diameter of turning.

b. Procedure:

Turning test shall be measured at 100% Main engine Load (full-throttle) then the

steering rudder to be moved maximum (as per design) to the starboard and portside,

and the position to be kept until the vessel reach the turning of 360O from the original

course.

c. Items to measure:

i. Vessels speed each 10 second interval by speed log

ii. Vessels heading angle each 10 second interval by gyro compass

iii. Shaft rpm each 10 second interval accordingly

iv. Wind direction and velocity, weather state, and sea depth at the beginning of the

test.

v. Tactical diameter and advanced diameter.

7. Z-MANEUVERING TEST (ZIG-ZAG TEST)

a. Purpose:

To examine the ships course stability and how the ship responds to the changes of

rudder angle.

b. Procedure:

Having the vessel initially in full-ahead-speed on 100% MCR, the Zigzag test is to be

carried out, as follows:

i. Direct the vessel to the heading 20O starboard.

ii. When the heading of the vessel has been reaching 20O to the starboard from the

initial course, portside the helm 20O .

iii. When the heading of the vessel has been reaching 20O to the portside from the

initial course, starboard the helm 20O .

iv. Repeatedly, carry out the step no ii.

v. When the vessels heading return to initial course, the test is finished.

c. Items to measure:

i. Vessels speed each interval 10 second by means of speed log.

01

Institute of Marine Engineering, Science and Technology (ImarEst)

Prepared by Hari Prastowo - Jurusan Teknik Sistem Perkapalan ITS

Tanggal 14 -feb-13

Date

Hal

5 of 9

Page

ii.

iii.

iv.

v.

vi.

WORKING INSTRUCTION

SEA TRIAL PROCEDURE

No. Revisi

Rev. Number

Vessel heading angle of each swing by means of gyrocompass.

Maximum heading angle of each swing by means of gyrocompass.

Shaft rpm each 10 second respectively.

Wind direction and velocity, sea state, and sea depth at the beginning of the test.

Required time for each change and holding of rudder angle (start and stop of the

actual rudder motion against the response of the actual vessel motion)

8. STEERING GEAR TEST

a. Purpose:

To examine the capability of the steering gear system and the redundant system of

the steering gear.

b. Procedure:

i. Simulation test for redundancy arrangement to be carried out to verify that, upon

any single failure, the propulsion and steering system remain in operational, or

the back-up propulsion and steering system shall be speedily brought into

service.

ii. For emergency steering gear test, the propulsion and steering system must be

able to be operated by local system or local panel in the steering gear room.

c. Test Items:

i. Functional test of each back-up system of the steering gear system by means of

local control in the steering gear room.

ii. Wind direction and velocity, sea state, and sea depth at the beginning and the

end of the test.

9. ANCHORING TEST.

a. Purpose:

To examine the performance of Windlass.

b. Place and Condition:

i. The vessel is to be brought to a standstill condition and headed into the wind

before commencing the test,.

ii. The test is to be done in the deep water area where sufficient for 3 shackle of

anchor chains.

c. Kind of Tests

i. Loading Test:

The windlass shall be functionally tested by hoisting up 55 mm (2 fathoms) of

chains from the state in which 82.5 (3 fathoms) of anchor chains are submerged

and freely suspended at commencing of lifting.

ii. Chain Drum Brake Test:

The chain drum brake shall be tested with the anchor dropping at every

approximately fathoms of chains to confirm safe paying out and holding of the

anchor chains by means of braking the chain drum.

d. Procedure:

01

Institute of Marine Engineering, Science and Technology (ImarEst)

Prepared by Hari Prastowo - Jurusan Teknik Sistem Perkapalan ITS

Tanggal 14 -feb-13

Date

Hal

6 of 9

Page

i.

ii.

iii.

iv.

v.

WORKING INSTRUCTION

SEA TRIAL PROCEDURE

No. Revisi

Rev. Number

Drop the starboard anchor by releasing the brake of the windlass, and

approximately 82.5 m (3 fathoms) of starboard anchor chains shall be run into

water. While dropping in progress, the anchor brake shall be tested.

Hoist 55m (2 fathoms) of starboard anchor chains by means of windlass.

