Beruflich Dokumente

Kultur Dokumente

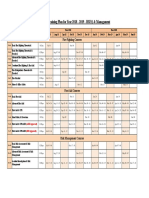

HSE Performance Criteria

Hochgeladen von

HossamKandilCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HSE Performance Criteria

Hochgeladen von

HossamKandilCopyright:

Verfügbare Formate

SITE MANAGEMENT VISIT

HSE PERFORMANCE GUIDANCE OBSERVATION CRITERIA

ITEM

POOR

1

SITE

HOUSE

KEEPING

PPE

COMPLIANCE

ELECTRICAL

SAFETY

LIFTING

OPERATIONS/

LIFTING

EQUIPMENT

MEDIOCRE

3

4

ADEQUATE

5

6

GOOD

7

EXCELLENT

9

10

Poor cable management

Waste materials lying

around

No waste containers

available

Imminent danger of

falling objects

Evidence of vermin

on site

Poor cable management

Some waste

materials lying

around

Waste containers

available

Some evidence of

vermin on site

Cable management

and routing employed

in some areas

Waste containers

available and used

Occasional items of

waste material lying

around

Some dedicated

storage areas on site

Dedicated storage

areas for materials

Cable management

and routing

employed but some

loose cable are

present

No loose materials or

equipment on site

Waste containers

available and

regularly emptied

Dedicated storage

areas for materials

Cable management

and routing employed

No loose materials or

equipment on site

Waste containers

available and

regularly emptied

Housekeeping plan

for site

No personnel

wearing PPE

PPE available is not

in good condition

Site PPE

requirements not

specified by signs on

site or in induction

Some personnel

wearing/using PPE

PPE available is not

in good condition

Site PPE

requirements

specified by signs

and in induction but

not complied with

Isolated instances of

personnel not

wearing PPE

PPE available is

mostly manufactured

to a recognised

standard

Site PPE policy

available

All personnel on site

wearing mandatory

PPE

All PPE on site

manufactured to a

recognised standard

Site PPE policy

available and

implemented

Dedicated PPE

storage available on

site but not used

All personnel on site

wearing mandatory

PPE

All PPE on site

manufactured to a

recognised standard

Site PPE policy

available and actively

enforced

Dedicated PPE

storage used on site

No Earth Leakage

Circuit Breakers

(ELCBs) installed

Damaged electrical

cables present

Unqualified

electricians employed

Diesel generators not

earthed

Electrical equipment

in poor condition

No electrical/isolation

PTW

Some ELCBs

installed

Some damaged

electrical cables

present

Some qualified

electricians employed

Some diesel

generators earthed

Some electrical

equipment in poor

condition

Electrical/isolation

PTW in place but not

used

ELCBs installed but

not tested

Some electrical

cables routed to

avoid traffic routes

and sharp edges

Some electrical

cabling used

protected against

cuts/abrasions

Most electrical

equipment in good

condition

Qualified electricians

employed

Electrical/isolation

PTW in place and

occasionally used

ELCBs installed and

tested weekly

Most electrical cables

routed to avoid traffic

routes and sharp

edges

Most electrical

cabling protected

against

cuts/abrasions

Electrical equipment

in good condition

Qualified and

competent

electricians employed

Electrical/isolation

PTW in place and

used

ELCBs installed and

tested daily

Electrical cables

routed to avoid traffic

routes and sharp

edges

Electrical cabling

protected against

cuts/abrasions

Electrical equipment

in good condition

Qualified and

competent

electricians employed

Electrical/isolation

PTW in place and

used

Risk assessment

conducted and

associated control

measures

implemented

Incorrect lifting

methods employed

Incorrect or

uncertified lifting

equipment being

used

Untrained personnel

No site supervision

Some incorrect lifting

methods employed

Some incorrect or

uncertified lifting

equipment being

used

Some trained

personnel

Inadequate site

supervision

Adequate supervision

on site

Trained personnel

displaying most

required

competences

Cranes inspected

occasionally

Most rigging and

lifting equipment

used has valid

certification available

on site

Crane load charts

available and some

safety devices fitted

and operational

Pre-use examination

of lifting equipment

conducted

Most crane safety

devices fitted and

operational

Cranes regularly

inspected

Trained and

competent personnel

Certified rigging and

lifting equipment

Lifting equipment

mainly compatible

with the load being

lifted

Adequate site

supervision

Pre-use examination

