Beruflich Dokumente

Kultur Dokumente

MEE1007 Manufacturing-Processes ETH 1 AC37

Hochgeladen von

Adi DwivediCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MEE1007 Manufacturing-Processes ETH 1 AC37

Hochgeladen von

Adi DwivediCopyright:

Verfügbare Formate

MEE1007 Manufacturing Processes

LTPJC

2 0203

Pre-Requisite: None

Module

Topics

Manufacturing

Manufacturing- The Role of Manufacturing Development in the growth of a

country Classification of manufacturing processess

Casting processes

Casting: Fundamentals of metal casting Pattern and mould making-Different

casting techniques-Melting practice and furnaces - Defects in casting Testing

and inspection of casting.

2

Joining Processes

Fusion welding processes-Solid state welding processes-Advanced welding

techniques-Weld quality Testing welded joints.

3

Metal forming Processes

Cold and Hot working-Bulk metal forming -Sheet metal forming High Energy

Rate Forming Processes: Explosive Forming Electro Hydraulic Forming

Electro Magnetic Forming.

4

Processing of Powder Metals, Ceramics, Glass and Plastics

Powder metallurgy- Shaping of ceramics-Glass-Processing of plastics: Injection

molding Blow molding Compression molding Transfer molding

Thermoforming.

5

Process selection

Systematic process selection-Process selection charts-Ranking process cost-Cost

modelling

Case studies

Aluminum Connecting Rod, Fan leaf with nylon material, Airbag canisters,

Joining a Steel Radiator, Car bonnet, Spark Plug Insulators, Ceramic knife,

Devices to open corked bottle, Aircraft wing spar, Forks for a racing bicycle,

Spark plug insulator, Insulation for refrigerator,etc.

Total Lecture Hours

# Mode of teaching: Flipped Class Room, [Lecture to be videotaped], Use of physical and

computer models to lecture, Visit to Industry, Min of 2 lectures by industry experts

# Evaluation mode: Quiz/Assignment /Exam.

L

Hrs

SLO

17

17

17

17

6,17

30

Lab

1. Plaster mould casting- Create a mould for slip casting of the given component

using suitable material and fabricate the component using slurry casting technique

2. Metal casting: Preparation of Green sand mold using different levels of moisture

content.

3. Join the given GI pipes as per the diagram and make it leak proof for supply of

water.

4. Arc welding Join the given thick metal sheets using suitable welding process.

The weld finish quality is not a constrain.

5. TIG welding: Prepare the TIG weldment of steel with 316 stainless steel.Find out

the efficiency of the weldment by tensile test

6. Make a Tray as per the given dimensions using sheet metal. The corners of the tray

has no leack proof constraint.

7. Identify the thickness variation of a sheet metal bend sample for different loading

conditions and observe the changes in microstructure using optical microscope.

8. Finding the stress level of the sheet metal component before and after annealing

9. To find the Green Density & Strength (hardness) of Cold-compacted/sintered

metal powder

10. Carpentry Dove tail joint: Join the given two wooden slabs perpendicular to each

other in their longer edges by selecting suitable joint which gives maximum

strength.

11. Make an wooden book stand without doors using suitable joints.

12. Demonstration of pouring the Non Ferrous Metal by using Crucible Tilting

Furnace

13. Finding out the optimum method of producing a WC tool.

Evaluation mode: Marks distribution for:

(i) selection of suitable process/materials

(ii) completion and finishing quality of the exercise

(iii) viva & record

Total lab hours 30

6,17

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Fundamentals of API Rotordynamic RequirementsDokument15 SeitenFundamentals of API Rotordynamic RequirementsJim Bohni100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- API 610 10th Edition (Iso 13709) Pump DatasheetDokument3 SeitenAPI 610 10th Edition (Iso 13709) Pump DatasheetMuhammad Azka50% (4)

- Ziekiwicnz PapersDokument45 SeitenZiekiwicnz Paperscop593anti776100% (1)

- Aluminium Tubular Busbars For HV SubstatDokument5 SeitenAluminium Tubular Busbars For HV Substatasi midobarNoch keine Bewertungen

- SpiraxSarco-B2-Steam Engineering Principles and Heat TransferDokument186 SeitenSpiraxSarco-B2-Steam Engineering Principles and Heat Transferdanenic100% (4)

- Torque, Speed and PowerDokument9 SeitenTorque, Speed and PowerratheeshNoch keine Bewertungen

- Circular On Winter Sem 2016-2017 Course RegistrationsDokument2 SeitenCircular On Winter Sem 2016-2017 Course RegistrationsAdi DwivediNoch keine Bewertungen

- Digital Assignment - 2Dokument1 SeiteDigital Assignment - 2Adi DwivediNoch keine Bewertungen

- 2017061769 (1)Dokument1 Seite2017061769 (1)Adi DwivediNoch keine Bewertungen

- FALLSEM2016-17 MAT1011 ETH 7576 29-SEP-2016 RM001 Double Integral ProblemsDokument103 SeitenFALLSEM2016-17 MAT1011 ETH 7576 29-SEP-2016 RM001 Double Integral ProblemsAdi DwivediNoch keine Bewertungen

- Digital Assignment IIIDokument1 SeiteDigital Assignment IIIAdi DwivediNoch keine Bewertungen

- Digital Assignment III PDFDokument1 SeiteDigital Assignment III PDFAdi DwivediNoch keine Bewertungen

- Digital Assignment - 1Dokument1 SeiteDigital Assignment - 1Adi DwivediNoch keine Bewertungen

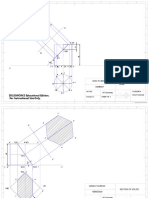

- Projection of LinesDokument1 SeiteProjection of LinesAdi DwivediNoch keine Bewertungen

