Beruflich Dokumente

Kultur Dokumente

03 - Installation & Maintenance

Hochgeladen von

akramsayeedCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

03 - Installation & Maintenance

Hochgeladen von

akramsayeedCopyright:

Verfügbare Formate

Day 1: Installation & Commissioning

April 2013

Presented by:

Calum Scott

Installation

General pre-requisites

Inspection of the equipment upon receipt

Storage during the period before the installation

- Protection carried out for a period of 60 days by the supplier

- Beyond this follow the instructions given by the supplier (evaporation of oil, rotation of

moving parts)

Getting equipped with adequate maintenance and tooling options

Follow the instructions given in the suppliers operation and maintenance manual

As far as possible, call the supplier for installation

COMPANY CONFIDENTIAL

April 23, 2013

Installation

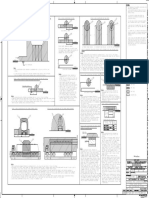

Setup of the pump assembly on a concrete foundation

Example pump assembly + motor

Field of application

Pump

Motor

COMPANY CONFIDENTIAL

The information given through this document are respective

and applicable to the following configuration:

April 23, 2013

Installation

Setup of the pump assembly on concrete foundation

Pre-alignment of motor with the pump

The three requirements

for a conforming

alignment

The equipment, once aligned, must meet the following requirements:

The faces of the coupling holves (1 and 3) must be perfectly parallel.

Spacing

of half-couplings

Coaxiality

of the output shafts

COMPANY CONFIDENTIAL

The spacing (D.B.R.F) between the faces of half-coupling must be adjusted for

disassembly and reassembly without difficulty of the "spacer" (2), while avoiding:

- An excessive clearance in the coupling,

- Any tension or compression on the coupling once assembled

- The spacing dimension must follow the value indicated by the coupling supplier

The axes of the output shafts (A and B) of the equipment must be perfectly aligned and at

360.

April 23, 2013

Installation

Connection and testing before startup of assembly

Connection of auxiliary

pipes

Connection of different API plans of the auxiliary pumps of the client

network.

Checking of alignment

of equipment

Check again the alignment of equipment after the connection of all the pipes

to the pump assembly.

Connection and

checking of drive

system

Before its coupling to the pump, connect the drive system

and check the direction of rotation of drive system.

For the drive of pumps carried out by an electrical motor, mark the

connections on the terminal box.

Checking of sealing

and lubrication

systems

Ensure that the mechanical seals and their auxiliary systems (respective API

plans) are correctly filled in. Check the levels of filling in of pump bearings

and motor.

Instrumentation check

If the pump group is delivered with instruments, check only the proper

tightening of sensor box on their respective sub-assemblies (bearings, seals,

motor).

COMPANY CONFIDENTIAL

April 23, 2013

Das könnte Ihnen auch gefallen

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideVon EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideBewertung: 4.5 von 5 Sternen4.5/5 (8)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreVon EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreBewertung: 4.5 von 5 Sternen4.5/5 (11)

- Saudi Aramco Engineering Standards-Electrical-CommissioningDokument61 SeitenSaudi Aramco Engineering Standards-Electrical-Commissioningsyedsalmanali9193% (15)

- Method Statement For Installation of Firefighting Pump SetDokument13 SeitenMethod Statement For Installation of Firefighting Pump SetRaj Kamal75% (4)

- Turbine ErectionDokument131 SeitenTurbine ErectionSam92% (12)

- Method Statement For Installation of Diesel Generator SetDokument3 SeitenMethod Statement For Installation of Diesel Generator SetIngersol Duraikannu100% (2)

- Outboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairVon EverandOutboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairBewertung: 3 von 5 Sternen3/5 (1)

- Basics of SwitchboardsDokument60 SeitenBasics of Switchboardsakramsayeed100% (1)

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BVon EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNoch keine Bewertungen

- Project Procurement Process ControlDokument4 SeitenProject Procurement Process Controlakramsayeed100% (1)

- 12.rotary Erection ProcedureDokument8 Seiten12.rotary Erection ProcedureDebashish ChatterjeeNoch keine Bewertungen

- Calculation CalblesizeDokument5 SeitenCalculation CalblesizeakramsayeedNoch keine Bewertungen