of lifting equipment

conducted

Crane safety devices

fitted and operational

Cranes regularly

inspected

Trained and

competent personnel

Risk assessment and

lift plan available for

complex lifts

Certified rigging and

lifting equipment

Lifting equipment

compatible with the

load being lifted

Adequate site

supervision

SITE MANAGEMENT VISIT

HSE PERFORMANCE GUIDANCE OBSERVATION CRITERIA

ITEM

POOR

1

VEHILCES /

MOBILE PLANT

PERMIT TO

WORK

ADEQUATE

5

6

GOOD

7

EXCELLENT

9

10

Personnel working at

height on incomplete

or poorly erected

scaffolding

Personnel working at

height with no fall

protection

Untrained personnel

erecting scaffolding

Some personnel

working at height on

incomplete or poorly

erected scaffolding

Scafftag system in

place but not used

Some personnel

observed working at

height with no fall

protection

Some untrained

personnel erecting

scaffolding

Scaffolding complete

Scafftag system used

to inspect and certify

scaffolding

Trained personnel

erecting scaffolding

Safety harness used

for work at height

Some lanyards

connected to

unsuitable anchor

points

Scaffolding complete,

safe and suitable for

the intended job

Scafftag system or

equivalent inspection

regime in place

Fall arrest equipment

regularly inspected

Trained and

competent personnel

for scaffold erection

Most personnel

trained for work at

height

Most tools and

materials used at

height are secured

Safety harness used

for work at height

with lanyard attached

to suitable overhead

anchor point

Scaffolding complete,

safe and suitable for

the intended job

Scafftag system or

equivalent inspection

regime in place

Fall arrest equipment

inspected prior to use

Trained and

competent personnel

for scaffold erection

and work at height

All tools and

materials used at

height are secured

Safety harness used

for work at height with

lanyard attached to

suitable overhead

anchor point

Working at height

minimised by design /

engineering

No designated

escape routes

Muster point not

identified or known by

site personnel

No fire-fighting

equipment available

Drills not conducted

Site housekeeping

poor

No control of

hotwork/smoking on

site

Limited escape

routes

Insufficient firefighting equipment

available or out of

date

Muster point

identified but not

known by site

personnel

Drills not conducted

Site housekeeping

mediocre

Limited control of

hotwork/smoking on

site

Sufficient escape

routes and fire

fighting equipment

available

Muster point

identified but not

known by all site

personnel

Drills conducted

infrequently

Site housekeeping

adequate

Hotwork controlled by

PTW

Site smoking policy

implemented but

compliance generally

poor

Sufficient escape

routes and fire

fighting equipment

available but not all

visibly marked

Muster point

identified and known

by all site personnel

Drills conducted

Site housekeeping

good

Hotwork controlled by

PTW

Site smoking policy

implemented with

good compliance

All escape routes and

fire fighting

equipment accessible

and visibly marked

Muster point

identified and known

by all site personnel

Drills regularly

conducted

Site housekeeping

excellent

Hotwork controlled by

PTW

Site smoking policy

fully implemented

Entry and exit of

vehicles to site not

monitored

No designated traffic

routes on site

Loading and

unloading of material

uncontrolled

Vehicles reverse on

site without alarms or

banksman

No parking facilities

on site

Vehicle and Plant

standards not set and

no inspections

conducted

Limited monitoring

of vehicles entering

and leaving site

Traffic routes

defined but not

marked

Loading and

unloading areas for

material defined but

not used

Vehicles reverse on

site with alarms but

uncontrolled

Parking facilities

defined but

insufficient and not

used

Vehicle and Plant

standards set but

not enforced

Limited monitoring

of vehicles entering

and leaving site

Traffic routes

defined and marked

Loading and

unloading areas for

material defined and

predominantly used

Vehicles reverse on

site with alarms and

banksman

Parking facilities

defined but

insufficient

Vehicle and Plant

standards set and

inspections

conducted

occasionally

Entry and exit of

vehicles monitored

on site

Traffic routes

defined and marked

Loading and

unloading areas for

material defined and

used

Vehicles reverse on

site with alarms and

banksman

Parking facilities

available and used

Vehicle and Plant

standards set and

inspections

