Beruflich Dokumente

Kultur Dokumente

Bricks Manufacturing

Hochgeladen von

kamlCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bricks Manufacturing

Hochgeladen von

kamlCopyright:

Verfügbare Formate

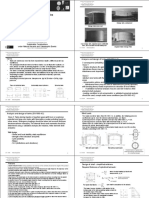

CONCRETE BLOCK MACHINES

FULL AUTOMATIC

CONCRETE BLOCK

MAKING PLANT

NFP

1236

CONCRETE BLOCK MACHINES

Professionalism Lies Beneath Details...

The vibration table, which consists of 3

separate parts, contains six 6000 rpm

vibration motors. With this combination,

high frequency vibration is created so

compaction process inside the mold is

optimized.

Column mills and bearings are strengthened and

heightened so mold activity inside the frame is

better stabilized. NFP-1236 is able to produce

higher concrete blocks with this modification.

Air bellows are used in fixation points of compaction head. This innovative

fixation mechanism optimizes the vibration applied to the mold so the

quality and strength of concrete blocks are increased. By using air bellows

instead of bolts on fixing the compaction head to the machine frame,

lifetime and durability of the machine is increased. Any possible wear and

failure on the machine related to the vibration is also prevented with this

mechanism.

NFP-1236 comes with a manual screw jack

mechanism to easily adjust the machine

frame's height. An electrical screw jack

mechanism is optionally provided so the height

adjustment can be performed automatically.

With this screw jack mechanism, NFP-1236 is

able to produce the highest concrete blocks in

its class.

Air bellows are used on fixation points of the

mold instead of fixation bolts. With this fixation

mechanism, molds are fixed to the machine

frame rapidly and easily. Because the mold is

not fixed directly to the machine frame, possible

wear and failures related to the vibration are

prevented. The major benefit of this fixation

system is the application of better vibration to

the mold.

NFP-1236 has an extensible machine frame

that can be opened and closed automatically

by the help of electrical motors. Time

consuming processes such as mold change

and periodic maintenance can be performed

easily and rapidly with this structure.

Rapid Mold Changing Unit is optionally

provided with NFP-1236. This unit makes it

possible to change the molds rapidly and

easily, even by 1 personnel. This unit also

helps to minimize time and labor spent on

traditional time-consuming mold change

operations.

The new and innovative control panel,

developed by NAMTA engineers, offers a

touch-screen LCD monitor and a practical

Graphical User Interface (GUI). All units of

the whole plant are indicated in this GUI so

supervisors can access every control easily.

CONCRETE BLOCK MACHINES

NFP

1236

FULL AUTOMATIC

CONCRETE BLOCK

MAKING PLANT

Define the industry standards with

NFP-1236

NFP-1236 is designed and manufactured with more than 50 years of

change operations can be easily performed. With the new hydraulic

experience and dedication of NAMTA engineers, defining the

system, cycle times are shortened and production capacity is

industry standards with its performance and production capacity.

increased.

NFP-1236 is built on the NHP-736 basis whose stability and

Mold fixation system of the machine is revised by using pneumatic

reliability is proven through many years in the industry. With its

bellows on the fixation points of mold and compaction head. With

elevated and strengthened frame and column mills, the machine is

this improved fixation system, vibration is fairly distributed through

able to produce various concrete blocks with increased heights. This

the mold so overall strength and quality of concrete blocks are

re-designed extensible machine frame is equipped with an electric

improved. "Rapid Mold Changing Unit" is optionally provided with the

powered open-close mechanism so periodic maintenance and mold

machine; this unit fastens and simplifies mold changing process.

CONCRETE BLOCK MACHINES

Power under control...

With the PLC automation software which is developed by NAMTA

a touch-screen LCD monitor with an easy to use graphical user

R&D engineers, the whole NFP-1236 plant needs only one

interface. Automation system also provides an archiving and

supervisor personnel to operate. The whole plant operates fully

reporting tool. Supervisors can access archived production data

automatic so production quality for each cycle and production

anytime; this data can also be printed out with a dot-matrix and/or

capacity for each working shift are maintained and stabilized.

inkjet printer connected to the system. Remote access capabilities

Automation system also makes it possible to operate the plant in

are optionally provided with the automation system.

various speeds.