Drop the portside anchor by releasing the brake of the windlass, and

approximately 55 m (2 fathoms) of portside anchor chains shall be run into water.

While dropping in progress, the anchor brake shall be tested.

Hoist 27.5 m (1 fathoms) of portside anchor chains by means of windlass.

Hoist 27.5 m (1 fathoms) of both sides anchor chains and anchors.

e. Items of Measurement:

i. Weather, wind velocity and direction, and water depth.

ii. Hoisting speed (required time for hoisting 1 fathoms).

10. BLACK-OUT TEST

a. Purpose:

This test is to be done during the sea trial, to ensure the safety of the vessel upon the

loss of electric power for automatic starting and connecting Main Switch Board of the

Standby Generator.

b. Items of measurement:

Required time to start and to connect Main Switch Board of the standby generator

after loss of the electrical power supply.

11. ENDURANCE TRIAL

a. Purpose:

To examine the Main Engine endurance performance in continuous operation of

Service Continuous Rating, and to measure performance of the Main Engine in terms

of Power, RPM, Fuel Consumption, and durability.

b. Procedure:

Endurance trial shall be carried out for at least six (6) hours continuous operation at

NCR (85% MCR). During the endurance trial, Fuel Consumption of Main Engine shall

be measured for operational reference.

c. Items of measurement:

i. Fuel Oil consumption by means of flow meter.

ii. Shaft revolutions.

iii. ME rpm

iv. Main Engine load / power

v. Other necessary data regarding Main Engine performance such as:

Cooling temperature (in & out) and flow rate

LO temperature (in & out)

LO pressure

Exhaust gas temperature

Air and ambient temperature in Engine room

etc

01

Institute of Marine Engineering, Science and Technology (ImarEst)

Prepared by Hari Prastowo - Jurusan Teknik Sistem Perkapalan ITS

Tanggal 14 -feb-13

Date

Hal

7 of 9

Page

WORKING INSTRUCTION

SEA TRIAL PROCEDURE

No. Revisi

Rev. Number

12. NOISE AND LOCAL VIBRATION TEST.

12.1. NOISE TEST

a. General:

During official sea trial, measurements of noise levels is to be done in all spaces of

private cabins on Accommodation Decks, Wheelhouse, and Machinery Spaces.

Noise levels are to be recorded and submitted to the ship owner and other parties

concerned. One copy of the record shall remain onboard.

b. Conditions of Measurement:

The noise is to be measured under following conditions:

i. Main propulsion machinery shall be run at Normal Continuous Rating.

ii. Other auxiliary machineries, navigation instruments, etc, shall be operated

throughout the measurement period as required for normal seagoing condition

during sea trial.

iii. Mechanical ventilation and air condition equipment shall be in normal operation,

taking into account that the capacity is in accordance to the design conditions.

iv. All doors and windows of rooms are to be closed.

v. Spaces shall be furnished with all necessary equipment. Measurement without

soft furnishings may be made, but no allowance shall be made for their absence.

vi. The depth of water under the vessels keel and the presence of large reflecting

surfaces in the ships vicinity may affect the readings obtained, and shall be,

therefore, be noted in noise survey report.

vii. The meteorological conditions such as wind and rain, as well as sea state, shall

be such that they do not influence the measurement.

c. Measurement procedure:

i. During the noise level measurements, only those of concerned in ship operation

and noise measurement are allowed to present in the measured spaces.

ii. The sound level meter shall be calibrated with the calibrator before and after

measurements. The batteries shall also be checked immediately before each

period of use.

iii. Readings of sound pressure level shall be taken in decibels using an A-weighting

filter: dB(A).

iv. The meter shall be set to slow response and the readings made only to the

nearest decibel. A measuring time of at least 5 seconds shall be allowed. If a

meter fluctuate in level within a range of no more than 5 dB(A) maximum to

minimum, an estimation of the level shall be made by averaging with eye.

v. If the range fluctuations are in excess of 5 dB(A) or the sound is cyclic, irregular

or intermittent in operation, an integrating meter shall be used set to A-weighting.