conducted regularly

Entry and exit of

vehicles monitored

on site

Physical segregation

of site vehicle and

pedestrian traffic

routes

Loading and

unloading areas

defined and used

Vehicle reversing

minimised via site

design

Site parking facilities

available and used

Vehicle and Plant

standards set and

regular inspections

conducted

Work carried out

without permit

Necessary

precautions not being

taken or enforced

Work carried out with

permit

Necessary

precautions not being

taken or enforced

Work carried out with

permit

Not all necessary

precautions being

taken or enforced

Work carried out with

permit

All necessary

precautions being

taken and enforced

Risk assessment

conducted and

associated control

measures

implemented

Work carried out with

permit

All necessary

precautions being

taken and enforced

WORK AT

HEIGHT /

SCAFFOLDS

FIRE

PREVENTION/

FIRE-FIGHTING

EQUIPMENT

MEDIOCRE

3

4

SITE MANAGEMENT VISIT

HSE PERFORMANCE GUIDANCE OBSERVATION CRITERIA

ITEM

POOR

MEDIOCRE

3

4

ADEQUATE

5

6

Incorrect storage,

unsecured,

unidentified

substances

No control measures/

PPE used when

handling

Excessive inventory

stored at location

No material safety

data sheets available

No COSHH / Health

Risk Assessments

available

Substances

identified but

incorrect/unsecured

storage

Insufficient control

measures/PPE used

when handling

Excessive inventory

stored at location

Incomplete material

safety data sheets /

assessments

available

Substances

identified but

improvements

required to ensure

secure storage

Sufficient control

measures/PPE used

when handling

Material safety data

sheets available

Inventory sufficient

but greater than

operational needs

stored at location

Substances

identified, secured

and correctly stored

Sufficient control

measures/PPE used

when handling

Inventory sufficient

for operations stored

at location

Material safety data

sheets available and

understood by most

personnel

Inventory sufficient

for operations stored

at location and

distribution of

substances

controlled

All substances

segregated, labelled

and secured

Data sheets

available and

understood by

personnel

Control

measures/PPE used

when handling

Tools/machinery used

without guards

Equipment being

used unsuitable for

task

Equipment in poor

condition

Personnel untrained

in use of

tools/equipment

Some

tools/machinery in

use without proper

guards

Some equipment in

poor condition

Some personnel

trained in use of

tools/equipment

Some equipment

being used is

unsuitable for the

task

Most tools/machinery

in use with proper

guards and some

safety devices

Most equipment in

good condition but

only breakdown

maintenance

employed

Most personnel

trained in use of

tools/equipment

Most equipment used

is suitable for the task

All tools/machinery in

use with proper

guards and most

safety devices

Equipment in good

condition and

regularly maintained

Equipment being

used is suitable for

the task

Personnel on site are

trained in the use of

tools/equipment

Pre-use examination

of tools/equipment

Some risk

assessments

conducted for use of

tools and equipment

on site

All tools/machinery in

use with proper

guards and safety

devices

Equipment in good

condition and subject

to planned

maintainance

Equipment being

used is suitable for

the task

Personnel on site are

trained in the use of

tools/equipment

Pre-use examination

of tools/equipment

Risk assessment

conducted for use of

tools and equipment

on site

HAZARDOUS

SUBSTANCES

HAND TOOLS /

EQUIPMENT

GOOD

7

EXCELLENT

9

10

Das könnte Ihnen auch gefallen

- HSW Act 1974 Tool Box TalkDokument2 SeitenHSW Act 1974 Tool Box TalkbashirdarakNoch keine Bewertungen

- HSE Committee Meeting Rev1Dokument25 SeitenHSE Committee Meeting Rev1Khaled Ismail100% (1)

- HSE Performance MonitoringDokument5 SeitenHSE Performance MonitoringUnachukwu Sopulu SopsyNoch keine Bewertungen

- 3.3.7 Hazdarous Waste LogDokument2 Seiten3.3.7 Hazdarous Waste LogSubzone ThreeNoch keine Bewertungen

- Record Retention Checklist Rev.0Dokument2 SeitenRecord Retention Checklist Rev.0Sameer ParambathNoch keine Bewertungen

- Annex 07 - ODS-QHSE-SP-04 - Training & Competency ProcedureDokument6 SeitenAnnex 07 - ODS-QHSE-SP-04 - Training & Competency ProcedureFahmi AbdullahNoch keine Bewertungen

- Minutes of Meeting-RC Safety Staff Meeting 6 23SEP15-Final DraftDokument5 SeitenMinutes of Meeting-RC Safety Staff Meeting 6 23SEP15-Final DraftMohammed Jai Sujiya KhanNoch keine Bewertungen