Supervisors can access to the control system via any access point

NAMTA engineers evaluated the traditional PLC control panel to a

over LAN and/or internet. Any failure on the system can be

compact and simplified solution. This recently developed control

diagnosed and firmware update can be performed through remote

panel benefits the latest improvements in PLC technology and offers

access connection.

CONCRETE BLOCK MACHINES

Scalable plants to fulfill various requirements

The NFP-1236 is a full automatic, stationary concrete block making

(with 3 stations each) to transfer materials between the units of the

plant that is able to produce paving stones, curbstones and hollow

plant. NFP-1236 operates fully automatic; each unit of the plant

blocks by using different molds on the machine. The plant consists

communicates each other real-time and they are controlled via PLC

of one NFP-1236 full automatic PLC block making machine with

automation software. This makes it possible to operate the whole

pallet stacking unit, one PLC Twin Shaft concrete mixers with

plant with only 1 personnel minimizing labor expenses. The main

a capacity of 1200 lt./cycle, one PLC Spiral Blade mixer with

machine produces concrete block on wooden or steel pallets.

a capacity of 600 lt./cycle, one 3x25 m aggregate silos and

scaling unit, one 2x25 m aggregate silos and scaling unit, one

NAMTA uses top quality products of various industry leading

block stacking unit that transfers dry blocks from production

companies in manufacturing state-of-the-art concrete block making

pallets to transport pallets and two aerial conveying systems

machines and their supplementary equipments.

CONCRETE BLOCK MACHINES

Smart solutions, protecting investors

The major difference between the NFP-1236 and its variants is its

production cycle is created. Dependency to human labor is

Cuber unit. This unit collects dried products with its robot arm and

minimized with this system so labor expenses decrease

transfers them from production pallets to transports pallets. Empty

dramatically, protecting the whole investment in the long term.

pallets then re-enter to the production line thus an uninterrupted

CONCRETE BLOCK MACHINES

NFP 1236

Concrete Block

Making Plant

CONCRETE BLOCK MACHINES

NFP 1236 - TECHNICAL SPECIFICATIONS:

Control

Full Automatic (PLC)

Pallet Size

1.150x1.500 mm. (Legged)

Usable Area on Pallet

1.050x1.250 mm.

Maximum Block Height

500 mm.*

Minimum Block Height

50 mm.

Frame Dimensions (Width-Length-Height)

2.450x9.000x4.350 mm.

Frame Weight.

19.200 kg.

Hydraulic Tank Capacity

1.050 lt./1.400 lt.

Material Bucket Capacity

2.650 lt.

Filling Box Capacity

400 lt.

Bottom Vibrators

6x2 kW (max.150 kN)

Top Vibrators

2x2 kW (max. 50 kN)

Total Electric Motor Powers (Machine)

107 kW

Total Electric Motor Powers (Whole Plant)

256 kW

Paving Stones

Curbstones

*This value is limited with the leg height of production pallets.

NFP 1236 - PRODUCTION CAPACITY:

Stones Per Cycle

Hollow Blocks

Behaton Paving Stone (163x198x80mm.)

36 pieces

Rectangular Paving Stone (98x198x80mm.)

54 pieces

Square Paving Stone (198x198x80mm.)

99 pieces

Curbstone (180x700x300mm.)

4 pieces

Curbstone (150x500x300mm.)

8 pieces

Curbstone (100x500x200mm.)

12 pieces

Hollow Block (190x390x190mm.)

12 pieces

Hollow Block (150x390x190mm.)

16 pieces

Hollow Block (100x390x190mm.)

22 pieces

Behaton Paving Stone (163x198x80mm.)

1.200 m

Rectangular Paving Stone (98x198x80mm.)

1.300 m

Square Paving Stone (198x198x80mm.)

1.200 m

Curbstone (180x700x300mm.)

4.800 pieces

Production Capacity per Shift Curbstone (150x500x300mm.)

(8 hours)

Curbstone (100x500x200mm.)

9.600 pieces

14.400 pieces

Hollow Block (190x390x190mm.)

14.400 pieces

Hollow Block (150x390x190mm.)