- Technical Specifications For Spring Hanger and Piping Support Inspection For Chilca Uno CCPP (Rev8)Dokument20 SeitenTechnical Specifications For Spring Hanger and Piping Support Inspection For Chilca Uno CCPP (Rev8)Anibal Quezada100% (3)

- Boat Mechanical Systems Handbook (PB): How to Design, Install, and Recognize Proper Systems in BoatsVon EverandBoat Mechanical Systems Handbook (PB): How to Design, Install, and Recognize Proper Systems in BoatsNoch keine Bewertungen

- TestingDokument28 SeitenTestingsbpathiNoch keine Bewertungen

- Machinery Component Maintenance and RepairVon EverandMachinery Component Maintenance and RepairBewertung: 5 von 5 Sternen5/5 (1)

- Water Pipe SizingDokument40 SeitenWater Pipe SizingAfzal Khan100% (2)

- 101 7th Level SpellsDokument33 Seiten101 7th Level SpellsParakee100% (2)

- Method Statement For Installation of Firefighting Pump Set PDFDokument13 SeitenMethod Statement For Installation of Firefighting Pump Set PDFAhmed Issa100% (1)

- Guidelines Traction Motor Repair ModDokument6 SeitenGuidelines Traction Motor Repair Modqmscert100% (1)

- Evaluating Gas Turbine TestingDokument27 SeitenEvaluating Gas Turbine TestingReshmi Vinu100% (2)

- Pump & CompDokument23 SeitenPump & CompilliasuddinNoch keine Bewertungen

- Part Inspection Standard (May 2013)Dokument9 SeitenPart Inspection Standard (May 2013)san moedano100% (1)

- Solo Run For MotorsDokument8 SeitenSolo Run For MotorsMohamed Haleem100% (1)

- Lost Islamic History Reclaiming Muslim Ci - FirasDokument203 SeitenLost Islamic History Reclaiming Muslim Ci - FirasAbu Abbas Al-Hanafi Al-Athari89% (9)

- Sid97 3GDokument28 SeitenSid97 3GdzakubNoch keine Bewertungen

- CP-117 - Project Engineering - CoPDokument92 SeitenCP-117 - Project Engineering - CoPkanakarao1100% (5)

- Power Take-Off (PTO) Driveshaft Design Safety ChecklistDokument4 SeitenPower Take-Off (PTO) Driveshaft Design Safety ChecklistShivamSinghNoch keine Bewertungen

- Contractor Quality Control (CQC) Plan: Project NumberDokument31 SeitenContractor Quality Control (CQC) Plan: Project NumberGilbert chuksNoch keine Bewertungen

- CHEVRON Compressors Installation and Pre CommissioningDokument36 SeitenCHEVRON Compressors Installation and Pre CommissioningArief Budiman Hermani100% (7)

- ABB Inverter ACS 150Dokument130 SeitenABB Inverter ACS 150Joe Electricneutron100% (1)

- Bazam Company ProfileDokument30 SeitenBazam Company ProfileIbrahimrashid Billow HusseinNoch keine Bewertungen

- BGAS-CSWIP-BG-22-12 BGAS-CSWIP 2nd Edition April 2019 PDFDokument30 SeitenBGAS-CSWIP-BG-22-12 BGAS-CSWIP 2nd Edition April 2019 PDFEjazNoch keine Bewertungen

- 26 32 13.13 Emergency GeneratorDokument9 Seiten26 32 13.13 Emergency Generator-Deny D'hana-Noch keine Bewertungen

- Week 5 Waste Management in Singapore Case Study For SSE1201 v6Dokument34 SeitenWeek 5 Waste Management in Singapore Case Study For SSE1201 v6ZihNoch keine Bewertungen

- Method of Statement For Installation of Compressed AirDokument9 SeitenMethod of Statement For Installation of Compressed AirrkssNoch keine Bewertungen

- Interconnection Design Gas PipelinesDokument96 SeitenInterconnection Design Gas PipelinesBeatriz Adams Garcia100% (2)

- Airy Wave TheoryDokument14 SeitenAiry Wave TheoryAnirban Guha50% (2)