- GTSC Egypt Training Plan For Year 2018 - 2019 - HSEQ & ManagamentDokument11 SeitenGTSC Egypt Training Plan For Year 2018 - 2019 - HSEQ & ManagamentAR El Patron KadryNoch keine Bewertungen

- 03 04 AMM Daily HSE Statistics Report AprDokument1 Seite03 04 AMM Daily HSE Statistics Report AprPT. ANUGRAH MIRAN MANDIRINoch keine Bewertungen

- 1.J - Site Logistics PlanDokument1 Seite1.J - Site Logistics Planyusufu0% (2)

- HSE Bulletin 26 Crane CollapseDokument1 SeiteHSE Bulletin 26 Crane Collapseajeet kumar singhNoch keine Bewertungen

- Monthly HSE PerformanceReport REV2Dokument2 SeitenMonthly HSE PerformanceReport REV2parthaNoch keine Bewertungen

- Costain BBS ProgrammeDokument55 SeitenCostain BBS ProgrammeAli ZafarNoch keine Bewertungen

- RRC Risk Assessment Dec 2010Dokument14 SeitenRRC Risk Assessment Dec 2010Li ChenNoch keine Bewertungen

- HSE Auditing ProcedureDokument15 SeitenHSE Auditing Proceduresudeesh kumarNoch keine Bewertungen

- F-025-Power Tool Inspection ChecklistDokument2 SeitenF-025-Power Tool Inspection ChecklistAbdus SamadNoch keine Bewertungen

- Ilo C 155Dokument11 SeitenIlo C 155Munawar Sher MuhammadNoch keine Bewertungen

- HSE Plan 2015 - Original PDFDokument43 SeitenHSE Plan 2015 - Original PDFAnkit DudejaNoch keine Bewertungen

- Natural Gas Pipeline Safety Walk ReportDokument2 SeitenNatural Gas Pipeline Safety Walk ReportNibhaNoch keine Bewertungen

- HSE Manual Unlimited EnergyDokument74 SeitenHSE Manual Unlimited Energysangar sabirNoch keine Bewertungen

- Tun Razak Exchange, Retail Plot 1: Appendix 4 - Emergency Response PlanDokument32 SeitenTun Razak Exchange, Retail Plot 1: Appendix 4 - Emergency Response PlanMatthew Mohan PerumalNoch keine Bewertungen

- Safety Moment There Is No Shortcut To Safety 448cuoDokument6 SeitenSafety Moment There Is No Shortcut To Safety 448cuoInnocent BhaikwaNoch keine Bewertungen

- Monthly Safety Report (April)Dokument8 SeitenMonthly Safety Report (April)csacas sacscNoch keine Bewertungen

- Health & Safety On SiteDokument4 SeitenHealth & Safety On SiteshaukatNoch keine Bewertungen

- Emergency Response Planning Kec - Epc Waste Collection Area Constction - SibaDokument8 SeitenEmergency Response Planning Kec - Epc Waste Collection Area Constction - SibaAli AlahmaNoch keine Bewertungen

- Muhammad Umer (Executive HSE&Q) : Career ObjectiveDokument2 SeitenMuhammad Umer (Executive HSE&Q) : Career ObjectiveHR Agha SteelNoch keine Bewertungen

- CSP2017-Safety Audit PlanDokument14 SeitenCSP2017-Safety Audit PlanGaryNoch keine Bewertungen

- SOP-015 - Inspection, Tagging & Color Coding - ReviewedDokument4 SeitenSOP-015 - Inspection, Tagging & Color Coding - ReviewedShahulNoch keine Bewertungen

- ESH&S Plan Semi - Mobile Coal WashingDokument76 SeitenESH&S Plan Semi - Mobile Coal WashingWahyu NugrahaNoch keine Bewertungen

- Asbestos Safety ProcedureDokument3 SeitenAsbestos Safety ProceduresyedmoazamNoch keine Bewertungen

- Model For HSSE ReportDokument2 SeitenModel For HSSE ReportMidha Neer50% (2)

- Annual Hse ReportDokument8 SeitenAnnual Hse Reportbakari hamisiNoch keine Bewertungen

- Lifting Machine Entity Registration - IonDokument5 SeitenLifting Machine Entity Registration - IonJason Fourie100% (1)

- Sinai Fields HSE Annual Report 2004Dokument15 SeitenSinai Fields HSE Annual Report 2004HosamMohamedNoch keine Bewertungen