19.200 pieces

Hollow Block (100x390x190mm.)

26.400 pieces

These technical values are based on standard specifications and may vary on

customer's requirements, installation type and location. NAMTA keeps the right of

changing technical specifications if necessary.

Capacity value is theoretical value. It may vary according to aggregates structure,

operator, weather and accommodation conditions.

CONCRETE MACHINES &

CONCRETE PRODUCTS

LTD. CO.

a Ankara Asfalt 26. km

Kemalpaa zmir TURKEY

t +90(232) 878 13 59

f +90(232) 878 77 65

e info@namtas.com

w www.namtas.com

Das könnte Ihnen auch gefallen

- Magnetic Particle Equipment Selection GuideDokument16 SeitenMagnetic Particle Equipment Selection GuideWellington S. FrançaNoch keine Bewertungen

- Air Jet Weaving MachineDokument8 SeitenAir Jet Weaving MachineDwi Fitria ApriliantiNoch keine Bewertungen

- Marzoli Vouk: Draw FramesDokument22 SeitenMarzoli Vouk: Draw FramesHameedullah AnsariNoch keine Bewertungen

- Index ABC Siemens Fanuc enDokument16 SeitenIndex ABC Siemens Fanuc enioancasian2015100% (1)

- QFT5 .8.10eng New081028 31752Dokument46 SeitenQFT5 .8.10eng New081028 31752Thein Htoon lwinNoch keine Bewertungen

- Spraymec 8100 VC 100075480Dokument12 SeitenSpraymec 8100 VC 100075480Hamid CRNoch keine Bewertungen

- HM 35-300 enDokument24 SeitenHM 35-300 enairshow19Noch keine Bewertungen

- Standing Up To Any Challenge. Famup MC and MCP: E M Conomy MeansDokument8 SeitenStanding Up To Any Challenge. Famup MC and MCP: E M Conomy MeansskidamdnevnoNoch keine Bewertungen

- Magnetic Particle Inspection EquipmentDokument16 SeitenMagnetic Particle Inspection EquipmentSergio CalderonNoch keine Bewertungen

- T100A en v2 0911Dokument8 SeitenT100A en v2 0911Παναγιώτης ΤσάπαςNoch keine Bewertungen

- SLG Brochure enDokument8 SeitenSLG Brochure enMoustaffaNoch keine Bewertungen

- CL Chiraginternational PDFDokument12 SeitenCL Chiraginternational PDFQ8123Noch keine Bewertungen

- Caterpillar 320cDokument28 SeitenCaterpillar 320ccamelia_pirjan5776100% (2)

- Top Drive Brochure PDFDokument6 SeitenTop Drive Brochure PDFaldino020203100% (1)

- Anwendungsbericht LinMot Toelke Closure ENDokument4 SeitenAnwendungsbericht LinMot Toelke Closure ENMohsin AhmadNoch keine Bewertungen

- MF 750 CS - enDokument18 SeitenMF 750 CS - ensteph_4458Noch keine Bewertungen

- Brochure FANUC RoboshotDokument32 SeitenBrochure FANUC Roboshotkamaleon85Noch keine Bewertungen

- Batching PlantDokument8 SeitenBatching Plantsofyanshah100% (1)

- 2010 PBT e InternetDokument20 Seiten2010 PBT e InternetMohammed RiyazNoch keine Bewertungen

- Modern Developments in Spinning and Weaving MachineryDokument20 SeitenModern Developments in Spinning and Weaving MachinerysuganNoch keine Bewertungen

- Technology Working For You.: Approved PrecisionDokument11 SeitenTechnology Working For You.: Approved PrecisionDavid Alejandro TellezNoch keine Bewertungen

- Batching Plant PDFDokument12 SeitenBatching Plant PDFskb25100% (1)

- Eurotech BV SeriesDokument8 SeitenEurotech BV SeriesCNC SYSTEMSNoch keine Bewertungen

- Wheeled-Range Broch LowqDokument12 SeitenWheeled-Range Broch LowqLee LiNoch keine Bewertungen

- Top DriveDokument4 SeitenTop DriveJorge FreireNoch keine Bewertungen

- Batching PlantDokument12 SeitenBatching PlantPratik LikharNoch keine Bewertungen