- Vacuum Distillation Colume: Mass Transfer Lab AssignmentDokument4 SeitenVacuum Distillation Colume: Mass Transfer Lab AssignmentMalik HamidNoch keine Bewertungen

- 60 - 15540 - HVAC Pumps and SpecialtiesDokument4 Seiten60 - 15540 - HVAC Pumps and Specialtiesnestor159357Noch keine Bewertungen

- Report Installion Engine AmirDokument4 SeitenReport Installion Engine Amiry4pvpb4qqbNoch keine Bewertungen

- 90 - 15540 - HVAC Pumps and SpecialtiesDokument4 Seiten90 - 15540 - HVAC Pumps and Specialtiesnestor159357Noch keine Bewertungen

- 80 - 15540 - HVAC Pumps and SpecialtiesDokument5 Seiten80 - 15540 - HVAC Pumps and Specialtiesnestor159357Noch keine Bewertungen

- 1510 - 15540 - HVAC Pumps and SpecialtiesDokument5 Seiten1510 - 15540 - HVAC Pumps and Specialtiesnestor159357Noch keine Bewertungen

- 23-019 Installation Procedures Mechanical WtemplateDokument7 Seiten23-019 Installation Procedures Mechanical WtemplateAli Khalid QureshiNoch keine Bewertungen

- Pump Installation and CommissioningDokument19 SeitenPump Installation and CommissioningSélcio PaulinaNoch keine Bewertungen

- Ump Fan-Air Om Manual - Rev Dec 2014Dokument12 SeitenUmp Fan-Air Om Manual - Rev Dec 2014api-252481722Noch keine Bewertungen

- SID97-3C ADJUSTMENT of Continental Fuel InjectionDokument41 SeitenSID97-3C ADJUSTMENT of Continental Fuel InjectionTito Teixeira100% (1)

- MTS S105400 FP 000002Dokument35 SeitenMTS S105400 FP 000002Adel MorsyNoch keine Bewertungen

- Part 1 - General: SpecificationsDokument6 SeitenPart 1 - General: SpecificationsDiego Plata VasquezNoch keine Bewertungen

- Installation Dresser MeterDokument32 SeitenInstallation Dresser MeterCoco GalindoNoch keine Bewertungen

- Classification of Tests:: Testing Procedures of A PumpDokument8 SeitenClassification of Tests:: Testing Procedures of A PumpMohamad Izwan HussienNoch keine Bewertungen

- Installation Manual SKC Series Pump-1Dokument26 SeitenInstallation Manual SKC Series Pump-1Huraira AliNoch keine Bewertungen

- Series e 80 SpecificationsDokument7 SeitenSeries e 80 SpecificationsJavier CastilloNoch keine Bewertungen

- Sam Industries PumpDokument52 SeitenSam Industries PumpHunney KotiyaNoch keine Bewertungen

- APH PresentationDokument36 SeitenAPH PresentationBhargav Chaudhari100% (1)

- My Spec's CommenstDokument13 SeitenMy Spec's CommenstAhmed LabibNoch keine Bewertungen

- Project Standard Specification: Sump Pumps 15446 - Page 1/10Dokument10 SeitenProject Standard Specification: Sump Pumps 15446 - Page 1/10adel rihanaNoch keine Bewertungen

- Corolla Matrix Turbo Kit InstallationDokument23 SeitenCorolla Matrix Turbo Kit InstallationSolymar CardonaNoch keine Bewertungen

- Project Standard Specification: Sewage Pumps 15445 - Page 1/12Dokument12 SeitenProject Standard Specification: Sewage Pumps 15445 - Page 1/12adel rihanaNoch keine Bewertungen

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Dokument1 SeiteEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Sudhakar KarnanNoch keine Bewertungen

- Sid97 3eDokument39 SeitenSid97 3eJoshua HoskinsNoch keine Bewertungen

- Rotating Equipment Installation ProcedureDokument2 SeitenRotating Equipment Installation ProcedureathithancapeNoch keine Bewertungen

- Part 1 - General 1.01 SECTION Includes A. RunningDokument35 SeitenPart 1 - General 1.01 SECTION Includes A. RunningPeem'zPlNoch keine Bewertungen