- Cps 0460 Incident Notification ReportDokument2 SeitenCps 0460 Incident Notification ReporttabaquiNoch keine Bewertungen

- Company Safety Rules - Safety Controllers - Conversion Training For IPR-GDF Suez - Sept 2012Dokument150 SeitenCompany Safety Rules - Safety Controllers - Conversion Training For IPR-GDF Suez - Sept 2012Abrar Mojeeb100% (1)

- Construction Site Inspection Check List ALMCDokument2 SeitenConstruction Site Inspection Check List ALMCAmeerHamzaWarraichNoch keine Bewertungen

- HSE Officer Harshal Sen resumeDokument3 SeitenHSE Officer Harshal Sen resumeSohail AlamNoch keine Bewertungen

- Contractor HSE Management Pre-QualificationDokument7 SeitenContractor HSE Management Pre-QualificationebyjoyNoch keine Bewertungen

- HSE Plan and Recommendations For Executing The ProjectDokument5 SeitenHSE Plan and Recommendations For Executing The ProjectfarrukhNoch keine Bewertungen

- ToolBox Talk 5Dokument2 SeitenToolBox Talk 5bashirdarakNoch keine Bewertungen

- Incident-sharing-and-Statistics-Standard-10.2018 OPALDokument28 SeitenIncident-sharing-and-Statistics-Standard-10.2018 OPALSHRISH SHUKLA100% (1)

- Consulting Workers On Health and SafetyDokument77 SeitenConsulting Workers On Health and SafetyMurat AnlıNoch keine Bewertungen

- Sarikei Substation HSE ReportDokument15 SeitenSarikei Substation HSE Reportfatimah beluhiNoch keine Bewertungen

- ALDAR OSH EHS Alert - Common Hazards Associated With Tipper Truck OperationsDokument1 SeiteALDAR OSH EHS Alert - Common Hazards Associated With Tipper Truck OperationsVenkadesh Periathambi100% (1)

- Berba SPC HSE Management PlanDokument60 SeitenBerba SPC HSE Management PlanfrancisNoch keine Bewertungen

- Rescue Plan SRS 1Dokument4 SeitenRescue Plan SRS 1Salah Abd EldayemNoch keine Bewertungen

- Job Safety Analysis - Work SheetDokument4 SeitenJob Safety Analysis - Work Sheetrickie7809Noch keine Bewertungen

- Site Visitor Management PlanDokument8 SeitenSite Visitor Management Planhanshul sisodiyaNoch keine Bewertungen

- Bses Safety Alert 02-2018 PDFDokument1 SeiteBses Safety Alert 02-2018 PDFChyeAmshariYumanNoch keine Bewertungen

- Health and Safety Rep AppointmentDokument2 SeitenHealth and Safety Rep Appointmentridhwaan singh100% (1)

- Nebosh Legislation Quiz AnswersDokument1 SeiteNebosh Legislation Quiz AnswersAsad AwanNoch keine Bewertungen

- HSE Safety AuditsDokument3 SeitenHSE Safety Auditsvlad100% (1)

- Mobile Scaffolding Inspection Checklist: Project Name: DateDokument1 SeiteMobile Scaffolding Inspection Checklist: Project Name: DateMehtab Uddin mmNoch keine Bewertungen

- INDOKOMAS BUANA PERKASA PROJECT HSE MONTHLY REPORTDokument5 SeitenINDOKOMAS BUANA PERKASA PROJECT HSE MONTHLY REPORTBiyan YogaNoch keine Bewertungen

- Laydown Yard Safety ChecklistDokument5 SeitenLaydown Yard Safety ChecklistTomin ThomasNoch keine Bewertungen

- Safe System Of Work A Complete Guide - 2020 EditionVon EverandSafe System Of Work A Complete Guide - 2020 EditionNoch keine Bewertungen

- Buncefield ReportDokument36 SeitenBuncefield ReportAndrei Chih100% (1)

- Safety in The Installation and Use of Gas Systems and AppliancesDokument100 SeitenSafety in The Installation and Use of Gas Systems and AppliancesHossamKandilNoch keine Bewertungen

- ACOP Confined Spaces HSEDokument46 SeitenACOP Confined Spaces HSEjohnmillsetechNoch keine Bewertungen

- Lesson 2 Contractors, Mechanical Integrity, Management of Chain, and Emergency PlanningDokument13 SeitenLesson 2 Contractors, Mechanical Integrity, Management of Chain, and Emergency PlanningHossamKandilNoch keine Bewertungen