Integration shall be made over a period of at least 30 seconds.

vi. At positions of high noise, spot checks shall be performed with the meter set to

fast response if considered necessary, to ensure the safety of a person taking

measurement.

d. Measurement Positions:

The measurements are to be taken on deck in the center of the room. Measurements

shall be taken at positions as follows:

i. Engine Room:

01

Institute of Marine Engineering, Science and Technology (ImarEst)

Prepared by Hari Prastowo - Jurusan Teknik Sistem Perkapalan ITS

Tanggal 14 -feb-13

Date

Hal

8 of 9

Page

ii.

iii.

iv.

v.

WORKING INSTRUCTION

SEA TRIAL PROCEDURE

No. Revisi

Rev. Number

Measurement shall be taken at four (4) representative positions per each deck

level in engine room to upper deck.

Pump Room:

Measurement shall be taken at four (4) representative positions per each deck

level in pump room.

Navigation Spaces:

Measurement shall be taken with all auxiliary equipment such as radar, echo

sounder, window wiper, clear view screen, etc in operation. However, audible

signals, telephone or similar need not to be taken into consideration.

Accommodation Spaces:

Generally, one measurement shall be made in the middle such as cabins,

hospital, office, mess room and recreation room.

Service Spaces:

The service spaces such as galley, pantry, and laundry, are to be measured.

However, the measurement may be done without equipments in operations.

12.2. LOCAL VIBRATION TEST

a. General:

This procedure describes the measurement of vibration response of

accommodations spaces. The purpose of measurement is to find out the vibration

level and to investigate the dynamic characteristic of the ship.

b. Procedure:

i. Measuring acceleration and vibration frequency at the direction of transversal and

vertical at the priority points A, B, and C, which measured at each rpm of the

Main Engine. The objective is to find the Resonance Frequency Point.

ii. Measuring acceleration and vibration frequency at the direction of transversal and

vertical at points of accommodations and engine room. Measurement is to be

carried out at NCR.

iii. Velocity of vibration shall be measured with a portable Vibration-meter. The

measurement shall be carried out not in simultaneous way but one by one.

13. FIRE FIGHTING EQUIPMENT TEST

a. Purpose:

This test is to be performed during sea trial, to ensure the Fire Fighting Equipment

can be well operated.

b. Items of Measurement:

All fire fighting equipment shall be functionally tested, including:

Fire main hydrants on decks and accommodation deck

Some portable fire extinguishers.

Fire alarms and fire detectors in all rooms

Emergency fire pumps.

14. LIFE SAVING EQUIPMENT TEST

a. Purpose:

This test is to be performed during sea trial, to ensure the Live saving Equipment can

be well operated.

b. Items of Measurement:

Some of life saving equipment shall be functionally tested, including:

01

Institute of Marine Engineering, Science and Technology (ImarEst)

Prepared by Hari Prastowo - Jurusan Teknik Sistem Perkapalan ITS

Tanggal 14 -feb-13

Date

Hal

9 of 9

Page

WORKING INSTRUCTION

SEA TRIAL PROCEDURE

No. Revisi

Rev. Number

Life boats:

- Life boat is to be fully loaded in accordance to persons capacity.

- Lowering davits in loaded condition by means of local handle inside the

life boat.

- Releasing life boat from davits by means of local handle.

- Starting up onboard engine in the lifeboat.

- Test of maneuvering of the life boat (turning and zigzag)

- Rechecking provisions that required to be provided onboard.

Life rafts:

- Checking hydraulic release units and validating expire date.

- If necessary, launching the life raft for simulation.

Life buoys:

- Check the number and availability on the approved on-board-location as

per stated on the Safety Plan

- Simulation of man over board function.

EPIRB and SART equipment:

- Check expire date

- Check battery power

- Check transmitted signal on the navigation equipments.