- Projection of PointsDokument1 SeiteProjection of PointsAdi DwivediNoch keine Bewertungen

- Perspective Projections PDFDokument1 SeitePerspective Projections PDFAdi DwivediNoch keine Bewertungen

- Perspective ProjectionsDokument1 SeitePerspective ProjectionsAdi DwivediNoch keine Bewertungen

- Isometric and Perspective ProjectionsDokument1 SeiteIsometric and Perspective ProjectionsAdi DwivediNoch keine Bewertungen

- 16bme0029t6f PDFDokument5 Seiten16bme0029t6f PDFAdi DwivediNoch keine Bewertungen

- Projection of Solids PDFDokument1 SeiteProjection of Solids PDFAdi DwivediNoch keine Bewertungen

- Engineering Drawing 2Dokument2 SeitenEngineering Drawing 2Adi DwivediNoch keine Bewertungen

- Engineering Drawing DimenseningDokument1 SeiteEngineering Drawing DimenseningAdi DwivediNoch keine Bewertungen

- P Q R S T U P P' Q' R' S' 4' (5') 3' (6') 3 4 5: Development of SurfacesDokument3 SeitenP Q R S T U P P' Q' R' S' 4' (5') 3' (6') 3 4 5: Development of SurfacesAdi DwivediNoch keine Bewertungen

- Unit V - Unid End Questions - EMDokument6 SeitenUnit V - Unid End Questions - EMNaresh JonnaNoch keine Bewertungen

- University BADJI MOKHTAR ANNABADokument6 SeitenUniversity BADJI MOKHTAR ANNABAmeghlaouirami5Noch keine Bewertungen

- Frigoscandia: LVS Refrigeration™ SystemDokument4 SeitenFrigoscandia: LVS Refrigeration™ Systempatricebertrand100% (1)

- Andreotti, Forterre, Pouliquen - Granular Media - Between Fluid and Solid PDFDokument471 SeitenAndreotti, Forterre, Pouliquen - Granular Media - Between Fluid and Solid PDFsandy_mandalNoch keine Bewertungen

- Materials Science Manual Chapter 4Dokument21 SeitenMaterials Science Manual Chapter 4aoguNoch keine Bewertungen

- 1S1920 - SW - Fluid Mechanics: Name DateDokument12 Seiten1S1920 - SW - Fluid Mechanics: Name DateBosz' AceNoch keine Bewertungen

- AP Chemistry Unit 10 Packet 1 AnswersDokument26 SeitenAP Chemistry Unit 10 Packet 1 AnswersBrandon BaxterNoch keine Bewertungen

- CFD Computational of A Supersonic Flow Past Axisymetric Nozzle Boattail With Jet Exhaust PDFDokument1 SeiteCFD Computational of A Supersonic Flow Past Axisymetric Nozzle Boattail With Jet Exhaust PDFmojicapNoch keine Bewertungen

- The Value of Surface Tension of A Liquid at Critical Temperature IsDokument10 SeitenThe Value of Surface Tension of A Liquid at Critical Temperature Issagarchidre114Noch keine Bewertungen

- MR Afnan CVDokument3 SeitenMR Afnan CVShazada Dauod Khan100% (1)

- 2.0 Theory: at The End of The Lab Session Students Should Be AbleDokument5 Seiten2.0 Theory: at The End of The Lab Session Students Should Be AbleMuhammad Danish Mohd SizaNoch keine Bewertungen

- A New Algorithm For The Rotation of Horizontal Components of Shear-Wave Seismic DataDokument14 SeitenA New Algorithm For The Rotation of Horizontal Components of Shear-Wave Seismic DataDante Leon CortesNoch keine Bewertungen

- Adatlap PDFDokument12 SeitenAdatlap PDFAnuradha SivakumarNoch keine Bewertungen

- tHREAD 2 MATERI OL 2 (PG Gerak)Dokument4 SeitentHREAD 2 MATERI OL 2 (PG Gerak)festus wikannandaNoch keine Bewertungen

- NosaDokument9 SeitenNosaosaroboNoch keine Bewertungen

- Lecture17 PDFDokument9 SeitenLecture17 PDFHuseyin OztoprakNoch keine Bewertungen

- Pruebas Standar para PlasticosDokument41 SeitenPruebas Standar para PlasticosEduardo SalgadoNoch keine Bewertungen

- Havells Light LHEBJVP7PZ2W015Dokument2 SeitenHavells Light LHEBJVP7PZ2W015aneeshNoch keine Bewertungen

- Effects of Nonuniform Tire Contact Stresses On Pavement ResponseDokument7 SeitenEffects of Nonuniform Tire Contact Stresses On Pavement ResponseBarnali DebnathNoch keine Bewertungen

- Development of Analytical Methods For Fuselage DesignDokument13 SeitenDevelopment of Analytical Methods For Fuselage DesignSaidu Bala MadaksNoch keine Bewertungen

- Construction Materials and Testing Apparatus & Equipment: Essential QuestionsDokument9 SeitenConstruction Materials and Testing Apparatus & Equipment: Essential QuestionsDiane de OcampoNoch keine Bewertungen

- Price Summary: Date: 22/5/2019Dokument72 SeitenPrice Summary: Date: 22/5/2019Reda ChattahyNoch keine Bewertungen

- Effect of Shot Peening Operation On Gears PDFDokument9 SeitenEffect of Shot Peening Operation On Gears PDFasdNoch keine Bewertungen

- Climate of PakistanDokument23 SeitenClimate of PakistanRayyan MalikNoch keine Bewertungen