- New Exams IGC-2Dokument4 SeitenNew Exams IGC-2HossamKandil67% (3)

- Safety in The Installation and Use of Gas Systems and AppliancesDokument100 SeitenSafety in The Installation and Use of Gas Systems and AppliancesHossamKandilNoch keine Bewertungen

- ACOP Confined Spaces HSEDokument46 SeitenACOP Confined Spaces HSEjohnmillsetechNoch keine Bewertungen

- HSSE HandbookDokument58 SeitenHSSE HandbookHossamKandilNoch keine Bewertungen

- Computing and Communications ResourcesDokument54 SeitenComputing and Communications ResourcesHossamKandilNoch keine Bewertungen

- Lesson 5 Energized Electrical Work PermitDokument7 SeitenLesson 5 Energized Electrical Work PermitHossamKandilNoch keine Bewertungen

- HSSE HandbookDokument58 SeitenHSSE HandbookHossamKandilNoch keine Bewertungen

- Lesson 1 Why Is OSHA Important To YouDokument5 SeitenLesson 1 Why Is OSHA Important To YouHossamKandil100% (1)

- HSG 250 - Guidance On Permit To Work SystemsDokument40 SeitenHSG 250 - Guidance On Permit To Work SystemsRusihan Rehan100% (1)

- Arabic Question With Answers Unit GC2 UpdatedDokument4 SeitenArabic Question With Answers Unit GC2 UpdatedHossamKandilNoch keine Bewertungen

- Manufacture of Synthetic RubberDokument22 SeitenManufacture of Synthetic RubberHossamKandilNoch keine Bewertungen

- 05 - 02 - Direct vs. Indirect Costs Introduction - For Web SiteDokument17 Seiten05 - 02 - Direct vs. Indirect Costs Introduction - For Web SiteTomce HristovskiNoch keine Bewertungen

- Examiners Reports IGC1 September 2013 IGC1Dokument10 SeitenExaminers Reports IGC1 September 2013 IGC1Jude Harrison67% (3)

- Updated New IGC3 - SampleDokument9 SeitenUpdated New IGC3 - SampleHossamKandil100% (1)

- 20 Revision Questions With Model AnswersDokument33 Seiten20 Revision Questions With Model AnswersHossamKandilNoch keine Bewertungen

- Sample Safe System of WorkDokument13 SeitenSample Safe System of WorkHossamKandil50% (4)

- New Jays Int Cert Revision Book Week 1 and 2Dokument99 SeitenNew Jays Int Cert Revision Book Week 1 and 2HossamKandil100% (1)

- WWW - Fermanagh.gov - Uk - Pubuploads - Health and Safety Policy StatementDokument11 SeitenWWW - Fermanagh.gov - Uk - Pubuploads - Health and Safety Policy StatementProf C.S.PurushothamanNoch keine Bewertungen

- Example Practiical Observation SheetsDokument7 SeitenExample Practiical Observation SheetsHossamKandilNoch keine Bewertungen

- Tutorial Chemical Reaction Using MatlabDokument1 SeiteTutorial Chemical Reaction Using MatlabHossamKandilNoch keine Bewertungen

- Management Style Answers - Paper - 1Dokument7 SeitenManagement Style Answers - Paper - 1anthros13Noch keine Bewertungen

- Lecture 5 Electrical BridgesDokument18 SeitenLecture 5 Electrical BridgesHossamKandilNoch keine Bewertungen

- Pharos University EE212 Electrical Measurement & Interface Moving Iron InstrumentsDokument11 SeitenPharos University EE212 Electrical Measurement & Interface Moving Iron InstrumentsHossamKandilNoch keine Bewertungen

- Highway Interchanges MoyanaDokument14 SeitenHighway Interchanges MoyanaPanashe GoraNoch keine Bewertungen

- Unit Conversion ExcelDokument10 SeitenUnit Conversion ExcelBeza GetachewNoch keine Bewertungen

- Manual For Bicycle and Pedestrian Bridges - Ducth StrandardDokument92 SeitenManual For Bicycle and Pedestrian Bridges - Ducth StrandardAlejandro Guardia Carrasco100% (1)

- 3.3 India - Mr. Tony MathewDokument30 Seiten3.3 India - Mr. Tony Mathewvarunsingh214761Noch keine Bewertungen