01

Das könnte Ihnen auch gefallen

- SEA TRIAL TESTSDokument31 SeitenSEA TRIAL TESTSRokhmatu SivaNoch keine Bewertungen

- Sea Trail+AnnexDokument37 SeitenSea Trail+AnnexAhmed Hassan100% (1)

- Sea TrialsDokument18 SeitenSea TrialsHussien Elmasry100% (1)

- SEA TRIAL TESTS AND CONDITIONSDokument31 SeitenSEA TRIAL TESTS AND CONDITIONS123habib123fikri100% (7)

- SEA TRIAL Procedure (Rev1) PDFDokument9 SeitenSEA TRIAL Procedure (Rev1) PDFRiyoNoch keine Bewertungen

- Preparation For Dry DockingDokument4 SeitenPreparation For Dry Dockingrajishrrr0% (1)

- Preparation For Dry DockingDokument8 SeitenPreparation For Dry DockingWin Min100% (8)

- Ittc Snames - Sea TrialDokument10 SeitenIttc Snames - Sea TrialIqbal Hussain100% (1)

- Survey DrydockDokument20 SeitenSurvey DrydockHarshad Tallur100% (3)

- 1.procedure of Sea TrialDokument51 Seiten1.procedure of Sea Trialvran77100% (6)

- Forms for Sea TrialsDokument72 SeitenForms for Sea Trialsrp100% (3)

- A Complete Guide of Bringing A Ship To Dry Dock - MySeaTimeDokument12 SeitenA Complete Guide of Bringing A Ship To Dry Dock - MySeaTimeMalancha Bose Mukherjee100% (1)

- Planned Maintenance System Annex01Dokument5 SeitenPlanned Maintenance System Annex01Jeros GarciaNoch keine Bewertungen

- Full Scale Meas Sea TrialDokument30 SeitenFull Scale Meas Sea TrialLukman Tarigan Sumatra100% (1)

- CPM in ShipbuildingDokument29 SeitenCPM in ShipbuildingLai Quoc50% (2)

- Docking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.Dokument3 SeitenDocking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.capone55Noch keine Bewertungen

- Pilot Boat PO - Sea Trial ReportDokument16 SeitenPilot Boat PO - Sea Trial ReportKyaw Oo100% (2)

- Sea Trial ProcedureDokument111 SeitenSea Trial Procedurerp75% (4)

- Estimating The Cost-Ship RepairDokument29 SeitenEstimating The Cost-Ship RepairMohammad Sholikhan Arif100% (1)

- Checklist For TakeoverDokument3 SeitenChecklist For TakeoverMariyath Muraleedharan KiranNoch keine Bewertungen

- DSQS-Daewoo Shipbuilding Quality StandardDokument134 SeitenDSQS-Daewoo Shipbuilding Quality StandardGoga100% (2)

- Ship Design Reference GuideDokument5 SeitenShip Design Reference Guidepraveench1888Noch keine Bewertungen

- Ship RepairDokument5 SeitenShip Repairycgoyal100% (1)

- Tug Boat PDFDokument18 SeitenTug Boat PDFwisnukerNoch keine Bewertungen

- Guide For Sea Trials PDFDokument111 SeitenGuide For Sea Trials PDFnawkong67% (3)

- IACS Survey and CertificationDokument745 SeitenIACS Survey and Certificationudaysrp100% (5)

- A Lecture On Dry DockingDokument12 SeitenA Lecture On Dry DockingChristopher JebarajNoch keine Bewertungen

- Dry Docking OperationsDokument5 SeitenDry Docking Operationshutsonianp100% (2)

- Ch10 Maintenance of The Ship and Equipment Revised CH 10Dokument68 SeitenCh10 Maintenance of The Ship and Equipment Revised CH 10joreyvil100% (1)

- 26m Crew Boat SpecDokument18 Seiten26m Crew Boat SpecadhityamspNoch keine Bewertungen

- 0015-2 GL Guidelines For Approval of Construct, Towage and InstallDokument22 Seiten0015-2 GL Guidelines For Approval of Construct, Towage and InstalldamnagedNoch keine Bewertungen

- Shipbuilding ProcessDokument83 SeitenShipbuilding ProcessGD Ardianta50% (4)

- Dry Docking Calculations and Safety RequirementsDokument200 SeitenDry Docking Calculations and Safety Requirementsnitishforindia100% (3)

- Basic Ship TheoryDokument83 SeitenBasic Ship TheorySidik SetiawanNoch keine Bewertungen

- Dry Docking ProcedureDokument3 SeitenDry Docking ProcedurenattiemobsterNoch keine Bewertungen

- SWBSDokument20 SeitenSWBSPatrick Fernandes100% (1)