- Dynamic Acera: WT HP BKT CapDokument8 SeitenDynamic Acera: WT HP BKT CapSilviaMoreno0% (1)

- EN - Top-of-the-Range Automatic Compression Testers For Cubes and Cylinders AUTOMAX PRODokument7 SeitenEN - Top-of-the-Range Automatic Compression Testers For Cubes and Cylinders AUTOMAX PROHaikalNoch keine Bewertungen

- Takamaz XC XLseriesDokument24 SeitenTakamaz XC XLseriesPham LongNoch keine Bewertungen

- Technical Description KMCDokument6 SeitenTechnical Description KMCJuan Francisco Marin MendiolaNoch keine Bewertungen

- Volkmann CTwisterDokument20 SeitenVolkmann CTwisterimma coverNoch keine Bewertungen

- Arc Welding RobotDokument33 SeitenArc Welding Robotrakeshkaushik100% (1)

- CNC 3 Index UkDokument2 SeitenCNC 3 Index UkHemily RoseNoch keine Bewertungen

- MultiCam 3000-Series CNC WaterjetDokument12 SeitenMultiCam 3000-Series CNC WaterjetDaniel AustinNoch keine Bewertungen

- CNC Lathe Machines PDFDokument7 SeitenCNC Lathe Machines PDFMetwally Naser100% (1)

- Pipelayer: Engine Engine (Continued)Dokument20 SeitenPipelayer: Engine Engine (Continued)Daniel Marx ChillitupaNoch keine Bewertungen

- Manual de DragalinaDokument28 SeitenManual de DragalinaedwardNoch keine Bewertungen

- Ps2600 BrochureDokument8 SeitenPs2600 BrochureMochamad HafidzNoch keine Bewertungen

- Brick Making Machinery2Dokument12 SeitenBrick Making Machinery2Sameera PalliyaGurugeNoch keine Bewertungen

- CTX 310Dokument12 SeitenCTX 310Staic RominaNoch keine Bewertungen

- Prospekt Venture 13 15 GB 14540Dokument16 SeitenProspekt Venture 13 15 GB 14540Pat MontalbanoNoch keine Bewertungen

- Excavator PC210 8Dokument24 SeitenExcavator PC210 8Bálint Géza100% (2)

- Pipelayer: Engine Weights Lift CapacityDokument16 SeitenPipelayer: Engine Weights Lift CapacityEVCYNoch keine Bewertungen

- Block Making Machine Compacta by PrensolandDokument31 SeitenBlock Making Machine Compacta by PrensolandprensolandNoch keine Bewertungen

- Amp MBW 800amp@2006 SmallDokument4 SeitenAmp MBW 800amp@2006 Smalljanuar92021068100% (1)

- Ala PDF FFDokument13 SeitenAla PDF FFDarshan PatelNoch keine Bewertungen

- ART Metaltek XB1200 For PDFDokument6 SeitenART Metaltek XB1200 For PDFandrea772Noch keine Bewertungen

- Hydro Turbines - Bulb, The Complete Solution For Low HeadsDokument12 SeitenHydro Turbines - Bulb, The Complete Solution For Low HeadspalanaruvaNoch keine Bewertungen

- Batching Plant PDFDokument8 SeitenBatching Plant PDFfakhli bisaNoch keine Bewertungen

- Lockformer Vulcan Catalog PDFDokument6 SeitenLockformer Vulcan Catalog PDFgvlaxmipathiNoch keine Bewertungen

- TP TP: Turret Punch Turret PunchDokument20 SeitenTP TP: Turret Punch Turret PunchMaly AliNoch keine Bewertungen

- Mikrotron RUMULDokument8 SeitenMikrotron RUMULBenito AllendesNoch keine Bewertungen

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusVon EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNoch keine Bewertungen

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationVon EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNoch keine Bewertungen

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneVon EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNoch keine Bewertungen

- Distributed Process Control ReportVon EverandDistributed Process Control ReportNoch keine Bewertungen

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsVon EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNoch keine Bewertungen

- PyroSimManual PDFDokument155 SeitenPyroSimManual PDFkamlNoch keine Bewertungen

- Grafik QS CompleteDokument204 SeitenGrafik QS CompletekamlNoch keine Bewertungen