- Literature Review On Road Accident AnalyDokument4 SeitenLiterature Review On Road Accident AnalyGedion WoldesenbetNoch keine Bewertungen

- Preboard-MSTE Answer KeyDokument11 SeitenPreboard-MSTE Answer KeyJae Han100% (1)

- Smart Cities Towards Liveable Malaysia PDFDokument45 SeitenSmart Cities Towards Liveable Malaysia PDFmikocan 99Noch keine Bewertungen

- LED After-Images Cause Vision Issues for 40 CharactersDokument3 SeitenLED After-Images Cause Vision Issues for 40 CharactersshounakroyNoch keine Bewertungen

- KBRT Project Monthly Report Summary for September 2017Dokument15 SeitenKBRT Project Monthly Report Summary for September 2017Muhammad Sadiq AftabNoch keine Bewertungen

- Los Angeles City Staff Billboard OptionsDokument11 SeitenLos Angeles City Staff Billboard OptionsSharon Kpcc McNaryNoch keine Bewertungen

- Asist: Design and Construction of Suspension FootbridgesDokument36 SeitenAsist: Design and Construction of Suspension FootbridgesKemoHNoch keine Bewertungen

- The Three E's of Traffic Safety EducationDokument28 SeitenThe Three E's of Traffic Safety EducationGii-anNe Raymundo CuyanNoch keine Bewertungen

- 8.Cross Cutting(交叉学科)Dokument220 Seiten8.Cross Cutting(交叉学科)nnadoziekenneth5Noch keine Bewertungen

- SBP 1119-2 BI Trial SPM 2015Dokument17 SeitenSBP 1119-2 BI Trial SPM 2015ScRembau100% (1)

- Traffic signal warrants analysisDokument16 SeitenTraffic signal warrants analysisfarah100% (1)

- Managed Freeways Freeway Ramp Signals Handbook Jul 2013 AppendicesDokument28 SeitenManaged Freeways Freeway Ramp Signals Handbook Jul 2013 AppendicesZebaAnjumNoch keine Bewertungen

- National Highway Authority of India, Mancherial - Warangal - Draft EIA ReportDokument438 SeitenNational Highway Authority of India, Mancherial - Warangal - Draft EIA Reportsantoshkumar945Noch keine Bewertungen

- ORN 40 Measurement of Axle LoadsDokument26 SeitenORN 40 Measurement of Axle LoadsMichaelNoch keine Bewertungen

- Driving Test Dump-1 PDFDokument8 SeitenDriving Test Dump-1 PDFAmudhavaani KarunanidhiNoch keine Bewertungen

- CE 3201 Introduction To Transportation EngineeringDokument3 SeitenCE 3201 Introduction To Transportation EngineeringPaco TrooperNoch keine Bewertungen

- CIS14-2009 - Guidelines On Construction Activities at NightDokument69 SeitenCIS14-2009 - Guidelines On Construction Activities at NightVincent 2020Noch keine Bewertungen

- Traffic IslandsDokument38 SeitenTraffic IslandsMark RipaniNoch keine Bewertungen

- As 1742.6-2004 Manual of Uniform Traffic Control Devices Tourist and Services SignsDokument9 SeitenAs 1742.6-2004 Manual of Uniform Traffic Control Devices Tourist and Services SignsSAI Global - APACNoch keine Bewertungen

- General KnowledgeDokument25 SeitenGeneral KnowledgeShakil KhanNoch keine Bewertungen

- Test Bank For Retailing Management 10th Edition Michael Levy Barton Weitz Dhruv Grewal DownloadDokument41 SeitenTest Bank For Retailing Management 10th Edition Michael Levy Barton Weitz Dhruv Grewal Downloadjoshuakiddgfbijcdpxr100% (21)

- Vocabulary - TrafficDokument3 SeitenVocabulary - TrafficJelena MitrovicNoch keine Bewertungen

- 7 Chapter-III-RDokument37 Seiten7 Chapter-III-RRiot AyaseNoch keine Bewertungen

- DomingoDokument4 SeitenDomingoDenver MugasNoch keine Bewertungen

- Harley Davidson Touring Models 2007 International Owners ManualDokument92 SeitenHarley Davidson Touring Models 2007 International Owners ManualJoseph Langford0% (1)

- IRC SP 12-2015 Guidelines For Parking Facility in Urban RoadsDokument59 SeitenIRC SP 12-2015 Guidelines For Parking Facility in Urban RoadsjitendraNoch keine Bewertungen