- Ship Planned Maintenance System Database ConceptDokument11 SeitenShip Planned Maintenance System Database ConceptamasrurNoch keine Bewertungen

- LlyodsDokument73 SeitenLlyodskoib789Noch keine Bewertungen

- FG-18 Report of Sea Trial 200-215) PDFDokument16 SeitenFG-18 Report of Sea Trial 200-215) PDFvran77Noch keine Bewertungen

- Inclining Test ProceduresDokument74 SeitenInclining Test ProceduresIonut ArdeleanuNoch keine Bewertungen

- Report 1 ESTIMATION OF THE SHIP RESISTANCEDokument16 SeitenReport 1 ESTIMATION OF THE SHIP RESISTANCEpsda kseNoch keine Bewertungen

- Inclining Test Procedure-ExampleDokument28 SeitenInclining Test Procedure-Exampletalabiz50% (2)

- Enhanced Hull SurveyDokument31 SeitenEnhanced Hull SurveyArjun KarkeraNoch keine Bewertungen

- Machinery Planned Maintenance and Condition Monitoring, March 2013Dokument28 SeitenMachinery Planned Maintenance and Condition Monitoring, March 2013sailorgeorge1100% (1)

- Training New BuildingDokument88 SeitenTraining New BuildingIrdhan Kabutono WunaNoch keine Bewertungen

- 1 Course Notes - Dry Docking and Planned MaintenanceDokument19 Seiten1 Course Notes - Dry Docking and Planned Maintenancedarrelsilva100% (2)

- Dry DockDokument10 SeitenDry Dockmoonspellanarchy8810100% (1)

- Ship Machinery Maintenance Lecture 281106Dokument26 SeitenShip Machinery Maintenance Lecture 281106Ravikumar Gangadharan100% (3)

- JSQS Japan Shipbuilding Quality StandardDokument178 SeitenJSQS Japan Shipbuilding Quality StandardchachaNoch keine Bewertungen

- Anchor Handling Manual (Being Reviewed)Dokument46 SeitenAnchor Handling Manual (Being Reviewed)captafuentes100% (1)

- Bollard Pull Test ProcedureDokument8 SeitenBollard Pull Test ProcedureMey Rudy100% (2)

- Sea Trial ProgramDokument2 SeitenSea Trial ProgramAlex MilarNoch keine Bewertungen

- Guidelines For Safe AnchoringDokument7 SeitenGuidelines For Safe Anchoringziqiang liNoch keine Bewertungen

- Sea TrialspdfDokument4 SeitenSea TrialspdfhemanthvdkNoch keine Bewertungen

- Ship Maneuvering Data and StandardsDokument32 SeitenShip Maneuvering Data and StandardsSanyam Raheja90% (10)

- Resolution MSC.137Dokument6 SeitenResolution MSC.137Alexandre Gonçalves da RochaNoch keine Bewertungen

- Rules: For The Classification and Construction of Sea-Going ShipsDokument8 SeitenRules: For The Classification and Construction of Sea-Going ShipsbuddhansamratNoch keine Bewertungen

- Understanding Different Types of Ship ManoeuvresDokument9 SeitenUnderstanding Different Types of Ship ManoeuvresGiorgi Kandelaki100% (1)

- Chief Mate OralDokument8 SeitenChief Mate OralJonathan McCarthyNoch keine Bewertungen

- Maneuvre of VesselDokument70 SeitenManeuvre of VesselLuisPazPerdomo100% (1)

- Global Warming Is Getting WorseDokument2 SeitenGlobal Warming Is Getting Worsealex-bookNoch keine Bewertungen

- The Ultimate Guide to Finding Your Perfect SofaDokument23 SeitenThe Ultimate Guide to Finding Your Perfect Sofageorge.rogerNoch keine Bewertungen

- TS398 Insulator Standards As Per Chattisgarh BoardDokument38 SeitenTS398 Insulator Standards As Per Chattisgarh Boardjagadeesh_kumar_20Noch keine Bewertungen

- Disha Publication provides books for competitive exams onlineDokument16 SeitenDisha Publication provides books for competitive exams onlineAravind BhomboreNoch keine Bewertungen