- Pump Technical SpecDokument9 SeitenPump Technical Specpprateek18Noch keine Bewertungen

- Attachment p.3Dokument8 SeitenAttachment p.3Azizee PalilNoch keine Bewertungen

- Pile Dynamic Analyzer TestingDokument4 SeitenPile Dynamic Analyzer TestingYudha ArdiiansyahNoch keine Bewertungen

- 3-3-4. MOS Installation of PumpDokument4 Seiten3-3-4. MOS Installation of PumpHajiAliNoch keine Bewertungen

- Specification For Internal Gear Pumps: 1.0 General DescriptionDokument7 SeitenSpecification For Internal Gear Pumps: 1.0 General DescriptionHassan ShafiqueNoch keine Bewertungen

- Kae-Kze-Kba-Kbz 050108 RNV o & M ManualDokument26 SeitenKae-Kze-Kba-Kbz 050108 RNV o & M ManualKS Pavan NarayanNoch keine Bewertungen

- Generator System Pre-Startup Checklist: PurposeDokument5 SeitenGenerator System Pre-Startup Checklist: PurposeFoe AungNoch keine Bewertungen

- Corken SC Side Channel Pump EnglishDokument40 SeitenCorken SC Side Channel Pump EnglishEliecer PeñalbaNoch keine Bewertungen

- Due Diligence in OshDokument8 SeitenDue Diligence in OshMohammad Zairul Indra ShapriNoch keine Bewertungen

- Hr-F-001-Training Need IndexDokument1 SeiteHr-F-001-Training Need IndexakramsayeedNoch keine Bewertungen

- QC017-0 Handover ChecklistDokument1 SeiteQC017-0 Handover ChecklistakramsayeedNoch keine Bewertungen

- Incoloy Alloy 825Dokument4 SeitenIncoloy Alloy 825Roman PaduaNoch keine Bewertungen

- Casting Material WCB PDFDokument9 SeitenCasting Material WCB PDFChinmoyee SharmaNoch keine Bewertungen

- QC018-0 NDE-PWHT RequestDokument1 SeiteQC018-0 NDE-PWHT RequestakramsayeedNoch keine Bewertungen

- QC009-0 Pressure Test PreparationDokument1 SeiteQC009-0 Pressure Test PreparationakramsayeedNoch keine Bewertungen

- Comparators For The Definition of Surface Quality of CastingsDokument2 SeitenComparators For The Definition of Surface Quality of Castingsimrakesh8014Noch keine Bewertungen

- Mohazzma - (Short)Dokument3 SeitenMohazzma - (Short)akramsayeedNoch keine Bewertungen

- QC013-0 Non Conformance ReportDokument1 SeiteQC013-0 Non Conformance ReportakramsayeedNoch keine Bewertungen

- QC010-0 PunchlistDokument1 SeiteQC010-0 PunchlistakramsayeedNoch keine Bewertungen

- Ramazan Kareem 1433 (July-Aug 2012) : S.No Items Description Price Date RemarksDokument2 SeitenRamazan Kareem 1433 (July-Aug 2012) : S.No Items Description Price Date RemarksakramsayeedNoch keine Bewertungen

- Quiz QuestionsDokument5 SeitenQuiz Questionssathish_51Noch keine Bewertungen

- American Wire GaugeDokument2 SeitenAmerican Wire GaugeAkram Sayeed100% (1)

- IP Explanation and RatingsDokument3 SeitenIP Explanation and RatingsakramsayeedNoch keine Bewertungen

- Name: Email: Cell #:: Danish Khan Jadoon Seismic QC GeophysicistDokument4 SeitenName: Email: Cell #:: Danish Khan Jadoon Seismic QC GeophysicistakramsayeedNoch keine Bewertungen

- Fiber Optics CableDokument64 SeitenFiber Optics CableakramsayeedNoch keine Bewertungen

- LA RegisterDokument1 SeiteLA RegisterakramsayeedNoch keine Bewertungen

- Electrical Equipment TestsDokument1 SeiteElectrical Equipment TestsakramsayeedNoch keine Bewertungen

- Employment News PDFDokument24 SeitenEmployment News PDFLokesh NayakNoch keine Bewertungen