- ConduitDokument77 SeitenConduitkamlNoch keine Bewertungen

- Brick MakingDokument3 SeitenBrick MakingkamlNoch keine Bewertungen

- 6.01 Brick MakingDokument15 Seiten6.01 Brick MakingRameez BedekarNoch keine Bewertungen

- GRAFIK Eye QS General PDFDokument20 SeitenGRAFIK Eye QS General PDFkamlNoch keine Bewertungen

- CycEL InstructionsDokument9 SeitenCycEL InstructionskamlNoch keine Bewertungen

- Fiberglass StructuresDokument12 SeitenFiberglass Structureskaml100% (1)

- Breadfruit Project FINAL PDFDokument99 SeitenBreadfruit Project FINAL PDFkamlNoch keine Bewertungen

- CycEL InstructionsDokument9 SeitenCycEL InstructionskamlNoch keine Bewertungen

- Fault Level CalculationDokument6 SeitenFault Level Calculationmn_sundaraamNoch keine Bewertungen

- Cement MixerDokument3 SeitenCement MixerGreg Phillpotts100% (5)

- Articulated Jib Tower CraneDokument6 SeitenArticulated Jib Tower CranekamlNoch keine Bewertungen

- 700pxx Iseng1200 PDFDokument4 Seiten700pxx Iseng1200 PDFkamlNoch keine Bewertungen

- Baby TractorDokument3 SeitenBaby TractorFrenchwolf420Noch keine Bewertungen

- Chemin CritiqueDokument1 SeiteChemin CritiquekamlNoch keine Bewertungen

- Sargent Duplicarver PDFDokument11 SeitenSargent Duplicarver PDFkamlNoch keine Bewertungen

- 20060156658Dokument8 Seiten20060156658kamlNoch keine Bewertungen

- Irsst Lift TruckDokument6 SeitenIrsst Lift TruckEhab Yahia KhalelNoch keine Bewertungen

- PatentStorm Document ResourceDokument12 SeitenPatentStorm Document ResourcekamlNoch keine Bewertungen

- Micro Scissor LiftDokument2 SeitenMicro Scissor LiftkamlNoch keine Bewertungen

- PDFDokument35 SeitenPDFkamlNoch keine Bewertungen

- Provided by Patentstorm, HTTP://WWW - Patentstorm.UsDokument35 SeitenProvided by Patentstorm, HTTP://WWW - Patentstorm.UskamlNoch keine Bewertungen

- PDFDokument10 SeitenPDFkamlNoch keine Bewertungen

- 5069592Dokument2 Seiten5069592kamlNoch keine Bewertungen

- Schedule Dates Cbna Sheet 1 of 1Dokument7 SeitenSchedule Dates Cbna Sheet 1 of 1kamlNoch keine Bewertungen

- Electric Lift & Electric DriveDokument2 SeitenElectric Lift & Electric DrivekamlNoch keine Bewertungen

- 1.37662!CHRISGAS - D127 and D28 - Cost Estimate For A Biomass PlantDokument1 Seite1.37662!CHRISGAS - D127 and D28 - Cost Estimate For A Biomass PlantkamlNoch keine Bewertungen

- Chemin CritiqueDokument1 SeiteChemin CritiquekamlNoch keine Bewertungen

- Topic12 PDFDokument12 SeitenTopic12 PDFkamlNoch keine Bewertungen

- Handwound Macadamia Nut Cracker GuideDokument3 SeitenHandwound Macadamia Nut Cracker Guiderahuljain833Noch keine Bewertungen

- Zeppelin Standard SilosDokument83 SeitenZeppelin Standard SilosdgcereijoNoch keine Bewertungen

- Parametric Study On Double Wall Freestanding Steel StackDokument5 SeitenParametric Study On Double Wall Freestanding Steel StacknehaNoch keine Bewertungen

- Simulation of Silo Filling and Discharge Using ANSYS and Comparison With Experimental DataDokument10 SeitenSimulation of Silo Filling and Discharge Using ANSYS and Comparison With Experimental DataSami Houhamdi100% (1)