- RGB-WS-2017 Doc 06g Goyal-RGBDokument31 SeitenRGB-WS-2017 Doc 06g Goyal-RGBtinyjamesNoch keine Bewertungen

- .No. Base Form Meaning Past Form Past Participle Form S / Es/ Ies Ing' FormDokument47 Seiten.No. Base Form Meaning Past Form Past Participle Form S / Es/ Ies Ing' Formbarun1977Noch keine Bewertungen

- HypothermiaDokument5 SeitenHypothermiaSäbïná D. GabätöNoch keine Bewertungen

- Berry and Reeder (2014) - Objective Identification of The Intertropical Convergence ZoneDokument17 SeitenBerry and Reeder (2014) - Objective Identification of The Intertropical Convergence ZonePriscila SantosNoch keine Bewertungen

- CAA Prep QuestionsDokument18 SeitenCAA Prep QuestionsUmaid KhanNoch keine Bewertungen

- Philippine Atmospheric, Geophysical and Astronomical Services AdministrationDokument5 SeitenPhilippine Atmospheric, Geophysical and Astronomical Services AdministrationjulieanngarciaNoch keine Bewertungen

- Test 1Dokument21 SeitenTest 1pranjal singhNoch keine Bewertungen

- Hydrology For EngineersDokument358 SeitenHydrology For Engineerstheia2894% (18)

- Compendium PDFDokument128 SeitenCompendium PDFshwetaNoch keine Bewertungen

- Chapter 1 Communication Principles ADokument10 SeitenChapter 1 Communication Principles AJericho SorianoNoch keine Bewertungen

- Lab #1: Measuring Temperature AccuratelyDokument8 SeitenLab #1: Measuring Temperature AccuratelyMoslem DaneshNoch keine Bewertungen

- Coal Runoff Analysis Complete ReportDokument32 SeitenCoal Runoff Analysis Complete ReportArif SusetyoNoch keine Bewertungen

- Fluidization of Bulk SolidsDokument77 SeitenFluidization of Bulk SolidsManfredHeyde100% (1)

- Ashrae-Psychart Eng N SI PDFDokument2 SeitenAshrae-Psychart Eng N SI PDFJonaz CruzNoch keine Bewertungen

- The Best American Poetry 2011 and 2012 (Selected Poems)Dokument18 SeitenThe Best American Poetry 2011 and 2012 (Selected Poems)Simon and Schuster100% (2)

- BS en 61394-2011 (2012)Dokument24 SeitenBS en 61394-2011 (2012)Yayan RnsNoch keine Bewertungen

- Geomorphology Sapping Features Colorado Plateau Howard 1988Dokument115 SeitenGeomorphology Sapping Features Colorado Plateau Howard 1988BaculitesNoch keine Bewertungen

- Air Heater PerformanceDokument20 SeitenAir Heater PerformanceSam100% (1)

- Cambridge Learner Guide For As and A Level GeographyDokument58 SeitenCambridge Learner Guide For As and A Level GeographyEvgeny GenadievichNoch keine Bewertungen

- Rizal National High School Table of Specification Third Summative Test in Science 9Dokument5 SeitenRizal National High School Table of Specification Third Summative Test in Science 9Christine Joy DelaPena Sanico100% (20)

- AC Vs DCDokument17 SeitenAC Vs DCKhalid UsmanNoch keine Bewertungen

- Swimming Pool Calculation for Family Tube PoolDokument63 SeitenSwimming Pool Calculation for Family Tube Poolwanroy80% (5)

- Heat Capacity and Thermal ExpansionDokument14 SeitenHeat Capacity and Thermal ExpansionSunday Glo M. CabuyaoNoch keine Bewertungen

- DR Floods Kill 6 as Rains Double Monthly AverageDokument12 SeitenDR Floods Kill 6 as Rains Double Monthly AverageHardiati AimanNoch keine Bewertungen

- ODB - Bio (Ecology) PDFDokument1 SeiteODB - Bio (Ecology) PDFHyacenth Azada TumbaliNoch keine Bewertungen

- Floods and SocietyDokument5 SeitenFloods and SocietyaviralpareekNoch keine Bewertungen