- Employment News PDFDokument24 SeitenEmployment News PDFLokesh NayakNoch keine Bewertungen

- M Arka Az Se Ctor Rep Ort 2 2014: K Ksa P Petroch Hemic CalsDokument8 SeitenM Arka Az Se Ctor Rep Ort 2 2014: K Ksa P Petroch Hemic CalsakramsayeedNoch keine Bewertungen

- The Verified Log Book Will Become Mandatory For Renewal From January 2017Dokument1 SeiteThe Verified Log Book Will Become Mandatory For Renewal From January 2017vijay rajputNoch keine Bewertungen

- First Time Quality Communications Plan Checklist.2Dokument1 SeiteFirst Time Quality Communications Plan Checklist.2akramsayeedNoch keine Bewertungen

- Leyte Geothermal Power Progressive Employees UnionDokument3 SeitenLeyte Geothermal Power Progressive Employees Unionaags_06Noch keine Bewertungen

- Modified Draft DCPRDokument344 SeitenModified Draft DCPRratnesh vaviaNoch keine Bewertungen

- Chapter 2 ElectricityDokument31 SeitenChapter 2 ElectricityArshad MalikNoch keine Bewertungen

- Manual-4 6 7Dokument412 SeitenManual-4 6 7Nina Brown100% (1)

- Aquarea Split Systems Installation Handbook 2013 (A2W-SPX-130305-012)Dokument80 SeitenAquarea Split Systems Installation Handbook 2013 (A2W-SPX-130305-012)Anonymous ec2P0F5iKXNoch keine Bewertungen

- .0 .0 Pelton - WheelDokument4 Seiten.0 .0 Pelton - WheelRabei RomulusNoch keine Bewertungen

- PWMcircuit 08Dokument10 SeitenPWMcircuit 08kcarringNoch keine Bewertungen

- P501D808 (Idt8n)Dokument56 SeitenP501D808 (Idt8n)ariasroberthNoch keine Bewertungen

- Experiment #8 Title: Power Factor Correction: II. Wiring CircuitDokument13 SeitenExperiment #8 Title: Power Factor Correction: II. Wiring CircuitNesleeNoch keine Bewertungen

- LMI B1 Series Parts List Metering Pump PDFDokument4 SeitenLMI B1 Series Parts List Metering Pump PDFRoberto MejiaNoch keine Bewertungen

- Assignment#1Dokument5 SeitenAssignment#1Hennesey LouriceNoch keine Bewertungen

- Peugeot Elystar Diagnostic AidDokument13 SeitenPeugeot Elystar Diagnostic Aidpiter4012Noch keine Bewertungen

- Curricula Civil - HstuDokument22 SeitenCurricula Civil - HstuMononNoch keine Bewertungen

- Cadbury CSRDokument14 SeitenCadbury CSRAdwait KhareNoch keine Bewertungen

- CH 1Dokument6 SeitenCH 1Dineshsingh ThakurNoch keine Bewertungen

- Sanchi - Chemical Accident - Iran - China - Process SafetyDokument6 SeitenSanchi - Chemical Accident - Iran - China - Process SafetySaba MirzahosseiniNoch keine Bewertungen

- Speed Control of Separately Excited DC Motor Using Power Electronic ConverterDokument5 SeitenSpeed Control of Separately Excited DC Motor Using Power Electronic ConverterIJIERT-International Journal of Innovations in Engineering Research and Technology100% (1)

- Inserto Clase 15KV 200a PDFDokument16 SeitenInserto Clase 15KV 200a PDFjavier vargasNoch keine Bewertungen

- Pneumatically Operated Valve P-12Dokument4 SeitenPneumatically Operated Valve P-12Weldmap DrawingNoch keine Bewertungen

- Ra-616190-001 (D-1) PDFDokument1 SeiteRa-616190-001 (D-1) PDFmuthuvelaaNoch keine Bewertungen

- Hphysics5 Roller Coaster Marbles Lab Report Jose GallardoDokument1 SeiteHphysics5 Roller Coaster Marbles Lab Report Jose Gallardoapi-345842338Noch keine Bewertungen

- Climbing Film EvaporatorDokument8 SeitenClimbing Film Evaporatorsaz140% (1)