- 6.the Solution Approach To Flow Problems Using Tivar 88Dokument11 Seiten6.the Solution Approach To Flow Problems Using Tivar 88hadiNoch keine Bewertungen

- SS2 HQ 5 PDFDokument11 SeitenSS2 HQ 5 PDFRocka TranNoch keine Bewertungen

- Agitators Tanks ThickenersDokument29 SeitenAgitators Tanks ThickenersJean DejardinNoch keine Bewertungen

- References Silos v4Dokument80 SeitenReferences Silos v4marioNoch keine Bewertungen

- Samson Ports and TerminalsDokument24 SeitenSamson Ports and TerminalsLiyenita WidjajaNoch keine Bewertungen

- Stanelle Product Catalog EngDokument229 SeitenStanelle Product Catalog EngGagrigoreNoch keine Bewertungen

- Pig Production 307pro 310pro Big Dutchman enDokument8 SeitenPig Production 307pro 310pro Big Dutchman enM Rahim SiregarNoch keine Bewertungen

- Conveying and StoringDokument28 SeitenConveying and StoringTin Nguyen100% (1)

- Tubular Chain Conveyors: Installation and Loop ArrangementsDokument12 SeitenTubular Chain Conveyors: Installation and Loop ArrangementsIvo KovachevNoch keine Bewertungen

- Katalog 2011Dokument68 SeitenKatalog 2011Aziz ELNoch keine Bewertungen

- Blending SiloTechniquesDokument6 SeitenBlending SiloTechniquesYaserElkelawy100% (1)

- Overall View On Nozzles For VSR BLASTER Air Cannons Normal and High Temperature AreasDokument2 SeitenOverall View On Nozzles For VSR BLASTER Air Cannons Normal and High Temperature AreasShyamal HansdaNoch keine Bewertungen

- Screw Conveyor Engineering Guide Pt1Dokument17 SeitenScrew Conveyor Engineering Guide Pt1vijayendraNoch keine Bewertungen

- Pbe - 200703-Conveying System Successfully Transfers Carbon Black Prills From Railcars To SilosDokument4 SeitenPbe - 200703-Conveying System Successfully Transfers Carbon Black Prills From Railcars To Silos설동하Noch keine Bewertungen

- Understanding Particle SegDokument10 SeitenUnderstanding Particle SegHarshaNoch keine Bewertungen

- Ash HandlingDokument30 SeitenAsh Handlingrmm99rmm99100% (2)

- Steelmaking and Casting at The New Minimill of Abinsky Electrometal Works LLCDokument15 SeitenSteelmaking and Casting at The New Minimill of Abinsky Electrometal Works LLCmetudgn100% (2)

- Bag Loading Systems PDFDokument11 SeitenBag Loading Systems PDFBatsukh GanchuluunNoch keine Bewertungen

- KARL KLINK Dry Broaching Machine in Double Column Table Up Design With D-DRIVEDokument2 SeitenKARL KLINK Dry Broaching Machine in Double Column Table Up Design With D-DRIVEVaikuntam RamamurthyNoch keine Bewertungen

- Coal Stockpile in Indian Power PlantsDokument9 SeitenCoal Stockpile in Indian Power PlantsAmit BhaduriNoch keine Bewertungen

- Hetauda Cement Industries Limited: Industrial Attachment atDokument40 SeitenHetauda Cement Industries Limited: Industrial Attachment atrishav khanalNoch keine Bewertungen

- Lime-Dosing Wam Inc Brochure 0114 EDIT PDFDokument4 SeitenLime-Dosing Wam Inc Brochure 0114 EDIT PDFWidiyanto WidiyantiNoch keine Bewertungen

- Kenya Grain Storage4 PDFDokument22 SeitenKenya Grain Storage4 PDFGeoffrey TanuiNoch keine Bewertungen

- Solids Handling ProblemsDokument45 SeitenSolids Handling ProblemsHarsha100% (1)

- Food Grain Storage Structures: Agricultural Structures and Environmental Control BTAP3105Dokument49 SeitenFood Grain Storage Structures: Agricultural Structures and Environmental Control BTAP3105Sri Himaja100% (1)

- Ros ManualDokument78 SeitenRos ManualDurga PrasadNoch keine Bewertungen